Its author, Vladimir Vasiliev chose for your snowmobile most common scheme: one track and two guided skiing. Motonarty have high dynamic performance, due to the small weight (about 130 kg) with a powerful engine. In tests they showed a very decent speed — 70 km/h, however, in heavy snow, and with one driver.

Track the car by Vladimir Vasiliev with a width of 400 mm. it is Curious that it is not rubber, but made from two strips of cotton cord. The width of each 180 mm with a thickness of 6.25 mm. the length of the support surface caterpillars of 1100 mm. “I have tried, — says Vladimir Vasiliev, is to use a conveyor belt, but when our cold (40-50 degrees below zero for our edges are not uncommon!) it freezes and loses all flexibility. Well, cotton is elastic”.

Frame Motonari Vladimir Vasiliev is welded from thin steel tubes. The engine and transmission are closed light, beautiful shape of the hood. In the front of the removable hatch through which provides a good approach to engine and transmission.

Ski the steel, profiled, provided with undercuts and suspension.

WITH V-BELT VARIATOR

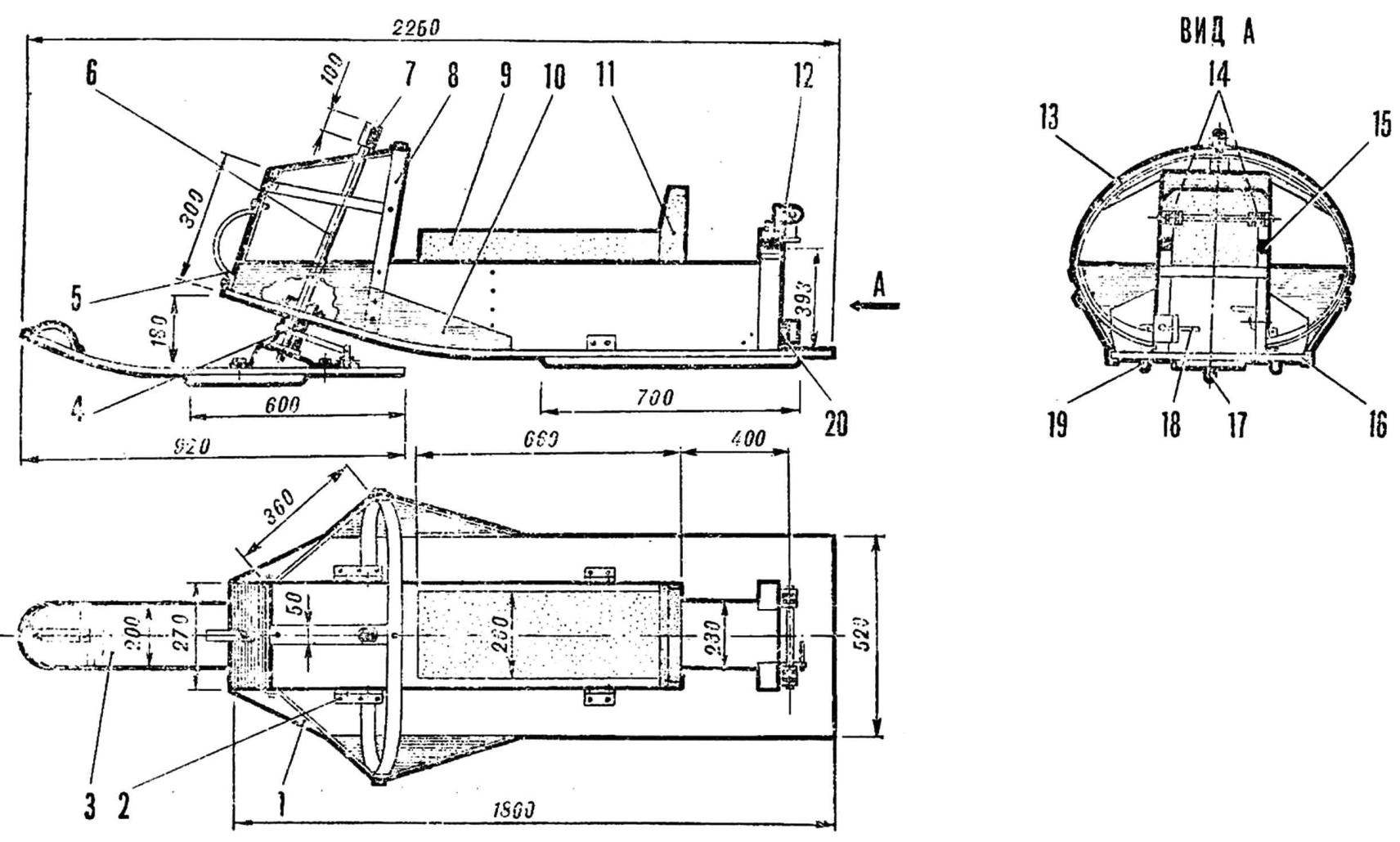

About a dozen snowmobiles of various designs built enthusiast technical creativity of the city of Khanty-Mansiysk V. F. Meledin. And motonarty with V-belt variator (Fig. 4 and 5) designed by A. Abdurashitov and V. Kurzenko under his leadership.

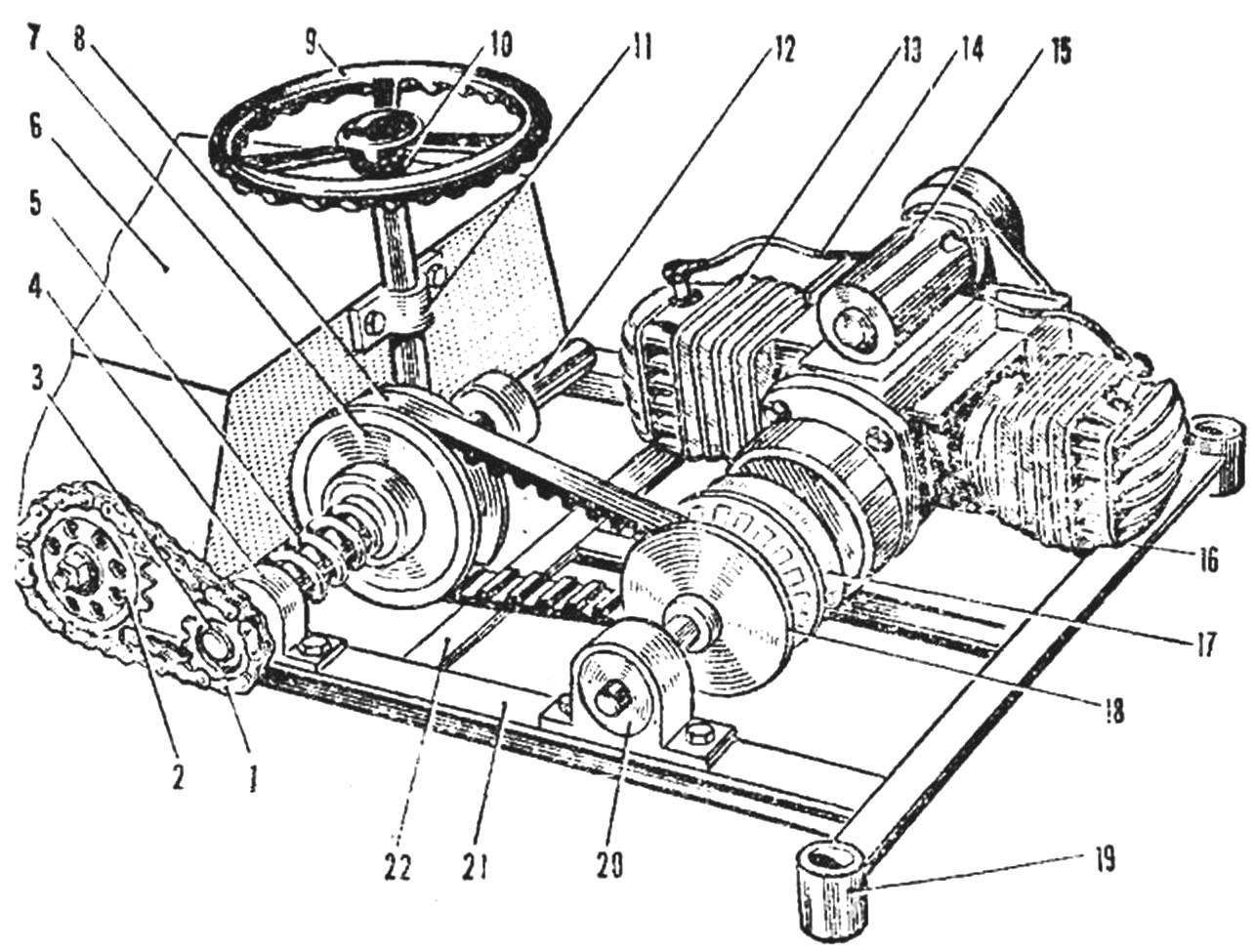

Fig. 4. Motonarty with V-belt variator.

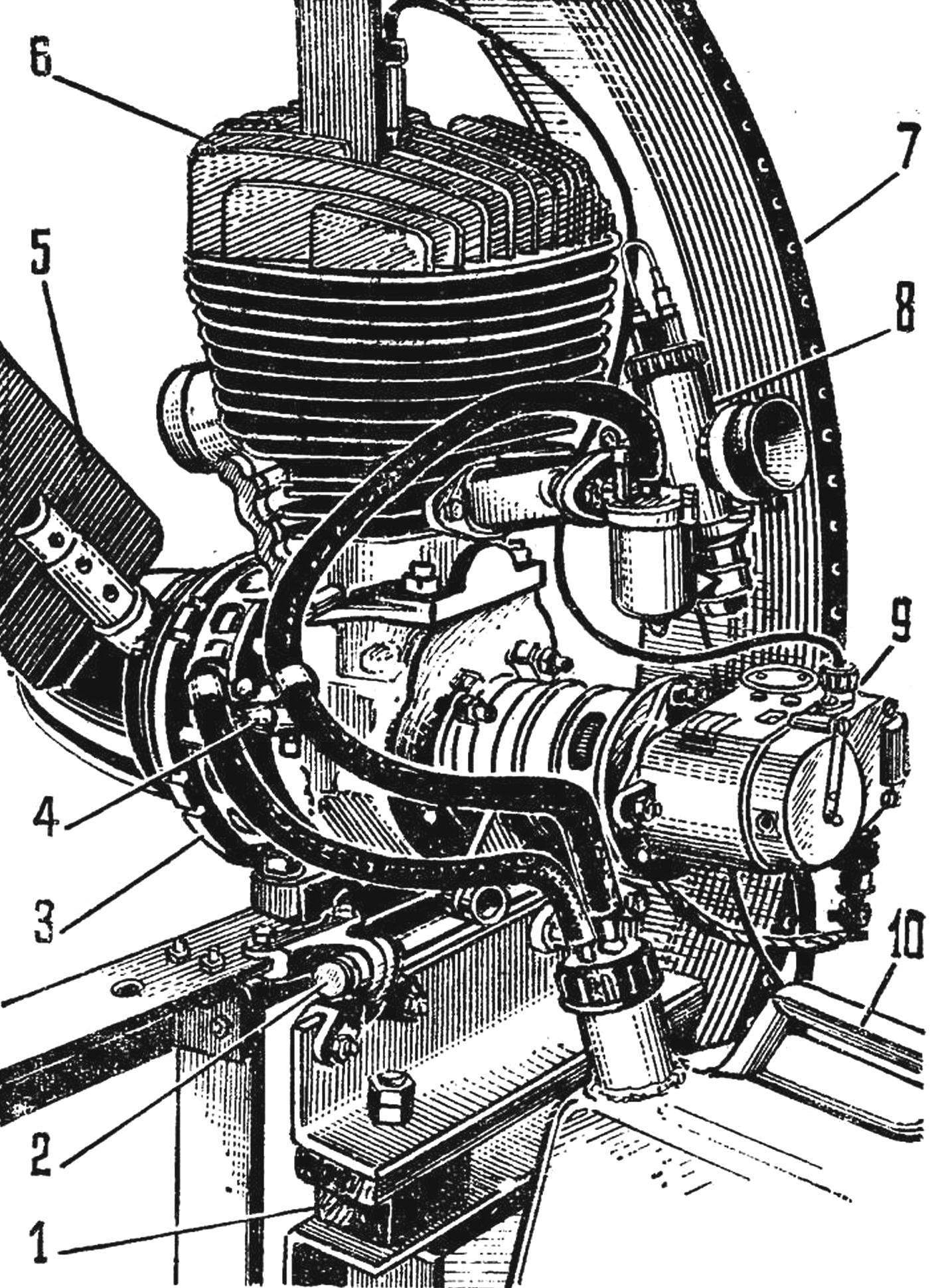

Fig. 5. Powerplant motoart Abdurashidova A. and V. Kurzenko:

1 — side chain transmission, 2 — sprocket drive shaft track, 3 g— sprocket side transmission, 4 — clip ball bearing, 5 — spring, 6 — driver seat, the 7 driven pulley of the CVT, 8 — belt variator 9 — steering wheel, 10 — steering wheel 11 — the mount of the steering column 12 to the shaft of the driven pulley of the CVT, 13 — motor, 14 — high voltage wire, 15 — generator 16 — cross beam of the chassis frame, 17 — casing centrifugal regulator, 18 — drive pulley variator, 19 — axle swivel axis of the ski 20, the bearing shaft 21 are a longitudinal beam of the frame, 22 — cross beam.

What caused the desire of khantymansii to put on my car this is, in General, unusual for motoart mechanism? The fact that the continuously variable transmission greatly simplifies the management of motonarty. It eliminates the streaking that occurs when switching speeds with conventional transmissions and resulting in breakage of the lug and break the chains and significant overloads in the transmission.

Motoart frame is welded of steel profile, corner 45×45 mm, it contains two longitudinal and three transverse element. At the ends of the front cross member is welded sleeve rotary axes of the skis. The sub frame of the same angular profile, it is welded to the front crossmember and the longitudinal beams of the frame.

Engine “Ural” rigidly secured to the underframe, the arrangement is transverse. On the engine flywheel through flange planted fixed pulley of the variator. It mounted centrifugal ‘controller and four-bladed fan for cooling the engine.

The weights of the centrifugal regulator treated very carefully — the difference in their weight does not exceed 1 g. Such precision enables the variator to work at optimal engine speeds.

The diameters of the driving and driven pulleys of the variator are, respectively, 260 and 320 mm. the Movable disc of the driven pulley is pressed against a spring external Ø 80 mm (the diameter of the stem springs — 10 mm). Belt variator standard tractor-100, wedge-shaped, size 35Х30 mm with notches on the inner surface. Transfer from the CVT to the drive axle track is the roller chain. The gear ratio of the sprockets is 1:2.

Driving wheel track made in the form of several layers of rubberized strap is tightened by bolts between two steel sprockets.

Track — two rubberized cloths, in the gap between them is gear. Lugs from a steel corner profile 20×20 mm, they privernuty bolted to the track. To prevent: gaps in the locations of the bolts under the head of the latter with the inner side of the tape placed steel plate.

Track rests on four rink with a pneumatic tire on each tape. For this khantymansii used motorolleri wheels. In addition, at the junction between the strips is another, a support, a skating rink: it serves as a guide as it prevents slipping of the tapes in hand. This is especially true on the curves, when the tape tracks is experiencing large lateral loads.

Managed motonarty the steering wheel. At the end of the steering column mounted bipod, the associated thrust with the levers on the pivot axis of the ski. Thrust have threaded lugs, with which you can change their length in order to adjust the “toe” of the ski.

V-belt CVT greatly facilitated the management of motonarty: adjust the speed of the pedal associated with the throttle valve of the carburetor, that is, changing the speed of rotation of the engine crankshaft.

Fuel tank — steel canister, mounted behind the seats of the driver and passenger. Fuel to the carburetor a diaphragm pump delivers the automotive type.

Motonarty reach speeds up to 50 km/h (for dense snow), and can tow a trailer sled with a load up to 200 kg.

NO CLAIM TO ORIGINALITY

design, I built motonarty, in accordance with the drawings and descriptions published in your magazine — so begins the letter to the editor V. Kalashnikov from Norilsk. — I wanted to do and experience this mode of transport in our severe Northern conditions. And they have .in the mountains, in the woods, on the lakes, the snow thickness reaches 8 m and in the open areas of little snow — sastrugi. But cold — down to 40° and below.”

Motonarty V. Kalashnikov designed according to the scheme of 3X1, that means they have three bearing surfaces, two ski and one caterpillar. As the snowmobile from Khanty-Mansiysk, they also installed V-belt CVT. Engine — tractor of puskach PD-10 converted to an air-cooled (Fig. 6).

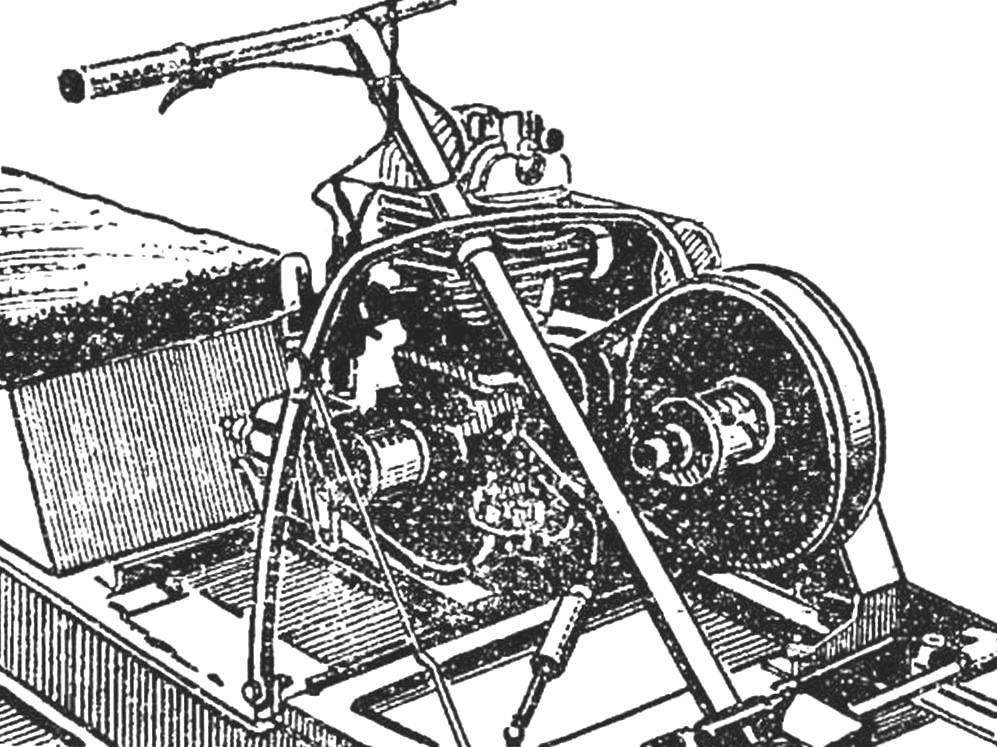

Fig. 6. A view of the power Assembly removed from the bonnet (motonarty V. Kalashnikov)

Caterpillar width of 500 mm from the conveyor belt. Grouser steel, of angular profile, connecting with a caterpillar with rivets.

V. Kalashnikov quite satisfied with my car, although there she is one “sin” — even in cold weather the engine quickly overheats. Apparently, when designing motoart necessary to provide forced cooling, in addition, it allows you to use warm air for heating the driver.

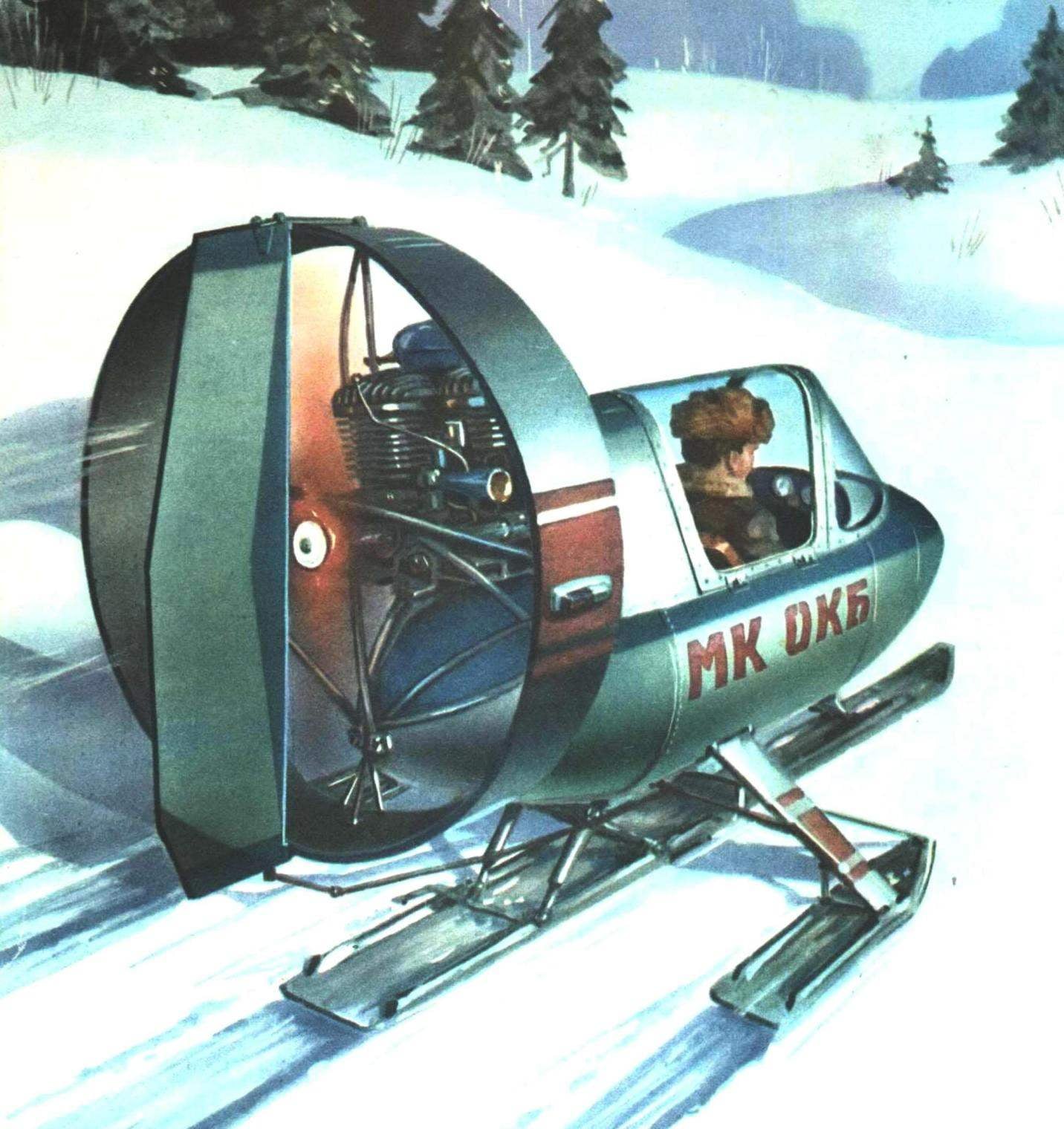

“TOURIST” — SNOWMOBILE FROM BRATSK

“The basis of design, — writes V. Timofeev, I put drawings and diagrams motoart “the Snowman”, published in “M-To” in 1972″.

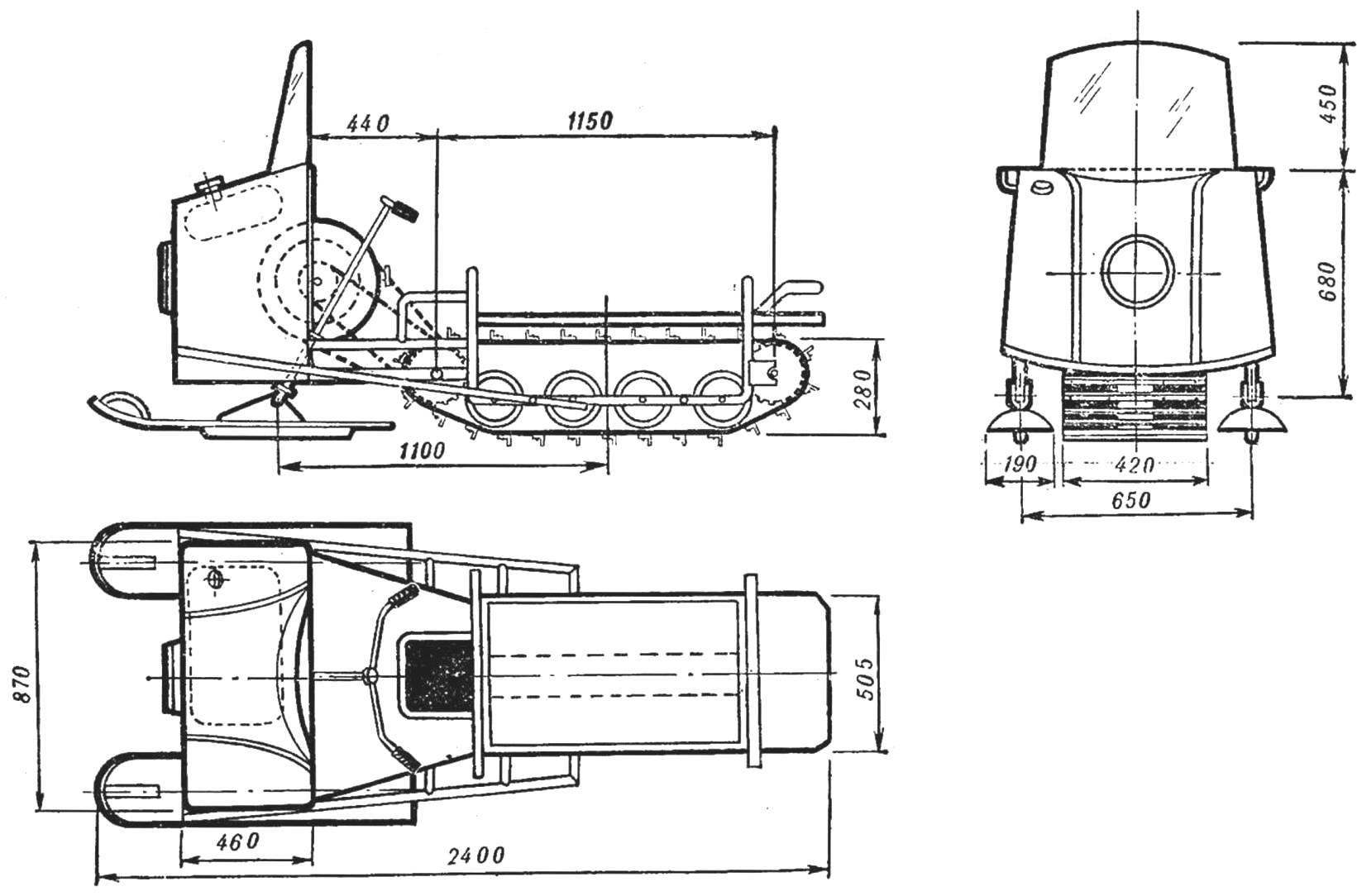

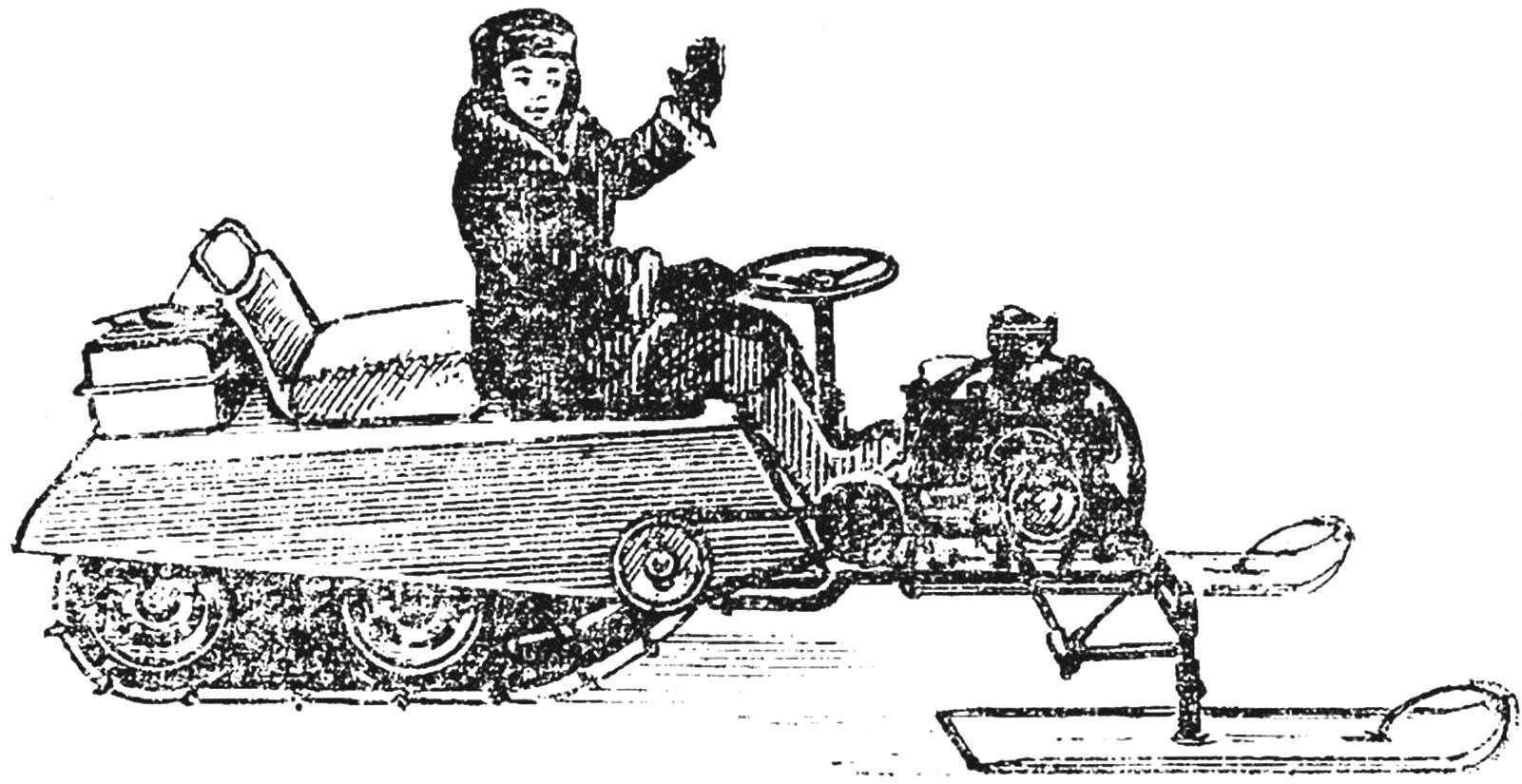

But only in base, because motonarty V. Timofeeva (see tab) differ from “the Snowman”. The frame of the snowmobile is welded from steel parts. Paneling — birch plywood, and plastic rests on the rivets. The steering column is borrowed from the Bicycle, and wheel — scooter-150. From the “Vyatka” is taken and the elements of lighting equipment.

Managed motonarty two front steering skis. Their axis — shortened front Bicycle fork associated steering trapeze of steel pipes. Ski suspended on springs.

The engine of the motorcycle IZH-Planeta is installed at the front of the sled and closed the hood. For easy maintenance the engine hood can be pushed forward: the front edge is attached to transverse angle of the swivel frame.

The engine is practically not subjected to alteration: saved the clutch, gearbox and kick starter. It differs from “regular” forced air cooling: air is supplied to the cylinder by the blower motor.

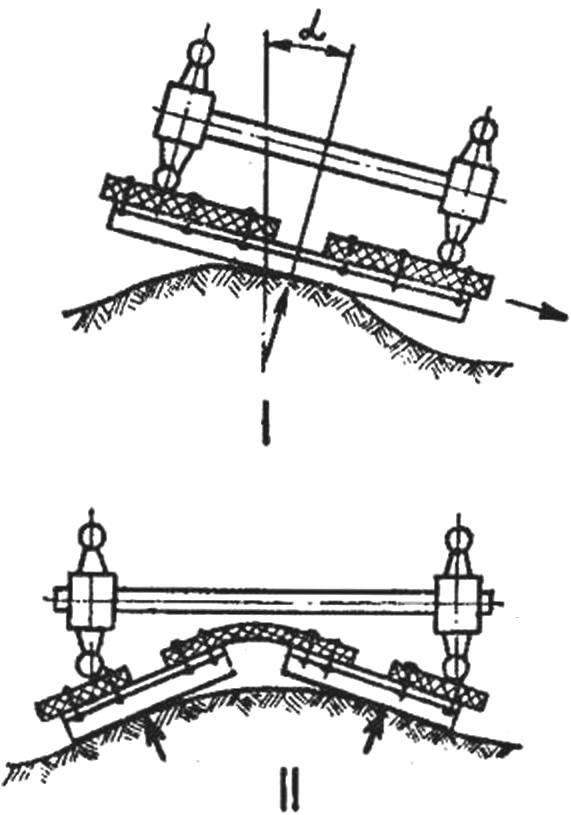

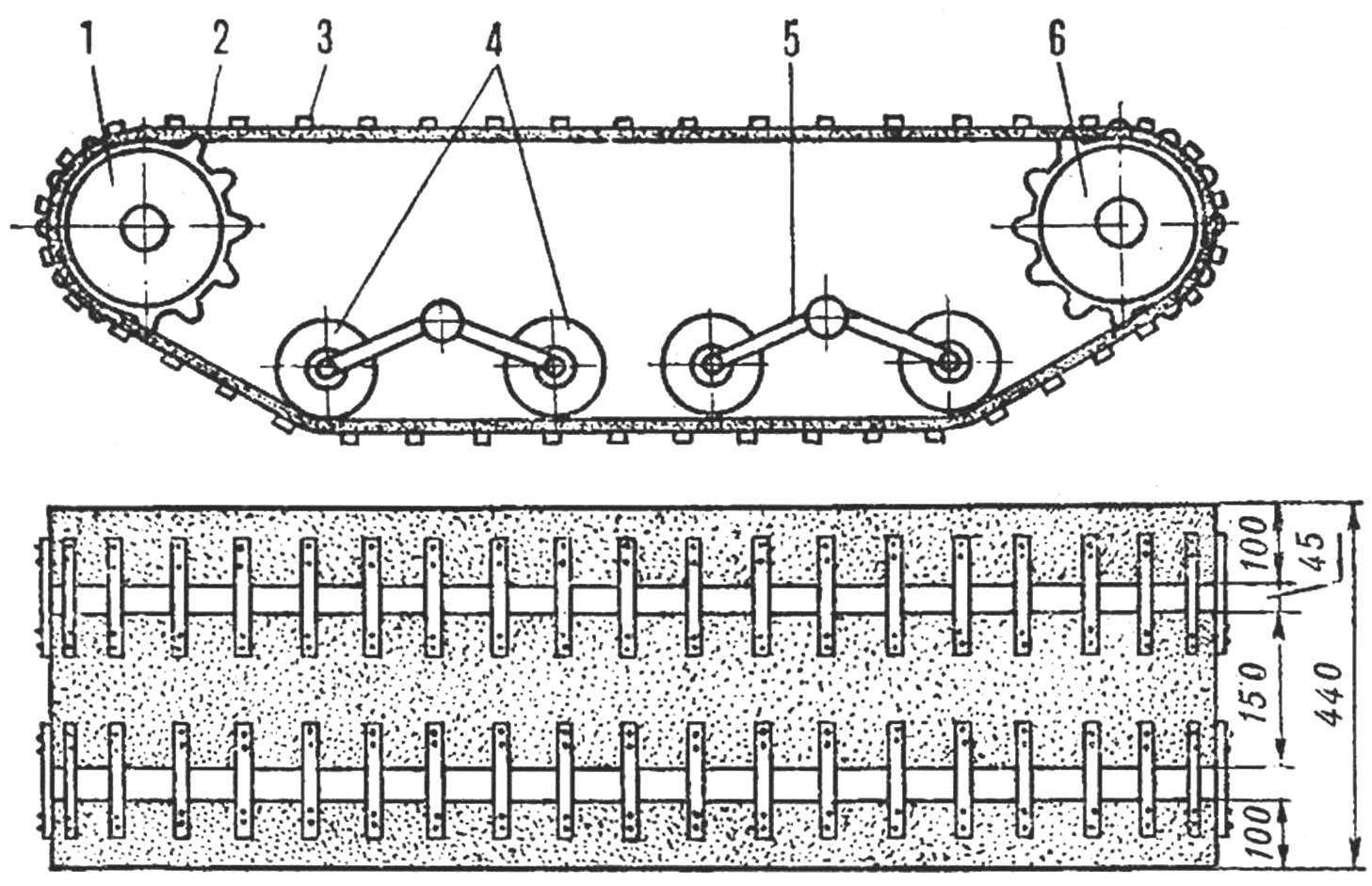

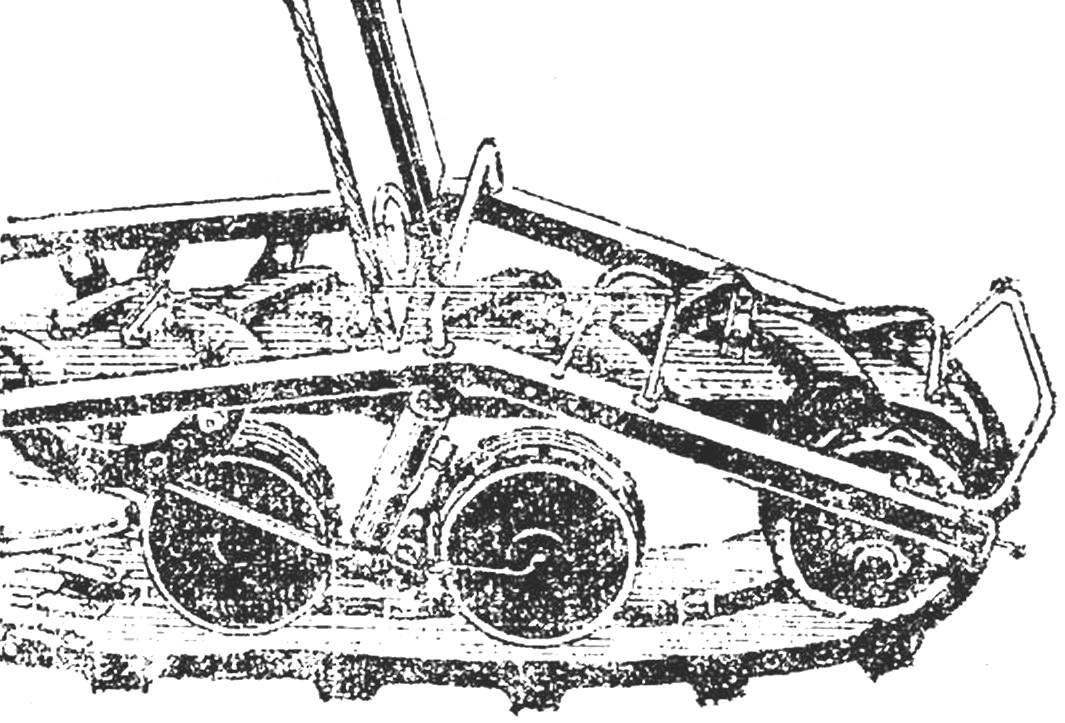

The original motonaga Timofeev — caterpillar mover (Fig. 7). It has no traditional support of Katko, who, even if a lot of them still do not provide uniform distribution of weight of the machine on crawler belt. In addition, when the rolling rollers through the lugs, there is an unpleasant vibration.

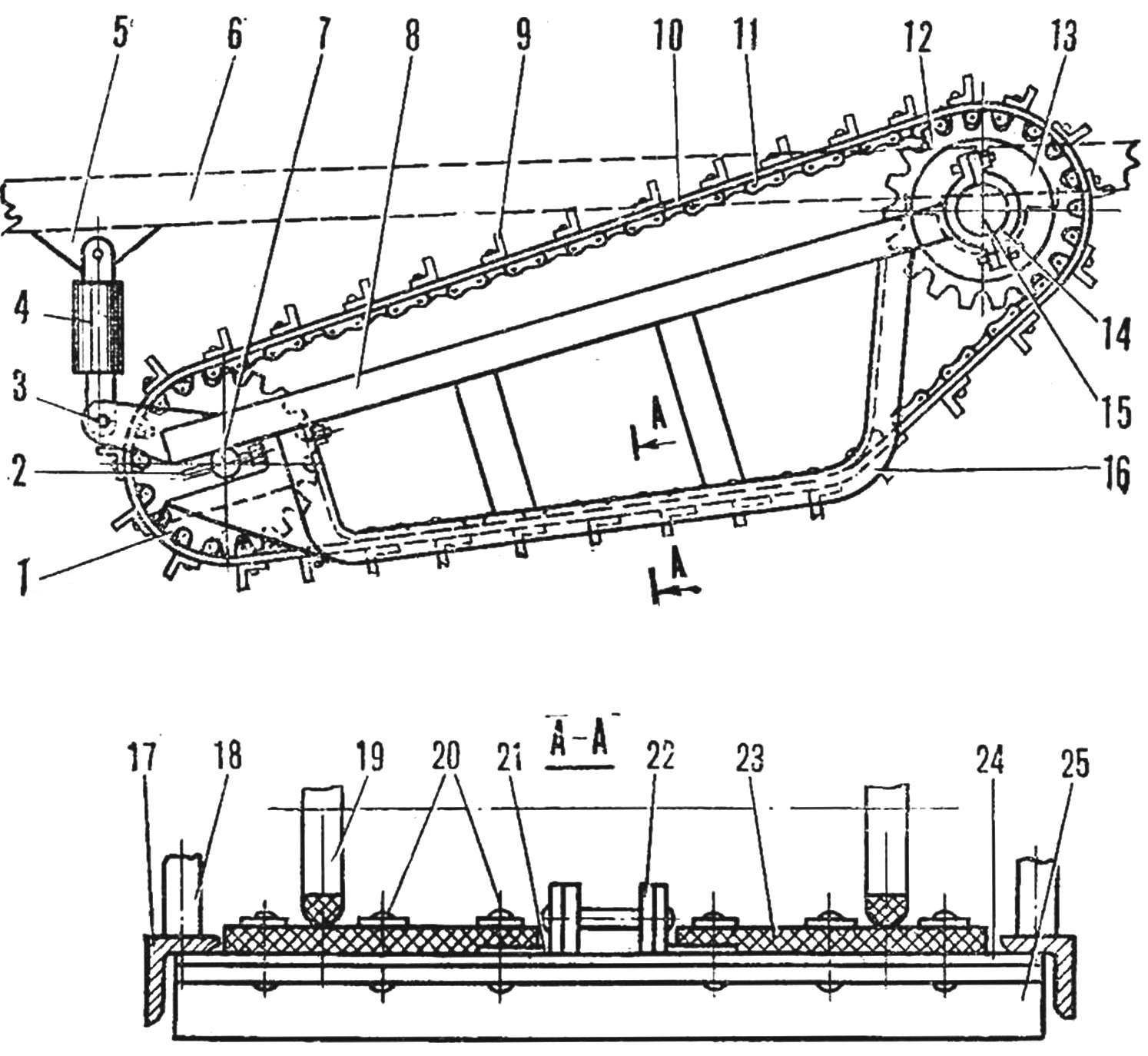

Fig. 7. Mover motoart “Tourist”:

1 — sprocket driven tape, 2 — bolt tensioning mechanism, 3 — bolt damper, 4 — absorber, 5 — ear of the shock absorber, 6 — body frame, 7 — axle stretch tape, 8 — carriage mover, 9 — lugs, 10 — track rubber-band, 11 — circuit, 12 — sprocket, 13 — track rollers, 14 — bearing suspension of the cradle 15 — front axle, 16, 17 — snake, 18 — tubular frame of the cradle 19 and the track roller, 20 — rivet, 21 — foot chain, 22 — chain 23 — track rubber-mite, 24 — textolite strap, 25 — grouser.

In motonartah V. Timofeeva road wheels replaced by skids; they are both guides of the tape. Their vertical shelf limit lateral movement of the track and completely eliminate any possibility of its slipping. The carriage of the propulsion unit is welded from steel tubes (top) and steel (lower part), which, in fact, are the runners. With housing frame it connects through the front drive axle track. The rear part of the carriage is joined to the frame via two spring struts. Thus, when driving on uneven snow and the road provided sufficient smoothness and softness.

Belt tension is regulated by moving the rear of its axis, is inserted in the longitudinal grooves of the carriage.

The caterpillar is made of two conveyor belts, the gap between them is leading chain. Ribbons are attached to the steel lugs associated with each hinge of the fifth circuit. Lugs are installed outside tapes and perevorachivayutsya bolts. The protruding parts thereof are based on the runners of the carriage. To reduce the resistance of sliding on the inner surface of the cleats installed textolite plates that slide along the working surface of the runners.

On the drive shaft of the track sprocket installed, the associated roller chain with the sprocket of the engine. In addition, it is equipped with two rubber-covered skating rink Ø 220 mm to prevent sagging of the belt and sprocket chain. Idler shaft the same host.

Test motoart “Tourist” showed that the flotation machine is good and the speed is sufficient.

IF THE SNOW RIBBED TRACK

from deep-sealing the wheels, it does not mean that he left the tractor. Such traces could pave the snowmobile “Vepr” I. Ryabtseva of the Tuva ASSR. Caterpillar motoart made of tyre tread tractor “Belarus” (Fig. 8).

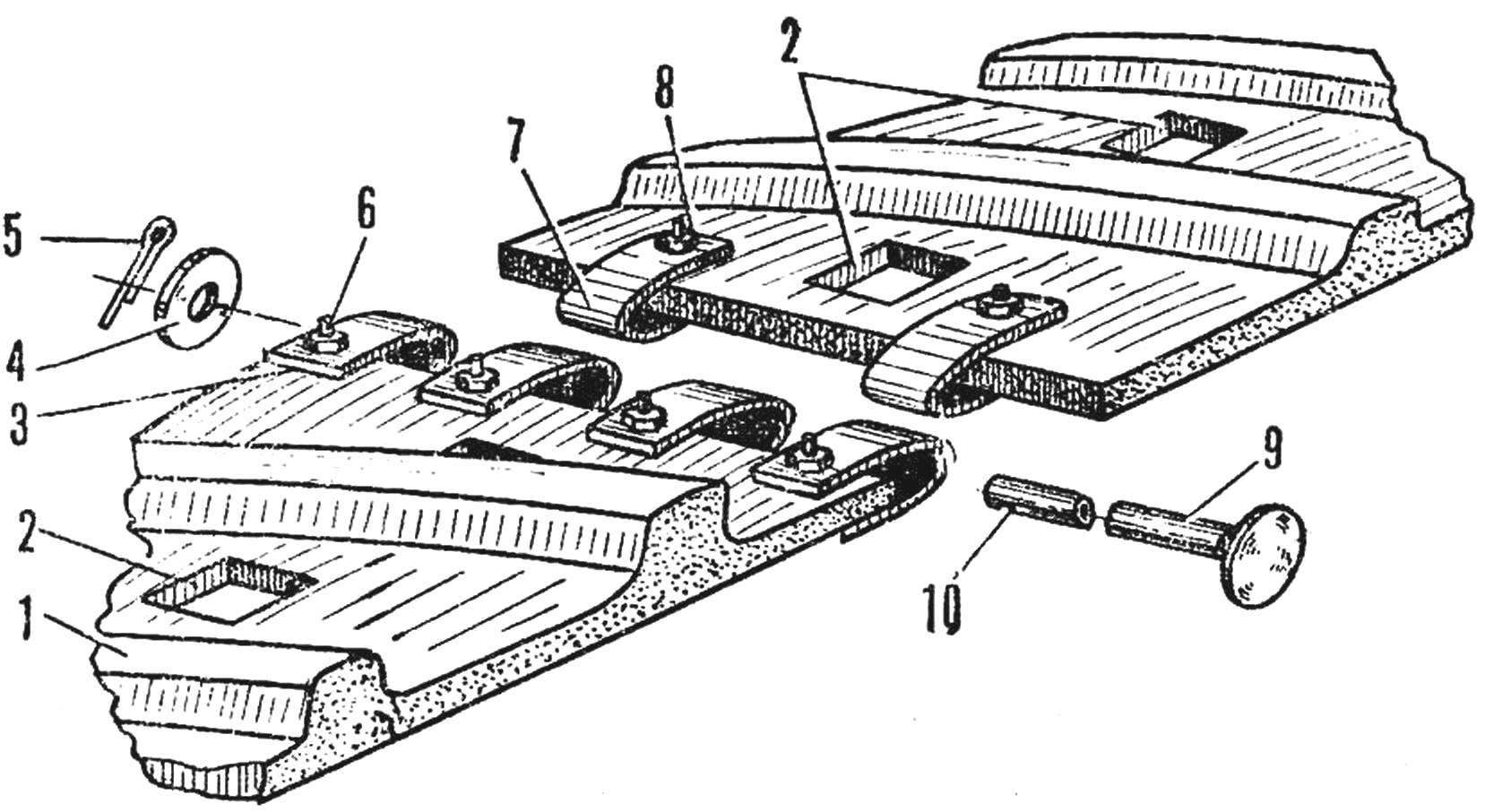

“The tape was even more “rib, than Transporter room,” — writes I. Ryabtsev. Track width — 320 mm. the Holes for the teeth of the drive sprocket is cut in the tape of a conventional chisel. To improve traction when driving motoart on Packed snow, ice on the tracks installed bolts protruding outward by 10 mm. the ends of the tape are joined simply and securely: using the staple-loops “stitched” steel finger 0 14 mm, which makes the tracks easily removable (Fig. 9).

Fig. 8. Mover motoart “Vepr”

Fig. 9. The abutment strips motoart “boar”:

1 — a tread of the tractor wheels, 2 — cut teeth sprocket, 3 — clamp-loop, 4 — puck, 5 — pin, 6 — bolt, 7 — and the bracket-hinge, 8 — Ganka, 9 — the pin, 10 — hole for the cotter pin.

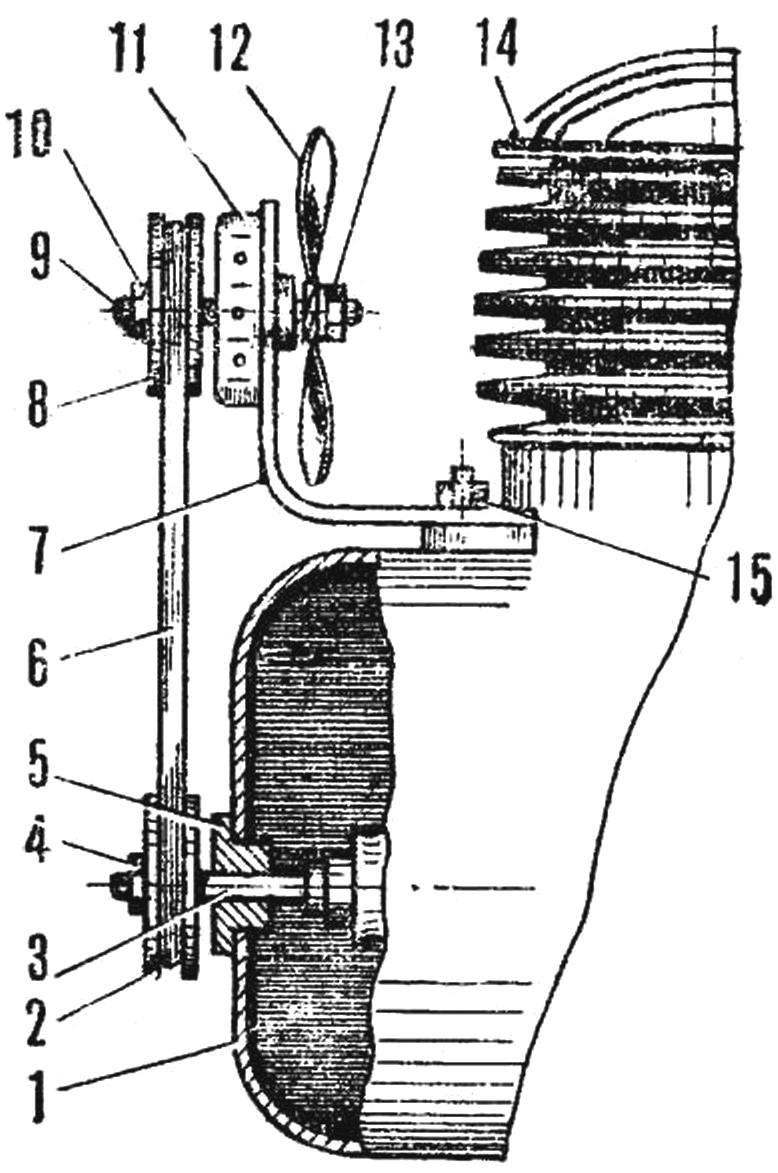

Fig. 10. Installation of the fan on the engine motoart “boar”:

1 — crankcase IZH-Planeta 2 — drive pulley, 3 — shaft, 4 — nut, 5 — seal, 6 — V-belt transmission, 7 — bracket 8 — driven pulley, 9 — roller impeller, 10 — nut, 11 — bearing, 12 — impeller, 13 — nut 14 — cylinder engine, 15 — a nut of fastening of a bracket of the fan.

“Vepr” in motion “enjoy” some of the techniques experienced skier: the control system allows to bring together socks ski for braking snowplough. This operation also condenses the snow, if it is too loose. Tests showed that the adopted method of movement is quite effective, although it creates additional resistance.

To protect the motor from overheating, it established a makeshift fan, the impeller of which is provided a V-belt. The pulley is mounted on the left side of the shank of the crankshaft, but instead the bolt is screwed up the cushion with square neck (POS. Figure 3. 10). Cover of a crankcase while drilled in the aisle seat cushion installed oil seal. The pulley seated on the square and locked the nut with washer. The fan is four-bladed, Ø 160 mm, its lobes cut of three-millimeter steel. It rotates in the bearing No. 202 inserted in the slot of the bracket.

Motonarty “boar” have a good ride and reach speeds up to 50 km/h on Packed snow and up to 20 km/h over the snow.

RIDING ON A “REIN”

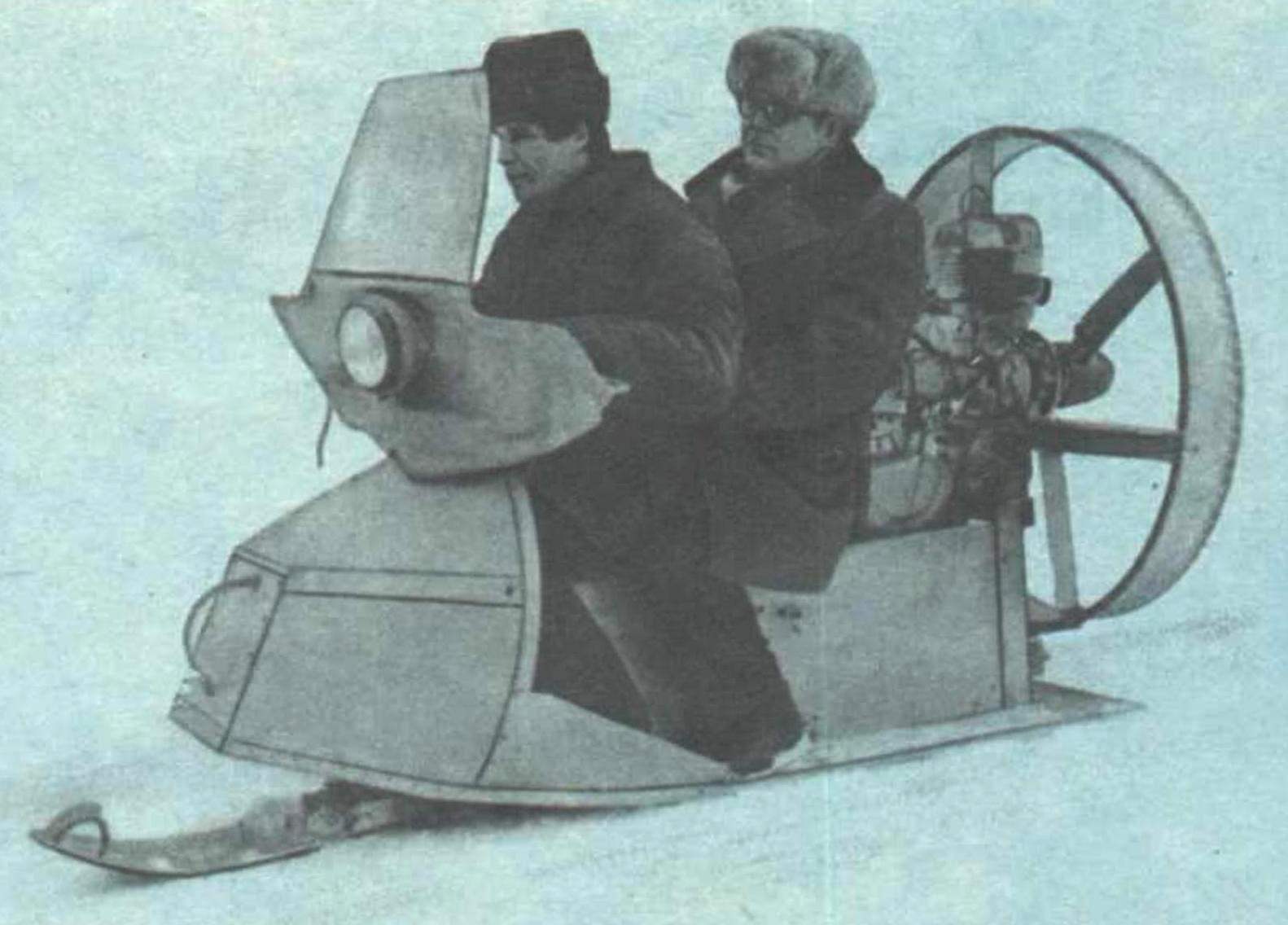

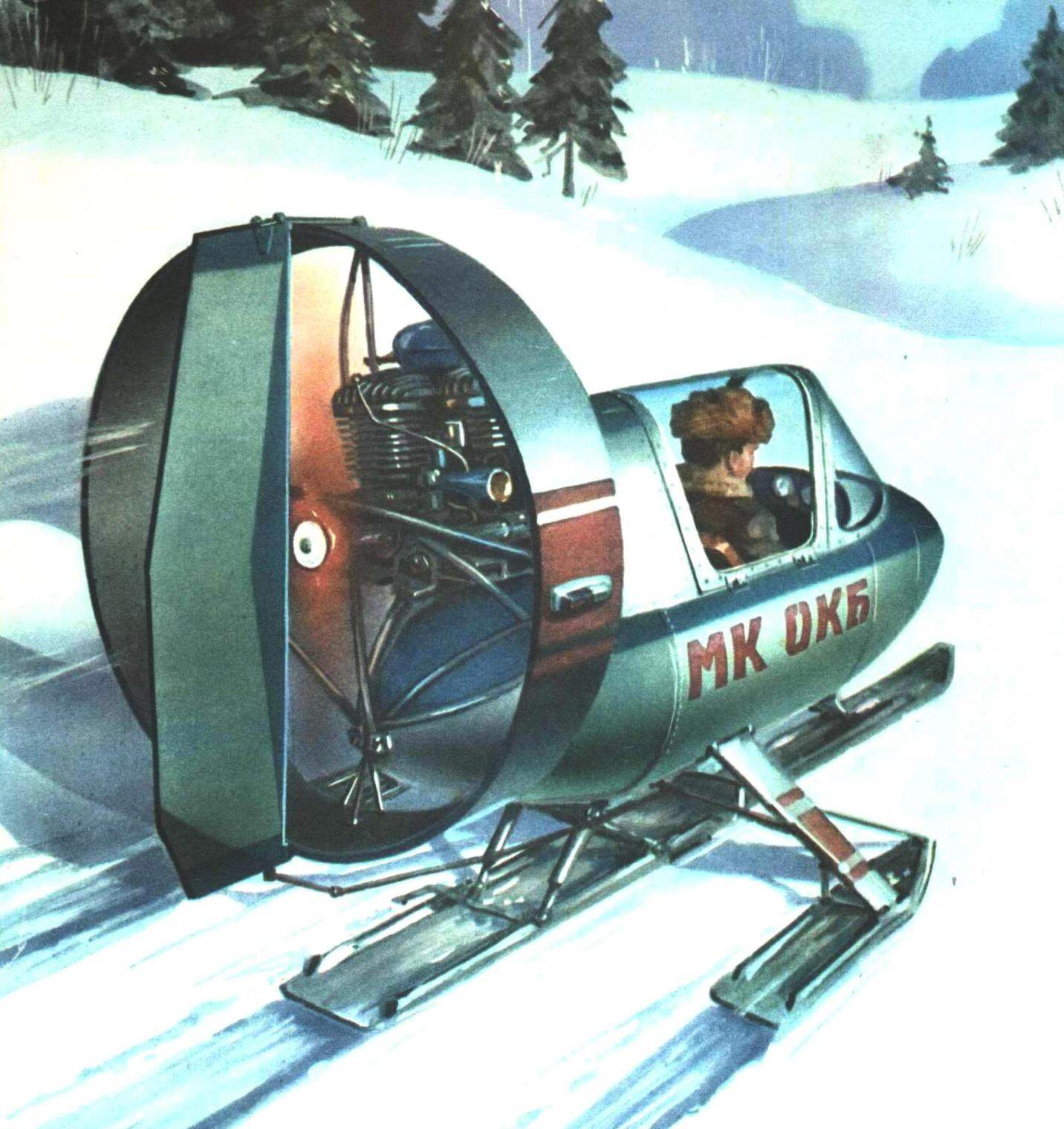

with speeds up to 80 km/h! The living deer, of course, that speed does not develop, and aeromatics (see box), built by R. Golembiewski from the city of Dobryanka, Perm region, it is quite affordable.

Aredigital has long attracted the designer, “Deer.” He set it on the boat, the snowmobile, produced the so-called aerodactyl and as a result, the original aeromatic.

“We in the city already has several such “deer,” writes R. Golembiewski, and by the end of winter there will be no less than a dozen”.

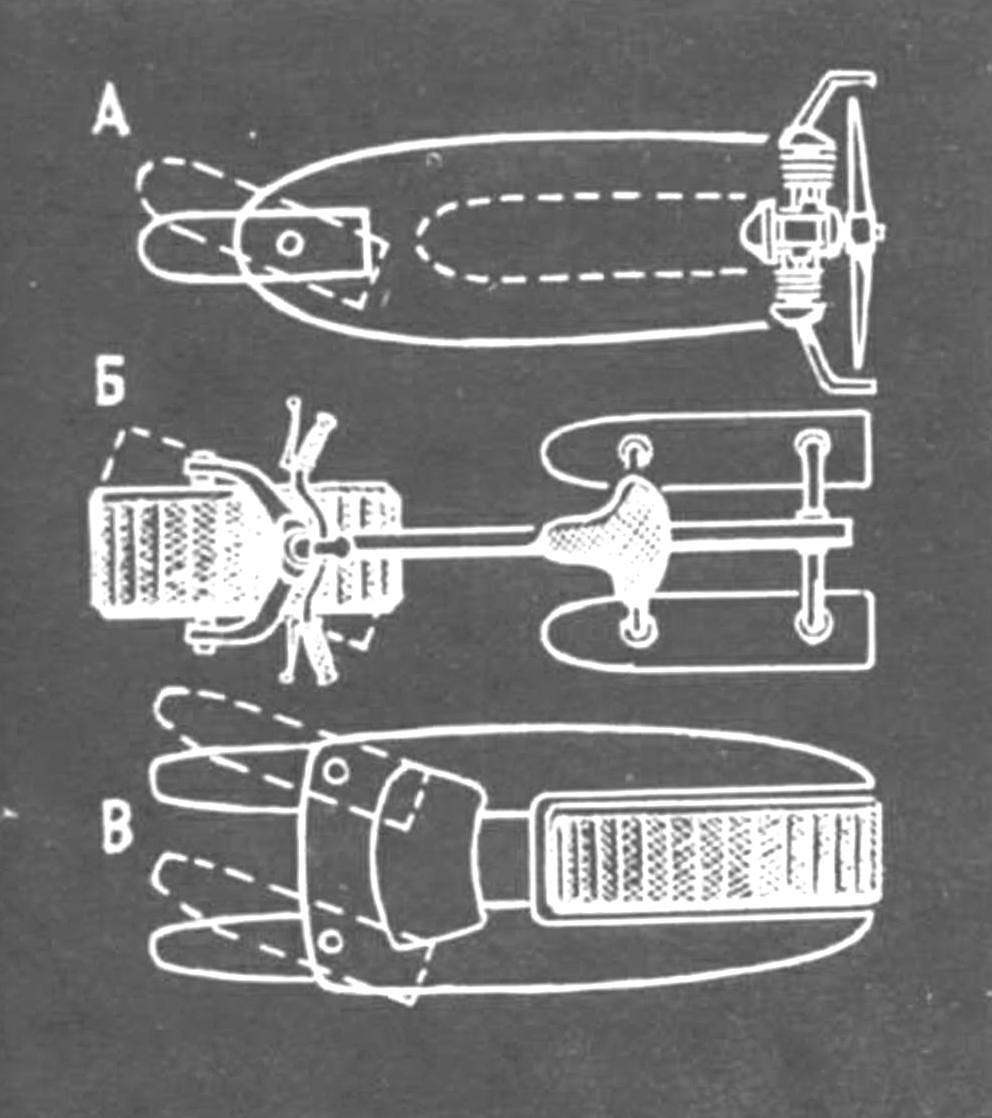

Fig. 11. Circuit housing Aeromotive “Deer”:

1 — housing, 2 corner mounting pegs, 3 — front ski, 4 — swivel, 5 — towing handrail, 6 — steering column 7 — attachment wheel-lights, 8 — frame bonnet, 9 — seat, 10 — shootbolt, 11 — seat 12 — castles motor mounting, 13 — a canvas hood, 14 — the top locks, 15 — rubber isolator, 16 — circular brace, 17, 19—tube undercuts, 18 — rod of fastening of the power plant, 20 — a rubber shock absorber.

Fig. 12. Rotor installation “Deer”:

1 — rubber isolator, 2 — lock mounting to body 3 — generator, 4 — ball valve fuel injection, 5 — rotor, 6 — cylinder, 7 — ring fence, 8 — carburetor К28Ж, 9 — magneto 10 — canister — fuel tank.

This snowmobile is built on dublenoj scheme. One of them is a wide — base running, the other small controls. Chassis the ski is integral with the body of the car — the driver and the passenger are seated on top of her. Itself ski and superstructure constructed from plywood with a thickness of 10 mm, individual sheets which are joined with dural corners and screws. Front hood — canvas cloth stretched on a frame of duralumin strips section 5×50 mm.

Management aarohanam using the steering wheel-lights, borrowed from the scooter. The front ski is directly linked to the steering column and has a spring shock absorber. At its sole for improved handling and installed a Central undercut.

Chassis the ski is edged with a metal strip and has two located on the edges of podraza (steel pipe Ø 12 mm), increasing the machine stability on the go. In addition, they warn of side-slipping of Aeromotive.

“Deer” is set converted into air-cooled engine PD-10, on the cylinder with a water jacket was replaced by a cylinder from the engine! motorcycle IZH. The engine crankcase as easy as possible.

Fuel tank — standard canister. Installed behind the seat, in front of the engine. The fuel supply to the carb due to excessive pressure in the crankcase pressure (only possible with a closed tube cans!).

Motor installation (Fig. 12) located in the rear of the case. Two-bladed propeller rotated within the aerodynamic rings, besides performing the function of the fence screw. The power plant is attached to the hull via rubber grommets to absorb vibration.

Aeromatic steady on the move and quite maneuverable. His speed with a passenger and a small load up to 50 km/h, with one driver—up to 80 km/h machine Weight with full fuel — 73,5 kg.

Machine A. Zavorotnaja, it can not only carry two people, but n tow skiers

Motonarty V. Timofeeva, they are distinguished by their beautiful appearance and well established structural diagram

The most common scheme a homemade snowmobile:

A diagram AERONET “Deer”; — tricycle, with front controlled caterpillar and lamivudine frame; tricycle with two front steerable skis.

Aeronorte “Deer” R. Golembiewski is a kind of snow bike original dublenoj schema aerodigestive

Not content with “the Bends” and “Snowstorms”, which established our industry, enthusiasts in many cities and especially villages create motonarty own design.

I. USENALIEV, engineer

If the village is unthinkable without the tens and hundreds of motorcycles, mopeds and bicycles, in the Northern part of the country, where winter lasts nine months of the year, the role of these public vehicles is increasingly performed motonarty. Without waiting for the industry will be able to meet the needs of northerners, many lovers of the snowmobile technicians design and make your metal samples, sometimes not inferior to industrial.

If the village is unthinkable without the tens and hundreds of motorcycles, mopeds and bicycles, in the Northern part of the country, where winter lasts nine months of the year, the role of these public vehicles is increasingly performed motonarty. Without waiting for the industry will be able to meet the needs of northerners, many lovers of the snowmobile technicians design and make your metal samples, sometimes not inferior to industrial.