a LITTLE SENSATION. “After the invention was patented not only in Australia but also abroad, the curtain of secrecy that until recently hid work Ralph Sarich several parted. The look of the new motor is strikingly different from its predecessors. A prototype orbital engine is a solid disk with a diameter of 40.6 cm, a thickness of 12.7 cm and weighing about 45 kg, which are placed around the rotor of the combustion chamber… Engine Serica develops up to 200 horsepower. According to experts, in the mass production of orbital engine due to the simple design (only 10 moving parts) will cost many times cheaper motors used in the automotive industry at the present time”. This information was placed in the newspaper “Pravda” on January 20, 1973.

a LITTLE SENSATION. “After the invention was patented not only in Australia but also abroad, the curtain of secrecy that until recently hid work Ralph Sarich several parted. The look of the new motor is strikingly different from its predecessors. A prototype orbital engine is a solid disk with a diameter of 40.6 cm, a thickness of 12.7 cm and weighing about 45 kg, which are placed around the rotor of the combustion chamber… Engine Serica develops up to 200 horsepower. According to experts, in the mass production of orbital engine due to the simple design (only 10 moving parts) will cost many times cheaper motors used in the automotive industry at the present time”. This information was placed in the newspaper “Pravda” on January 20, 1973.

Around the same time, news Agency the associated Press said, “the Australian company “broken hill Proprietary” signed an agreement under which pledged to support the Australian inventor Ralph Sarich in the quest to start the production engine of its design. This company is ready to invest 50 million Australian dollars in the production of engines of Sarica, if it proves technically and commercially viable.”

…The beginning of 70-ies was under the flag of expansion of production of rotary-piston engines Wankel. The Japanese company “Toyo Kogyo” increased manufacturing capacity for vehicles with the RPD. The concern General motors bought a license to manufacture a wide power range of engines for its cars and built a new automated plant for the production of RAPS. Therefore, reports on the establishment of a new, even more attractive at first glance, the engine naturally has stirred up the scientific and technical community, large companies and dealers.

WHO is HE, RALPH, SARICH? In 1973, the 34-year-old Australian engineer, a Yugoslav by birth, was forced to speak about itself the whole world. The flow of information, for the most part biased, created around the engine of Carica the aura of a new “miracle” of the twentieth century, can soon bury classical piston combustion engines. So, “according to Australian forecasters in the country by 1980, 99 percent of all automobile engines will be produced in the form of rotary motors of different modifications…”. This excerpt from the periodical press shows how hasty a conclusion from the outbreak at that time in Australia the information boom around the Sarich engine.

The inventor approached the creation of their offspring quite seriously, and most importantly — professionally. Sarich, until 1970, was engaged in hydraulic and pneumatic motors expansion type, therefore, no accident that he undertook the development of the rotary engine. The focus of Sarich was paid to the reduction of speed and friction of the individual elements of the motor. To cope with this problem, it’s used for main engine parts — piston — plane-parallel movement, called the orbital. To do this, the inventor used three eccentric. The solution to the problem of synchronization of the movement of the piston by means of eccentrics author orbital engine attributed to himself, but to clarify — he had a predecessor. This pole Gustaw rozycki, who was working on his engine in 30 years.

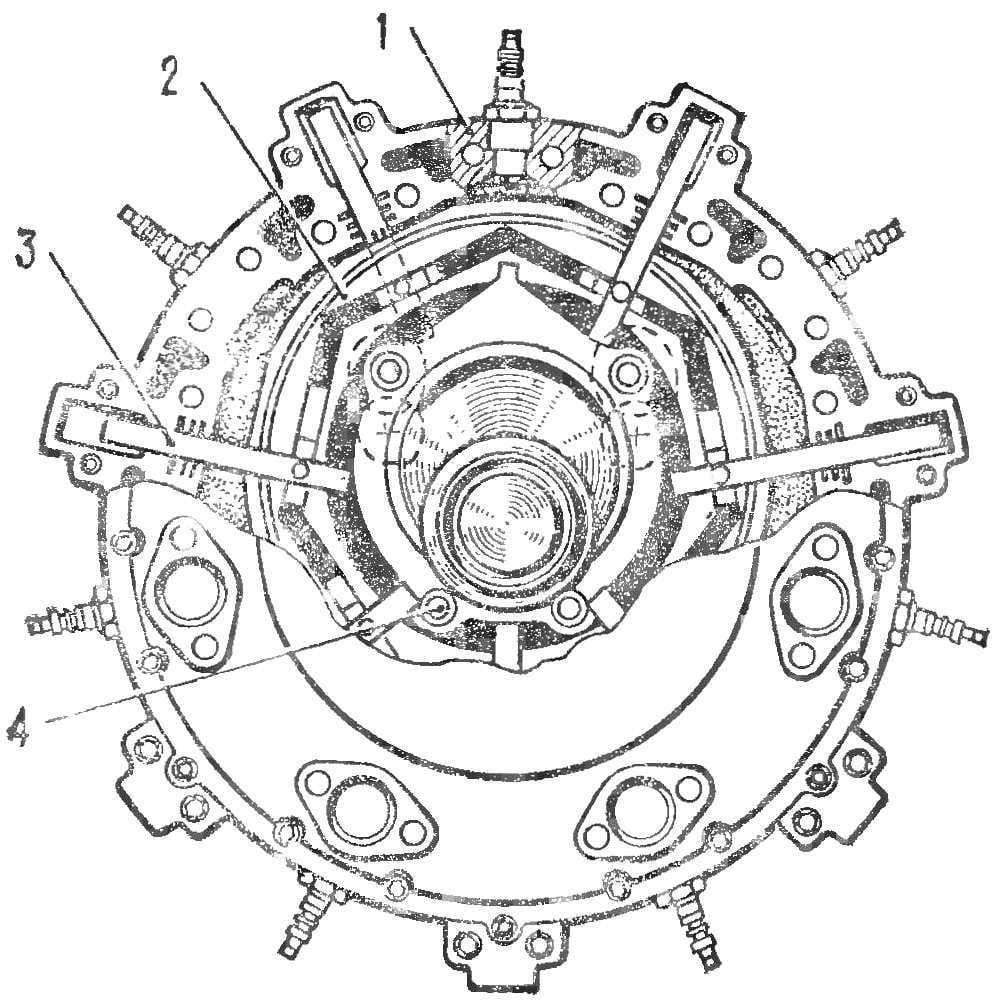

Design Ruzhitsky based on the fact that the two tribes, or eccentric with equal eccentricity, rotating, attached to the rotor or piston planetary motion. The rotor is placed in the housing, sealing elements divided into two or more chambers; the shape of the rotor and the housing vzaimopomoshi. Figure 1 shows the pattern is quite simple at first glance, the engine proposed Ruzhitsky. It incorporates four sealing plate, which make forward movement, not only in the slots of the rotor body, but also on the working surface of the body.

Fig. 1. The scheme of the engine Ruzhitsky:

1 — engine block 2 — rotor, 3 — o-blade, 4 — synchronizing eccentrics.

An Australian inventor has developed an original blade design that separates the engine chamber. He realized that if you use blades approved the expansion of cars, it almost certainly will fail.

Applied R. Saricam design has no analogues among the mass of the sealing elements proposed by many inventors. Some similarity can only be found in the engine Kraus, established in 1963. And at first glance the proposed Saricam seal of the orbital engine seems unworkable due to the presence in the combustion chambers of precision parts.

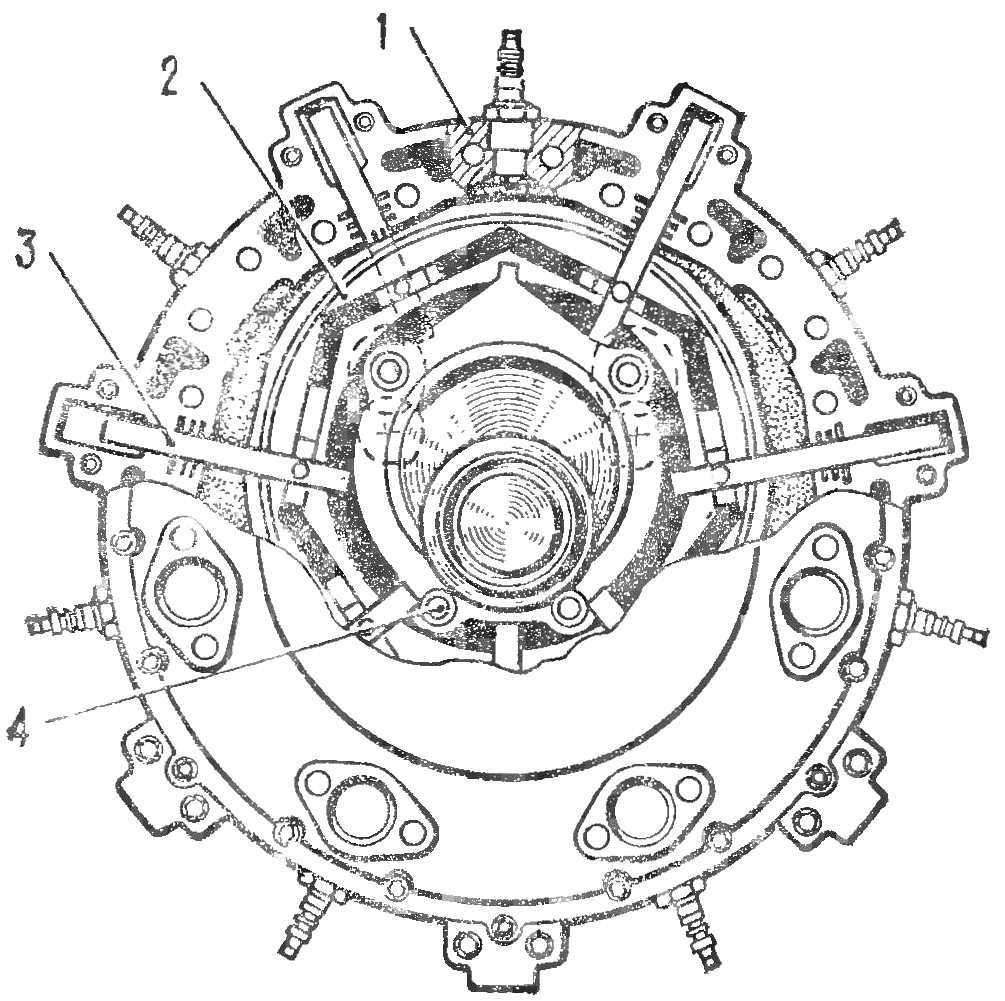

ORBITAL — WHAT does that MEAN! On the PTO shaft there is a crank on which you installed the piston. Three additional eccentric with eccentricity equal to the crank radius, do not allow the piston to rotate around the main shaft. For this eccentric included in the piston, and their shafts rotate in the engine block. With this system, synchronization of the piston during rotation of the shaft makes only figurative movement, and all the side faces during operation remain parallel to themselves. As can be seen, in part, the synchronization engine Sarich is virtually indistinguishable from design Ruzhitsky (compare figures 1 and 2).

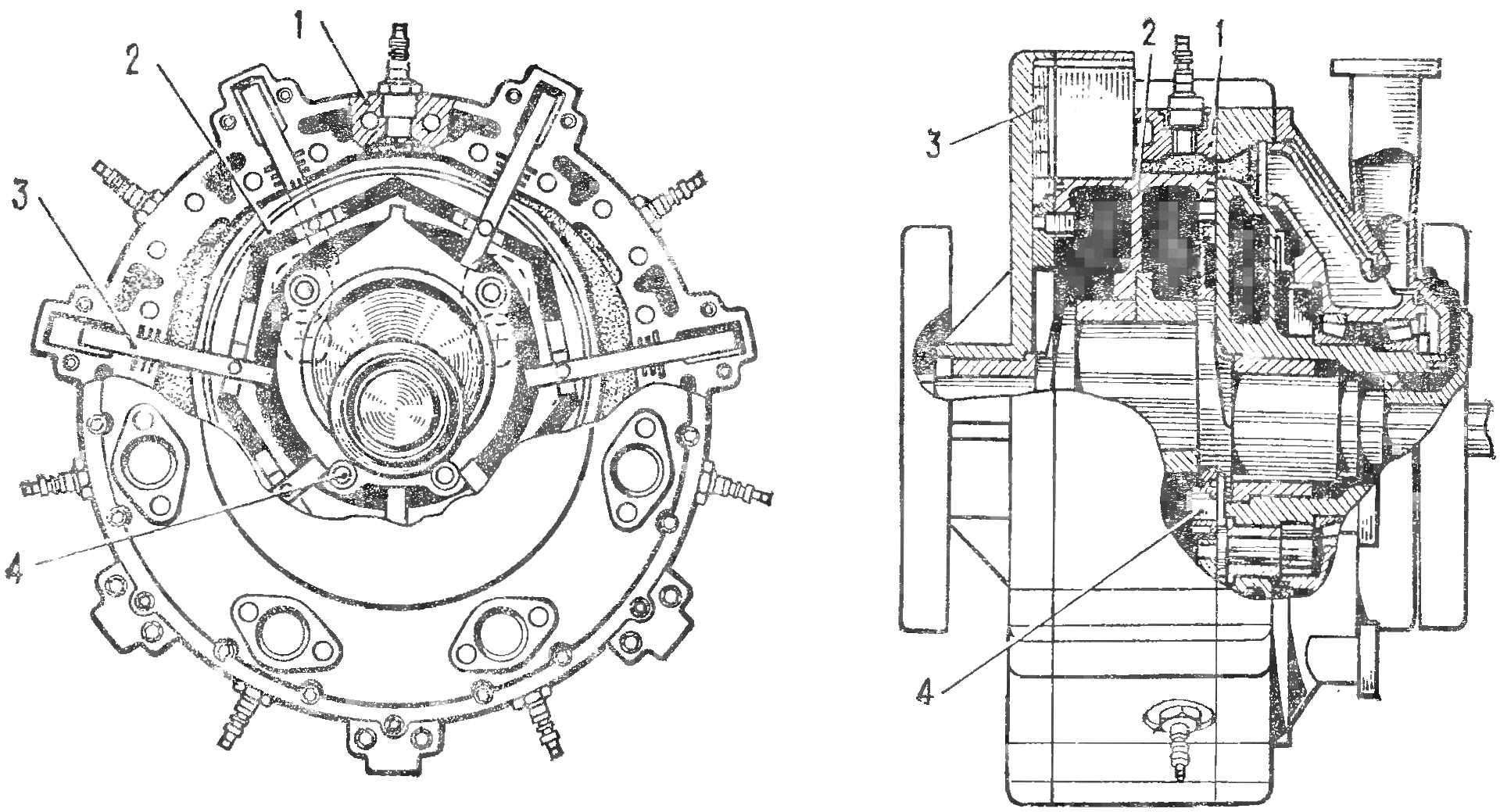

Chamber volume obtained by dividing the cavity between the housing and the piston valves apart when the rotation of the shaft varies from minimum to maximum, Without the presence of timing in this car is only possible two-stroke cycle. When dividing the cavity 6 cameras in a row, the engine will give 6 strokes per revolution of the output shaft, but the next turnover of the strokes will not. When alternating strokes using single flow the torque will be uniform. That is why Saric used an odd number of chambers. Figure 3 shows the individual phases of the cycle: the end of the suction — chamber is filled with fresh mixture, but the intake valve still open; the middle of the compression stroke when both valves are closed; start of the combustion, the piston came to top dead center (TDC); the beginning of the working stroke and the start of production. Over the next turnover will be cycles of release and absorption.

The cavity between the housing and the rotor is divided by several vanes, sliding in grooves of the housing and the end caps. The blades are driven through the control of slots at the ends of the piston, which includes a slide pivotally connected to the blades. Each vane consists of three parts: a Central and two lateral, bolted. Sealing of the working chambers, spring-loaded to provide sealing elements which are installed in grooves made in the housing grooves in the blade (at the point of intersection with the side walls); in the Central part of the scapula (the junction with the rotor); in the annular grooves at the ends of the rotor at its periphery.

IF you will BE WORTHY… After the publication of the description of the orbital engine and after the first noisy enthusiasm appeared sharply critical and even negative statements in the press. And the forefront of this criticism was aimed at the design of the blades and sealing elements, that is, the apparatus for which, according to the author, he paid special attention. Criticism basically boiled down to the following: effective sealing of the working chambers difficult to implement, and according to opponents, is not possible due to the large perimeter of the sealing contour, a large number of joints, seals and significant displacement of the blades. The removal of heat from the blades and their effective lubrication of difficult doubt eliminating wear and scuffing from very significant gas forces acting unilaterally on the shoulder, and the inertia forces resulting from movement of the blades, which move mass commensurate with the pistons of piston engines. The well-known difficulties connected with the high manufacturing precision required to ensure the relative positioning of the grooves in the housing and covers, as well as scenes of the piston, minimal gaps in the joints, of the equality of the radius of the crank output shaft with a radius of the eccentrics, and so on.

Without going into a detailed analysis of the device, we quote the designer of the company “championship” Phil Irving: “If the first engine that are going to test, will prove worthy of the expectations of its adherents, it is necessary to conduct significant development work before it could become a common competitors to the “old faithful servant””.

AND yet IT MOVES. six years have Passed since the beginning of the development of the orbital engine. What are the successes and what challenges are faced by the creators of the new engine! Just before the creators, since currently, Saric heads rather numerous group of employees.

In early 1977, the author of these lines took part in a conversation with R. Saricam that the inventor began with the words: “Forget about what the press wrote. Listen to us Development started as recently as 1972, but has already achieved some success. So, the release of carbon monoxide from the exhaust gases lower than that of the piston. The economy is worse. But since that time we have spent slightly more than $ 2 million in th as the Wankel engine have already spent 600-700 million dollars, the Stirling engine is about $ 150 million. That is, we are still at a very early stage of development of the engine. In our design there are pros and cons of course.”

Fig. 2. Sarich Engine:

1 — engine block 2 — rotor, 3 — o-blade, 4 — synchronizing eccentrics.

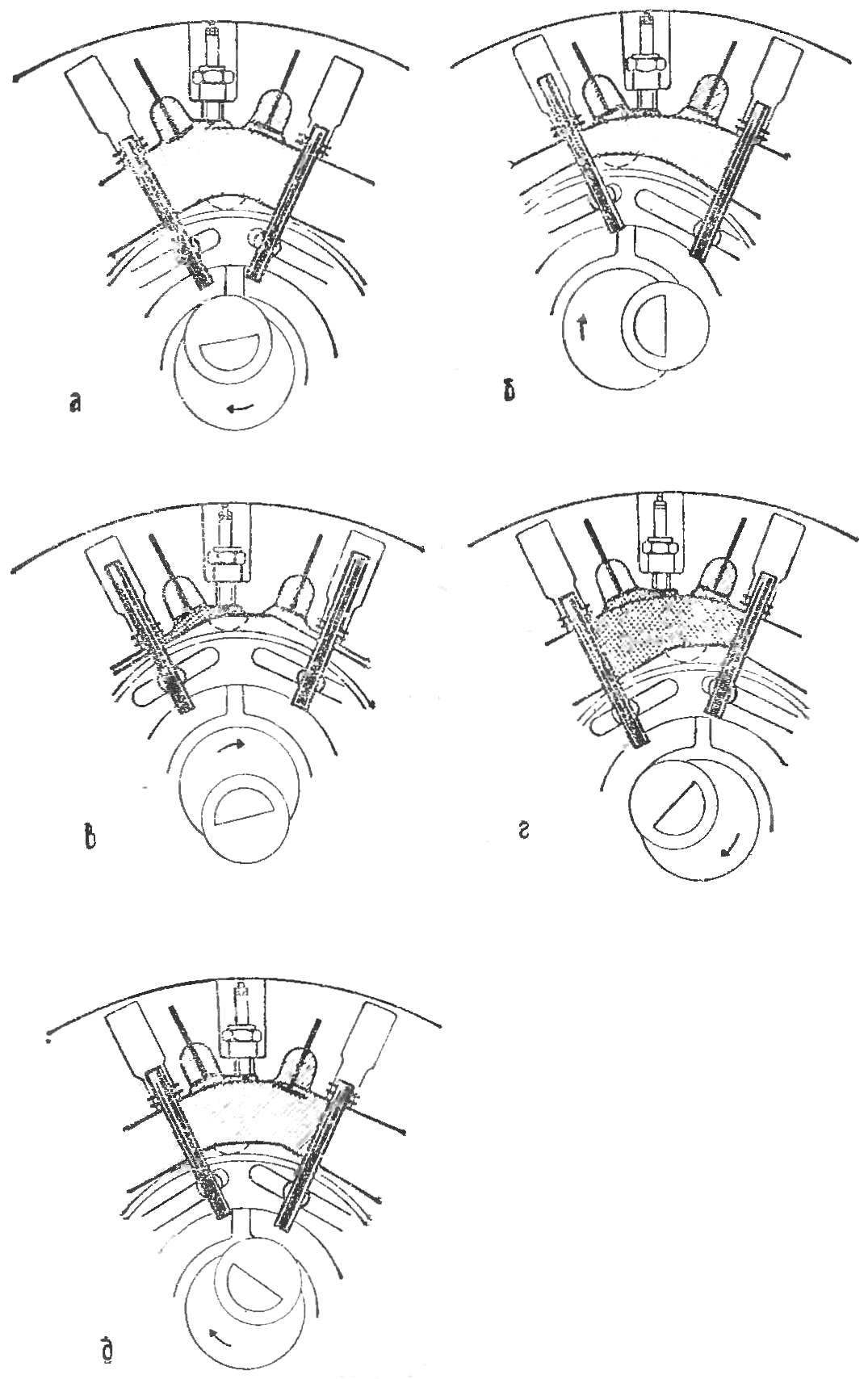

Fig. 3. Diagram of engine Sarich:

a — end suction, b — middle of the compression stroke, in — VMT, g — the beginning of the stroke, d is the start of production.

After these introductory words to the audience were shown a film depicting the principle of operation of the motor and its design it was shown specific examples of the application of the motor to drive the motor boats, or cars, which two thirds of the engine compartment are left blank. Currently the firm has two types of engine: the spool and valve timing. The preference of the spool (smaller size) version; improve its structure being reinforced. For ignition it uses 4 glow plugs installed in spool.

The author believes that, despite the fact that the sealing system is complex, it has advantages over used in the Wankel engine. So, not changing the angle of the seal to the sliding surface, and the speed of the latter is only 40% of the speed of the Wankel engine, which reduces the centrifugal force. The blades forcibly cooled. According to the developers, warm and so good plays in the body. Obviously, the bottleneck of the design is to seal the gaps in the corners of the combustion chamber.

At what can orbital now? Costs fuel costs correspond to the “Wankel” model 1970, when he was a rising star. And although the authors “regret” their first-born, without giving them the full load, the engines “cool”. And not only cool, but also work, helping their creators to overcome the “baby” of the disease and to work out the concept of this new engine — one of the few rotary that came out of the paper stage and embodied in the metal.

And yet the fear such a fact. Despite the obvious benefits of the orbital weight and dimensions the cost of several million dollars has not allowed for the last 4 years to achieve apparent success. Given in the conversation data is basically the same as in publications, 1974— 1975. Isn’t the reason that the reserves for further improvement of this design has been exhausted?

Indeed, until now, the prototypes are forced to work on a mixture of gasoline with oil in the ratio of 25 : 1, i.e., on the same fuel and two-stroke engines. This fact will allow the orbital engine and pass rigorous exams in the limits of the content of toxic components in the exhaust gases. However, in the future, Saric expects to provide lubrication of seals by feeding them oil from the tree that is a rather complicated engineering problem. The inventor was forced to conclude that the friction losses in the orbital engine is higher than a piston, although it still tested at about half load. So, the motor with a working volume of 3.5 l is not output to the load more of 16.1 KGM @ 1600 — 2000 rpm With increasing load and should be expected to further increase friction in the mechanism. And although Saric focused on the fact that the engine consumes fuel at the level of the rotary, but the level of seven years ago, has long been surpassed, and the implementation of the stratification of the charge in the working chamber brought them to a row with piston engines.

Still, orbital spinning, spurring our imagination and expanding the horizons of the familiar.

I. ZINOVIEV, engineer