1 — bus-28 3,5X5, 2 — wheel, 3 — bolt M8 4 — M8 screws with cylindrical head, 5 — hub, 6 — gland washer 7 — nut M12 8 — drive shaft 9 — bearing 201, 10, the bearing 202, 11 — brake drum, 12 — supporting the brake disc, 13 — mounting flange of the brake disk 14 — bolt M6, 15 — rear axle beam.

The slave (right) half-bridge. Foundation — beam with welded flange for mounting a brake disk. The last is joined with a flange with three bolts. The wheel drive shaft is pressed into the beam of the half-bridge n end-to-end secured by two rivets. On the axis there are two bearing — 202 and 201, 202 and the bearing outer ring pressed into a pre-bored hole in the brake drum, and a bearing 201 in the hole of the hub, which is connected with the brake drum with three bolts.

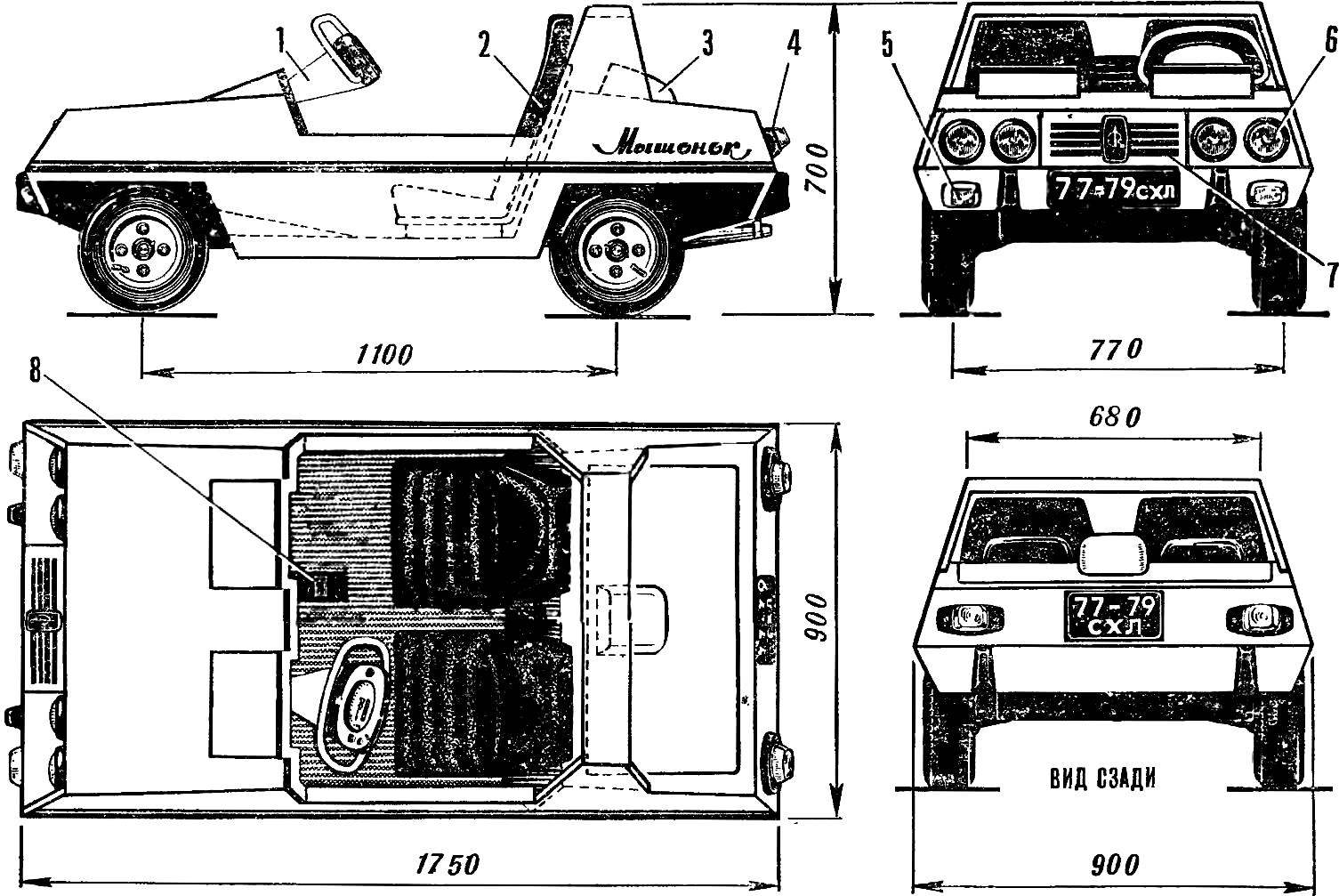

Engine “Mouse” by motorbike, type D-5.

Engine mount (Fig. 6) under the NC motor welded steel pipe outer Ø 18 mm. It consists of a front support I of the rear pillar, to which are fastened lugs cut from steel sheet. To the standard fixing points of the engine bolts attached to the brackets. By adjusting the tension of the chain — bolt, he started pushing the pin of the bracket moves the motor along the slots in the lugs in the vertical direction. The carburetor associated with the engine transition pipe, because the engine is flooded with ago. Fuel tank capacity of 2 liters is located under the hood.

Fig. 6. Engine mounting:

1 — front support engine mounts, 2 rear strut engine mounts, 3 — nut M8, 4 — front bracket engine mounts, 5 — lug front, 6 — carburetor-To-346, 7 — a reducer, 8 — engine D-5, 9 — rear bracket-engine, 10 — lug rear, 11 — nut, M8, 12 — beam rear axle, 13 — adjusting bolt M6 14 — spar frame, 15 — rear crossmember of the frame.

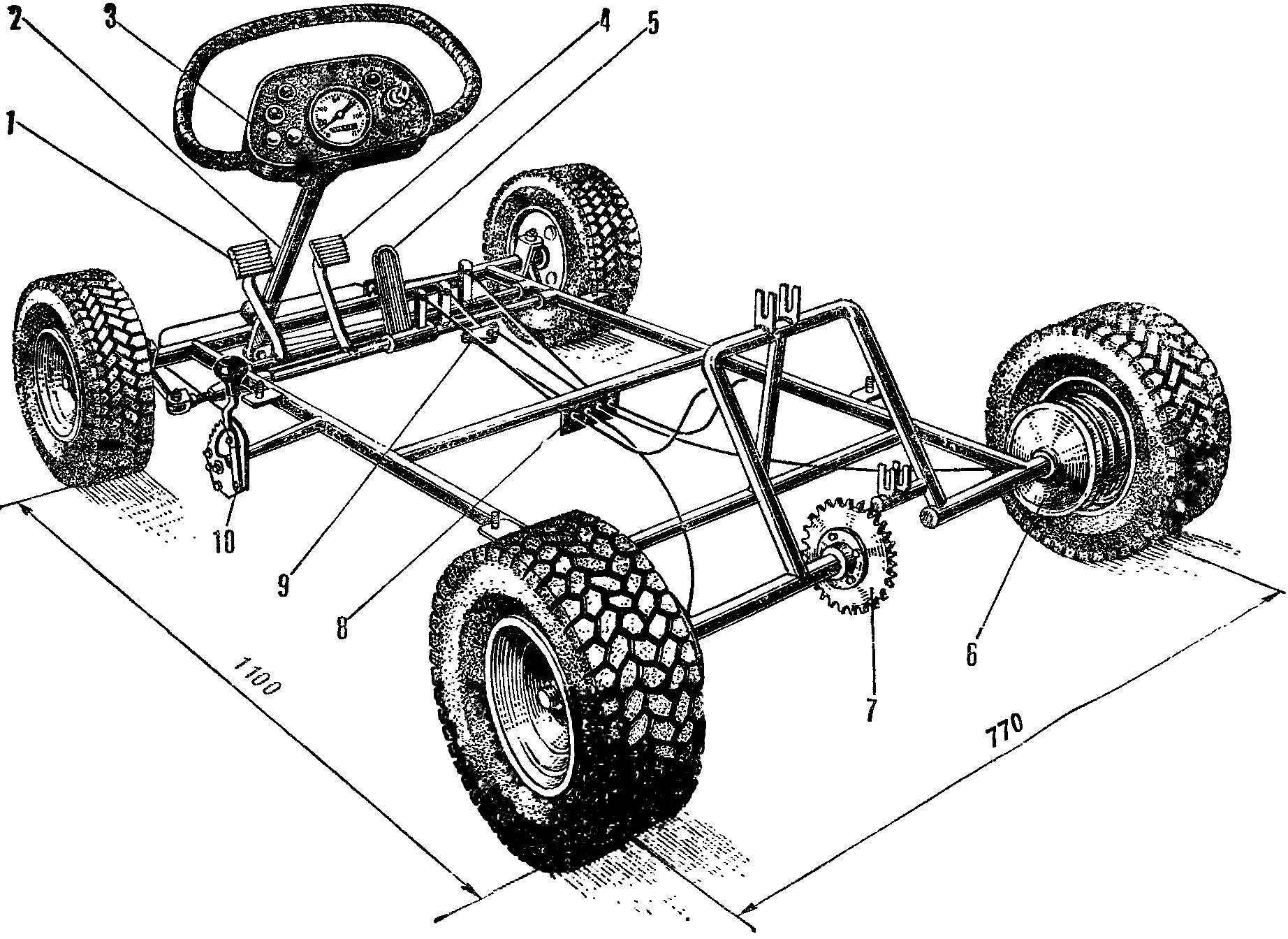

Steering (Fig. 7). It’s main unit — steering column welded to the end of steering a plow, curved polutoratysyachnogo of the steel sheet. With the swing arm front wheel it connects rods. The upper end of the column ends closed steering wheel (pipe Ø 12 mm). There is also a tie bar with the dashboard. Rotating the steering column in two textolite bearings: the first is mounted on the front beam of the frame, and the second on the counter. Both fixed steel plates. Prevent longitudinal displacement of the thrust ring.

Fig. 7. The controls of the car:

1 — steering wheel 2 — steering column 3 — bearing housing, 4 — thrust washer, 5 — steering 6 — wheel plow, 7 — levers pedals, 8 — brake pedal and clutch, 9 — equalizer tension of the brake cables, 10 — adjusting stops 11 — front cross member of the frame, 12, 19 — bearing, 13 — grommet mount backup pedals, 14 — ring 15 — sleeve accelerator pedal 16 — accelerator 17 — shaft of a brake pedal, 18 — shaft of the clutch pedal.

For adjusting the length of the tie rod have a threaded bushing.

All steering joints have rubber bushings. The steering angle is 30°.

Clutch pedal and brake (Fig. 7) is made of steel tubes Ø 12 mm. Shafts of pedals enshrined in textolite bearings mounted on the front crossmember of the frame and the side members. Gas pedal — three-millimeter steel plate, welded to the sleeve. Its axis is the shaft of the brake pedal.

Control cables — motorcycle, adjustable threaded stops. Cables brakes connect to the brake drums using a tension leveler. The machine is provided extra pedals for the instructor, for which the shafts of the pedals welded steel sleeve.

The body of the car hardwood. I collected it on the glue and screws with 7 mm plywood (cladding), two longitudinal rods and two transverse frames. The outside is plastered with fiberglass on epoxy resin with subsequent caulking, priming and painting nitroenamels. The front wheels inside closed flaps of sheet steel with a thickness of 1 mm. Seat made of pipe Ø 15 mm plywood on top covered with foam rubber and artificial leather. Provided even adjusting the seat position depending on the height of the driver and passenger seats: longitudinal moving seats on rails can be fixed in the selected position by the stoppers.

The electric car is powered by the battery collected from the twelve elements of the “373”, this four lights (on bike) and front position lamps and direction indicators (motorcycle type), and brake light, and sound.

The dashboard, on which are mounted speedometer, headlight switches and flashers turn, signal button and indicator lamp, mounted in the steering bar. The last case is laminated on the blank papier-mâché and then hardened the surface with fiberglass.

Frame and car body are connected by four threaded studs, so to break the machine, simply Unscrew the four wing nuts, disconnect the fuel line and electrical connector.

In conclusion I will add, I started work on the car in 1977 and finished in 1979. Total time spent on construction (not including turning), about 380 hours. The little car turned out, I think, durable, in any case, during the operation of any trouble it has not happened.

V. VESELOV, graphic designer, winner of the NTTM-74, Kholmsk, Sakhalin region.

Recommend to read AND PAINT, AND LACQUER Few people know that packaging Styrofoam is the perfect base for the manufacture of varnishes and paints. The first are obtained by dissolving the foam in solvent "647" or butyl acetate.... SPRAY THE AUSTERE For several years now to paint a variety of products I use simple and reliable "compressor". A source of compressed air there are two rubber pump-"frogs" to inflate inflatable...  Leafing through a binder of “Modeler” in 1975, I noticed an article in the No. 3 car, “rainbow,” built by young technicians from Tbilisi. Enjoy the car, I decided for their children to make such.

Leafing through a binder of “Modeler” in 1975, I noticed an article in the No. 3 car, “rainbow,” built by young technicians from Tbilisi. Enjoy the car, I decided for their children to make such.