Before starting to build the micromotorcycle, I spent a long time drawing various layout options, trying to anticipate on paper all possible errors and miscalculations that could arise during the work. Looking ahead, it should be noted that development on paper is one thing, and manufacturing is quite another. Many “rough spots” appeared even during the machine’s operation.

Initially, I thought I would make most of the parts myself, since I dreamed of a micromotorcycle unlike any published in technical magazines. But when the lovingly drawn mudguards, fuel tank, and seat were realized in metal, leatherette, and foam, they lost all their appeal compared to the drawings. Reluctantly, I had to use commercially available parts. But, as it turned out, this benefited my machine – it acquired a quite “commercial” appearance.

As for the motorcycle’s operational qualities and reliability, I am quite satisfied with them, since I have already ridden about 3000 km on it without any breakdowns. The only drawback (but that’s not my fault!) – the scooter tires are rather weak. For the front wheel it’s still acceptable, but for the rear… I have to put two on the rim at once, but even that doesn’t help much.

The maximum speed of the micromotorcycle is up to 50 km/h, it handles the road well and is quite stable. The dimensions allow it to be freely placed in the trunk of a “Moskvich”, and the weight is so small that it can be carried to the fifth floor (without an elevator) and “stashed” in any free corner of the apartment.

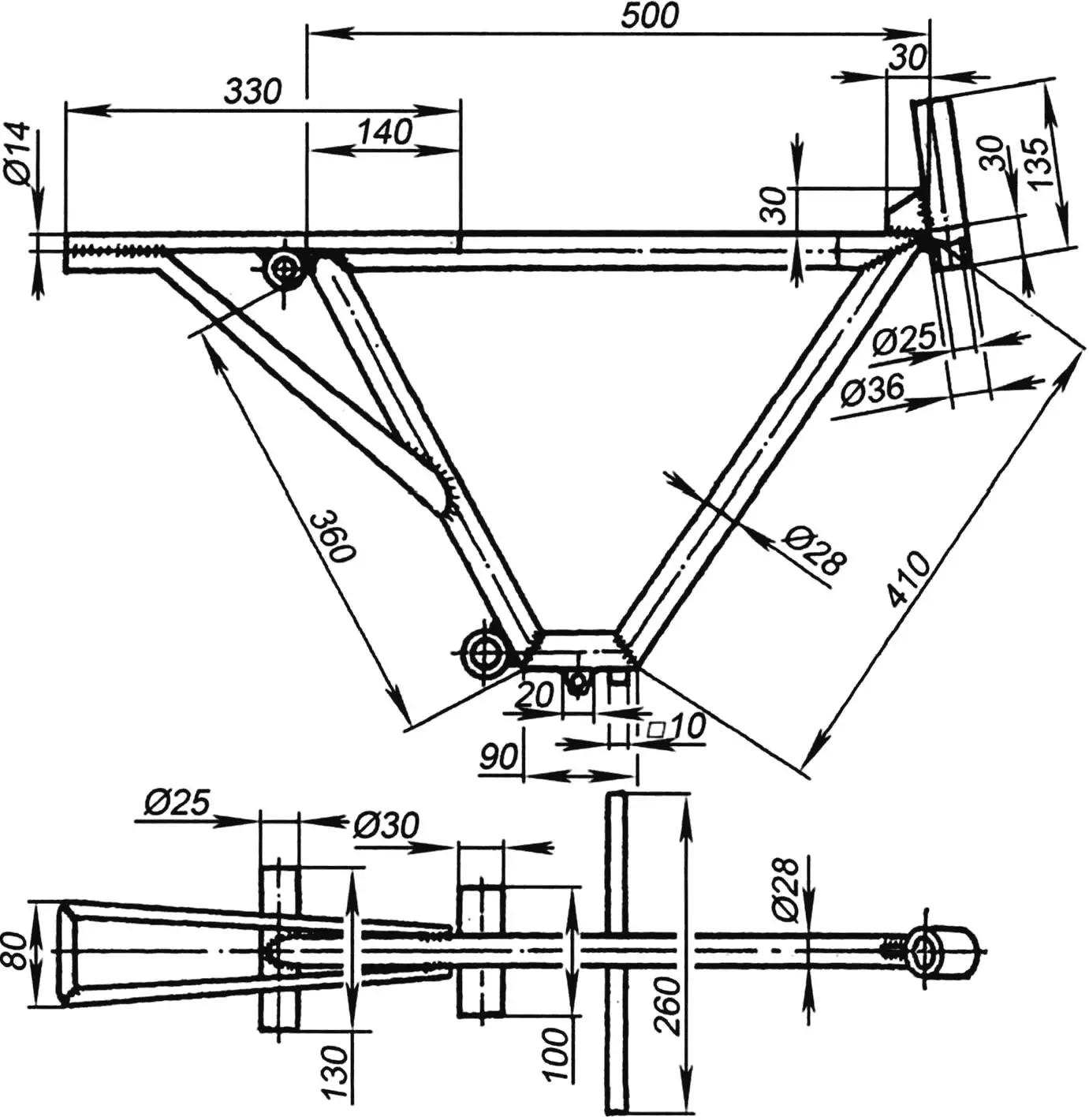

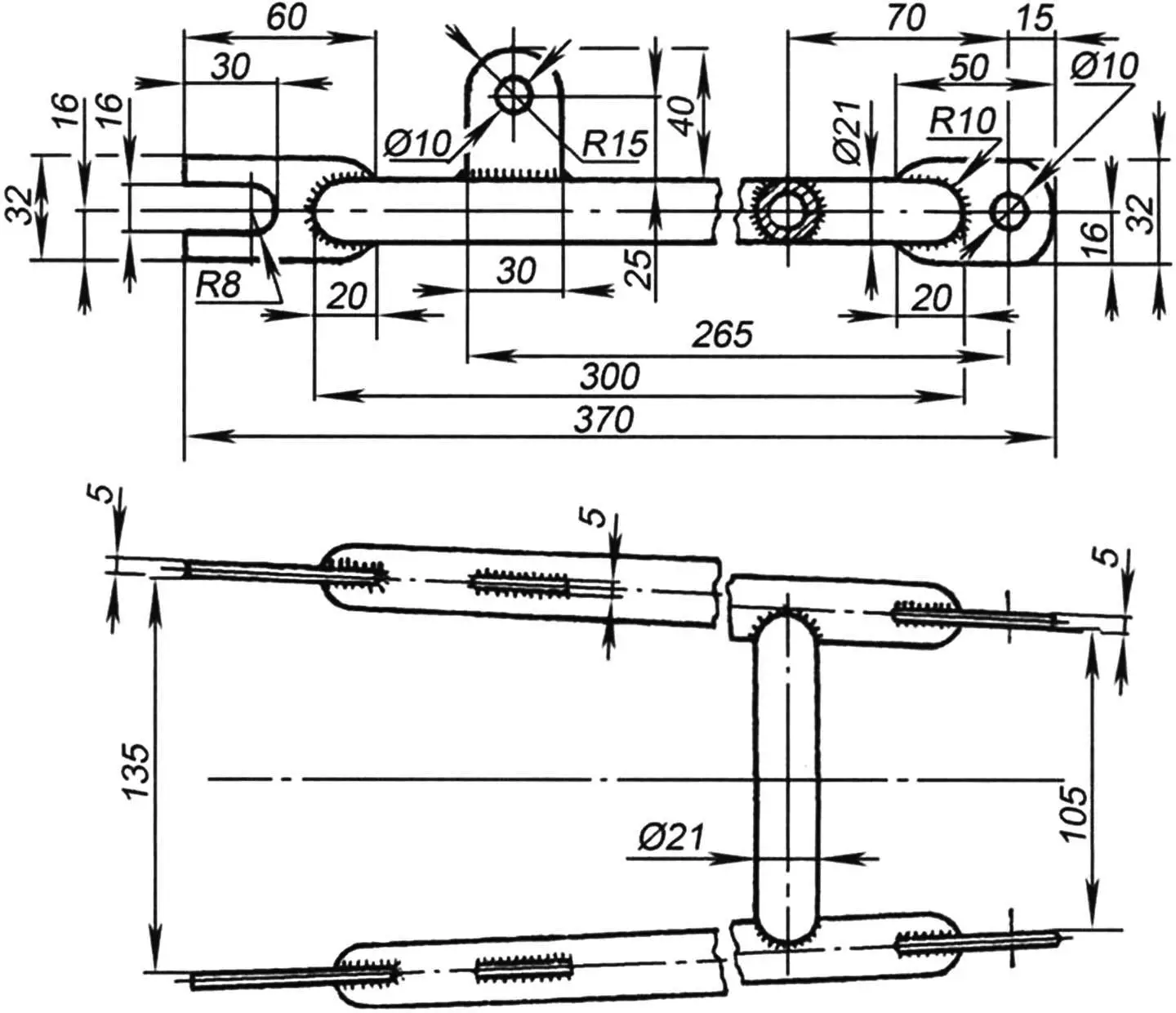

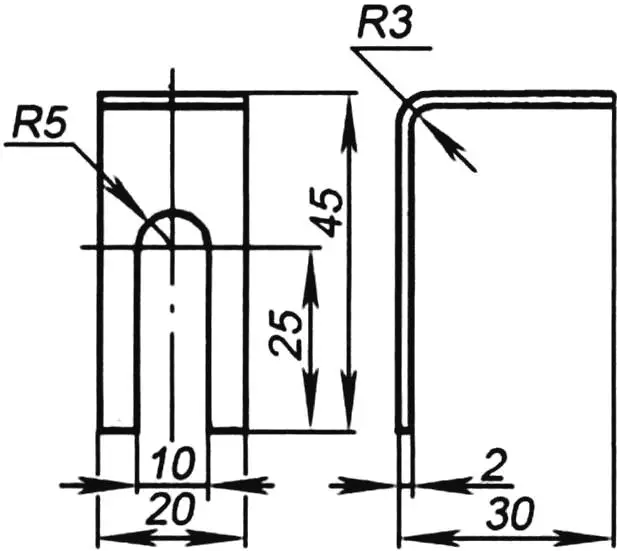

Well, now about the machine’s construction. The frame configuration was predetermined by the use of the D-6 engine. The tubes for it, 28 mm and 14 mm in diameter, were borrowed from an old bicycle frame. The rear swingarm suspension is welded from 21 mm diameter tubes. The front fork is from a “Riga” moped. I only had to shorten it: cut the fork legs and stanchions by 130 mm, and welded brackets to the bottom of the fork legs. The front wheel is from a children’s scooter – without modifications, a speedometer reducer is adapted to it. On the handlebar from a “Jawa” motorcycle are located the throttle sector, clutch lever, standard drum brake lever for the rear wheel, headlight and horn switches.

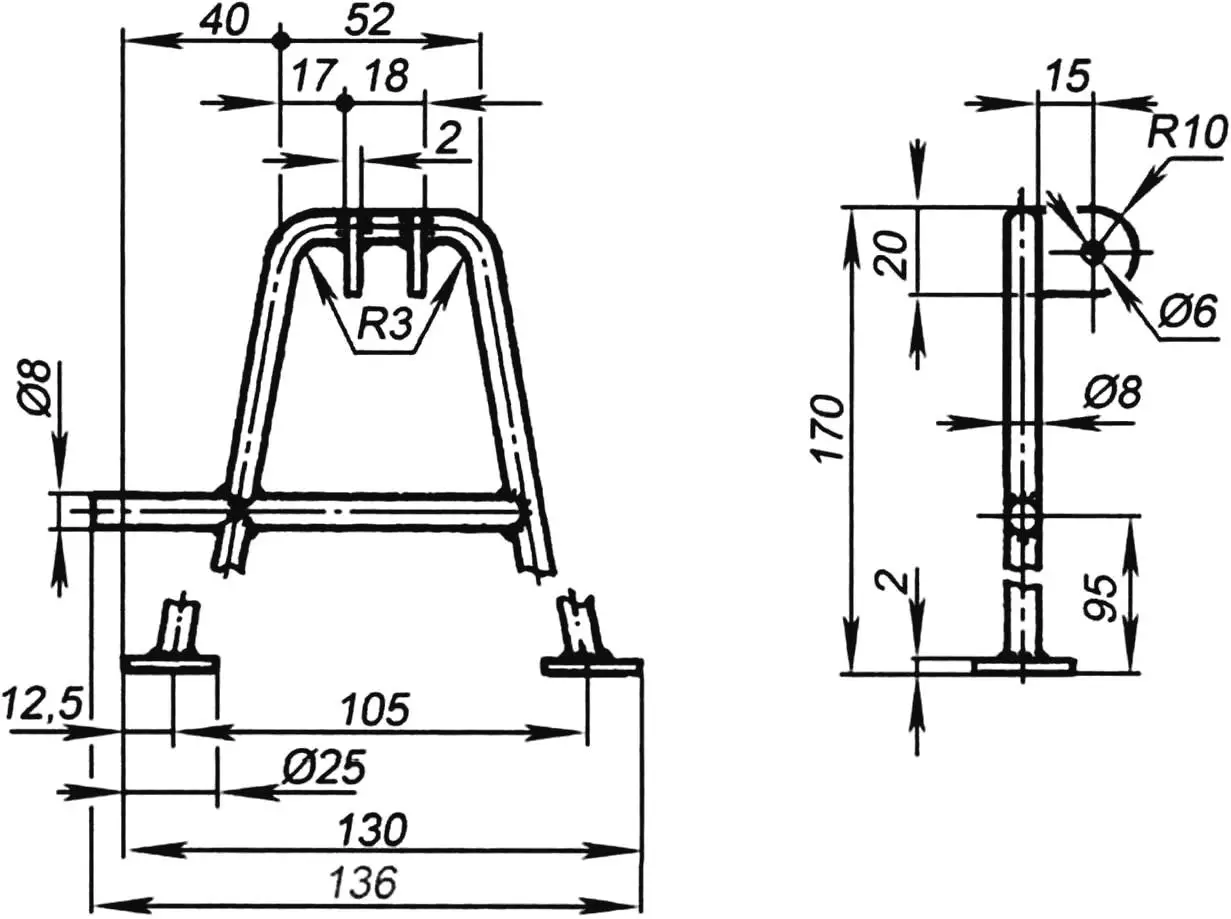

The headlight, fuel tank, seat, horn, rear shock absorbers, and muffler are standard, from a “Verkhovyna” moped. The mudguards from the same moped – I took one rear one and cut it in half. The pipe connecting the engine to the muffler is homemade, bent in place. The motorcycle stand is welded from 8-mm steel rod and pivotally mounted on the frame.

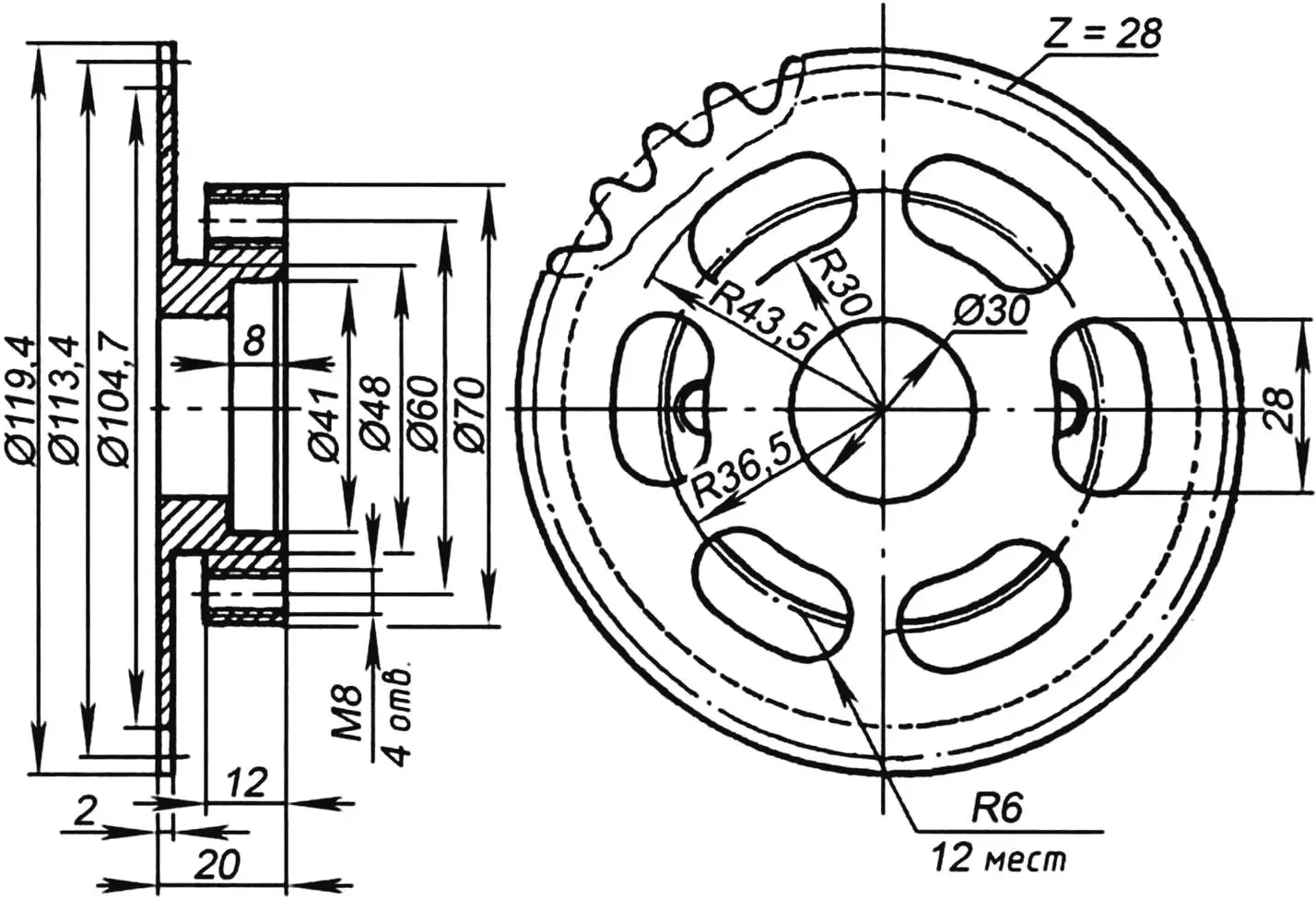

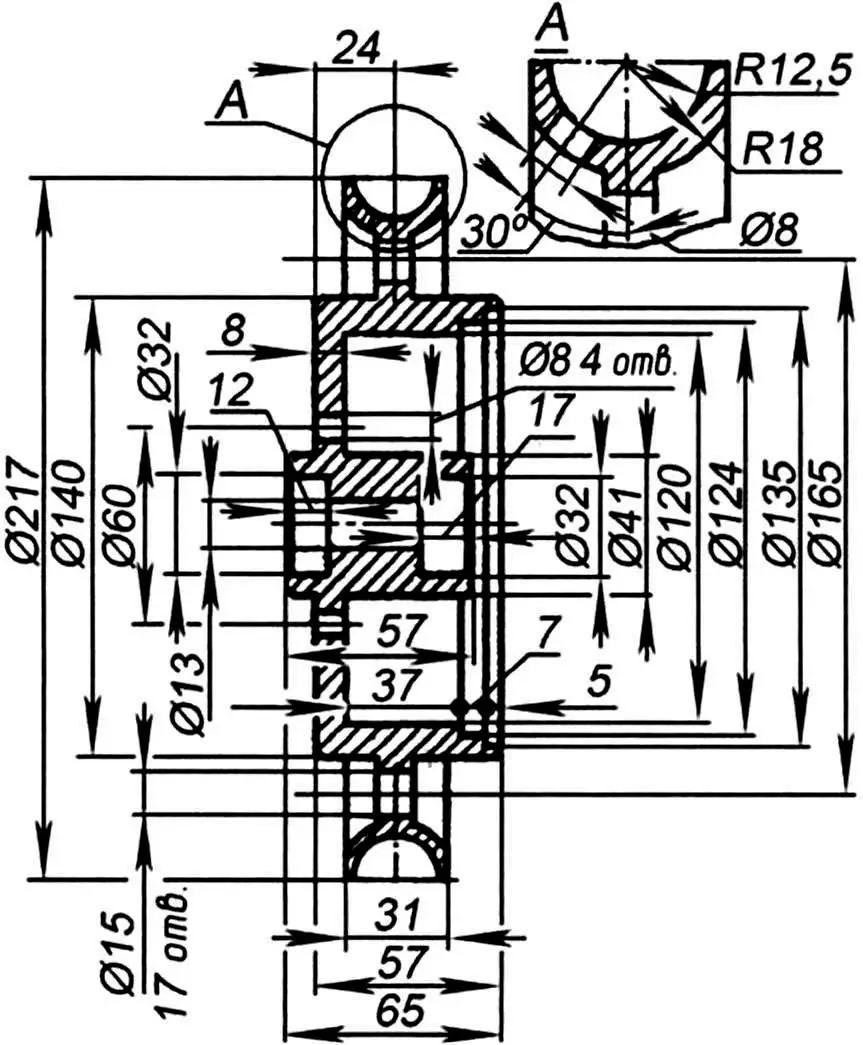

One of the most complex units is the rear wheel. It had to be turned from duralumin, since it bears the main load. The hub and rim are made as one piece, with two bearings inside the hub. The driven sprocket (Z=28) is welded to a steel flange. The brake drum is located on the right.

The tire on the rear wheel is double, glued from two scooter tires with “88” glue.

«Modelist-Konstruktor» No. 7’2013, V. BEREZHNOY, Kharkiv, Ukraine