A radio-controlled model of a racing sailboat yacht can be made from the most accessible materials. And instead of expensive branded equipment, you can use a remote control set that comes with modern toys.

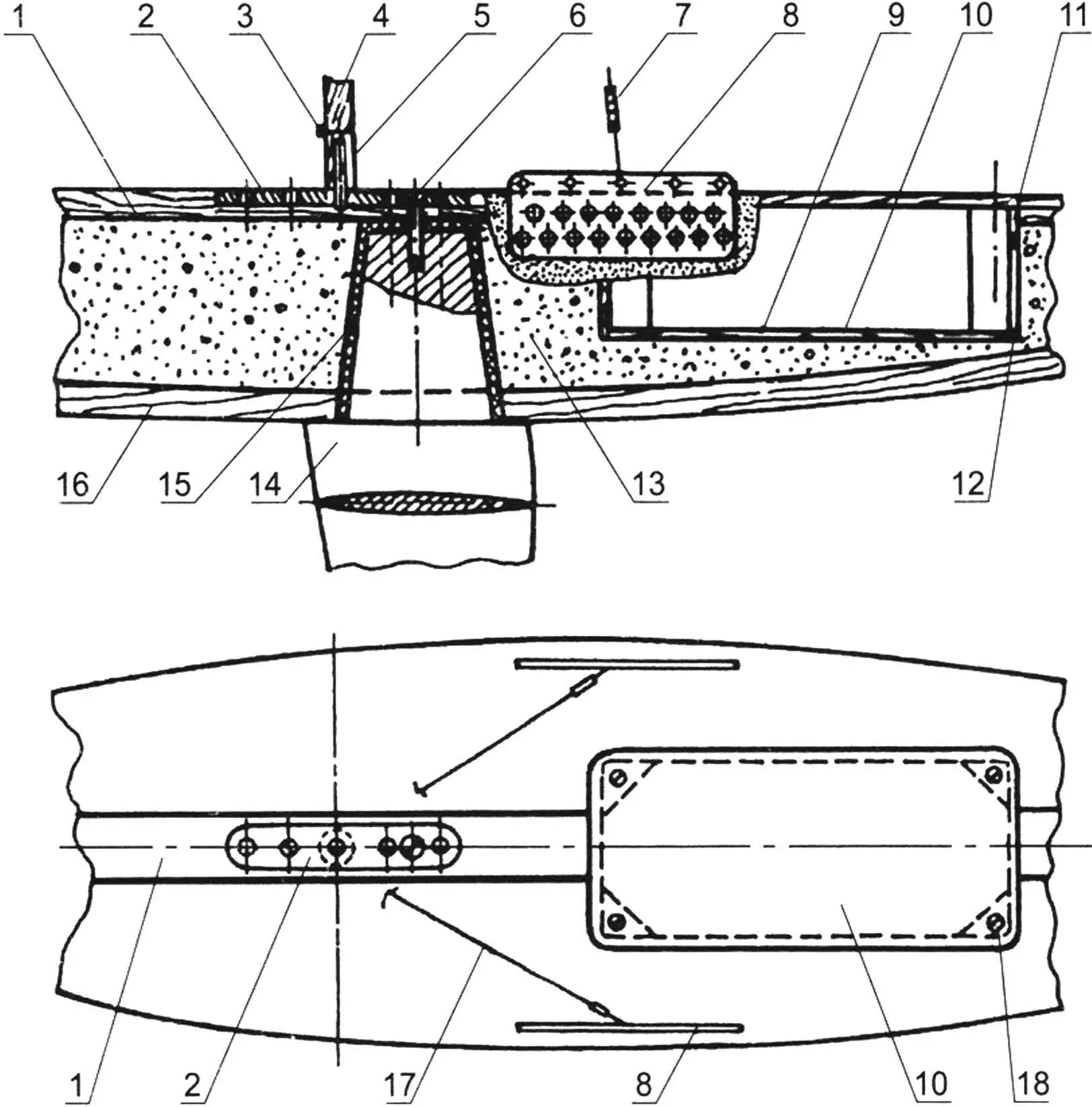

The model’s hull is made of packaging foam or PS-4-40 grade, reinforced with a flat wooden frame cut into the hull along its diametral plane. In addition to the frame, a box for the steering servo, a remote control receiver, power elements, a rudder hinge assembly, and a keel well molded from fiberglass and epoxy resin are also cut into it.

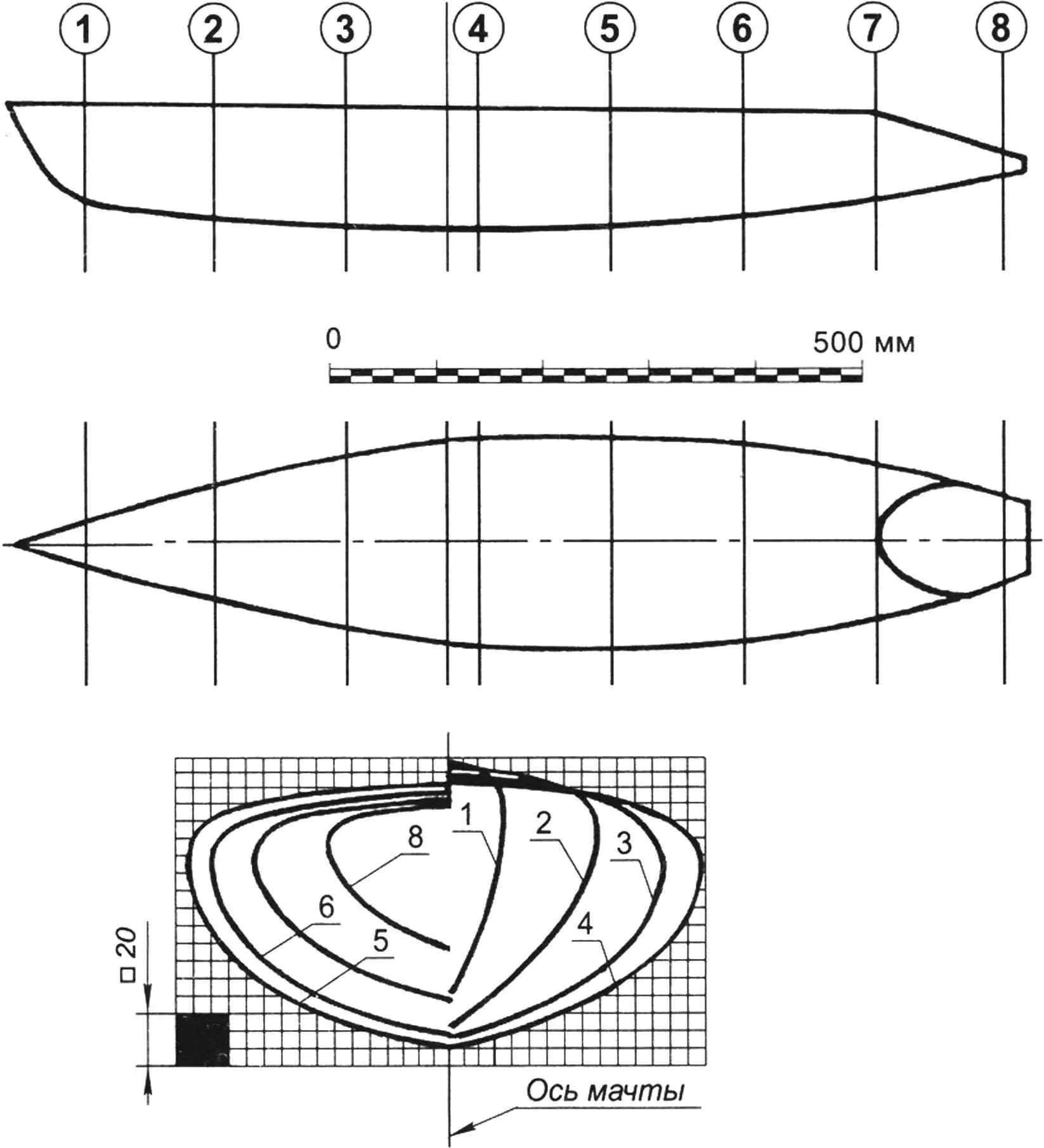

The hull construction begins with preparing a set of templates – the easiest way to make them is from thin plywood. And a foam blank of the hull of the required size can be assembled and glued from several blocks. According to the theoretical drawing, the diametral plane and contours of the “half-breadth” and “side” projections are marked on it. Then the excess is cut along the contour lines using a hot wire cutter.

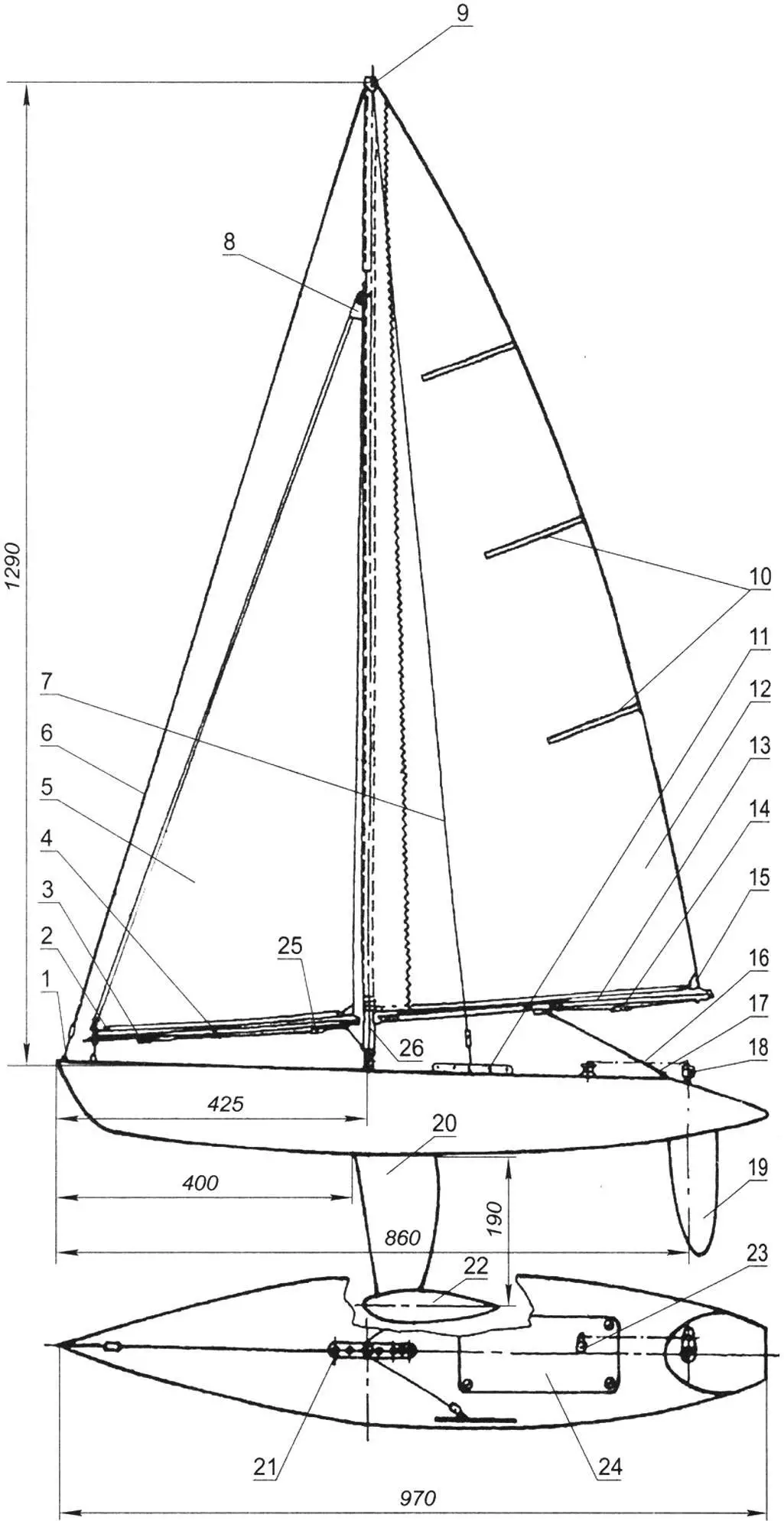

1 – forestay chainplate; 2, 8, 15 – bowties; 3 – jib boom (pine, batten 5×5 mm), 4 – jib sheet (nylon thread); 5 – jib (synthetic fabric or Mylar film); 6 – forestay (nylon thread); 7 – shroud (nylon thread); 9 – shroud and forestay attachment fitting; 10- battens; 11 – left shroud chainplate; 12 – mainsail (synthetic fabric or Mylar film); 13- main boom (pine, batten 5×5 mm); 14, 25 – tension strips (duralumin, sheet s1 mm); 16 – main sheet (nylon thread); 17 – cleat; 18 – rudder stock rocker; 19 – rudder blade (duralumin, sheet s4 mm); 20 – keel (duralumin, sheet s6 mm); 21 – mast step plate (duralumin, sheet s3 mm); 22 – bulb (lead 900 g); 23 – steering servo rocker; 24 – radio control compartment cover (plywood s4 mm); 26 – mast

Next, the hull section planes are marked and templates are “planted” on them – using cutters and a round rasp, “markers” are cut – the exact outlines of the future hull. It remains only to cut off the excess foam between the “markers”, and the hull is roughly ready. It is finally finished with sandpaper of various grits glued to wooden plates.

Now let’s work on the keel. For it, you will need sheet duralumin 6 mm thick and lead. The keel profile is symmetrical, with rounded front and pointed rear edges. The keel “tongue” has a pyramidal shape. The keel well is laminated from fiberglass and epoxy resin directly on this “tongue” – the lamination thickness is about 3 mm.

The keel bulb weighing about 900 g is cast from lead. The easiest way is to use the “sand casting” technology – in a sand-clay mold obtained by pressing into it up to the symmetry plane of the model a bulb turned from wood. The finished part is made from a pair of such castings, pulled together into a single whole with three or four self-tapping screws.

The next stage of hull construction is gluing the frame elements into it, as well as the keel well, for which grooves are cut in the foam under the wooden battens, plywood box and keel well, and all these parts are fixed in the hull with epoxy glue.

The prepared hull is finally sanded and covered with two or three layers of thin fiberglass or nylon over epoxy resin. After the binder cures, it is puttied and sanded again. Then the mast step plate, rudder hinge assembly, forestay and shroud chainplates are glued into it. The mast, which is a truncated cone, is cut from a quality pine batten: its larger diameter is 12 mm, smaller – 6 mm. A fitting made from a piece of copper tube 5×0.5 mm is fixed in the upper part of the mast. Holes with a diameter of 1 mm are drilled in three bent legs of the fitting for attaching the forestay and shrouds.

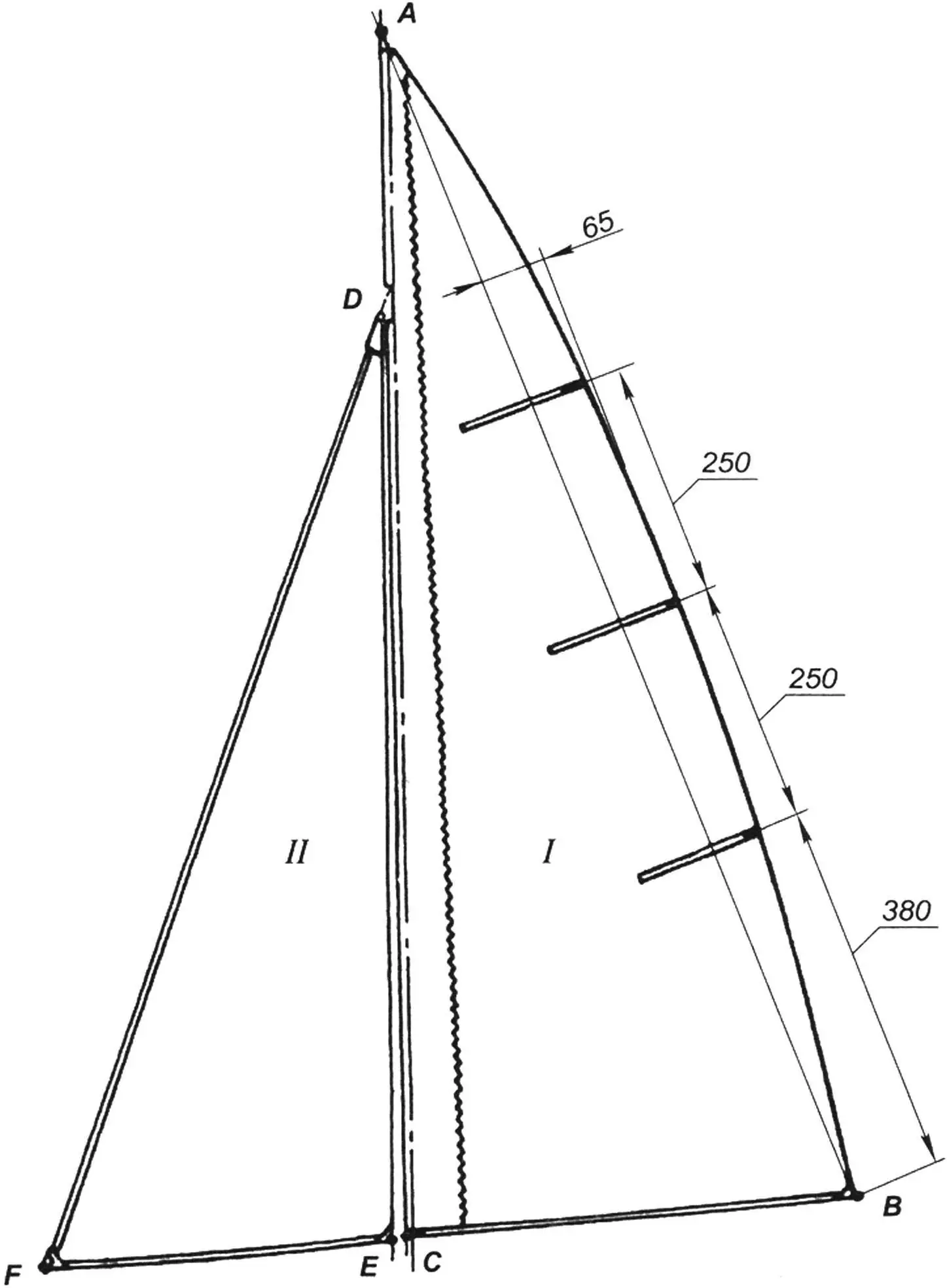

AB = 1290; AC = 1240;

BC = 460; DF = 1050;

DE = 950; EF = 360

The mast is installed on the hull using a pair of shrouds and a forestay. These standing rigging elements are pieces of strong synthetic thread or fishing line. Their upper ends are attached with loops, and the lower ones are fixed on special tension strips – duralumin strips with drilled holes.

The sails are cut from thin non-porous synthetic fabric. However, they can also be cut from Mylar film. When cutting the mainsail, it is necessary to provide an allowance for the mast pocket (its width in the lower part of the sail is 40 mm, in the upper part – 20 mm), hemming of the lower and rear edges. The latter is supported by three battens – plastic plates placed in batten pockets sewn on the sail.

1, 16 – wooden frame elements (pine, batten 30×10 mm); 2 – mast step plate (duralumin, sheet s3 mm); 3 – jib sheet cleat; 4 – mast (pine, batten 12×12 mm); 5 – mast heel (steel, wire Ø3 mm); 6 – keel mounting screw M4; 7 – tension strip (duralumin, sheet s1 mm); 8 – shroud chainplate (duralumin, sheet s1 mm); 9 – radio equipment compartment bottom (plywood s3 mm); 10 – radio equipment compartment cover (plywood s4 mm); 11 – “corner” (pine, batten 20×20 mm); 12 – radio equipment compartment wall (plywood s3 mm); 13 – hull base (PS-4-40 foam or packaging); 14 – keel (duralumin, sheet s6 mm); 15 – keel well (laminated from fiberglass and epoxy resin); 17 – shroud (nylon thread); 18 – hatch cover mounting screw M3

It is recommended to start debugging the yacht’s sailing qualities in an uncontrolled mode. The main thing here is to ensure that the center of lateral resistance of the hull and the center of sail coincide, when the yacht does not head up into the wind and does not bear away from it. To adjust this, it will most likely require correcting the mast position – it will have to be moved to another hole on the step plate. Also, within small limits, the center of sail can be changed by retensioning the shrouds and forestay, thereby deflecting the mast forward or backward. A properly tuned model is able to automatically maintain course relative to wind direction.

After installing the receiver and steering servo, no readjustment of the yacht is required. The proposed model is designed only for rudder drive.

«Modelist-Konstruktor» No. 4’2025, Sergey SOROKIN