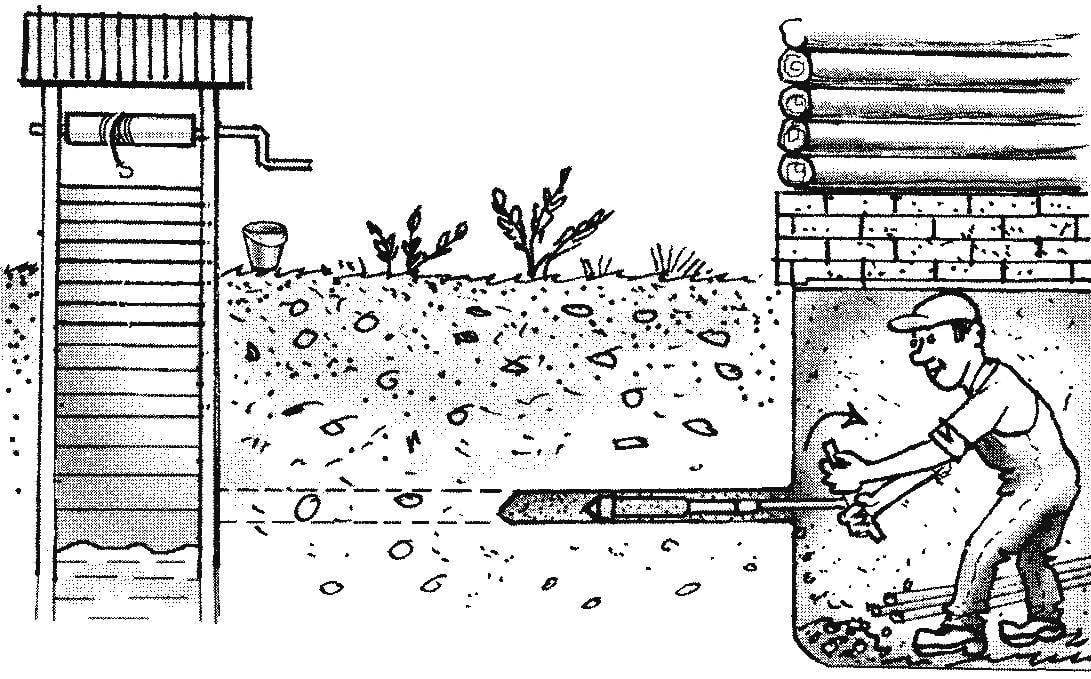

The idea is to make readers Boer came to me in the following everyday situations: having descended into the manor house, did not have time before winter to conduct water from the well. Dig the same trench though not long (about 5 m), but fairly deep (about 2 m) in the frozen ground seemed difficult. Not to wait for the next summer, I decided to drill a little below the freezing depth of soil horizontal borehole (the borehole of relatively small diameter) for laying in it steel pipe in 3/4″ for the supply of water from the well through the underground to the house.

The idea is to make readers Boer came to me in the following everyday situations: having descended into the manor house, did not have time before winter to conduct water from the well. Dig the same trench though not long (about 5 m), but fairly deep (about 2 m) in the frozen ground seemed difficult. Not to wait for the next summer, I decided to drill a little below the freezing depth of soil horizontal borehole (the borehole of relatively small diameter) for laying in it steel pipe in 3/4″ for the supply of water from the well through the underground to the house.

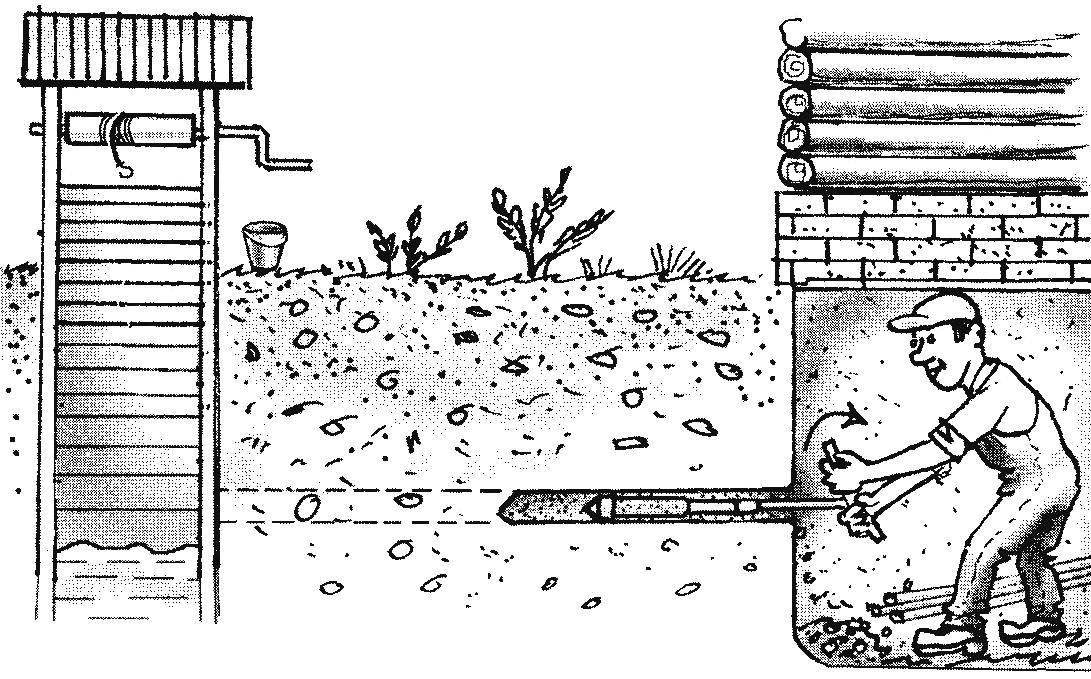

The design of the drill is simple. It consists of sets of blades, the guide ring of the housing, rod and sleeve. All of these parts are welded into a single structure. But there is a drill and a detachable part, consisting in turn of several. The first knob. It is a T-shaped weldment that consists of a rack and lever. Near the free end of the bar drilled hole diameter 4.2 mm through it with a pin-nail a crank connected with the sleeve. On the ends of the arm knob for convenience, you can put the handle from a suitable rubber hose.

Knives made of good spring steel (can be from old circular saw blades on wood) and is welded to the ring symmetrically about its center. Sharpen and respectively welded knives can be like for the rotation of the drill clockwise and against—as you prefer.

On the other hand to the ring welded to the ends of the arcuate body, full as a ring of steel strip with a thickness of 3 mm. To bending the arc of the housing are welded rod—cut half-inch steel water pipe. Rod length can be up to two meters, but for easy storage drill more than one meter to make it not worth it.

For the drill holes:

1—knife (spring steel, 2); 2—ring (steel, sheet s3); 3 — casing (steel, strip 30×3); 4—rod (pipe 1/2″); 5—bushing (pipe 3/4″), 6—pin(nail Ø4); 7— front of the knob (tube 1/2″); 8—handle tap wrench (pipe 1/2″); 9—additional rod; 10 — additional rod sleeve (pipe 3/4″)

On the free end of the rod is worn and welded sleeve made from a water pipe in 3/4″. Still in the sleeve near the free end is drilled diametrically hole (the same as in the front of the knob) under the pin to connect the crank.

Have a drill and a different—or rather, any other attachable parts—additional rods (one or several), made in the likeness of the main rod. Length of the additional rods can reach two meters.

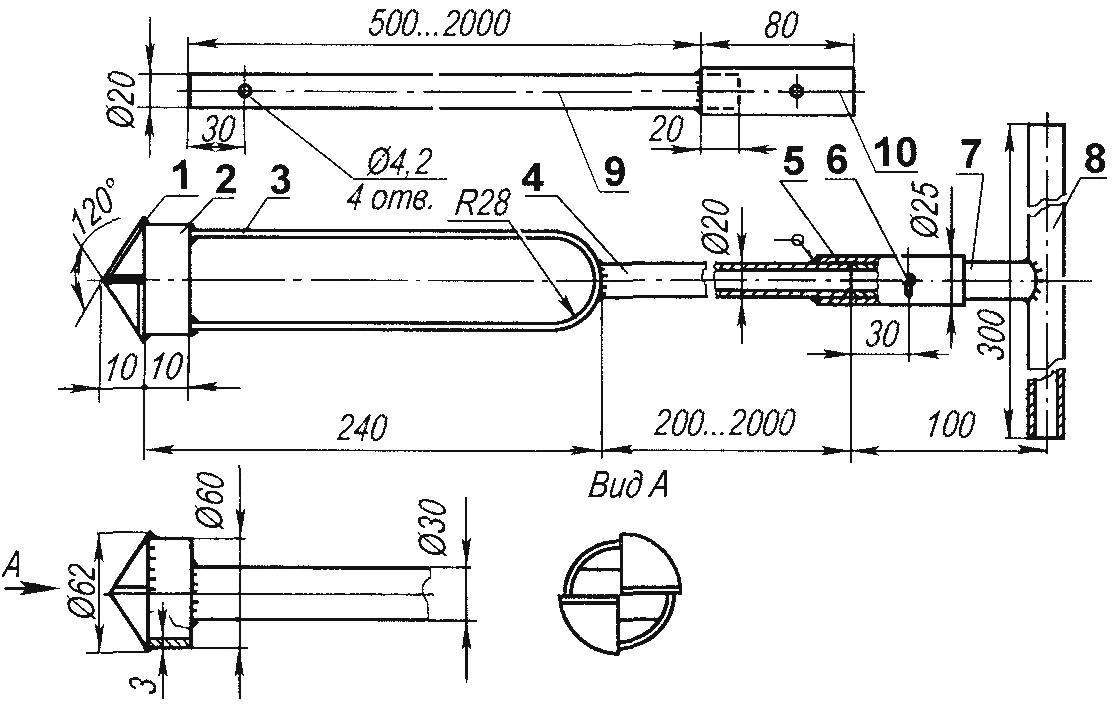

Before drilling has defined more precisely the direction from the underground to the well. The borehole was planned at a height of about 250 mm from the bottom of the underground and with a slope of about 10° in the direction of the well. Drilling technology is simple: installing the drill in the desired direction, tighten the crank 10 — 15 times with pressure. Then the drill need to pull and shake out of the casing and rings Packed soil. The procedure is repeated many times, with the additional elongation of the drill rods. Notice that with the aide of the point here is one and a half times faster.

Dobrev to the wall, punched a hole in it. In the hole put first casing pipe outer diameter slightly smaller than 60 mm, and it extended into the well the hose that was connected to the pump.

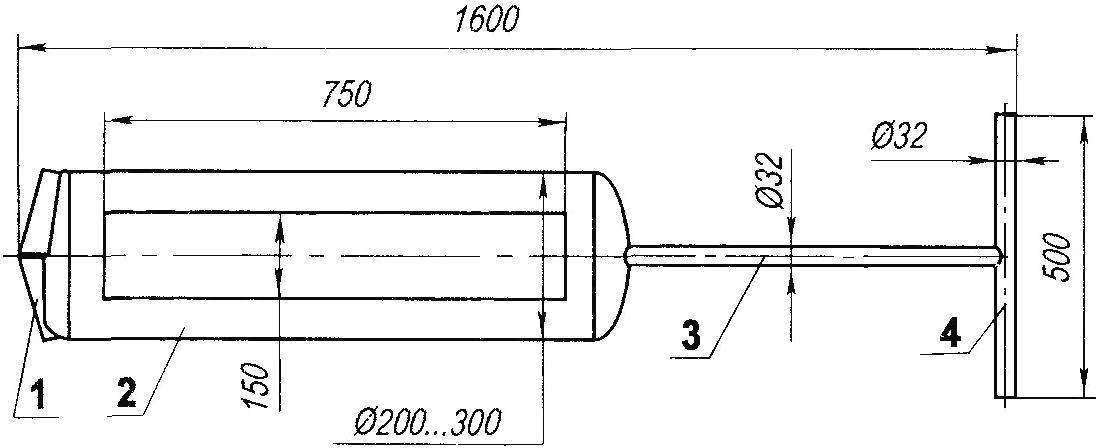

Drill for wells from the receiver:

1 — knife (spring steel, 2); 2 — housing (receiver from the car “KAMAZ”, modified); 3 — knob (tube 1″); 4 — arm knob (tube 1″)

Bur I do not lie. Used it I and to install posts for fence and drilling to a depth of 10 m under the Abyssinian (driven) wells. But it is often a device used by relatives, neighbors, acquaintances. There is even the experience of drilling horizontal hole under the road, without it overlapping. When laying a water pipe under this road, the owner saved 15 thousand rubles, which is charging him for this service of Goodsite.

In rural areas or suburban building often requires a Bur of larger diameter. So, it is easy to make in the image and likeness of the described receiver of the air brake system of the car “KAMAZ”. The receiver should be cut off one end and welding the knives. In the shell with opposite sides cut two oblong Windows — to remove accumulated soil. To the other end along the axis of the receiver to weld the rod or knob.

A. MATVEICHUK, Zavodoukovsk, Tyumen region.