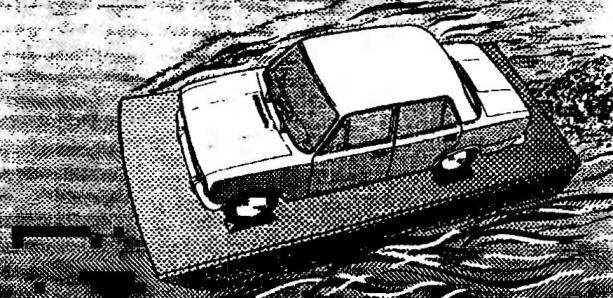

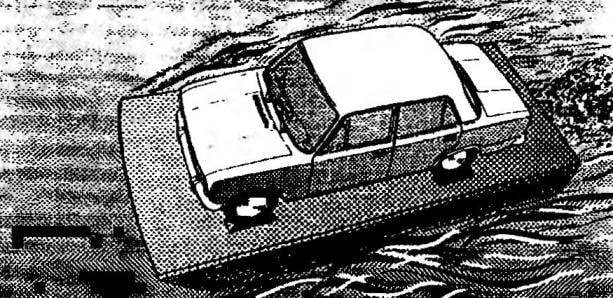

Good to live on the banks of the wide flowing river! However, this convenient transportation artery often becomes an annoying obstacle to communication between villages. Motorists sometimes have to travel to the city or village across the river for a few hours. Of course, you can take the boat or the boat, but then on the opposite shore will have to walk…

In such cases, nice to have a self-propelled pontoon, which is used drive the engine of the vehicle, and to control the course of his steering gear. You coming on to shore for a simple ramp enter on the pontoon and fix it on the car. All you can leave! Start engine, turn on the speed and the left wheel, stretched on two reels starts to rotate, driving the propeller associated with the shaft of the drum bevel gear. You need to turn?

You touch the wheel, the front wheels are moving together with the reference sites, located on the rotary device, moving the steering is feather bound by smartresume and rigid rod with the lever left of a reference platform. Well, if you need to slow down, engage reverse gear and full throttle!

At this pontoon, you can go quite a long swim, however, with one significant condition; on the end of the route shore should be such as to be able to move out on his pontoon, and then just as easy to boot back up.

To make such a pontoon can be from almost any available material.

Well, of course, make it of sheet steel, but easier to assemble wooden frame construction with sheathing of plywood.

The frame of the pontoon consists of two farms and six frames. Each farm is collected from a Board thickness of 50 and a width of 300 mm and a pair of wooden sticks, connected in a single longitudinal wooden braces.

After the installation of the trusses on the simplest slipway (for example, a pair of flat boards or bars across the frame of the pontoon) to them before you joined the pine bruski section 40×40 mm (horizontal elements of the frames), and then the side frames, which are connected with horizontal elements vpoldereva. On top of the last section are attached to the stringers — wooden bruski section 50×30 mm.

Composite amphibious vehicle:

1 —the car VAZ-2101; 2,5 — guides swivel front wheels; 3 — the case of the pontoon; 4 — balneoclinic; 6 — lever steering device; 7—traction drive steering gear; 8—duplica the levers of the steering gear; 9— starcrazy; 10 — bearing reel; 11 —leading drum drive propeller; 12 — bevel gear pair drive propeller; 13 — stern shaft; 14— the screw propeller; 15 — steering pen

Longitudinal section of the hull of the pontoon:

1,6 — horizontal elements of the frames (wooden bars 40×40); 2—top shelf farm (Board 300×50); 3 — deck sheathing (plywood s5); 4 — forstenii frame element (block 40×40); 5 — front crossmember (the bar 40×40); 7— brace (50×25 rail); 8 — bottom shelf farm (bar 50×50); 9— hull bottom (plywood s5); 10 — strengthening of the bottom (bar 40×40); 11 — trim (plywood 15); 12 — stern and transom frame element (block 40×40)

The cross section of the hull of the pontoon:

1 — piping (50×25 rail); 2-deck sheathing (plywood s5); 3 — top shelf farm (Board 300×50); 4 — braces (rail 50×25); 5.8 — stringers (sticks 50×40); 6,7 — horizontal elements of the frames (bars 40×40); 9 — hull bottom (plywood s5); 10 — side panel frame (40×40 block); 11 — sheathing Board (plywood s5); 12 — power trim parts of the bottom (plywood s5)

Support drum:

1 — bearing body; 2 — disk; 3 — the drum housing; 4 — shaft; 5 — bearing

Drum drive propeller:

1 — bearing body; 2 — disk; 3 — the drum housing; 4 — shaft; 5 — bearing; 6 — shaft; 7 — bevel gear; 8 — retaining washer; 9 — screw; 10 — key; 11 — clamp flexible coupling nut; 12 — washer; 13 — rubber grommet clutch

Samiria guide under the front wheels:

1 —the guide (channel 250×100); 2 — screw mounting rail to the wheel; 3 — bolt the hub to the top shelf farm; 4 — hub; 5 — support ring; 6 — the top shelf farm

The skin of the pontoon is made of plywood thickness of 5 mm. First sheathed flat part of the bottom, then the cheek, and then — side. The next stage — installation of mechanisms in the body of the pontoon; the drums drive of the propeller, the bevel gear pair, stern tube and shaft bracket shaft tube and rotating supports of the front wheels. The body of the pontoon is covered from the inside with a waterproof varnish — parquet or “pinoteks”, then mounted deck plating (inner surface is coated with varnish) and the whole building from the outside, primed, puttied and painted with several layers of water resistant enamel.

In the deck it is necessary to provide hermetically sealed hatches for inspection of the inside of the hull, ventilation and repair.

To produce a fully sealed enclosure of the pontoon is unlikely, therefore, recommended to remove water from places where it may accumulate. Make it easy for automotive fuel pump driven by a Cam on the drive shaft of the drum.

The drums represent the segments of a steel pipe with a diameter of 300 mm, which is fixed by welding the two steel disk and shaft speed. Bearing housing it is better to choose ready-made from decommissioned construction or agricultural mechanisms, as well as a couple of bevel gears for the reducer with a ratio of about one.

In the stepped shaft of the driving drum protectives hole with a diameter of 34 mm, it is necessary to fix the rubber coupling through which the torque is transmitted to bevel a few. The coupling is a rubber sleeve on the threaded shank.

For fixing reels for the loading or unloading of the vehicle is necessary to provide stoppers — steel rods that are inserted into holes drilled in the discs of the reels.

The steering device consists of two pivot bearings, which are collected on the basis of “Zhiguli” of the front wheel hubs. Completion of their complexity is not: all the excess is cut off and they are left with only the bearing housing of the hub but the axle knuckle. The bearing housings are mounted on the side members of the frame with two steel rings of 3 mm thickness and bolts, and the guides are cut from strips of suitable steel channel, is fixed by bolts on the flanges of the axles.

Feather the steering gear is made of plywood with thickness of 12 mm or sheet of aluminum with a thickness of 5 mm. On the steering shaft of the feather rests hinge — this makes it possible to avoid breakage when moving in shallow water. Himself steering shaft pivotally mounted in the shaft — a segment of steel pipe, equipped with bushings of nylon or PTFE.

Steering gear — with a rocking, swivel hard thrust, intermediate duplicera lever, cables with turnbuckles and secured to the steering shaft duplicera Executive arm. The kinematics of the drive is such that the rotation of the automobile steering wheel to the right causes the right circulation of self-propelled pontoon.

I. MNEVNIKI, engineer

Recommend to read MICROTRACKER “BEE” Almost from childhood read the magazine "modelist-Konstruktor". It has taught a lot of information about new designs, interesting ideas. Inspired by the publication in the journal, while... HELP OUT NEEDLE Do not rush to throw undeveloped stem of a ballpoint pen, when suddenly the paste will cease to act from it. Very often it is due to the fact that the open part of the thin plastic tube...