A “car” in combination with a cargo trailer is an extremely convenient vehicle. However, it is not without its shortcomings, which sometimes negate all its advantages. In particular, the maneuverability of a passenger car is significantly reduced and it becomes almost impossible to move in reverse – after all, motorists, unlike professional drivers, are poor at maneuvering multiple vehicles. The cross-country ability of the Zhigulenka or Zaporozhets with a massive “tail” on country and field roads is also low. So, you need a simple and inexpensive motorized truck like the Ant scooter, but with a closed cabin and a higher carrying capacity. And best of all – based on motorcycle components and assemblies: this will allow you to register it as a cargo motor vehicle. In addition, motorcycle units are much cheaper than automobile ones.

As always, I turned to the “Modelist-Constructor” files – in them you can always find almost any necessary technical solution for homemade projects. And indeed, my “Donkey” project included many ideas previously published in my favorite magazine.

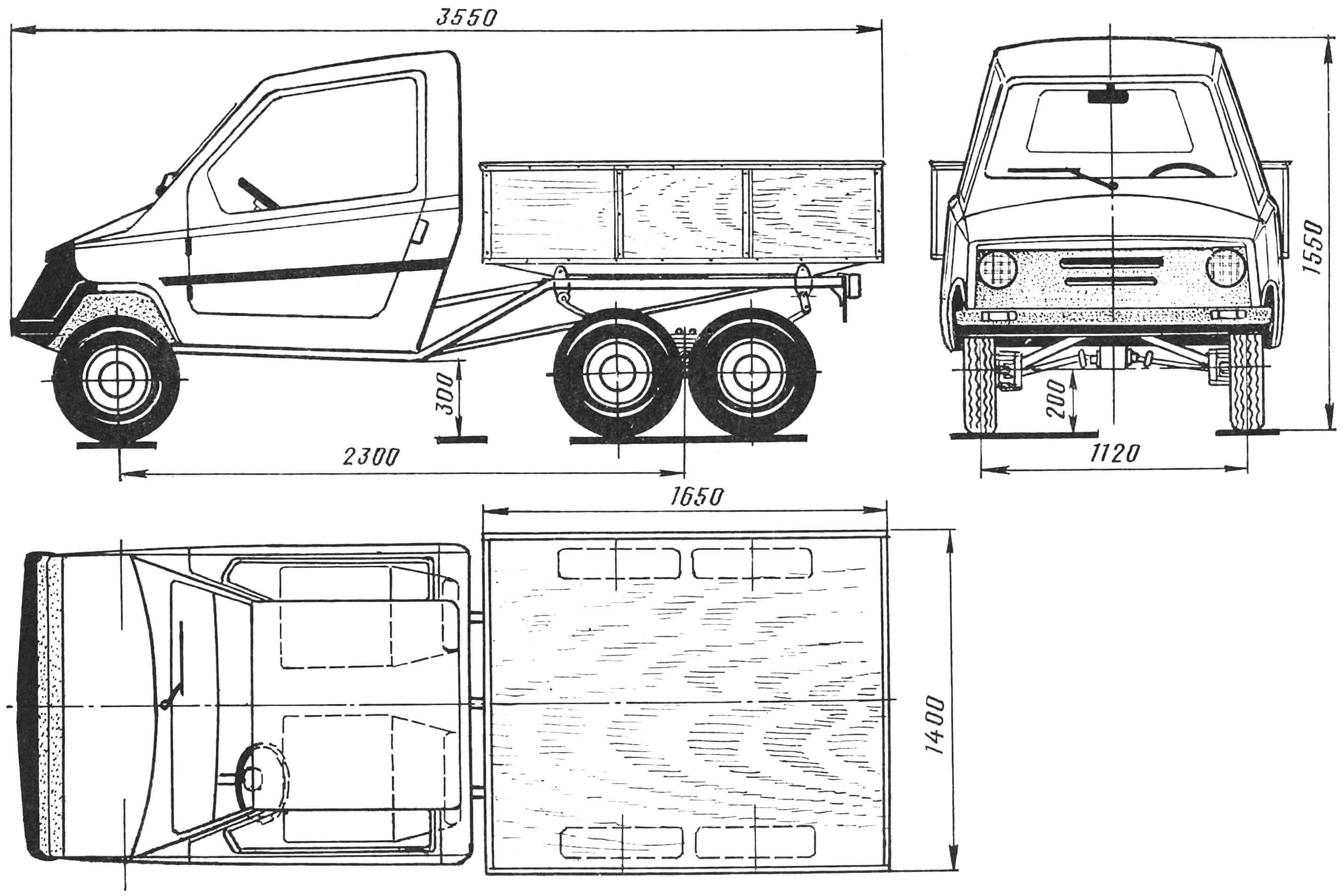

First, a little about the technical characteristics of a homemade motorized truck.

It is a front-wheel drive three-axle vehicle with a two-stroke liquid-cooled engine of the IZH-Jupiter-5 type. Such an unusual arrangement was not chosen by chance. Front-wheel drive, combined with a front-mounted engine, made it possible to get rid of lengthy transmissions and engine control using Bowden cables. In addition, the engine located at the front, in addition to the fan, is well cooled by the incoming air flow. Well, two rear axle axles appeared in order to bring the load on each of the rear wheels to normal. At first, however, it was supposed to make one axle in combination with double ramps (as on most two-axle trucks), but without excess power, laying four tracks instead of two is at least irrational.

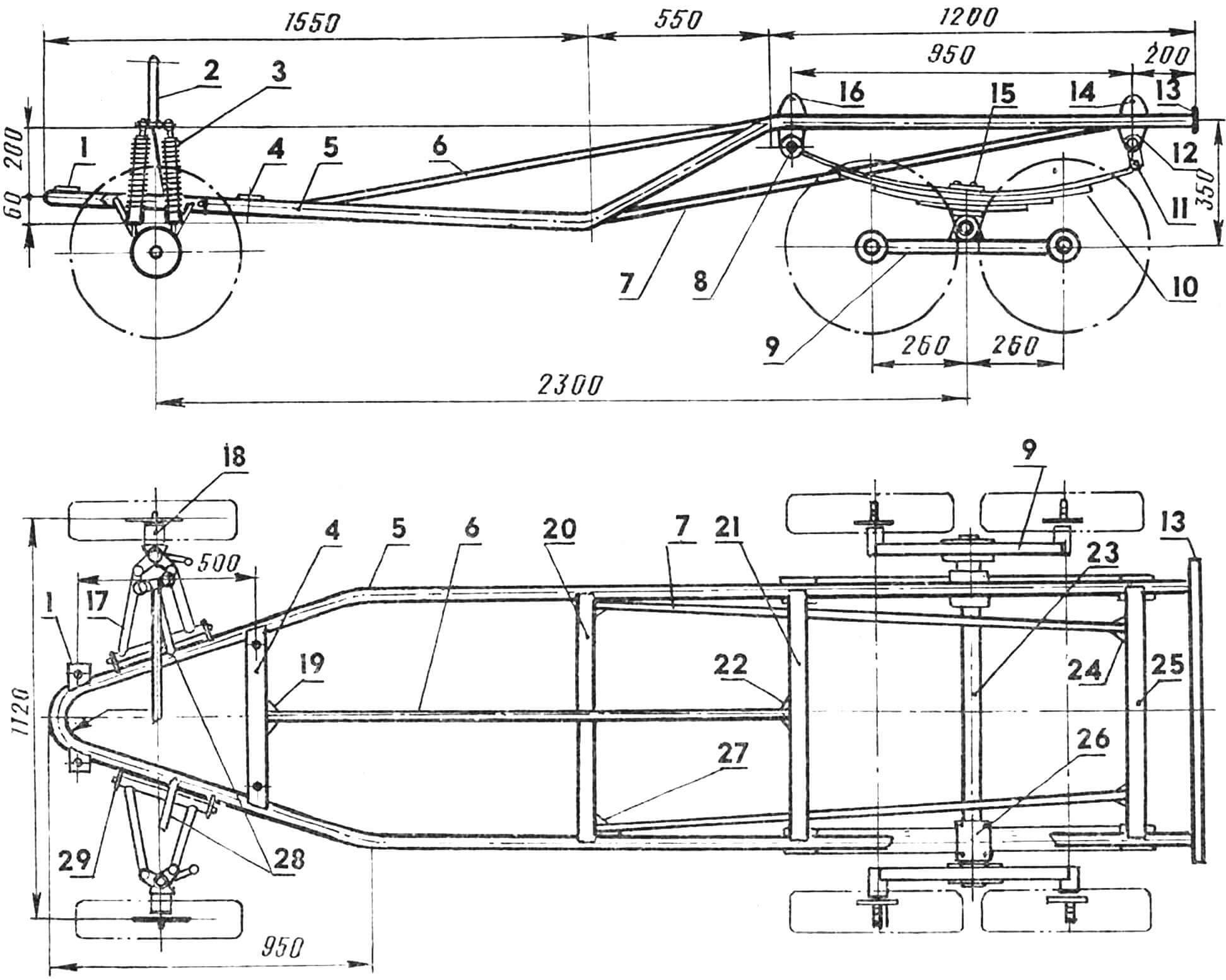

The basis of the “Donkey” is a spatial frame welded from steel pipes of round, square and rectangular sections. The drawings show a frame with spars bent from a single pipe. However, if there is no powerful pipe bender, the spars can also be made composite by welding them from several straight blanks. In this case, it is advisable to make the joints not straight, but diagonal.

A subframe is installed in the front part of the frame, on which the engine and the so-called main gear from the S3D motorized stroller are mounted. The easiest way is to make a subframe from an old IZH-Jupiter motorcycle frame (with any digital index), but it’s not too difficult to weld it yourself, in the image and likeness of the “Jupiter” frame. The subframe is attached to the motor-truck frame through rubber cushions, which significantly reduces vibrations transmitted to the truck frame.

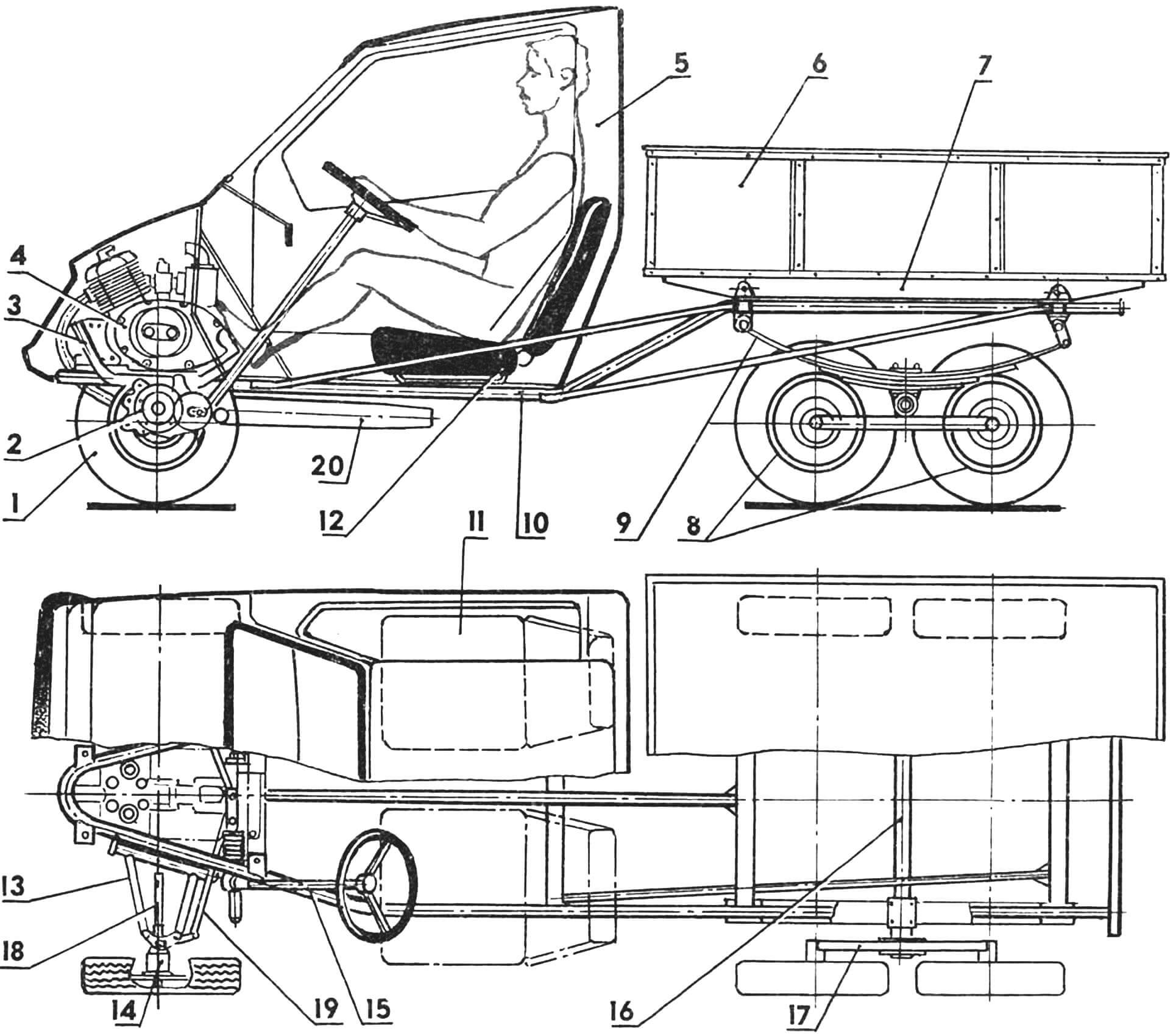

1 — front wheel, 2 — main gear, 3 — Engine subframe, 4 — engine (from the IZH-Yu-5 motorcycle), 5 — cabin, 6 — cargo body, 7 — body side members, 8 — rear axle wheels, 9 — rear axle spring, 10 — motorcycle truck frame, 11 — passenger seat, 12 — driver’s seat, 13 — front suspension wishbone, 14 — front wheel hub, 15 — steering device, 16 — rear axle axle, 17 — rear axle balancer, 18 — driveshaft of the front axle drive, 19 — transverse linkage steering linkage, 20 — exhaust pipe with muffler.

The engine, as already mentioned, is from the IZH-Jupiter-5 motorcycle: the liquid-cooled modification of this engine is ideally suited for all kinds of home-made vehicles. However, it is quite possible to use classic “air vents”, for which it is easy to organize cooling using an electric fan.

The front axle of the car is completely homemade, designed to use wheels with a rim widened by 50 mm from an S3D motorized stroller. The hubs use 7205K roller bearings. Crosspieces from the steering mechanism of a ZIL-130 car are used as constant-velocity joints for the front wheel drive. The front suspension arms are welded from steel pipes with . external diameter 30 mm and wall thickness 2.5 mm. The steering arm is a pedal crank on a road bike. The suspension of each of the front wheels is using a pair of motorcycle (“Izhevsk”) shock absorbers. In principle, here you can use elastic suspension elements from other motorcycles, as well as from a side Izhevsk motorcycle trailer.

1 — front support of the engine subframe (sheet steel 5 mm thick), 2 — traverse of the front suspension brackets, 3 — shock absorbers of the front suspension (from the IZh motorcycle), 4 — rear support of the engine subframe (steel channel 50×100 mm), 5 — side members frame (steel pipe with a diameter of 50×2), 6 – front brace (steel pipe with a diameter of 30×2), 7 – rear brace (steel pipe with a diameter of 30×2), 8 – front spring suspension fork (steel channel 50×70 mm) , 9 — rear axle balancing trolley, 10 — spring (from a mobile compressor unit), 11 — spring suspension link, 12 — rear spring suspension fork (steel channel 50×70 mm), 13 — rear frame cross member (steel angle 50×70 mm), 14,16 — attachment points for body side members (steel angle 50×70 mm), 15 — clamp with nuts and washers, 17 — transverse arm of the front suspension, 18 — front wheel hub, 19,22,24,27 — reinforcing gussets (sheet steel 3…4 mm thick), 20, 21, 25 — frame cross members (steel channel 50×100 mm), 23 — rear axle axle (steel pipe with a diameter of 50), 26 — spring cushion (steel sheet 5 mm thick ), 28 — front suspension shock absorber mounting struts, 29 — front suspension arm hinges.

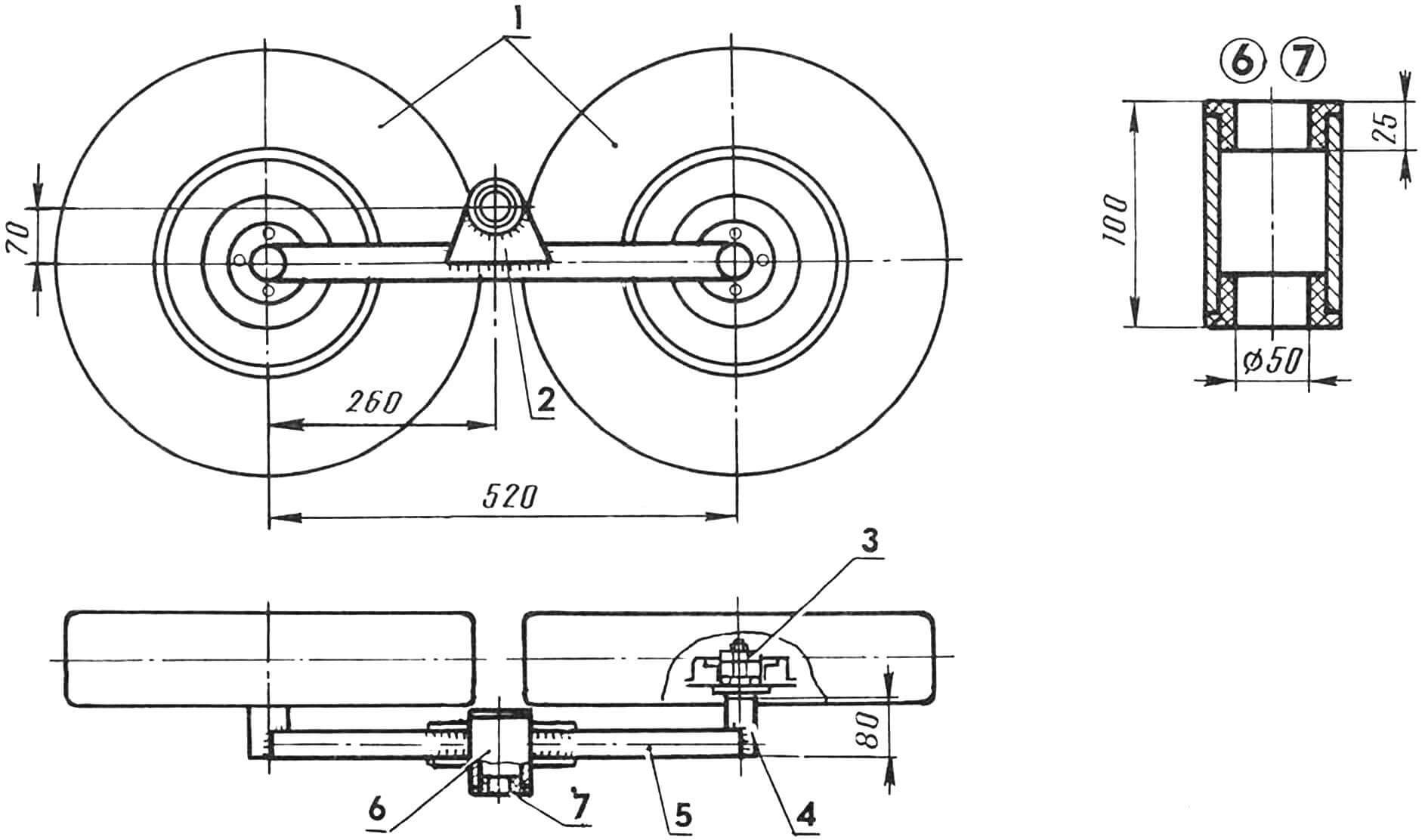

The rear axle is also homemade and is also designed for wheels from the SZD with a rim widened by 50 mm. The basis of the rear axle is a tubular axle mounted on a pair of semi-elliptical springs, on which balancing bogies with a pair of wheels are pivotally mounted. Each of the springs is assembled from four plates from a decommissioned mobile compressor unit.

The motor truck body is made of 12 mm thick plywood. It is assembled with screws and nuts using duralumin “corners” 2.5x50x50 mm. The same profiles are also used to increase the rigidity of plywood body panels. The base of the body consists of two wooden spars with a cross-section of 50×100 mm, which are secured to four brackets made of steel “angle” 50×70 mm, welded to the rear of the frame. The rear side of the body is folding. In addition, there is a removable awning made of artificial leather, stretched over a frame made of duralumin pipes.

The cabin of a motorized truck is a wooden frame covered with hardboard 4…5 mm thick. Installation of sheathing and frame using casein glue and small nails. The cabin floor is made of 10 mm thick plywood sheet. To improve water resistance, the frame and casing are covered with three or four layers of hot drying oil. The seats are from a S3D motorized stroller.

1 — rear axle wheels (from the SZD motorized stroller), 2 — gusset for fastening the balancer bushing (sheet steel 4 mm thick), 3 — rear wheel axle, 4 — rear wheel axle cage (steel pipe with a diameter of 50), 5 — balancer (steel square pipe 50), 6 – balancer bushing (steel pipe 65…70), 7 – liner (fluoroplastic, textolite or caprolon).

The steering mechanism is of the rack and pinion type, also from the S3D motorized stroller. This is also where the steering wheel comes from.

The gear shift knob is mounted under the driver’s right hand and is connected by a short tubular rod to a lever, which is a modified standard engine gear shift pedal. The reverse switch is also located under the right hand: it is connected to the corresponding lever of the main gear reducer by a short tubular rod.

The only cable drive on the car is at the carburetor throttle valve, but such a short section of cable in a Bowden sheath cannot create any significant trouble when operating the motorized truck.

The engine is started manually, using a convenient handle located under the dashboard, which ends with a nylon cable. The second end of the cable is fixed to a pulley mounted on the engine starting shaft.

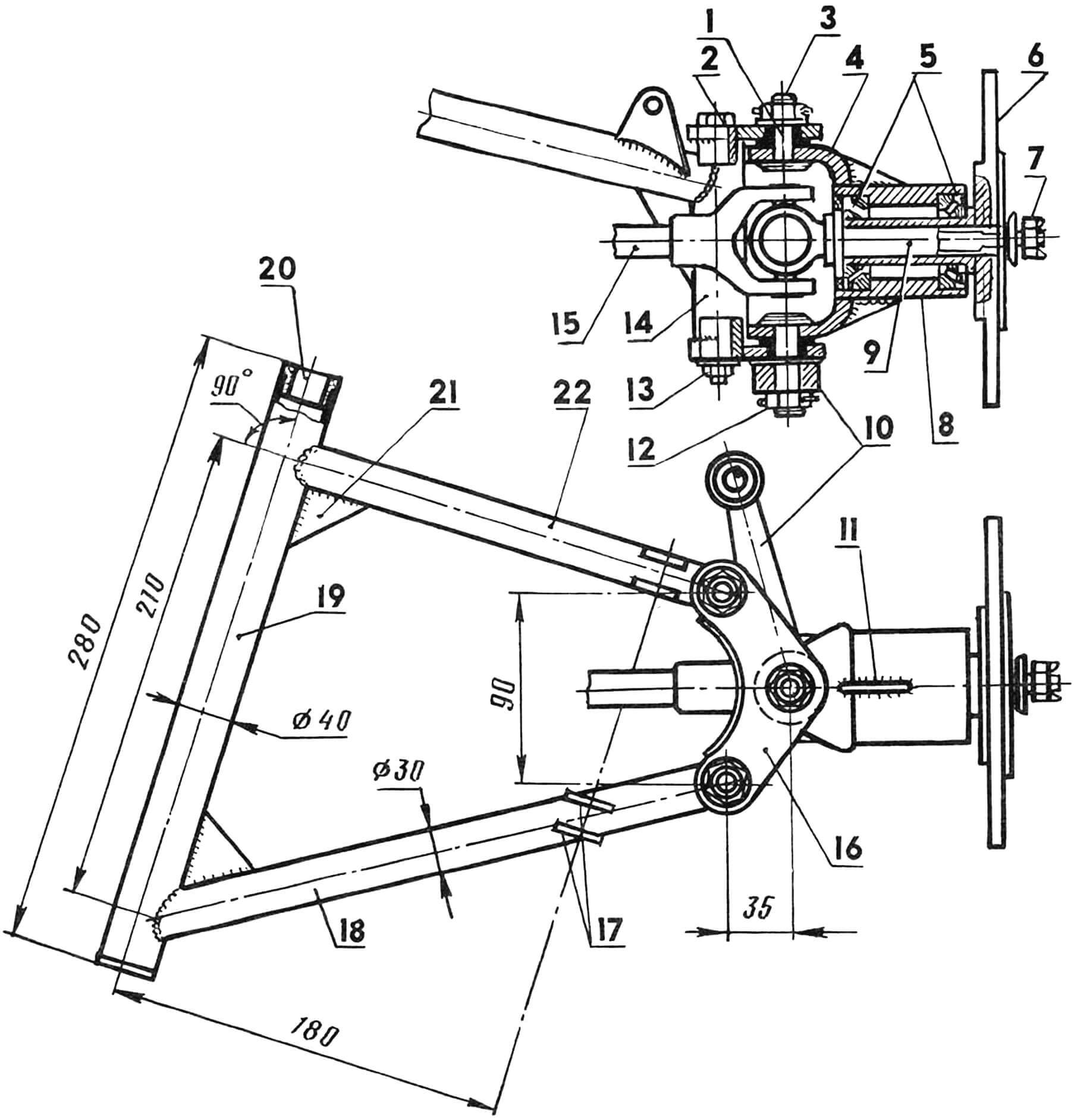

1 — steering knuckle axle, 2 — bridge mounting bolt, 3, 12 — nuts and cotter pins of the steering knuckle axles, 4 — steering knuckle (steel strip 5 mm thick or a section of channel), 5 — 7205K bearings, 6 — front wheel hub, 7 – nut M16x1.5, 8 – bearing housing, 9 – axle, 10 – steering linkage lever, 11 – reinforcing gusset, 13 – bridge fastening nut, 14 – stand, 15 – front wheel drive drive shaft, 16 – bridge, 17 – front suspension shock absorber fork, 18, 22 — front suspension arms, 19 — bearing housing of the front suspension arm, 20 — bushing, 21 — gusset.

The electrical circuit of the motorized truck is generally the same as that of the IZH-Jupiter-5 motorcycle, and contains a motorcycle battery, a rectifier-stabilizer unit and a turn signal relay used on this motorcycle.

The brake system of the car (brake drums, shields, pads, wheel brake cylinders and the main brake cylinder) is also from the S3D motorized stroller.

The car control pedal unit is mounted on the plywood floor of the cab. The gear shift and reverse levers are also installed on the floor.

I. KHOROSHEV, engineer