As a rule, the structures of velomobiles made by DIY enthusiasts correspond to their intended use. That is, if a velomobile is designed for sports, high-speed races, then all its structural features correspond to this, and it is unlikely that an elderly person will be able to use such a vehicle for daily trips. Conversely, the participation of a household cargo velomobile in sports events is completely excluded. This distinction is quite understandable since velomobiles of different types have completely different design principles, calculated loads, and as a result—construction of nodes and details, design. But, as it turned out, it is still possible to “harness a horse and a tender deer” into one team. Confirmation of this is the velomobile “Grupass” made by me.

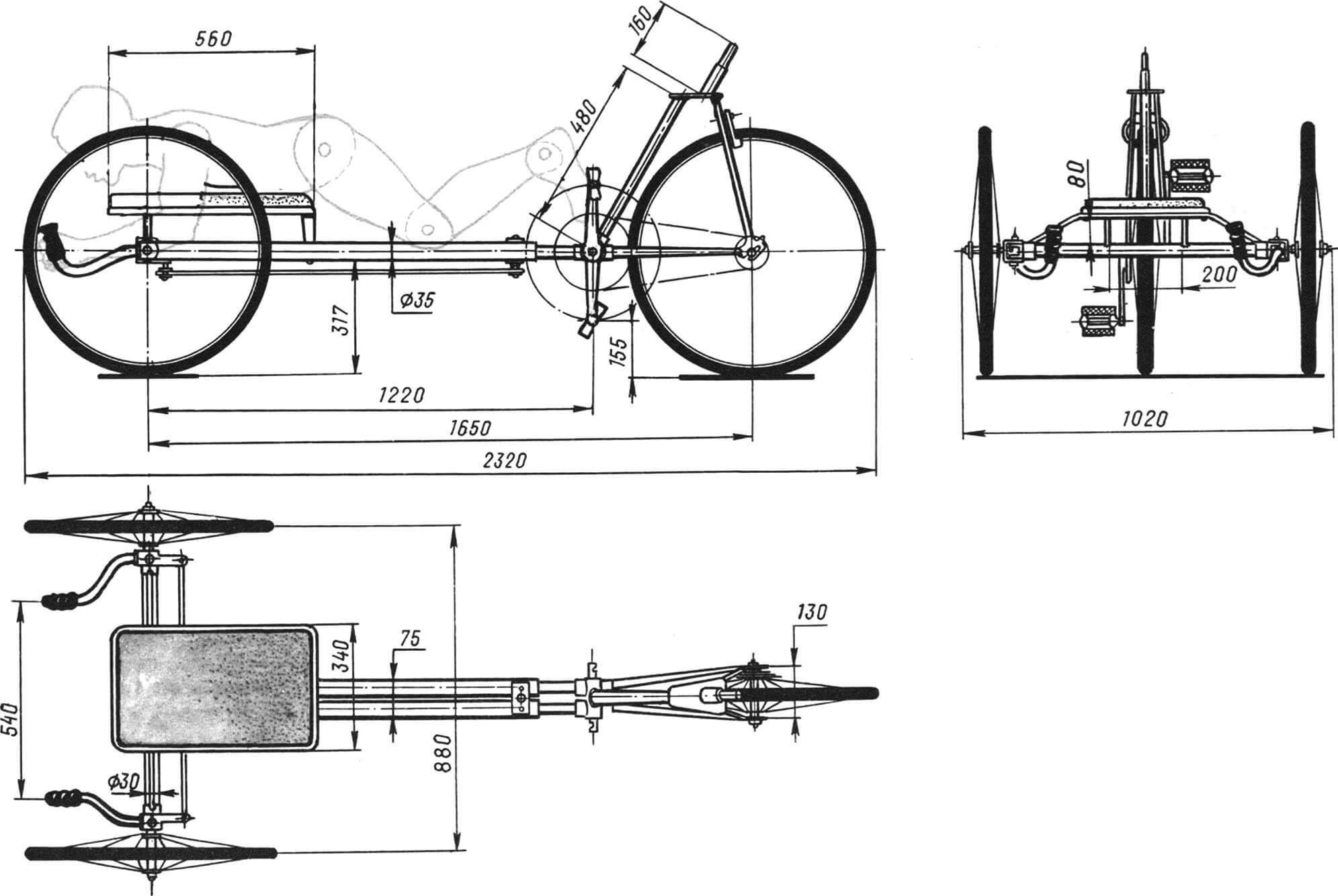

It was mainly developed for business trips within the city. Special attention was paid to maximizing the use of ready-made, purchased parts, as well as simplifying the entire structure. Excellent driving characteristics are achieved by using large-diameter wheels, a long elastic frame, and a hub from a sports bicycle with a multi-speed gearbox. A platform-box up to 1200 mm long is installed on the chassis of the velomobile in the front, allowing the transportation of quite bulky and massive loads, or a small couch for transporting children. However, such purely domestic use of the velomobile does not limit its sports capabilities since a “racing” modification is incorporated into the design. For this, the driver lies on a couch-seat, and control is carried out by a duplicate front handlebar. It is precisely this double use of the machine that suggested its name: “Grupass” is a “cargo-passenger high-speed” velomobile.

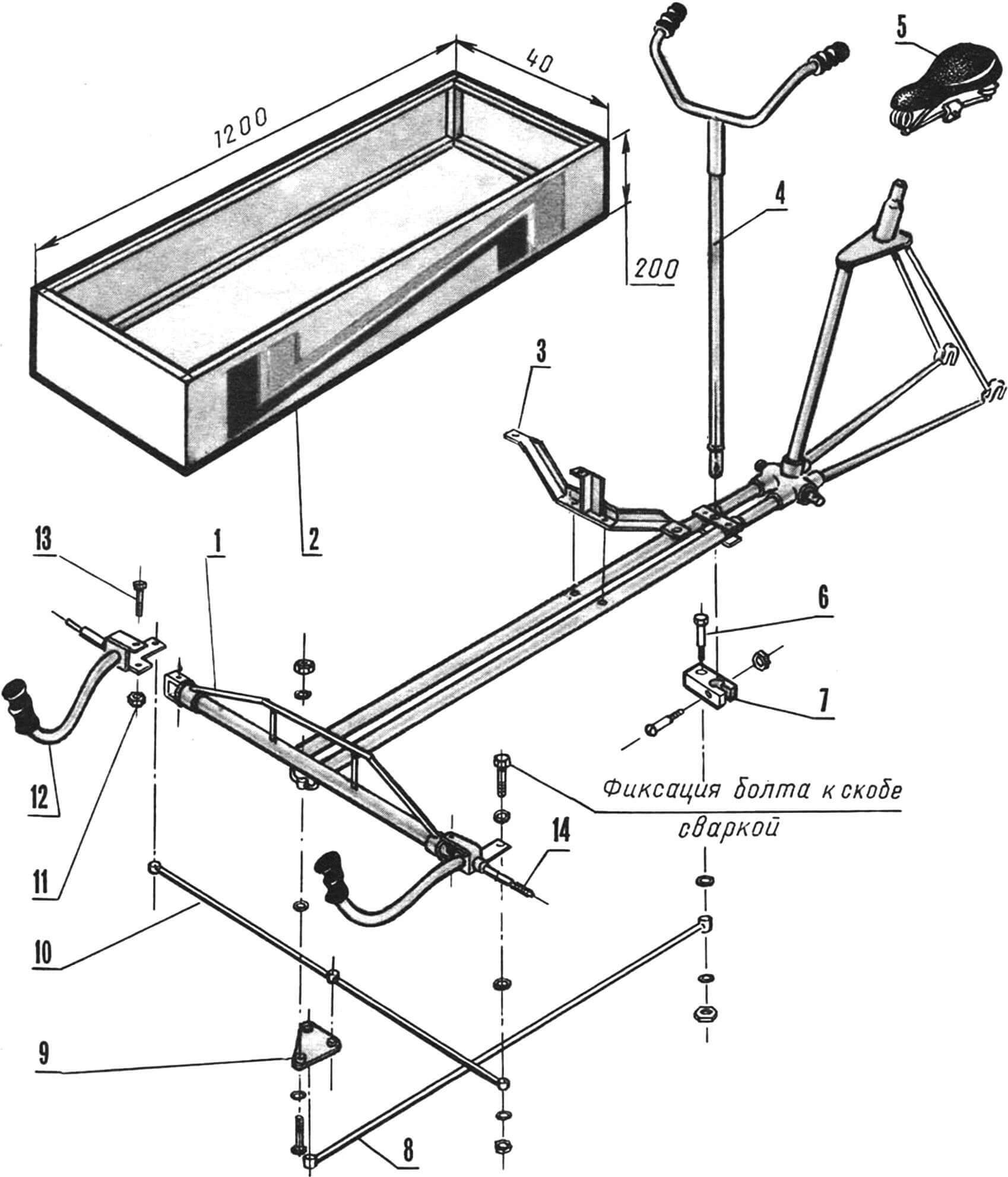

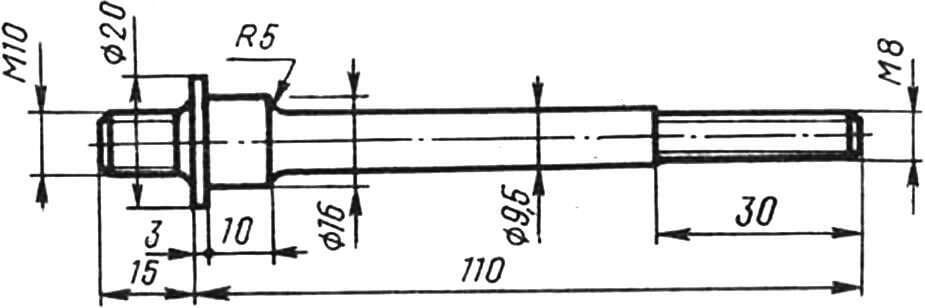

1 — frame (aluminum tubes Ø 35X 1.5 mm; bottom bracket and rear fork from a sports bicycle), 2 — body (plywood 3 mm thick, strips 20X20 mm), 3 — bracket-subframe (aluminum angle 3X25X25 mm), 4 — steering column, 5 — bicycle saddle, 6 — bolt M8, 7 — steering yoke, 8 — longitudinal steering rod (ski pole Ø 15 mm), 9 — lever (steel plate 1.5 mm thick), 10 — transverse steering rod (ski pole Ø 15 mm), 11 — nut M8 (2 pcs.), 12 — swivel joint (left, right — mirrored), 13 — bolt M8 fixing the swivel joint to the steering rod (2 pcs.), 14 — half-axle of the front wheel (2 pcs.).

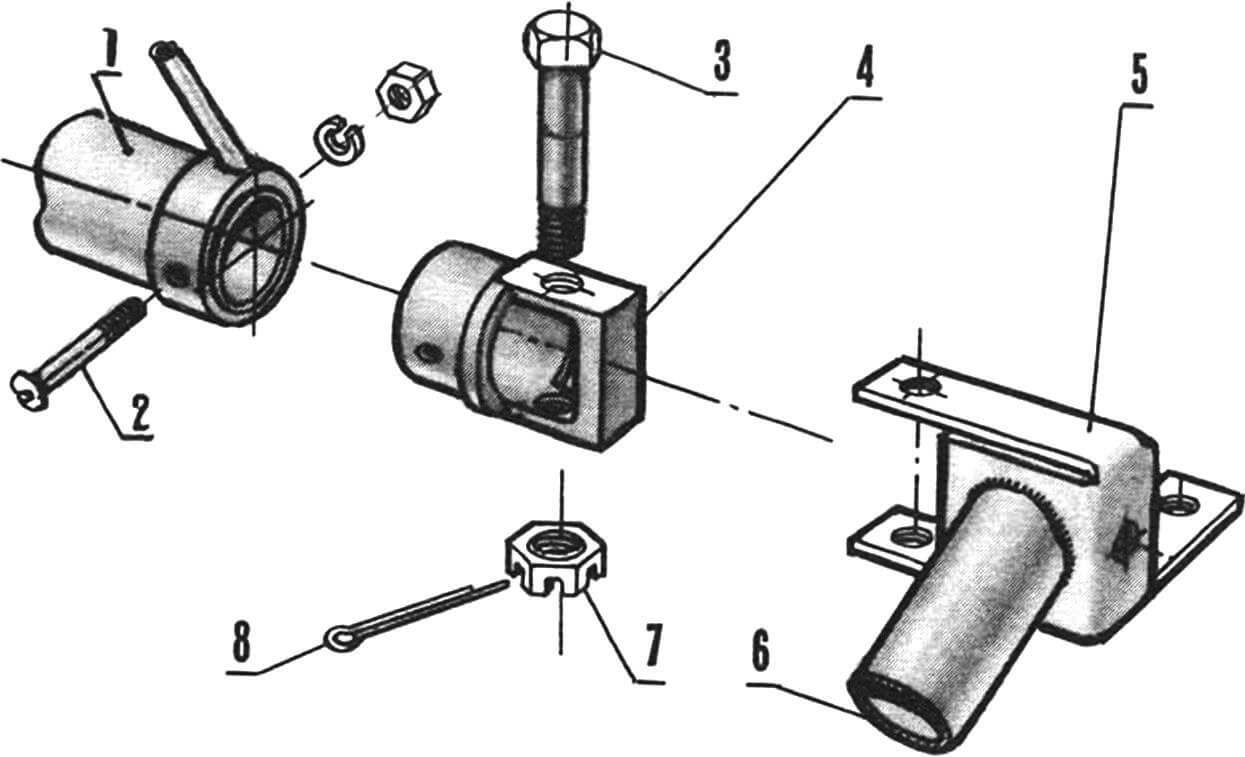

As already noted, the velomobile has a dual control system: for the cargo and sports options. In the first case, when the driver is on a bicycle-type seat, control is carried out by a regular bicycle handlebar installed at the rear of the machine. Ski poles are used as blanks for the steering rods. In the sports option (with the racer lying down), the velomobile is controlled by a “split” handlebar, the handles of which are welded directly to the swivel joints of the front wheels. These joints, left and right, have a mirrored construction and consist of a steel figurative pivot and a swivel fist. The fist has a box-like shape and, to reduce weight, is made of a steel sheet blank 1.5 mm thick. The joints are welded with continuous seams.

1 — cross member of the velomobile frame, 2 — bolt M6, 3 — bolt M10, 4 — bushing (steel), 5 — swivel joint (steel 1.5 mm thick), 6 — handlebar, 7 — nut crowned M10, 8 — cotter pin.

The transmission is entirely borrowed from a serial sports bicycle. A caliper brake is installed on the rear wheel. The wheels are standard bicycle wheels; however, for the cargo variant, it is desirable to use wheels from a road model or with double the number of spokes. The rear wheel is closed on one side with an aerodynamic cone.

If it is necessary to ride on city streets, it is not difficult to equip the machine with a standard bicycle electronics system with headlights, turn signals, and a brake light.

I believe that such a velomobile, due to its simplicity (it can be made in a few evenings) and versatility of use, can be confidently recommended to both city dwellers and rural residents, as well as all owners of country garden plots.

TECHNICAL CHARACTERISTICS OF VELOMOBILE “GROUPASS”

Length, mm: 2320

Width, mm: 1020

Height (sporting variant), mm: 900

Load capacity, kg: 150

Weight, kg: 13

Speed (sporting variant), km/h: up to 80

Transport speed, km/h: 18–30

A. MURAVLEV, Kolomna