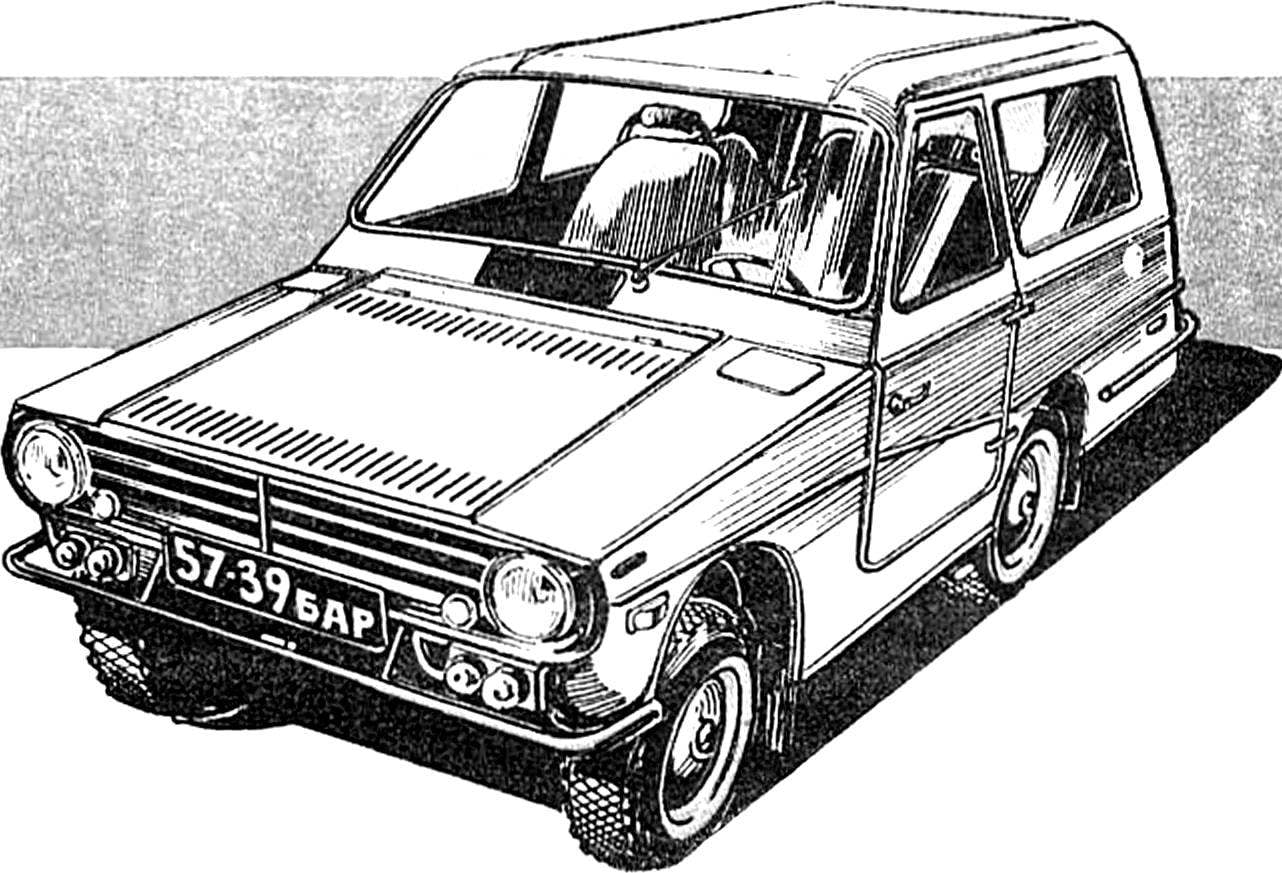

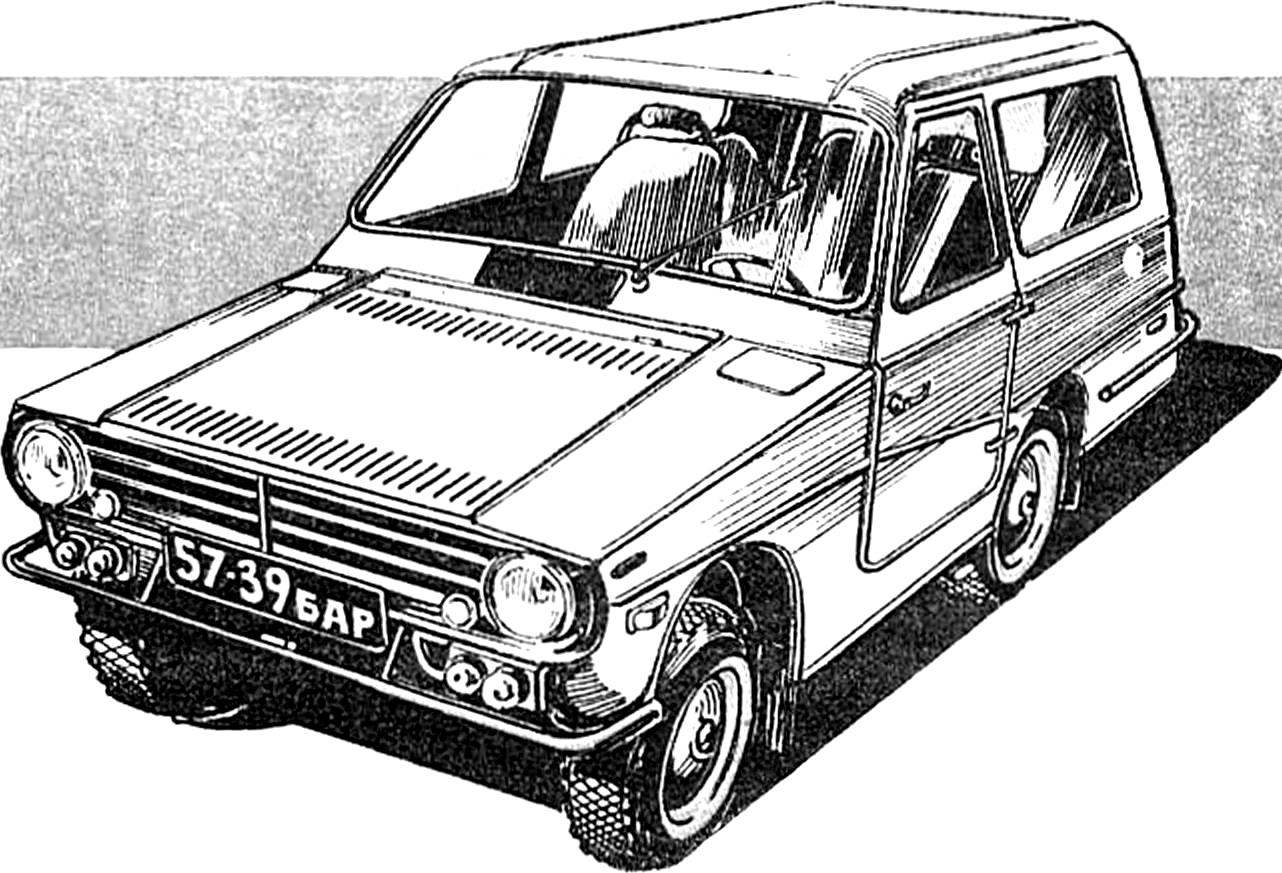

Little Micro-Car, “Breeze”:

1 — driver seat, 2 — exhaust, 3 — small driveshaft wheel drive, 4 — seat passengers, the 5 — bumper 6 — spring suspension, 7 — brake pedal 8, the brake rod, 9 — balance lever 10 to brake the rollers with the cable 11 brake lever 12 is a lever and control rod main gear, 13 — gear, 14 — propeller shaft 15 — muffler, 16 — engine M-72 with a transmission from the MT-10 motorcycle “Dnepr”, 17 — fan, 18 — tie rod, 19 — steering, 20 — duplici the lever 21 is of the transverse single-lever front suspension, 22 — single transverse arm rear suspension, 23 — the clutch pedal.

Main gear:

1 — flange u-joint, 2 — speed gear shaft, 3 — the packing speed of the shaft 4 — bearing No. 205, 5 — shim, 6 — intermediate gear shaft, 7 — bearing No. 302, 8 is a small pinion gear, 9 — the switching clutch, 10 — big pinion, 11 — bearing No. 204, 12 — differential sidecar from SZA, the 13 large driven gear, 14 — small, the driven gear 15, and the bearing housing, 16 — bearing No. 207, 17 — oil seal slow speed shaft 18, the flanges of the universal joints of the drive wheels, 19 — key (7 PCs.).

A few unusually located seats for passengers: the third sits between the first and second seats, but retracted to 450 mm, and the fourth passenger is located behind the axis of the rear wheels across the machine. Any other location of the seats requires a substantial increase in overall dimensions of the car. Seat made of cushions from the bus LAZ, lined with leather and have the plywood base. The cushion is placed on the frame of rectangular shape, which is a tool box. Bumpers made of titanium pipes. As frontal used rear glass from a ZAZ-968, side and rear plexiglass. The doors are mounted externally, so allow them to open 180°. Provided for locking the driver door in the open position (a similar solution was applied in small trucks “Tatra” in the 50-ies).

During operation of the vehicle revealed a number of shortcomings inherent in the suspension of the wheels of the wheelchair of SZA. These include the abundance of sliding friction pairs, requiring a complex repair; big mass; low reliability of the torsion bar front suspension, reinforced further coil springs, as well as a large number of lubrication points and the associated high level of maintenance. To avoid all these disadvantages, was assembled the front axle on a transverse wishbone single. A similar solution is applied on the car “Tatra” and passenger car “Hillmanimp” issued in 1963. This pendant has a very simple construction, small weight and minimum number of lubrication points. During the year, it was used a hydraulic vibration damper from the sidecar of SZA, but they have proven their low reliability. In 1986, the suspension has been reworked with the elimination of hydraulic shock absorbers, and positively used its main drawback is the constant change of gauge, which contributes to samagaltay vibrations of the body. The front axle has two symmetrical arm, the Foundation of which is a titanium tube Ø 25 mm, bent in the form of the letter L. In the ends of the tube are inserted the lugs of hinges fixed with pins. They are assembled with quick-release brass sleeve. From the opposite side, with two ladders and two clamps mounted supporting structure for the springs and pivot rotary unit from the sidecar of SZA. Squarely node and improved bushings replaced with needle bearings. Wheel used also from the sidecar, but tapered roller bearings are replaced by deep groove ball. This change greatly simplifies the adjustment of the bearing arrangement of the wheels and reduced mechanical losses. As the axes of the suspension arms are used a M12 bolt.

Transverse single-lever front suspension:

1 — tip hinge, 2 — lever (titanium pipe), 3 — clamp, 4 — a supporting structure of springs, 5 — step ladder, 6 — squarely host, 7 — pin, 8 — sleeve 9 — spring (from the top view is not shown).

To rework the front suspension springs were travel stops — turns them completely converged, thus there is deformation of the suspension even on very small bumps. To avoid this phenomenon, it was used the “absurd” decision — limiters steel wheels themselves. The wheel houses were installed arc made of pipes from a clamshell. Now at full spring compression the wheel hits the limiter tube, while it is partially podnimayutsya. In the course of two seasons, the machine worked without any deformation; no increased tire wear, no pulling to one side was observed. Due to the fact that the upgrade was successful, was similarly modified and the rear suspension. With the aim of improving patency adopted the same track front and rear wheels. As wishbone rear suspension used a water pipe 3/4″.

It should be noted that after removing gidrogelei machine yet acquired a tendency to sway, which ultimately is reflected in the decrease of the average speed on bad roads approximately 10%, but get rid of the repair and service of shock absorbers. Good results our experiments are explained by the low weight of the car, applying the suspension to changing track and a good selection of coil springs (like suspension single wishbone without gidroperita applied to the micro-car, only “Avtomol” Professor Ignatova).

Installed on the machine transmission from a motorcycle “Dnepr”, which made the main transmission two-stage. The total number of transmission — 4X2. Body homemade main gear is welded from a steel sheet with a thickness of 4.5 mm. holes for the prop shafts were processed on a boring machine.

Main gear has one pair of bevel gears (Z1 =17, Z=26, i1 =1,6) and two pairs of cylindrical (Z3 =31, Z4 =46, i2 =1.48 and Z5 =25, Z6 =52, i3 =2,1). Shafts with cylindrical gears are one above the other. Between the two lower gears is the differential from the sidecar of SZA. In the future gear ratio has been adjusted to improve traction characteristics (Z3 =29, Z4 =48, i2 =1.66 and Z5 =56, Z6 =21, i3 =2,68).

Large selection of gear ratios is very convenient to the mountains, allows you to move confidently on bad roads and with a trailer, make the drive more comfortable, as at 2,000 rpm and a speed of about 60 km/h the engine runs quietly.

Brake inputs to directly affect the mechanical, two rear wheels, the rope, the force is transmitted through four of the blocks. The design of the brakes allowed without significant changes to use the manual a separate drive for each wheel, which gave the opportunity to increase the traction qualities when driving on bad roads.

On the micro-car, only the muffler installed active type. It is a pipe with a diameter of 130 mm and a length of 220 mm with an internal partition. The muffler is worn on the horizontal section of the exhaust pipe Ø 32 mm, which are drilled a large number of holes of Ø 6 and 8 mm, and placed as close as possible to the engine. Exhaust pipe with length of 1300-1400 mm and ends at the left rear wheel, as on the GAZ-69. A time used a shortened exhaust pipe length of 400 mm. At full throttle there is a “direct” blowby, the engine “rattled”, but he added power at medium speed. On this basis, we can assume that the exhaust system is of great length has a significant resistance the exhaust gases and substantially dampens the power of the engine.

Steering gear — rack and pinion, borrowed from the sidecar of SZA and some modified. Steering knuckle arms layout considerations transferred and are in front of the pin. The force on them is transmitted through duplici the lever. Tail rods use spherical bearings type SHS. The steering wheel rim made of aluminum tube and covered with leatherette.

Steering:

1 — rack-and-pinion, 2 — brackets 3 — transitional kinematic link, 4 — duplici lever 5 — track rod 6 — steering shaft, 7 — bearings.

Brake system:

1 — brake levers rear drum brakes, 2 — blocks, 3 — wire Ø 3 mm, 4 — beam lever 5 hand brake lever right wheel, 6 — the lever of a manual brake left wheel with lock, 7 — brake thrust from the sidecar of SZA.

The engine of the motorcycle M-72 is equipped with a fan connected to the crankshaft via a rubber coupling. The fan shaft has a single bearing No. 201, and the second fulcrum is the crankshaft as the drive flange coupling tightly centered on the inner surface of the front gear on his sock. The fan hub is a collet and is fixed on the shaft due to forces of friction. The blades are made of titanium alloy.

The engine is doohickery ignition coil from the motorcycle “Ural”, which allowed to refuse a distributor-dispenser. Greatly simplified maintenance of the breaker contacts due to the lack of runner. When using doohickery coil spark appears at the spark both cylinders, but one of them is ready to ignite a combustible mixture, and in another the processes of gas exchange. It would therefore be very wise to move in the cylinder with a flammable working mixture, another electrical discharge from the opposite cylinder. Application dvuhruchevoj ignition system gives an increase in power efficiency by 3-5% (see: Beckman V. Racing motorcycles, mechanical engineering, 1969., p. 144). This system consists of two ignition coils, low voltage switch, standard breaker and the four candles, used for two months. Further exploitation prevented bad design of low-voltage switch having a large contact resistance, reaching 0.5 Ohms. The switch is connected alternately left, then the right high voltage ignition coil with the breaker contacts. When contact separation occurs indutsirovannye high voltage breakdown of the spark gap on two plugs for left and right cylinders. Two fuel tanks with a capacity of 11 l each are placed above the niches of the front wheels. Tanks are made of brass sheet thickness of 0.8 mm.

Little micro-car can be equipped with a PTO from the main gear. Thus the possibility of its use increase, it is to some extent a hybrid of car and tractor. Of course, to drive a car in the furrow is not necessary, but it can be used to cause the rotation of the hinged winch, pulling a plow, rotary drill, a cement mixer, you can cut firewood, result in rotation of the welding generator with a capacity of 10-14 kW, etc. of Course, empowerment will have to pay, for example, an increase in the mass. However, this is not such a big loss, the most important — at least to some extent to reduce the amount of manual labour.

A. SPEAR, P. SPEAR

Recommend to read MICROLAENA Modelers often have certain difficulties in acquiring light and noiseless gears, wheels, propeller, and propeller and other parts for improvised structures. At the same time, these... THE CREATORS OF “FIRE ARROWS” The emergence of missiles in Russia noted by the chroniclers in the Pskov chronicle of the XV century In 1680 in Moscow organized a special "school" for the production of lighting and...  Little micro-car “the Breeze” was created three years. It was conceived as a double jeep with a canvas roof, flat windshield, three doors, the side from which the glasses had not. A year later, the car was put on upgrades.

Little micro-car “the Breeze” was created three years. It was conceived as a double jeep with a canvas roof, flat windshield, three doors, the side from which the glasses had not. A year later, the car was put on upgrades.