Because of the deterioration of the old Velocimetry often have to fix. The new find does not always succeed there, but another size of industry and trade not able to keep up with “different-sized” Bicycle wheels in the population. However, if you learn how to lengthen or shorten the rubber tube on your bikes and scooters kids are always on the go.

Because of the deterioration of the old Velocimetry often have to fix. The new find does not always succeed there, but another size of industry and trade not able to keep up with “different-sized” Bicycle wheels in the population. However, if you learn how to lengthen or shorten the rubber tube on your bikes and scooters kids are always on the go.

From a larger chamber to a smaller size — no problem. Need to cut and paste one end to the other — the “tube in a tube”. For the formation of an annular sealed seam is advisable to use a mandrel, it greatly facilitates the operation.

The figures show the use of a cylinder of any material with a diameter close to the size of the lumen of the expanded tubing below the rubber “no fidgeting” on the mandrel. At the same time, as they say, variants are possible.

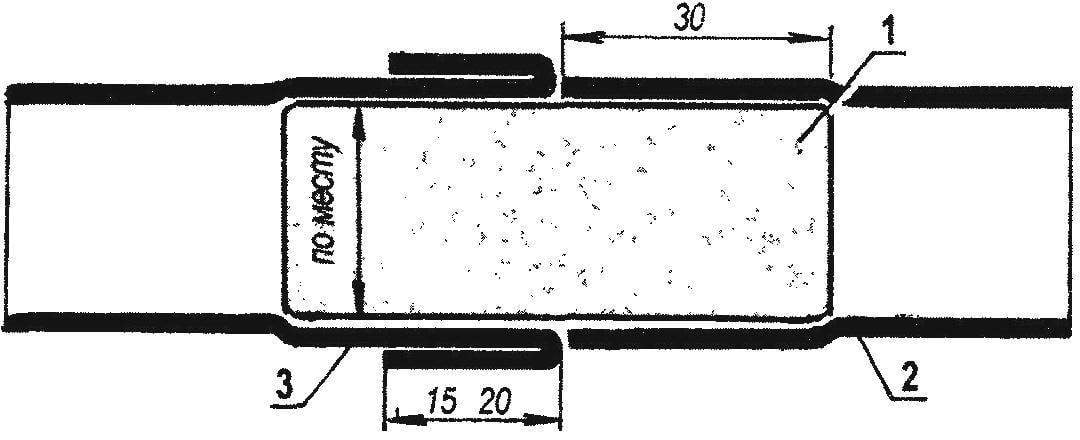

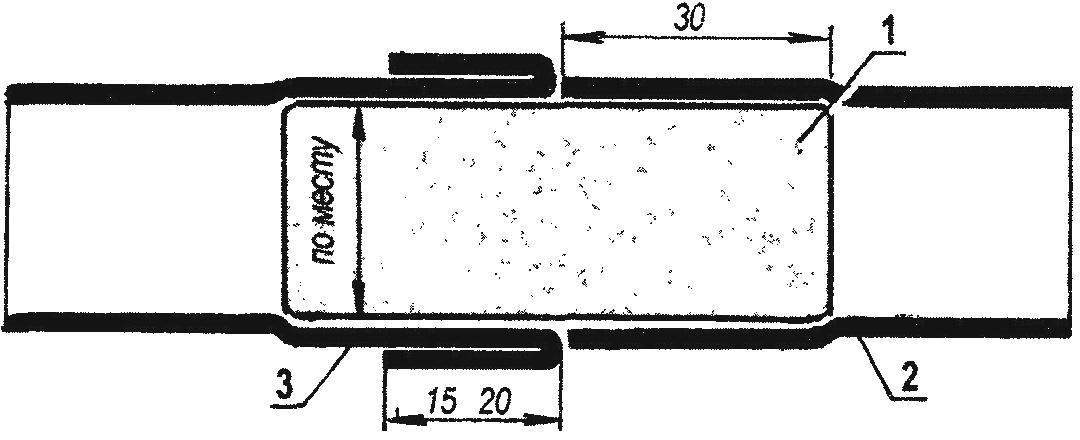

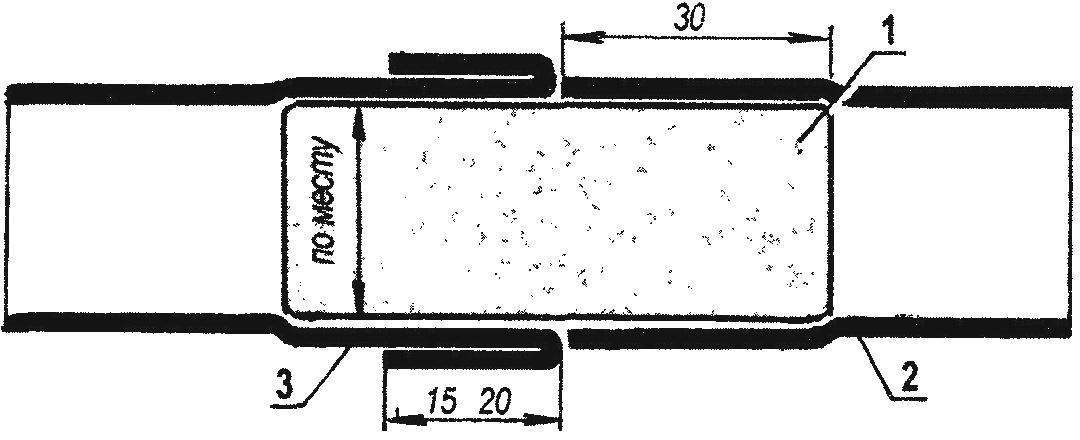

One of them (Fig.1) the end of the tube “3” is wrapped like a “cuff” for a distance of 15 — 20 mm to prepare the inner surface of the chamber to seal the End of tube “2”, pulled over the mandrel until it comes into contact with the “cuff”, is also treated as the outer surface for a distance of 15 — 20 mm — for the future of the seam.

After drying glue on the prepared to the connection areas have to slip under the “cuff” planed smooth stick and passing it around the mandrel, gradually expand the “cuff” and knurl the end of the “2”. Get precise alignment of the plots prepared by bonding (without the use of the mandrel is completely unattainable). To harden the fresh circular seam it is useful after removing the mandrel to tap lightly with a hammer.

Fig. 1. Docking Velocimetry using internal mandrels:

1, a cylindrical mandrel; 2 — level end of the camera, 3 — wrapped end of the camera (“cuff”)

So you can act when performing on-camera-reducing it all circumferential welds, except the last, closing when the mandrel is inside a closed cavity of the finished camera. To remove it, have to make a slight longitudinal cut, then seal a traditional patch of broad flat rubber.

“Surgery” of this kind, somewhat reducing condition of Velocimetry, can be avoided if apply, for example, investment casting mandrel made of wax or paraffin (in any hardware store there is a candle on the casting mandrel alone is enough). After the last seam section of the camera with such a mandrel it is necessary to lower in pre-heated to 60 — 70 degrees water and melted paraffin to release via the valve tube. As a variant of this trick you can also mention the “soluble” mandrel, at least a clump of damp, and then dried, or Packed bundles of ground salt (I know that sometimes a packet of salt have difficulty to break with a hammer). A hacksaw and a grater for vegetables such lump quite easy to “carve” a cylindrical mandrel, it is removed from the cavity of Velocimetry after two or three times rinsing with warm water through the valve tube.

Another embodiment of the connecting seam is based on the application of the simplified mandrel of 35 mm film strip, a half-meter segment which can be rolled into a fairly hard roll Film to roll “towards” its natural curvature, to insert to a depth of 30 mm, cleaned on the outside end of the tube and allow the roll to unwind a little, rcpaliwa tires (have even a little to help him). Continue to pull out of the roll 3 — 4 turns of the foil along its axis to the length of 30 — 40 mm and this protruding portion to enter in and also procured in advance prosharenny “cuff” of the second half of the future closing of the seam. After degreasing it with gasoline and glue to form the already known manner (splinter) last suture and vigorously promyat it. Remaining forever in the camera film due to the insignificance of its mass, its presence no harm will not bring.

Finally, we present long ago, someone invented but now known only to a few method of bonding the seam end by means of a spindle, a sly way leaving all the time off camera, although the formation of a circular weld is produced on her the same techniques of preparation and combining the areas of bonding, as in the above examples.

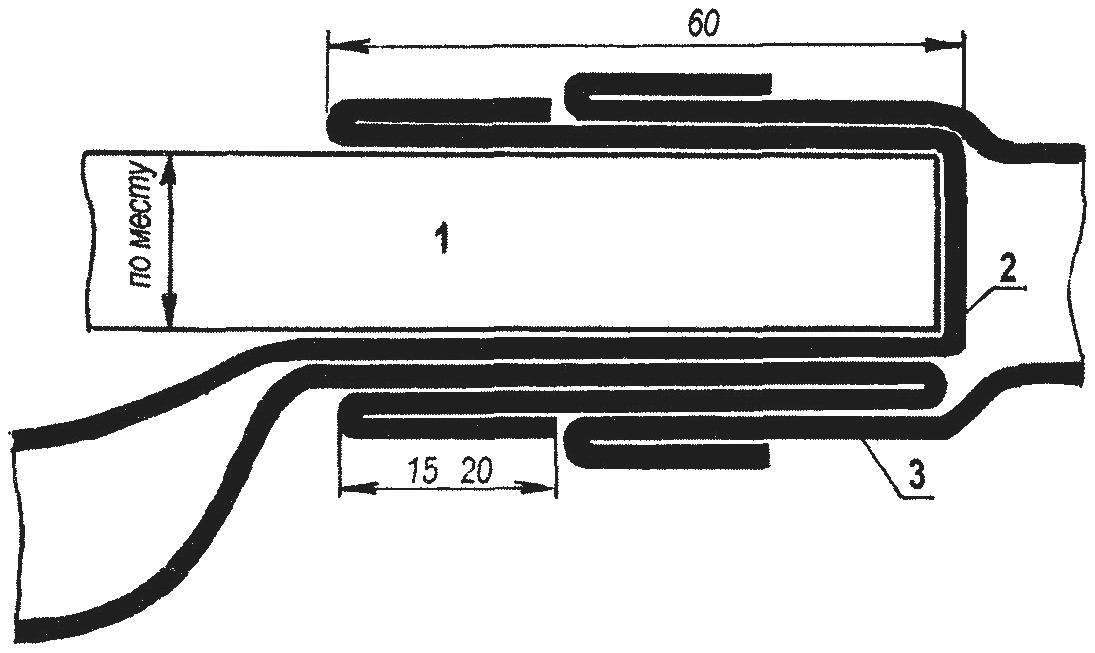

Fig. 2. Option dock Velocimetry using the external mandrel:

1 — mandrel-cylinder, 2 — folded end of the camera, a 3 “cuff” of the right end of the camera

Figure 2 shows this mandrel “1” inserted in folded and wrapped on a 60 mm “cuff” of the left end of the “2” in such a way that presses the tapered rubber left side to the “cuff” on the inside along its length. The free edge of the “cuff” wrapped up again on a plot of 15 — 20 mm, now towards the first bend, which creates the annular seam on the outer surface of the left end of the camera. The right end 3 of the chamber is stretched into the closed rubber of the left end of the mandrel, it is wrapped another “cuff” —area treatment of the bonding in the inner surface of the right end. After drying the adhesive layer on both surfaces connect the already described technique (using splinter), objaut, and then freely remove the mandrel, immediately eliminating the unnecessary and become more “cuffs” of the left end of the tube, stretching the plot of the finished connections. Don’t forget to tap it with a hammer!

The last method of gluing the mandrel may be of any length. Convenient to use as a mandrel rolls strips (for example, recorders), adjusting the diameter changes of the number of turns of paper.

V. KHAKHALIN, Dolgoprudny, Moscow oblast