The “Grasshopper” tricycle was designed and manufactured in the small-sized equipment design laboratory of the KYUT of the Novosibirsk academic campus by seventh-graders Anatoly Mikhailov, Viktor Krivonosov and Sergey Khakhtar.

This is a lightweight, front-wheel drive car with a Sh52 engine and torsion bar rear suspension. The wide track of the rear wheels in combination with independent suspension, front sprung drive, and brakes on both rear wheels provide a comfortable and safe ride on the tricycle, which is especially important at the first stage of learning to drive.

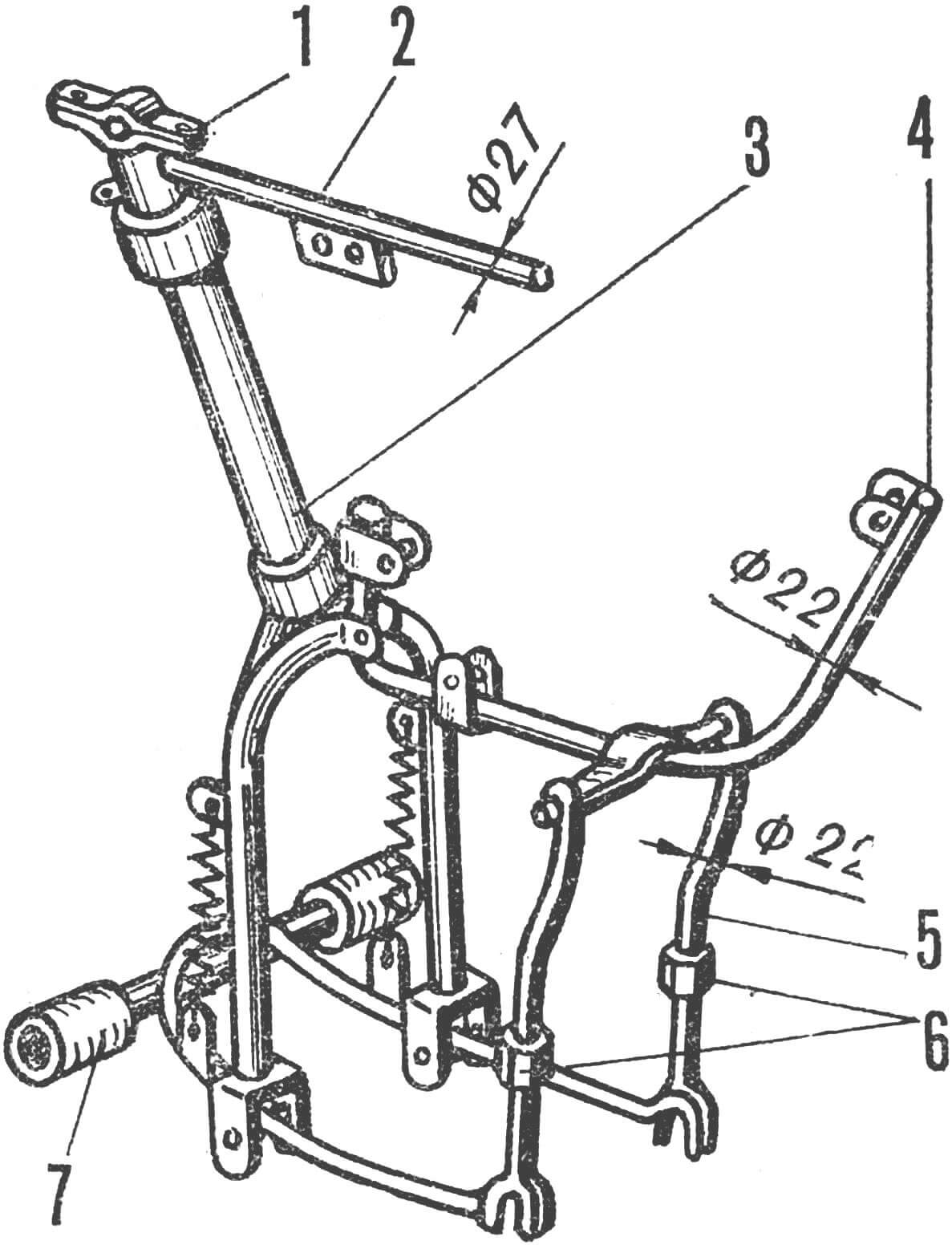

The front fork is taken from the T-200 scooter. The frame head is made of a Ø 38 mm pipe, to the ends of which cups for thrust bearings with a suitable internal diameter are welded. The excess top portion of the fork tube has been cut off. Parts from the T-200 scooter were also used to attach the steering wheel.

A steering wheel from any moped that has a device for switching engine speeds Sh52 is suitable. You can use a motorcycle (or scooter) steering wheel by installing a gear shift lever at its left handle.

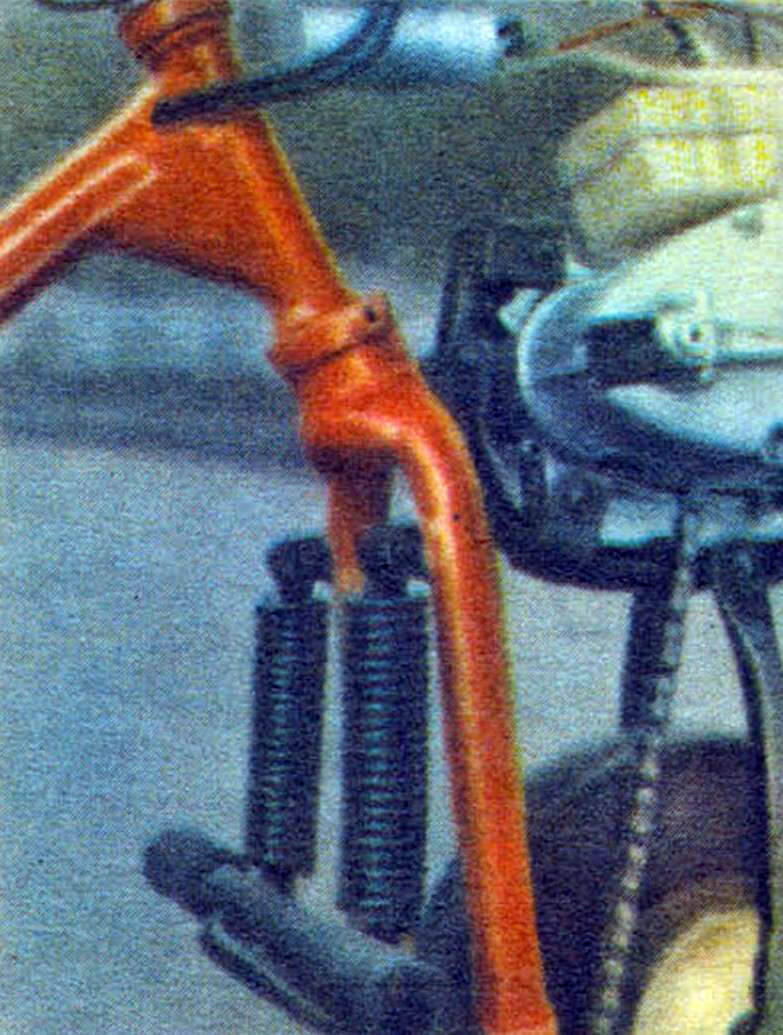

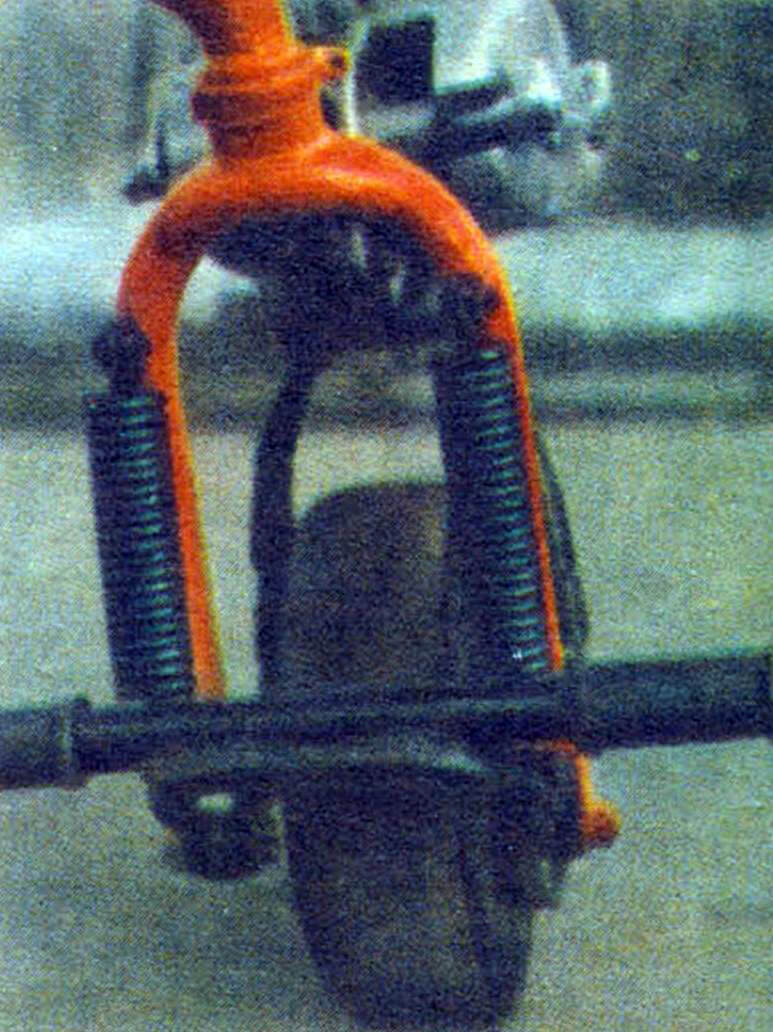

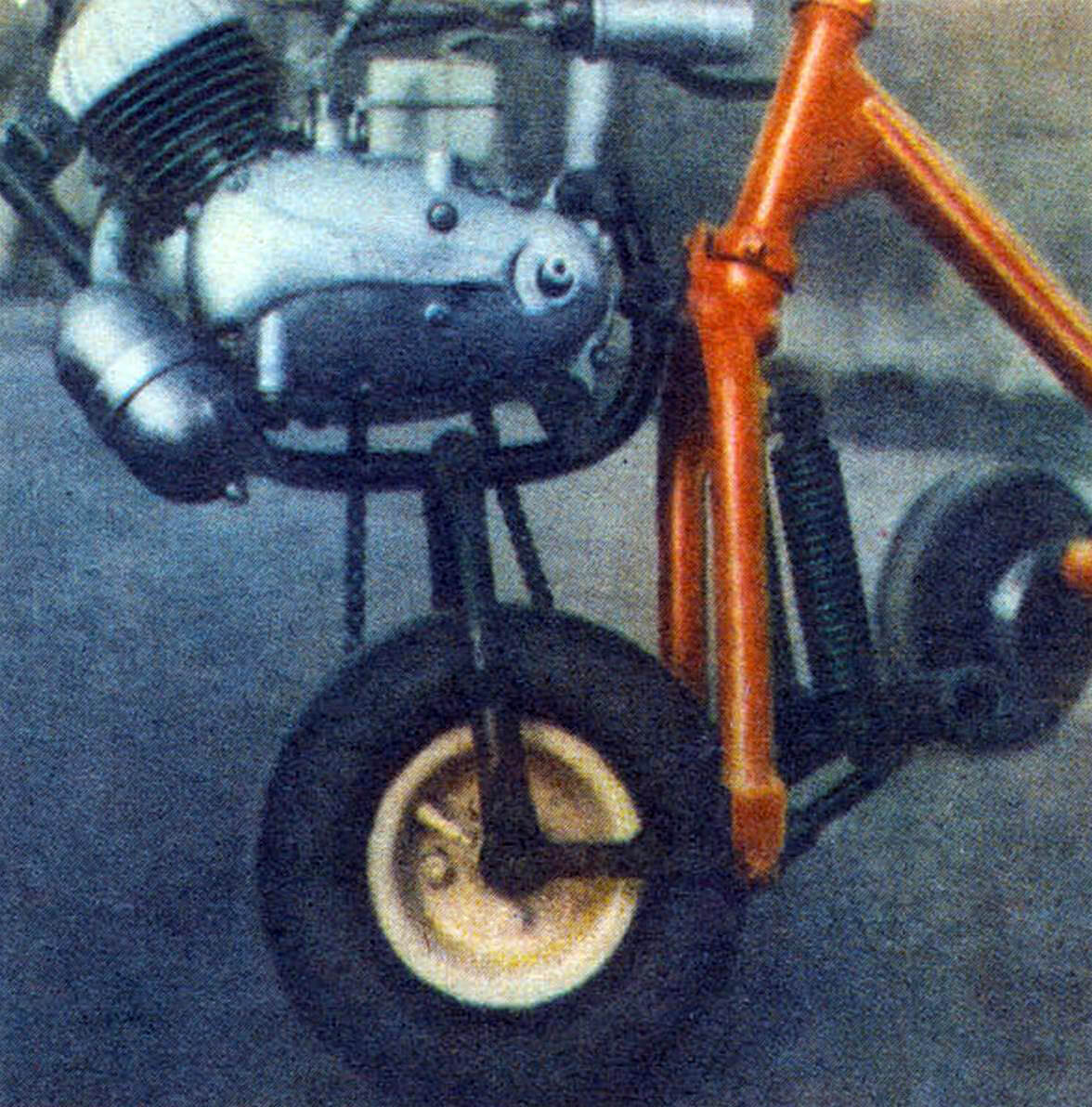

The front fork is equipped with a Sh52 engine from the Riga moped with a power of 2.2 liters. With. The bracket for it is made of a Ø 22 mm pipe in the form of an arc that goes around the engine from below, has eyes where the crankcase and cylinder head lugs are inserted, which are then secured with bolts. The cylinder head is rotated 180° for this purpose. The rear end of the bracket is pivotally attached to the steering column of the front fork, and the front end rests on the wheel axle through two split rods.

The arc-shaped bracket for installing the engine, the vertical fork, the rods and the lower swing arm of the front fork form a four-link hinge. Thanks to this, when traveling, the engine oscillates along with the wheel and the chain tension remains unchanged. To adjust it, the vertical split rods have nuts with right and left threads. M16 coupling bolts are screwed into the nuts, and by rotating them the chain is tensioned. To prevent self-loosening, the bolts have locknuts.

All tricycle controls are mounted on the steering wheel: on the right – the gas handle, brake lever, ignition switch and horn button; on the left is the gear shift lever in combination with the clutch lever and the decompressor lever. The steering wheel has a rotation limiter in the form of three stops, two of which are welded to the lower cup of the head tube of the frame, and the middle stop is welded to the fork.

The engine has undergone the following modifications: holes have been sawn in the right crankcase cover to allow the chain to pass down; the starting pedal is located on the right. It is converted into a motorcycle type, as on the Agidel micromotorcycle (see “Model Designer” No. 5, 1971). Muffler – shortened, taken from D5 engine; the exhaust pipe is shortened to a minimum, gases are exhausted at an angle of 90°, to the side. This compact muffler dampens exhaust noise well and the engine develops normal power.

A Ø 27 mm pipe is welded horizontally to the steering column, on which a gas tank from a motorbike and an ignition coil are mounted.

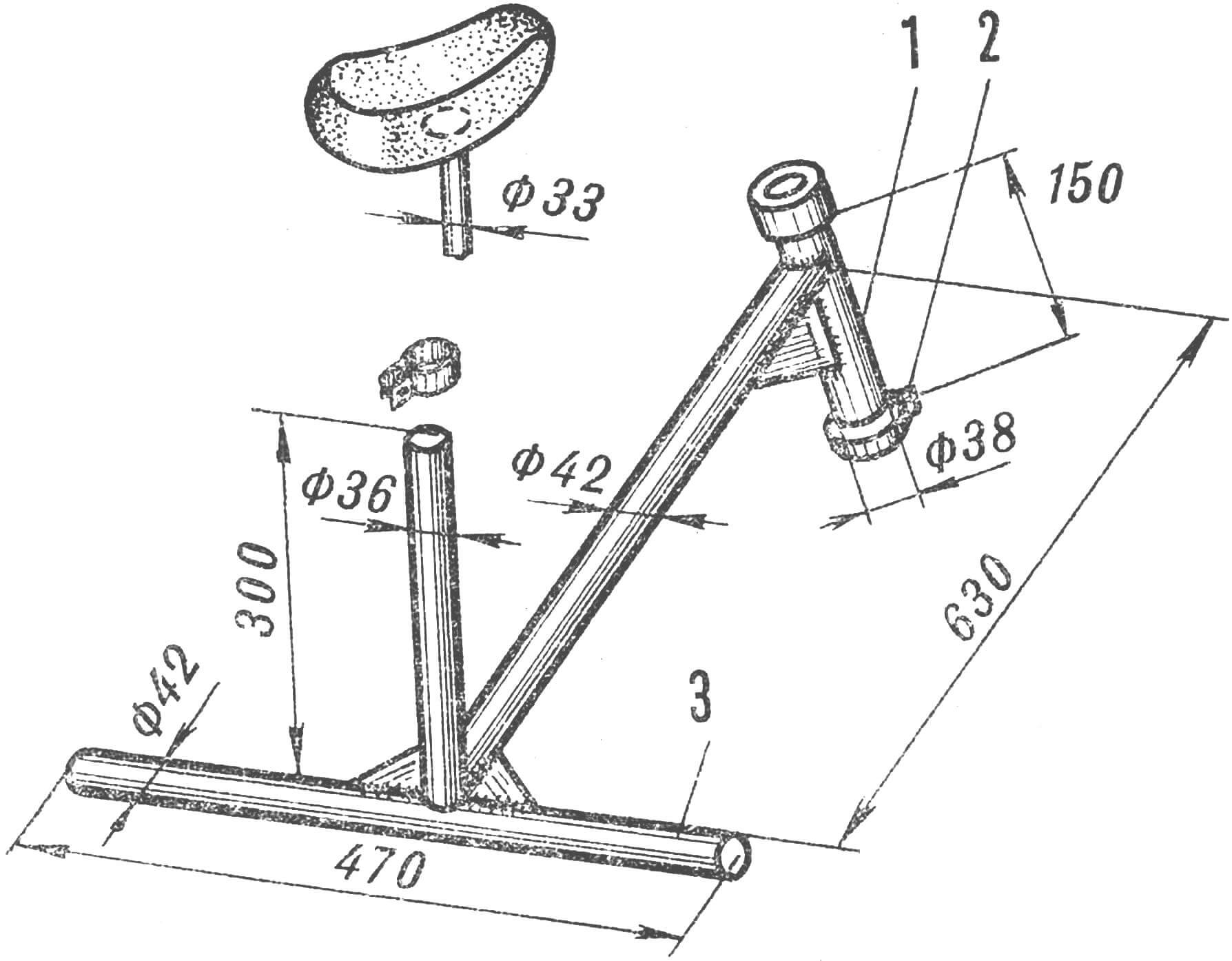

1 – head pipe; 2 — stop of the steering wheel limiter; 3 — rear axle pipe.

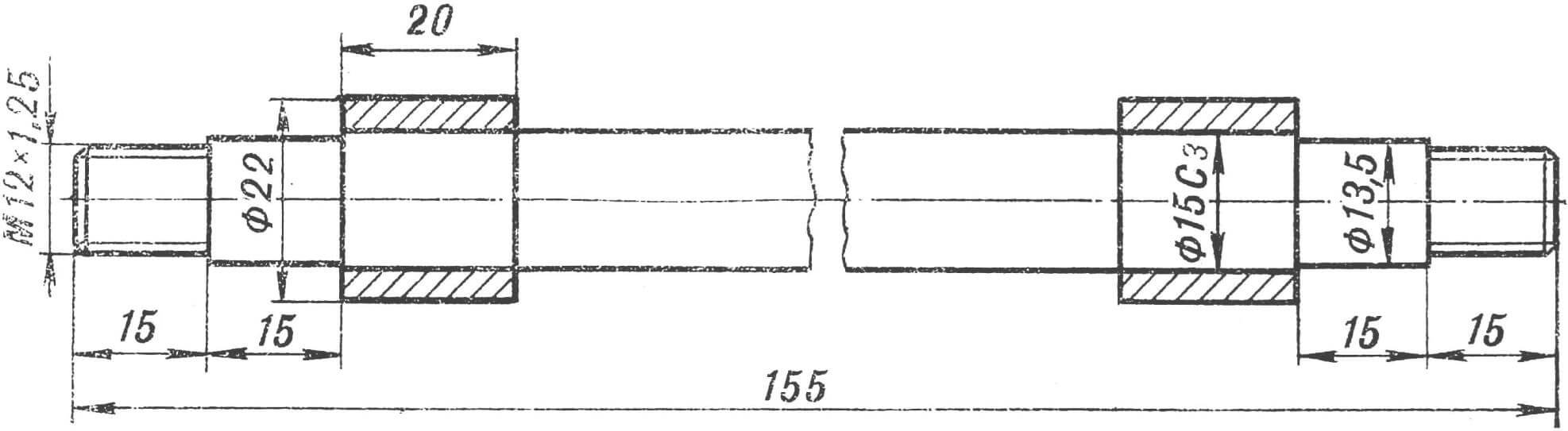

The rear axle consists of two pipes welded to the middle liner, which has a rectangular hole for five elastic torsion bar plates from the front axle of the C3A sidecar, working in torsion. Swinging arms are attached to the ends of the plates.

We used the Zaporozhets front axle levers found in scrap metal. The levers of the front axle of the C3A motorized stroller or levers made from angles welded in a U-shape are also suitable.

1 — steering wheel mounting parts (from the T-200 scooter); 2 — pipe for fastening the gas tank and ignition coil; 3 — fork (from the T-200 scooter); 4 — engine mounting bracket; 5 — split rods of the engine bracket support; 6 — threaded bushings for chain tension; 7 – step.

Axle shafts and support discs for shoe brakes are welded to the ends of the levers. The pads can be taken from the Voskhod or Java-50 motorcycle. The brakes on both rear wheels are actuated by a lever located on the right side of the steering wheel through flexible cables.

The rear axle and front fork of the tricycle are connected by an inclined pipe Ø 42 mm. The welding points are reinforced with U-shaped gussets. On the rear axle there is a vertically welded pipe to which the seat from the Riga moped is attached. Control cables and wires should be routed inside pipes whenever possible, which gives the machine an elegant appearance.

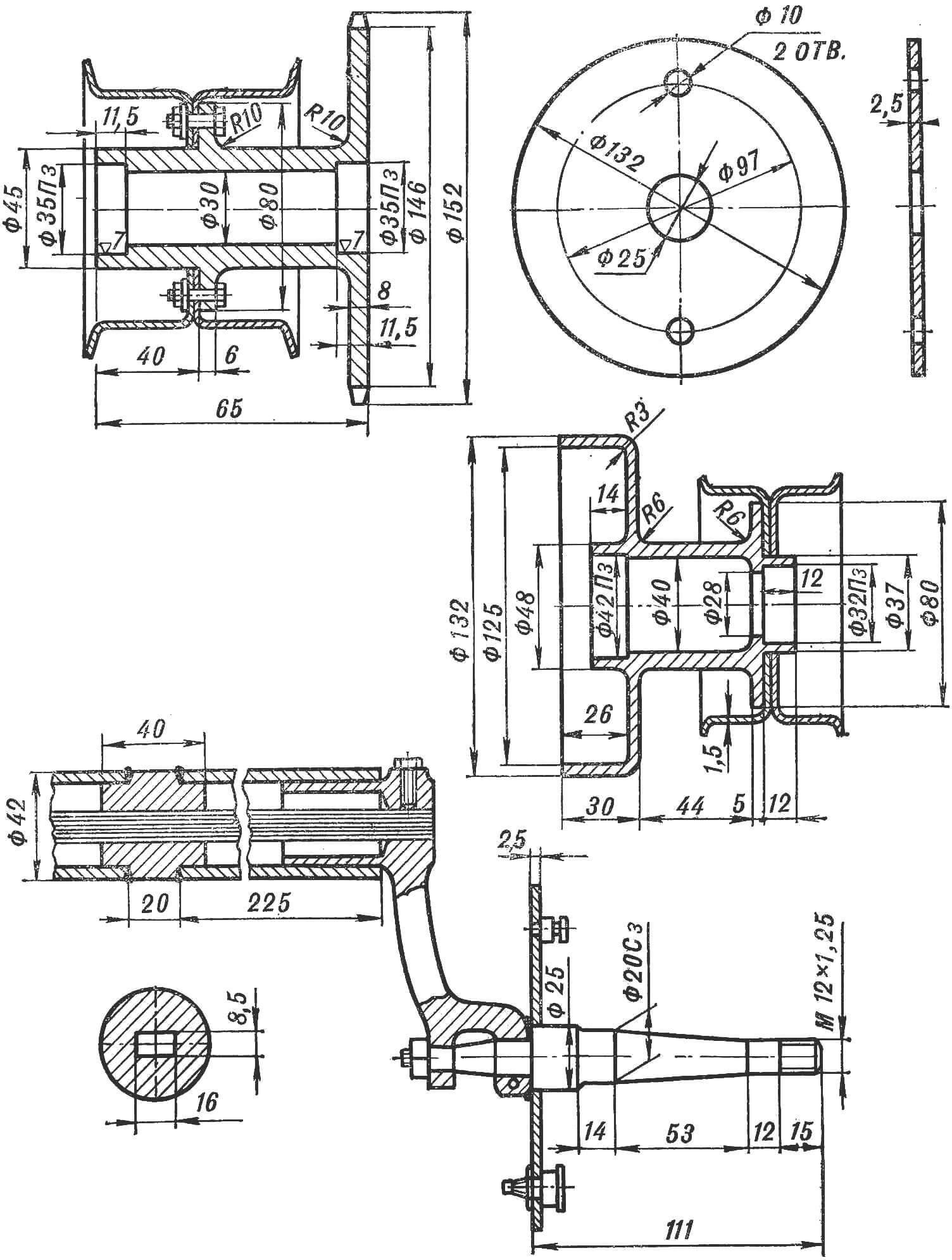

front wheel hub; brake support disc; rear wheel hub with brake drum; rear axle with torsion bar suspension.

Number of teeth Z = 36; Step t = 12.7; Ø start env. Before = 145.6; Chain roller Ø = 8.5 (mill Ø 8.7)

Wheels Ø 280 mm (3.5X5), the kind used by karting drivers. Wheel rims are made using the pressure method on a lathe. For this operation, it is necessary to machine a duralumin or steel punch to the shape of the future disk. The manufacturing technology is as follows: the punch is installed in the chuck, the disc blank is pressed against it through the lining with a tailstock quill, and at 700 spindle revolutions it is gradually compressed with a roller on the punch. After installation on the machine, it is advisable to cut the workpiece and grind it to the diameter. Its diameter depends on the shape of the punch. The drive wheel sprocket has 36 teeth.

During testing, the tricycle showed good driving performance. It is easy to control and stable when cornering, since the independent torsion bar suspension of the rear axle allows the driver to perform them with an internal roll. The presence of front-wheel drive eliminates any skidding that is inevitable with rear-wheel drive. The simplicity and originality of the design, reliability and low cost allow us to recommend the “Grasshopper” tricycle for production in children’s technical creativity circles.

TECHNICAL DATA:

Total length – 1230 mm

Height (max.) – 860 mm

Rear wheel track – 909 mm

Dry weight – 32 kg

Speed - 40 km/h.

V. TAMBOVTSEV