Once I found myself close to a real steam locomotive of the LV series – the famous Lebedyanka. And I immediately felt life in him. Everything there hissed, made noise, moved, soared, seethed and clicked. It could not be called a machine or mechanism. The definition suggested itself: “Living organism.” I have never experienced such a feeling from contact with technology before!

The locomotive seemed to be breathing, throwing out steam. He was like a buffalo, ready to run forward, rushing uncontrollably into the distance, raising columns of dust. Standing next to this monster, I felt its power, character, will and some kind of inexorable passion for the road and speed. There was a feeling that we were talking to him, although all this happened in silence: from heart to heart. Between machine and man.

The driver confirmed that he also experiences similar feelings, as if he were communicating with a living being. “I used to ride on electric locomotives,” he said, “and it was boring. Yes, they are now powerful and convenient, but, unfortunately, they are completely soulless. It’s probably no coincidence that almost all locomotives have their own names.”

Imagine that all the equipment used to be like this locomotive! Industrial machines, public and private transport, tractors and even airplanes were steam powered. The entire old world was filled with “animate” machines! Now it is difficult to feel the spirit of that time. So I wanted to create “something from the past” to feel what technology used to be like. Well, from an engineering point of view, of course, it was very interesting to study, do it yourself and configure something like that.

First experiments

So, I decided to build a small steam engine. And without any prospects or plans for the future. I wanted him to come to life, to move, to sneeze and puff somehow. In general, the goal of the project was to enjoy the operation of your own real steam engine.

Since the initial goal was not obligatory to anything, no specific calculations or drawings were made. Having understood how the simplest steam engine works, I figured out in my head the technical feasibility of creating it, and that’s it – the work began to boil.

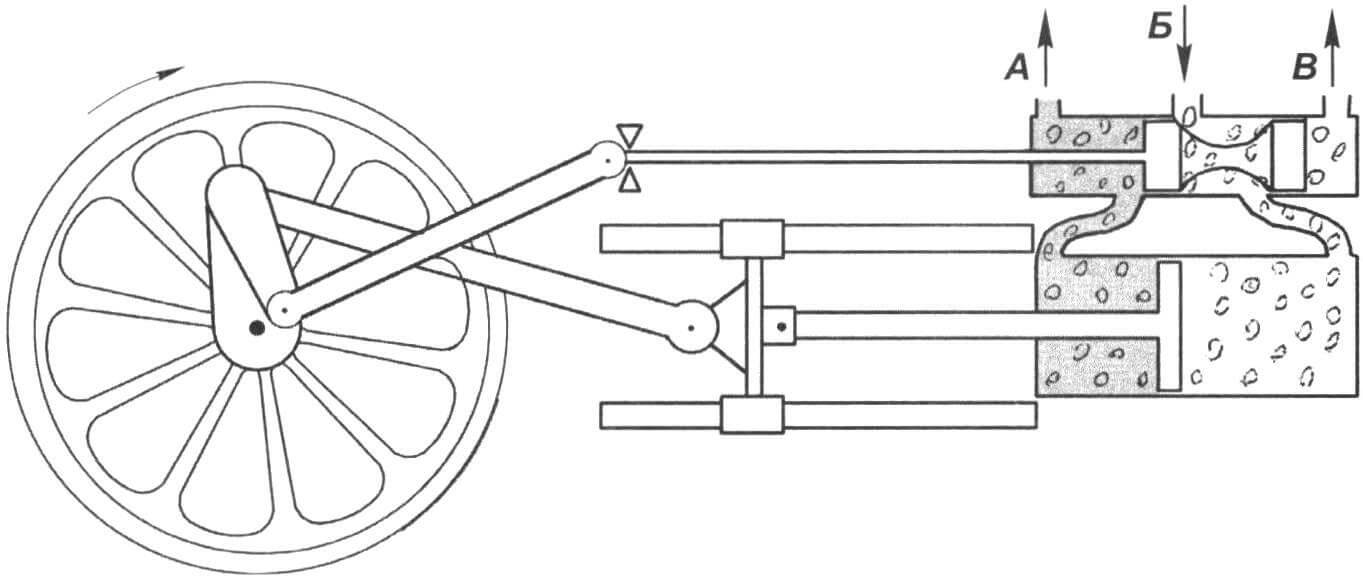

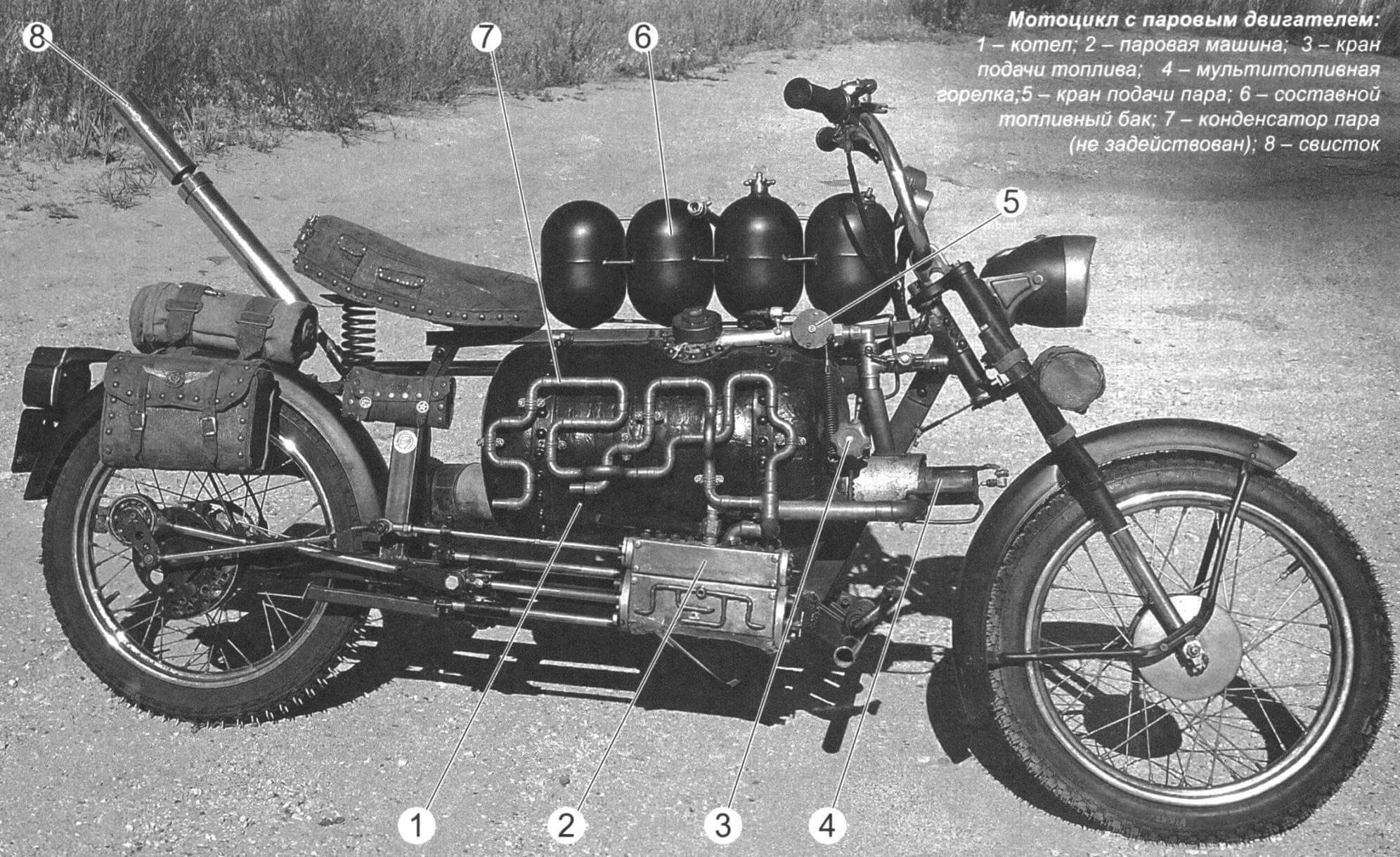

Steam under pressure is supplied to the top of the machine, to the spool mechanism (pipe B). Depending on the position of the spool, steam enters the left or right cavity of the cylinder and causes the piston to move, respectively, to the right or left. In the figure, the spool is in the position where steam enters the right cavity. The left one is connected to the atmosphere, and the remaining steam from the previous cycle exits through pipe A. When the wheel is turned, the rod associated with it moves the spool, then steam enters the left cavity of the cylinder, and the right one is connected to the atmosphere (port pipe B). The process repeats more often the faster the wheel rotates. Note that the steam can not be thrown away, but supplied to the steam condenser, and the resulting water can be returned back to the boiler. But the designer of the steam motorcycle deliberately abandoned this decision, considering the steam emitted into the street to be an integral feature of a steam engine – it is spectacular and beautiful!

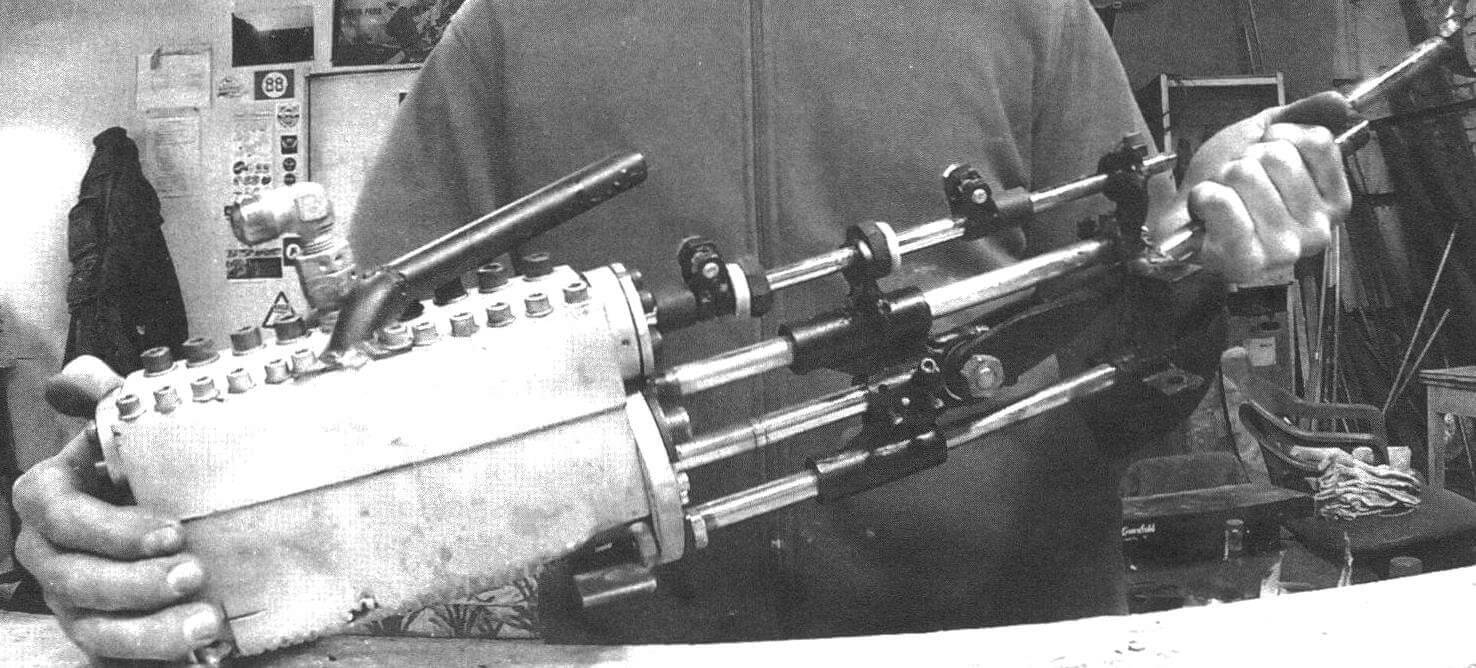

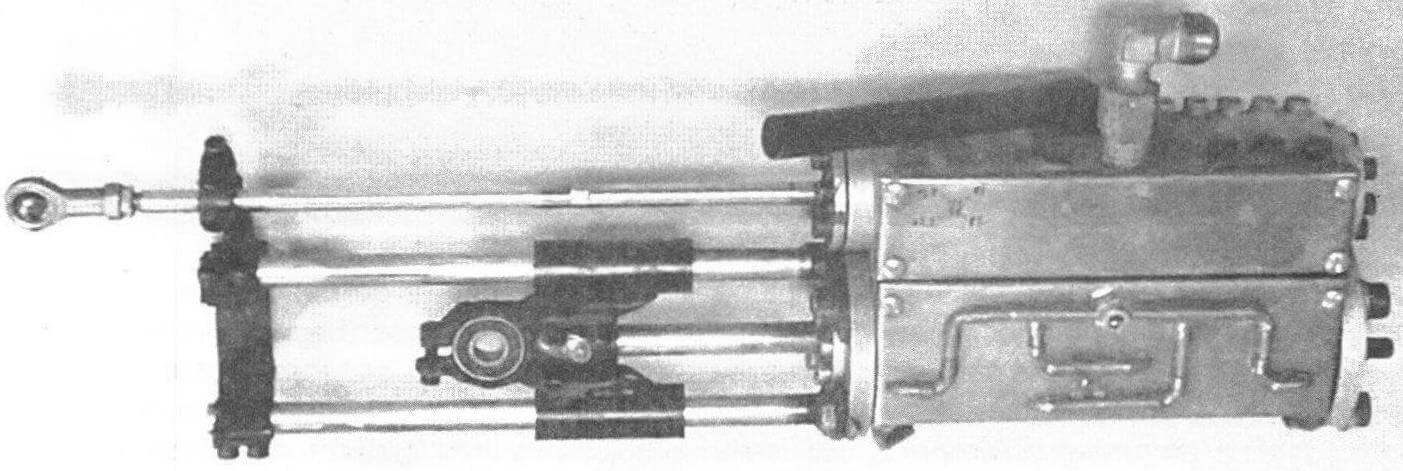

Having found some kind of stainless pipe in scrap metal, I filled it with molten aluminum from the outside. I ground the excess casting, polished it from the inside to a mirror – the master cylinder is ready. Then another casting was made – a large piece of aluminum. I drilled a huge through hole in it, using the largest drill I could find in the garage – this will be the steam distribution cylinder. I milled out the necessary steam channels. When joined together, these two castings formed the steam engine cylinder block with the necessary passages inside. Then everything was overgrown with many parts made from the same scrap metal.

It is clear that even the most primitive steam engine requires a flywheel. And my neighbor in the garage gave me a broken Karpaty moped. I looked at its rear wheel – what a flywheel! I made a small frame that held the wheel and the steam engine, and that’s how the engine turned out. I launched it and… everything worked as it should!

Having experienced a sea of positive emotions, it was quite logical that I decided to complete the structure into a full-fledged two-wheeled vehicle. The front wheel, fork, handlebars and fenders were taken from the Karpaty, the rest was again found at a scrap metal collection point and completed by hand…

During testing, the steam moped reached a speed of 40 km/h. However, the engine consumed such a large amount of steam that it was possible to drive no more than 600 meters, and then we had to wait 10 minutes for the boiler to heat up. And after the first test runs, I wanted to upgrade the engine to improve its parameters. Powerful theorists and lovers of steam technology have already joined in and calculated the optimal dimensions of the slide valve for an engine of my size. And again to the garage to saw and drill… Looking ahead, I will say that technologically the second version of my engine “jumped” immediately forward a century, since it is already equipped with a two-spool valve.

Steam motorcycle

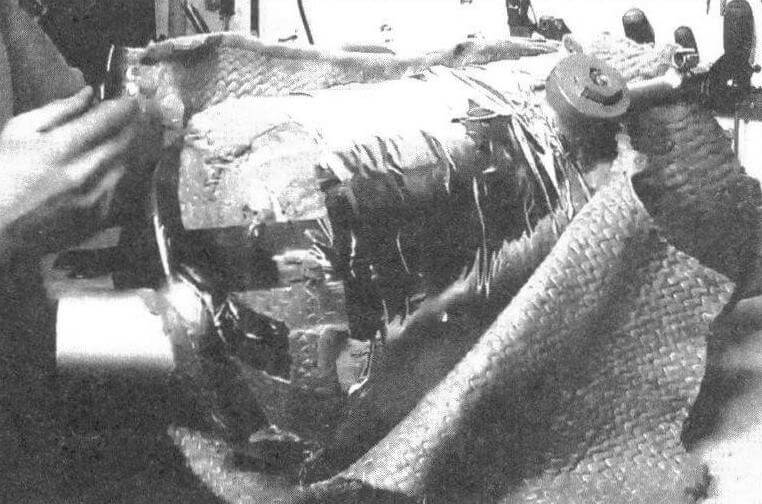

Unlike an internal combustion engine, a steam engine generates energy not in a cylinder, but in a boiler in which fire heats water. Real steam locomotives burn coal, wood or fuel oil in the furnace. Hot gases pass through a large number of tubes (heat exchanger), thereby maximizing the transfer of thermal energy to the water. In fact, the boiler can be heated with absolutely any fuel. You can even burn garbage, plastic bottles, paper or rubber – and the locomotive will run great. In my design there is so little space that there was no way to organize a large firebox. Therefore, I made it in the form of a pipe welded into the boiler, into which the burner is inserted. It is homemade, multi-fuel, capable of running on any liquid or gaseous fuel.

At the top of the motorcycle, above the boiler, there are fuel tanks made from decommissioned oxygen cylinders from a Tu-134 aircraft. They are connected in parallel, and their total volume is 7 liters. They can be filled with either liquid fuel, for example, kerosene or waste, or gaseous fuel. It turned out to be most convenient to use propane gas. Sometimes I fill the tanks with kerosene, and then also with propane. The gas presses on the kerosene, and the burner reaches maximum power. And when the liquid fuel runs out, it is automatically transferred to the propane remaining in the tanks. This can be seen by the color of the flame changing from bright yellow to blue.

Since the burner is under pressure, according to the law of injection, active movement of gases is created in the firebox without the use of any pipe to create draft. This is very convenient when it comes to wheeled transport.

After the water temperature reaches 100°C, the pressure increases with further heating. My motorcycle is designed to ride at a pressure of 16 bar, while the water temperature in the boiler reaches 200°C. The gas handle, connected by a cable to the ball valve, opens it, and steam from the boiler rushes into the steam engine. There it presses on the piston, and through the connecting rod (drawbar), the engine transmits work to the running wheel. There is also an eccentric (crank) on the wheel axis, which drives the spool valve, which switches the steam supply to the piston with the appropriate phase and amplitude. That’s all, actually. This is practically the most primitive design of a steam engine. Real steam locomotives also have a huge number of different devices that improve engine parameters. But I wanted to make the simplest version so that it had as few details as possible.

The controls on this motorcycle are also very basic. Since the steam engine provides maximum torque from zero rpm, no clutch or gearbox is needed. All control comes down to just the gas handle and the brake on the front wheel. I turned on the steam and went. The more you feed it, the faster you go.

Whistle

And one more knot that we can’t help but talk about. This is… a steam whistle. It’s incredibly loud! And since there is a huge release of steam through it, it is also very spectacular. And the strength of the sound is such that it is impossible to be nearby without covering your ears. You can hear it when the motorcycle itself is not even visible. And this is just a small one-voice whistle that produces only one note. Now imagine that real locomotives have five, seven or more of them. It is not surprising that when the railroad appeared in early America, the signals of steam locomotives caused terror and panic among Indians for many kilometers in the area. They called them “black demons.”

The design of my whistle is actually no different from the design of a regular football whistle. Air, in our case steam, is released through a thin annular slit and falls on a sharp circular edge. Here the flow is divided into two parts. The first (outer) flies past, and the second swirls in a special cavity (resonator). There a resonance of a certain frequency is formed, which depends on the density of the medium, the design dimensions and volume of this cavity.

At first I tried to make whistles based on my own sketches. They worked, but were difficult to tune and consumed excessive amounts of steam. Then I managed to find a drawing of a ship’s steam whistle, and I proportionally recalculated all its dimensions to suit my tasks. To make the signal, it was necessary to grind only three parts, and the rest was scrap metal: a half-inch pipe, an axle from a car shock absorber rod, and a hollow furniture leg from an office table served as a resonator.

My homemade whistle has an even louder, clearer and brighter sound than real steam locomotives. The fact is that they use a rather rough cast iron casting, so the cutting edge is blunt and not sharp. This results in hissing, rustling, and sometimes disruption of the flow. Sometimes, when listening to the signal of a steam locomotive, you will notice that some notes do not work or begin to sound only at a certain pressure. This is precisely a consequence of rough execution or an overly rounded cutting edge. Steam locomotives have a whistle with a larger diameter, but the circle of the resonator is divided into segments, each of which resonates at its own specific frequency. The length of the cutting edge of each resonator is much shorter than that of my single tone whistle. And the sound strength is correspondingly less. I listened close to the five-voice whistle of the Lebedyanka steam locomotive. The sound is, of course, amazing. But it doesn’t come to the point of ear pain when my motorcycle beeps. When I build a large steam motorcycle, I will definitely make five separate whistles, each of which will be tuned to a different note.

Technical results

Speed tests of a steam motorcycle surprised everyone! Both specialists and myself, who are not very experienced in this kind of technology: it accelerates to 60 km/h, while consuming almost three times less steam than an experimental moped. By the way, as it turned out, the world speed record for steam motorcycles is only 40 km/h. Thus, this little thing is something like Formula 1 in its class, or rather, the fastest motorcycle on the entire globe with a classic steam engine!

A motorcycle requires water and fuel to run. It is their supply that determines the operating time of the motor and the range. On one water refill (30 liters) you can travel about 15 km. At the same time, about 1.5-2 liters remain in the boiler. In general, the boiler has a volume of 40 liters, but it is better to fill it to about 2/3 of the volume. Of course, a motorcycle can run on two liters of water, but this is dangerous for the boiler, since the firebox begins to overheat and lengthen in size, as a result, over time the boiler may leak. However, when I need to go somewhere far away, I fill up with 35 liters. This is also possible, but an insufficient evaporation mirror will not allow the use of a whistle.

If you refuel with liquid fuel, then its consumption is less than with gas. But even if you use propane, the water in the boiler will still run out faster than the fuel for the burner.

Another feature: before going anywhere, the steam motorcycle needs to be heated, which takes 20-40 minutes. The heating time depends on the initial temperature of the water in the boiler, its quantity and type of fuel.

The maximum speed of the motorcycle, as noted above, is 60 km/h. It is limited not by the engine power, which is 2 hp, but by the speed of steam inlet and outlet in the steam engine. Therefore, to increase speed, huge wheels, sometimes more than 2 m in diameter, were installed on steam locomotives. In my case, the wheels are quite small, which determines the speed capabilities. And the power reserve of a motorcycle is greatly affected by the use of a whistle, which consumes a lot of water. On a long trip, it is better to abandon it and signal with a small mechanical impact-type bell.

Future plans

In the process of creating a small two-wheeled “steam locomotive”, I clarified many important technical points for myself. There was an understanding of what works well and what would be better done differently. Having gained some experience, I now want to start building the next, already large (maybe even huge!) steam motorcycle, which will no longer have the simplest, but, on the contrary, the most complex design. He will be able to drive on wood, and on coal, and in general on any garbage. The large size of the boiler will allow it to cover impressive distances and reach high speeds.

I’m already dreaming of going on a long autonomous journey with it. Fill up with water from rivers and puddles, and heat the boiler with whatever comes your way: dead wood, dry roadside bushes, waste or rubber. In my opinion, this will be an interesting experiment that has no analogues.

Alexey ILDUTOV (Tolyatti)