Versatility — the main advantage I have developed multi-operational machine for working wood. Him “on the shoulder” turning, pugovka, cutting the material, drilling, milling, tenoning operations. In the end, it is possible to sharpen a tool or make it into a joiner’s workbench.

Lathe. It is the basis of a “wagon” and consists of tables, bedplates, front and rear attendants, armrest, pad under the front headstock and the bracket for mounting the motor.

The skeleton of the tables made from a steel angle Frame 30×30 mm. — from the same profile, but with shelves 50×50 mm. Only for her it took four uprights and two rails, which are connected by bolts M8. The area under the front headstock is a “box” welded from two pieces of steel channel 100×50 mm length of 400 mm and a pair of steel plates 400×100 mm with a thickness of 2 mm, connected by M6 screws. The bracket under the motor — corner 50×50 mm 280 mm in length, attached to the headstock area. The box privernuty to the console editions of the bed rails with two bolts M12: one of them is the axis of rotation of the box with headstock, and a second locking horizontal or vertical position.

Motor (capacity of 1 kW at 2850 rpm) is attached to the bracket and connected with the spindle V-belt.

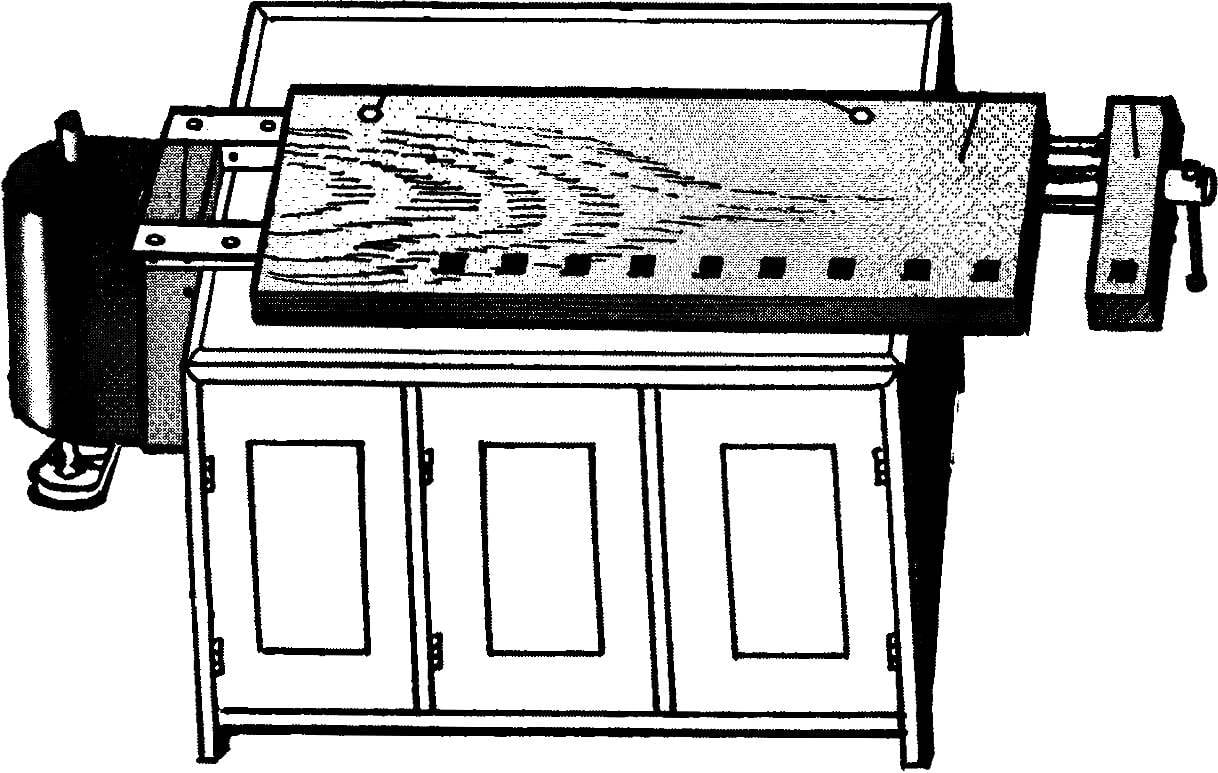

Versatile woodworking machine:

1 — frame tables (30×30 area); 2 — front frame (area 50×50, 4 pieces); 3 — guide frame (area 50×50, 2); 4 — Playground headstock (channel 100×50, L400); 5 — headstock; 6 — armrest; 7 — tailstock; 8 — table of the planing machine; 9 — knife-shaft; 10 — a bracket of the motor (area 50×50); 11 — electric motor.

This is a General structural diagram of the lathe. Now about the devices, turning it at will working in a number of other woodworking machines.

Circular saw. Made like a console and consists of a desktop circular saw and protective covers. To work her Desk is fixed on the bed rails using the four rack — steel rods (studs) with thread M16. The saw blade is mounted on the headstock spindle and clamping nut in between the washers and rings. Above the disc and under it install safety covers. In the lower cover, attachable to the frame, the hole and the pipe through which the discharged sawdust. On the table there is a fence: it can be moved along the guide rails, thereby adjusting the width of the cut material.

Circular saw:

1 — drive to the spindle; 2 — disc blades; 3 — upper safety cover; 4 — casing; 5 — thrust plate; 6 — desktop; 7 — rack; 8 — guides of the frame.

Surface planer. His table fixed on the frame of the bedside tables. The cutter block with replaceable blades — from the plane. To the shaft is attached a pulley with a diameter of 100 mm. the Drum is mounted in the left part of tables, one of the branches which is strojeconomica. To bring the cutter drum into rotation on the spindle put a pulley with a diameter of 80 mm Processed material is pressed against the roller with a spring, fixed on guides (not shown). Serves the material manually.

Surface planer:

1 — drive; 2 — spindle; 3 — pulley; 4 belt; 5 — Desk; 6 — knife drum.

Grinding machine. In order to convert a lathe in the press is enough on the spindle headstock to install grinding wheel and on the frame to secure the cover and the handrest.

Grinding machine:

1 — drive to the spindle; 2 — grinding wheel grind; 3 — casing; 4 — a podruchnik.

Tenoning machine. For this transformation the front headstock lathe, turning around the hinge bolts are transferred from horizontal to vertical position and fix the second bolt. On the spindle is fixed a circular saw or cutter. On the bed set the table of a circular saw, the height of it at the same time regulate nuts. The cutting depth is set by displacement of the casing and the fence.

Tenoning machine:

1 — drive; 2 — the screw; 3 — spindle; 4 — mill; 5 — casing; 6 — table; 7 — regulating nut; 8 — bolt axle M12; 9 — frame.

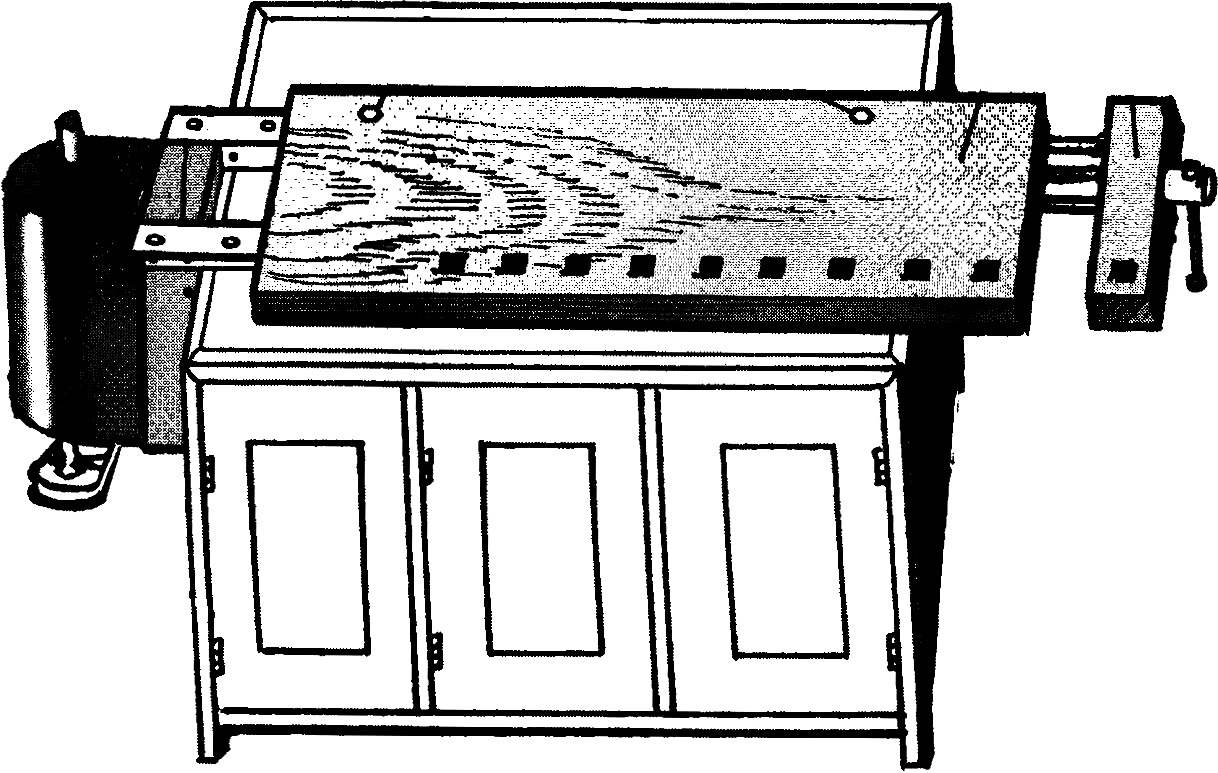

Carpentry bench. To make it out of the lathe, is fixed on the frame with two bolts verstachnuju a Board (900х250х40), which accomplished a number of square holes for the wedges. The second Board — clamping set to the right of the first, it is one square hole. Clamp the workpiece between the boards with a screw. On the Board below features steel corners: bench area with welded thereto guide bushings and nut, and clamping with guide rods and screw.

The joiner’s workbench:

1 — rails of the frame; 2 — bolt; 3 — bench Board; 4 — Board clamping vise; 5 — clamping screw; 6 — a bedside table.

In the inoperative position the two boards of the bench attached to the rear wall of the Cabinet.

All accessories to the machine stored in the Cabinet right of the Cabinet. Top shelf of the locker is designed for the auxiliary tool.

Thus, this universal machine hosted on one square meter, replaces a complex machine tools for working wood.

G. LYUBCHENKO str

Recommend to read FLYING UNDER THE ROOF For many school model aircraft clubs create room flying models is the only available form of modeling. Judge for yourself: the season of the competition model, as a rule, coincides with... TREAT THE BIKE Boys — people are desperate: the bike chase so that injuries are not only them, but also technology: the wheel rim is bent, the frame or the fork. If this happens, do not have to seek... Scroll back to top

Versatility — the main advantage I have developed multi-operational machine for working wood. Him “on the shoulder” turning, pugovka, cutting the material, drilling, milling, tenoning operations. In the end, it is possible to sharpen a tool or make it into a joiner’s workbench.

Versatility — the main advantage I have developed multi-operational machine for working wood. Him “on the shoulder” turning, pugovka, cutting the material, drilling, milling, tenoning operations. In the end, it is possible to sharpen a tool or make it into a joiner’s workbench.