Simple machine for the manufacture of a protective “shirt” to a milking apparatus. prepared for transportation created by the innovators Yanovskogo district Association of Lithuania. Usually they were transported in canvas bags or boxes that do not provide the required sterility and do not always meet the requirements of industrial hygiene and sanitation. In addition, such containers required after each use thorough disinfection with subsequent drying.

Simple machine for the manufacture of a protective “shirt” to a milking apparatus. prepared for transportation created by the innovators Yanovskogo district Association of Lithuania. Usually they were transported in canvas bags or boxes that do not provide the required sterility and do not always meet the requirements of industrial hygiene and sanitation. In addition, such containers required after each use thorough disinfection with subsequent drying.

The machine also enables to get a comfortable and secure disposable container use of a polymer film: hermetically sealed pouches meet the stringent demands of hygiene.

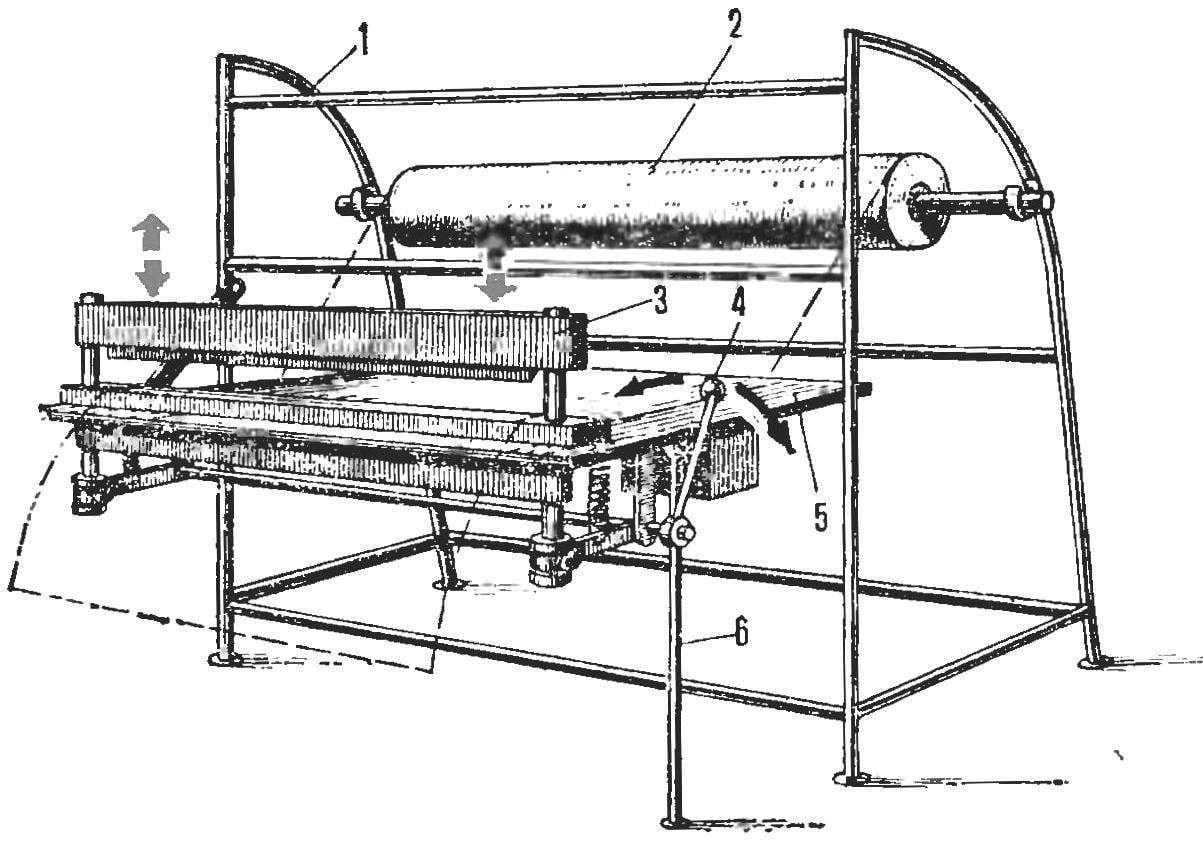

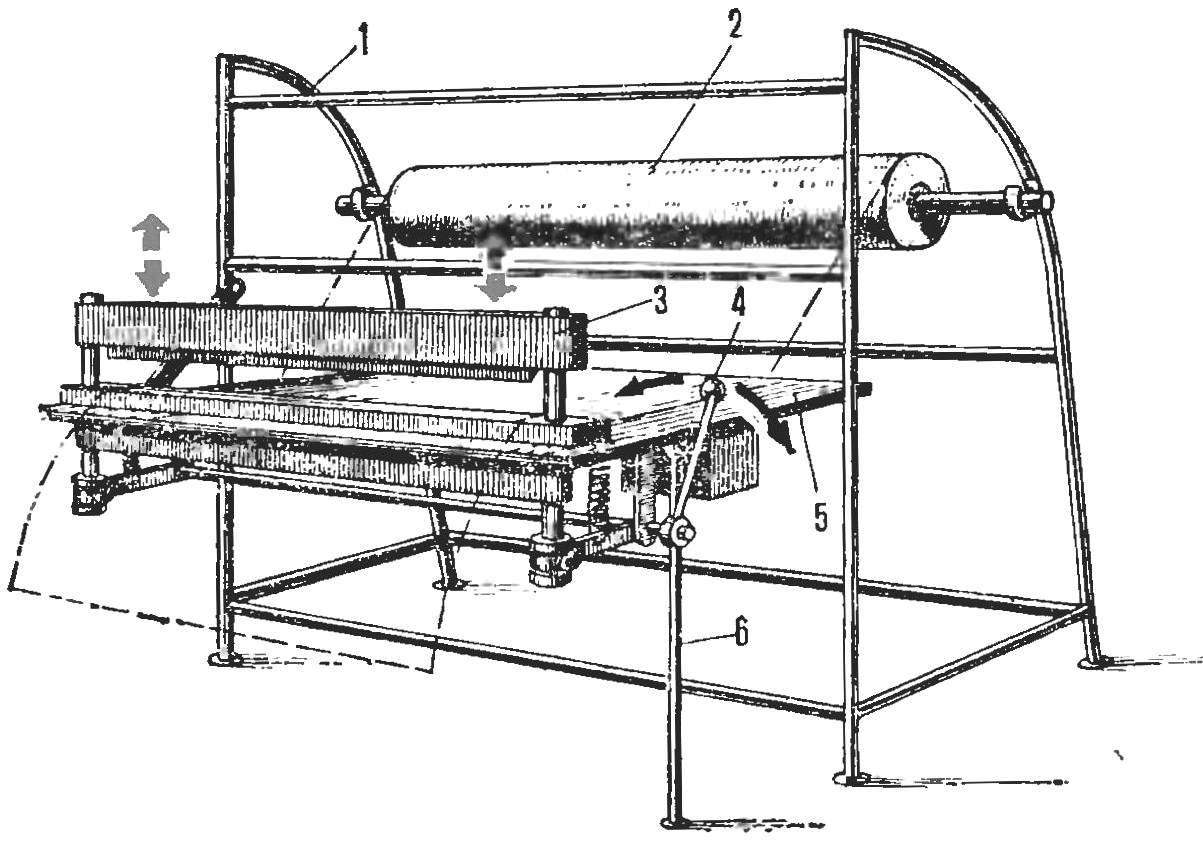

The installation consists of a frame welded construction, the table is made of the area and sheet steel 2 mm thick, shelves for bags welding mechanism and mount the film roll. The main working part of the fixture — welding mechanism, the clamp has a frame made of pipes ø20 mm, handle, recoil spring, heating element tungsten plates 10×2 mm limit switch and step down transformer. The heating element and the table field content frame covered with asbestos. For convenience, the table walls are not made of the folding.

Machine for packaging:

1 — frame, 2 — roll, 3 — welding strap, 4 — clamping handle, 5 — table, 6 — jointed leg.

Running machine the next edge. From a roll, the film is manually threaded through the frame and is served in the form of a tapered tube. Here it is disconnected, inside the stacked parts and components of the milking machine; then when you press the handle, the heating element is pressed against the film and instantly Nicolaas, weld it. Similarly, the second sealed end of the bag.

With the help of the machine one person can pack up to 100 units per hour.