“M-K” can rightfully be considered one of the founders of the bicycle-mobile industry in the country: it was on its pages that the description of the first, in many ways still imperfect, muscular vehicle “Vita” appeared in 1976. Remember? And what about the folding fagot “Hummingbird”? For 15 years, the magazine has been constantly introducing its readers to the most interesting homemade products.

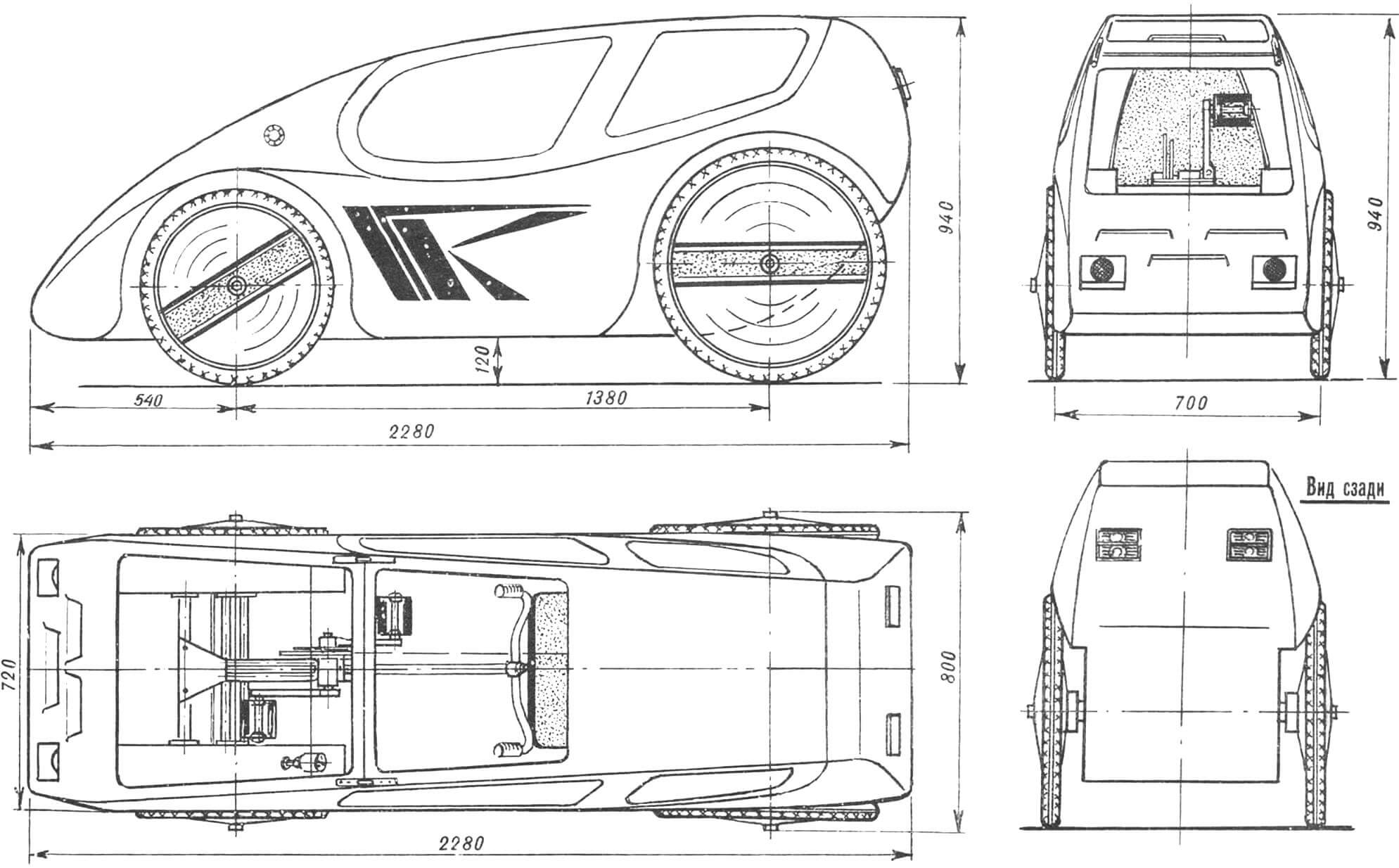

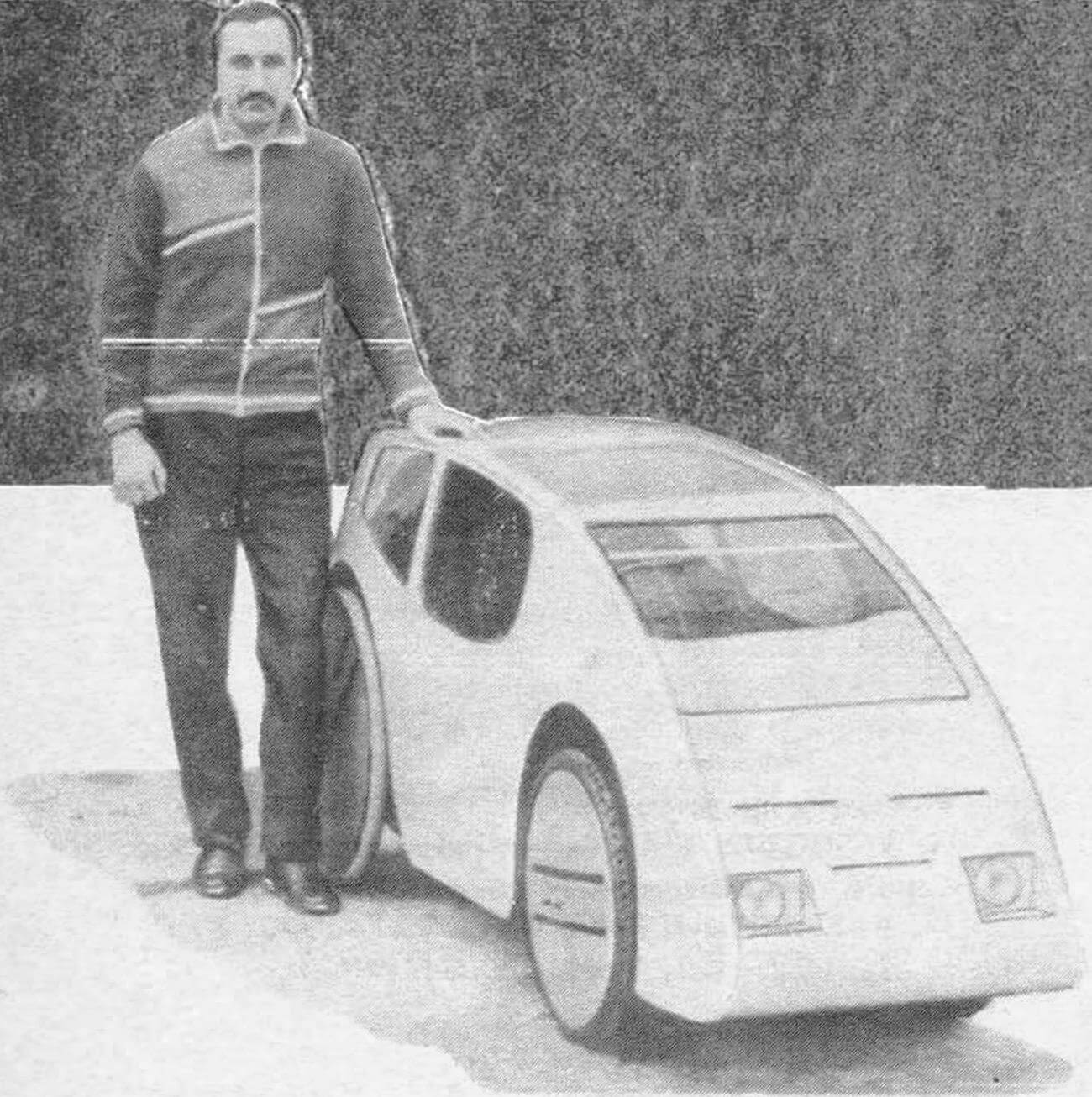

Today we bring to your attention another option – the HOPE velomobile, created by V. KRASNOV from Kolomna. Its appearance, in our opinion, begins a new round in the development of this type of transport. High ergonomic performance, good aerodynamics combined with a rational kinematic design, and modern design distinguish this machine.

Traveling allows a person to see the world, the country, and get to know their region. At the same time, each “knight errant” chooses the transport that best suits his goals, needs and capabilities. The stories of experienced velomobilists convincingly prove that a pedal vehicle in most cases is almost ideally suited for long routes. It allows you to move in comfortable conditions in any weather, carry a large load without causing excessive fatigue to the driver, and sometimes serve as a bed for the night or a means of crossing small water obstacles. At the same time, just like an ordinary bicycle, it helps you test and get to know yourself, assert yourself, and test the capabilities of your body.

For several years now, velomobilist competitions have been held in our country. One of its stages is a run along the Golden Ring of Russia. It was for such a route that the HOPE velomobile was designed and built. Reliance on one’s own strength, on the design, its reliability – these are the main factors that gave this name.

The velomobile has a load-bearing, fully enclosed plywood body with a cap that folds up and forward. The manufacturing technology is borrowed from the methods of building small boats from plywood: using wire twists and subsequent gluing of the seams with strips of fiberglass.

You should start by cutting out the bottom, wheel arches and sides. Holes Ø 1 mm are drilled along the contour of the workpieces in increments of 30…40 mm. Then the sides and wheel arches are “sewn” to the bottom using wire twists. After fixing the temporary inserts and spacers and leveling possible deformations of the body, the seams should be glued on the inside with a cloth using PVA and epoxy glue. If you use epoxy, you must glue it in a well-ventilated area.

The next stage is connecting the roof and the rear part and “adjusting” them in place. If after this you are satisfied with the appearance of the body and its design, then you can carefully, with sufficient allowance, cut out the upper skylight, and then glue all the seams from the inside. The number of layers of fabric ranges from 3 to 6. After completing work inside the body, remove the ends of the twists with pliers and bend the remaining wire along the seams.

Exterior work consists of slightly rounding the corners at the panel joints and covering the entire body with thin fabric in one layer. After the glue has completely dried or the resin has polymerized, you can cut out window openings and a removable cap. The necessary stops and reinforcement of the cap are glued along the contour.

The body glazing is made of 1.5 mm thick organic glass. The glass is glued using epoxy glue.

Chassis. The wheels used are from the Desna and Orlyonok bicycles. The front ones were used without modifications, but the number of spokes had to be increased on the rear ones to strengthen them. All wheels are covered with fabric cone caps, which improve the aerodynamics of the car and its appearance.

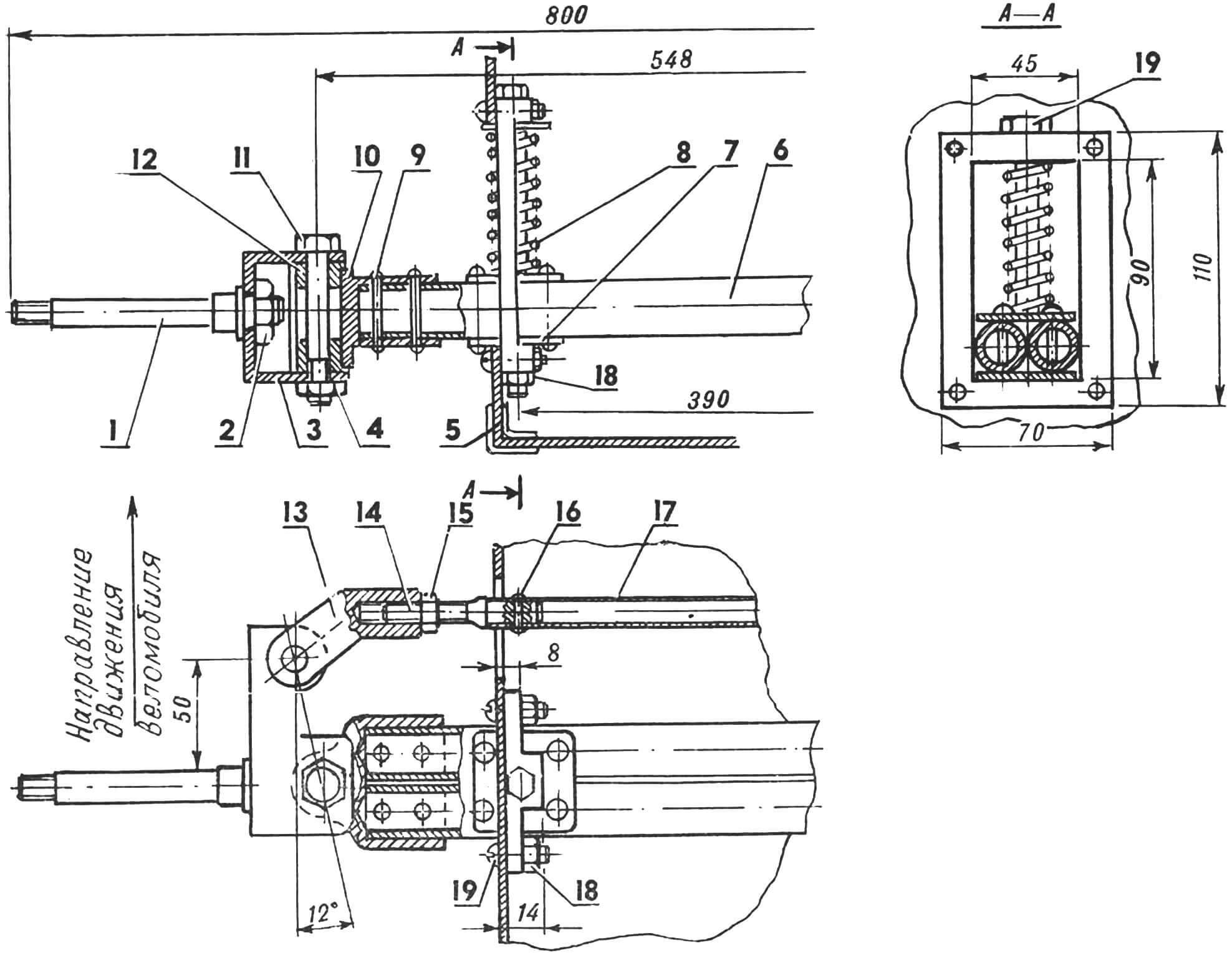

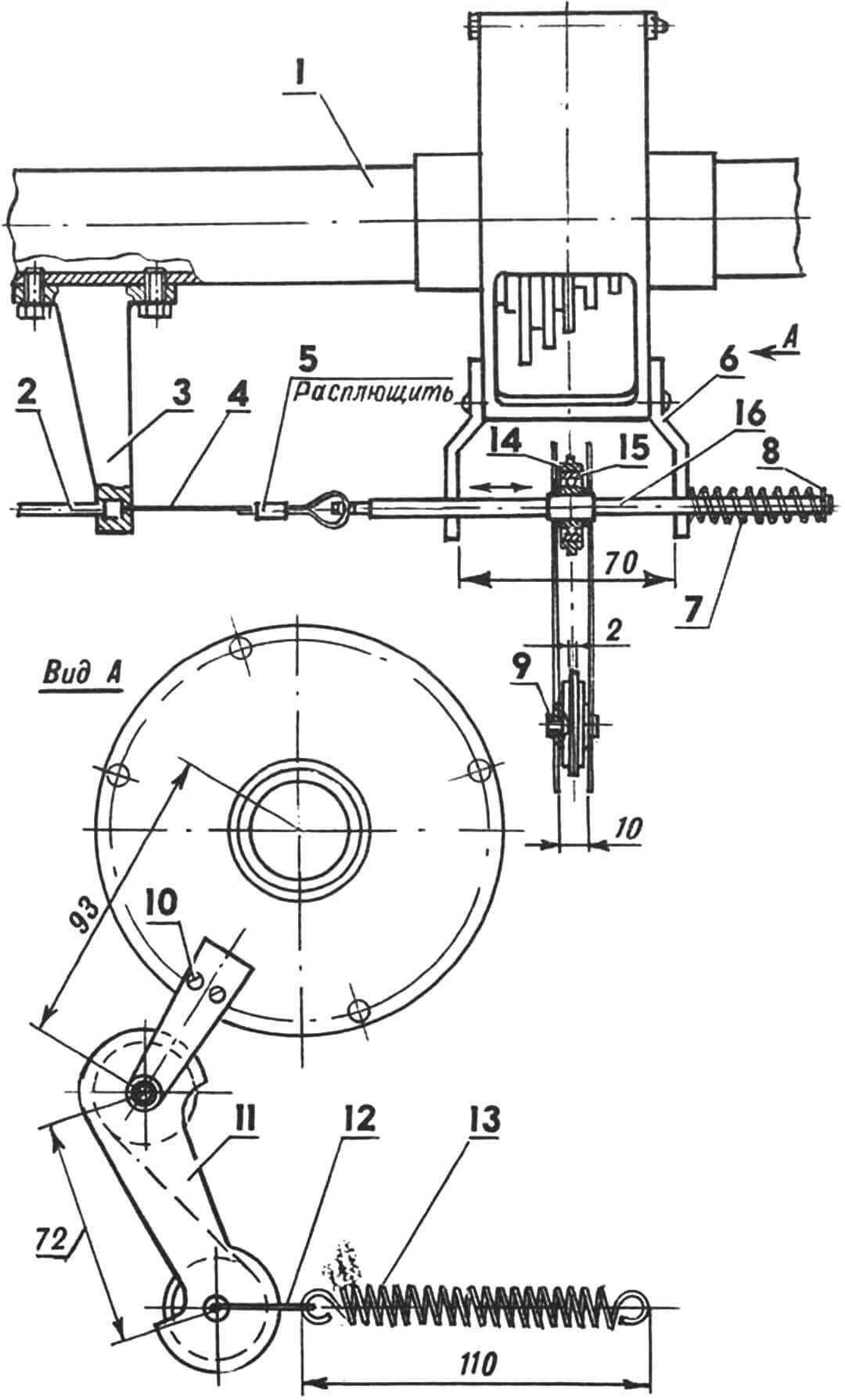

1 — front wheel axle (2 pcs.), 2 — M10 nut (2 pcs.), 3 — bracket (2 pcs.), 4 — M6 nut (2 pcs.), 5 — wheel arch (2 pcs.), 6 — double pipe-beam, 7 — lining (4 pcs.), 8 — spring (2 pcs.), 9 — rivet (16 pcs.), 10 — boss (2 pcs.), 11 — M6 bolt (2 pcs. .), 12 — bronze bushing (4 pcs.), 13 — adjusting fork (2 pcs.), 14 — M8 screw (2 pcs.), 15 — lock nut (2 pcs.), 16 — rivet (4 pcs.) , 17 — steering rod, 18 — M8 nut (2 pcs.), 19 — bolt (2 pcs.).

The velomobile is equipped with a soft spring suspension on the front and rear axles. The front axle consists of a double beam-pipe, on which the swivel axle bosses and guide linings are attached to move the beam in the vertical direction along the bolt rods. Springs are selected from valve mechanisms of passenger car engines. To ensure that the beam can skew relative to the bottom when moving over uneven surfaces, the lower pads have holes for guide rods with a diameter 0.7 mm larger than the diameter of the rod itself.

The steering rod with wheel alignment adjustment elements is located in front of the beam. The rotation of the steering wheel is transmitted through a bipod and an additional rod 180 mm long to the steering linkage through hinges with nylon bushings. The steering gear ratio is 1:2. The maximum wheel rotation angle is up to 30°, which provides a vehicle turning radius of 3.5 meters.

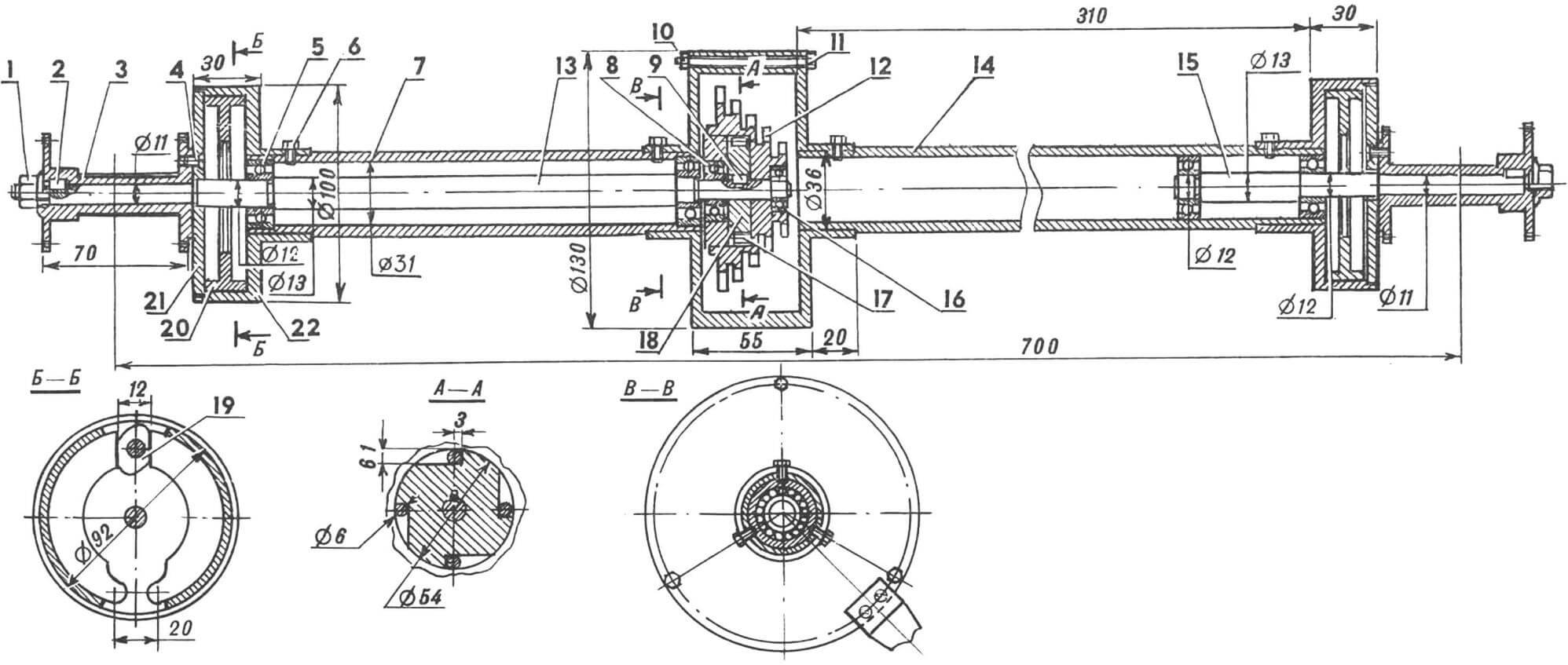

1 – M10 nut (2 pcs.), 2 – key (2 pcs.), 3 – bushing (2 pcs.), 4 – M5 screw (10 pcs.), 5 – bearing No. 201 (4 pcs.), 6 – M5 bolt (12 pcs.), 7 – pipe (length 216 mm), 8 – bearing No. 200, 9 – key, 10 – M6 nut (3 pcs.), 11 – M6 bolt (3 pcs.), 12 – sprocket block, 13 — drive shaft, 14 — pipe (length 310 mm), 15 — left shaft, 16 — bearing No. 27, 17 — roller Ø 6 mm (4 pcs.), 18 — ratchet, 19 — eccentric (2 pcs. .), 20 — block (4 pcs.), 21 — protective disc (2 pcs.), 22 — brake drum (2 pcs.).

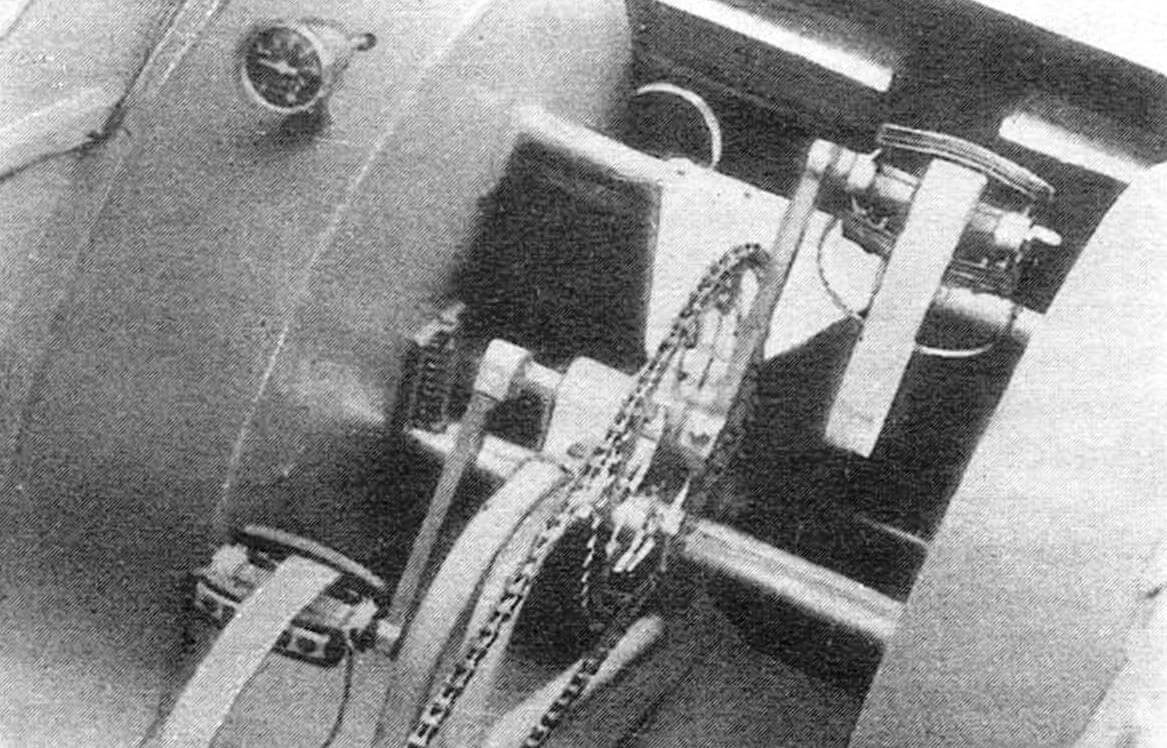

The rear axle consists of a block of sprockets with a number of teeth of 11, 14, 17, 20 and 24. It is connected through a homemade overrunning clutch to the rear right wheel shaft. The entire mechanism rotates inside the rear axle beam in bearings. The brakes are driven by cable, on both drums from one handle. The left wheel rotates freely on the axle. The rear axle is depreciated using three trailing arms and two springs from the saddle of the Minsk motorcycle of the first releases. The springs are fixed to the ends of the side arms, and the bridge is shifted 100 mm forward of them. This was done to increase the stiffness of the suspension. The central lever serves to reduce the deflection of the bridge under the action of a tensioned chain.

The carriage unit is homemade, has two sprockets with the number of teeth, 56 and 48, respectively. The chain is transferred to them using a switch from a sports bike.

1 — rear axle, 2 — cable braid, 3 — stand, 4 — cable, 5 — stopper (copper tube), 6 — bracket (2 pcs.), 7 — spring, 8 — split washer, 9 — axle-tube, 10 — M4 screw (4 pcs.), 11 — cheek (2 pcs.), 12 — bracket, 13 — spring, 14 — roller (2 pcs.), 15 — bearing, 16 — rod.

The mechanism for changing the gear on the driven sprockets is fixed to the casing of their block and consists of two cheek plates, two rollers, axles, return springs, three brackets and a pulling cable. The operation of the device is similar to that of a sports bike caliper. The total number of gears of the velomobile is 10, so it is possible to choose the most optimal one for any road.

The seat is semi-rigid. Its frame is assembled from pipes from a folding bed and plywood plates covered with foam rubber 30…40 mm thick. The top of the seat is covered with a cover made of “loose” fabric.

Since the velomobile moves in traffic, it is necessarily equipped with direction indicators and a “veloelectronics” system. It is also necessary to have a rearview mirror and, preferably, a velometer, which can be conveniently mounted on the niche of one of the front wheels. The bright, eye-catching body color also helps ensure safety: HOPE’s is yellow.

When traveling, two large bags for camping supplies and food are installed along the body. The first aid kit and repair kit are located in the bow trunk.

The conditions for a cyclist in a closed body are good: regardless of the weather, the windows do not fog up, and the air circulation is satisfactory – thanks to the directed air flows from the intake slots.

If desired, the velomobile can be made floating by sealing the front axle beam with rubber seals in the wheel arches. You can move through the water either with the help of a kayak oar or with ridge paddles attached to the rear wheels.

The first departure of “HOPE” took place in February 1990. He confirmed that the design was comfortable, lightweight, fast, and suitable for long trips.

A few words about myself. I have been involved in velomobiles since 1986. I have already made two devices. My first-born, the Kokra velomobile, was demonstrated in 1988 at the Golden Ring cycling festival and was awarded a diploma.

TECHNICAL CHARACTERISTICS OF THE VELOMOBILE “HOPE”

Length, mm — 2280

Width, mm – 800

Height, mm — 940

Track, mm – 700

Base, mm – 1380

Weight, kg – 34

Number of seats – 1

Number of gears – 10

Speed, km/h – up to 45