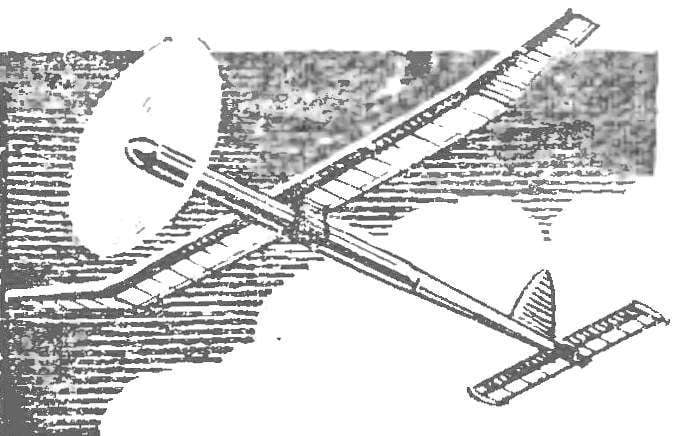

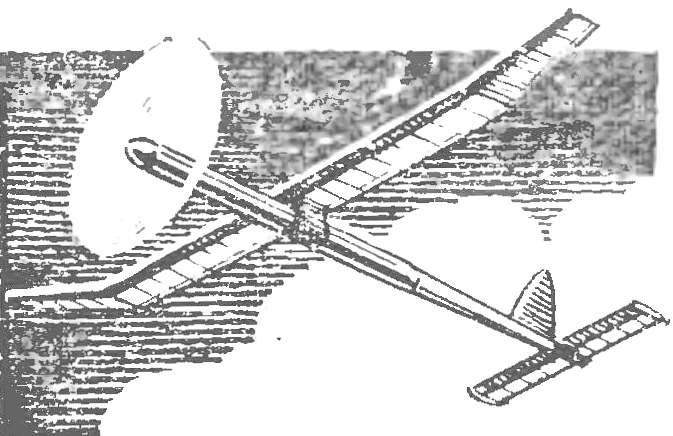

Rezinomotornaya model aircraft class b-1 designed and built in the aeromodelling circle of the pioneer Chkalovsky district of the city of Sverdlovsk schoolboy Vladimir Ivanov. Speaking with her, the young designer won the regional, zonal, Republican and all-Union competitions of the Fifth model airplanes young men and juniors. And at zonal and all-Union competitions resonatory showed the maximum score of 600 points. The championship of the USSR in Novosibirsk, she was recognized as the best in its class.

Rezinomotornaya model aircraft class b-1 designed and built in the aeromodelling circle of the pioneer Chkalovsky district of the city of Sverdlovsk schoolboy Vladimir Ivanov. Speaking with her, the young designer won the regional, zonal, Republican and all-Union competitions of the Fifth model airplanes young men and juniors. And at zonal and all-Union competitions resonatory showed the maximum score of 600 points. The championship of the USSR in Novosibirsk, she was recognized as the best in its class.

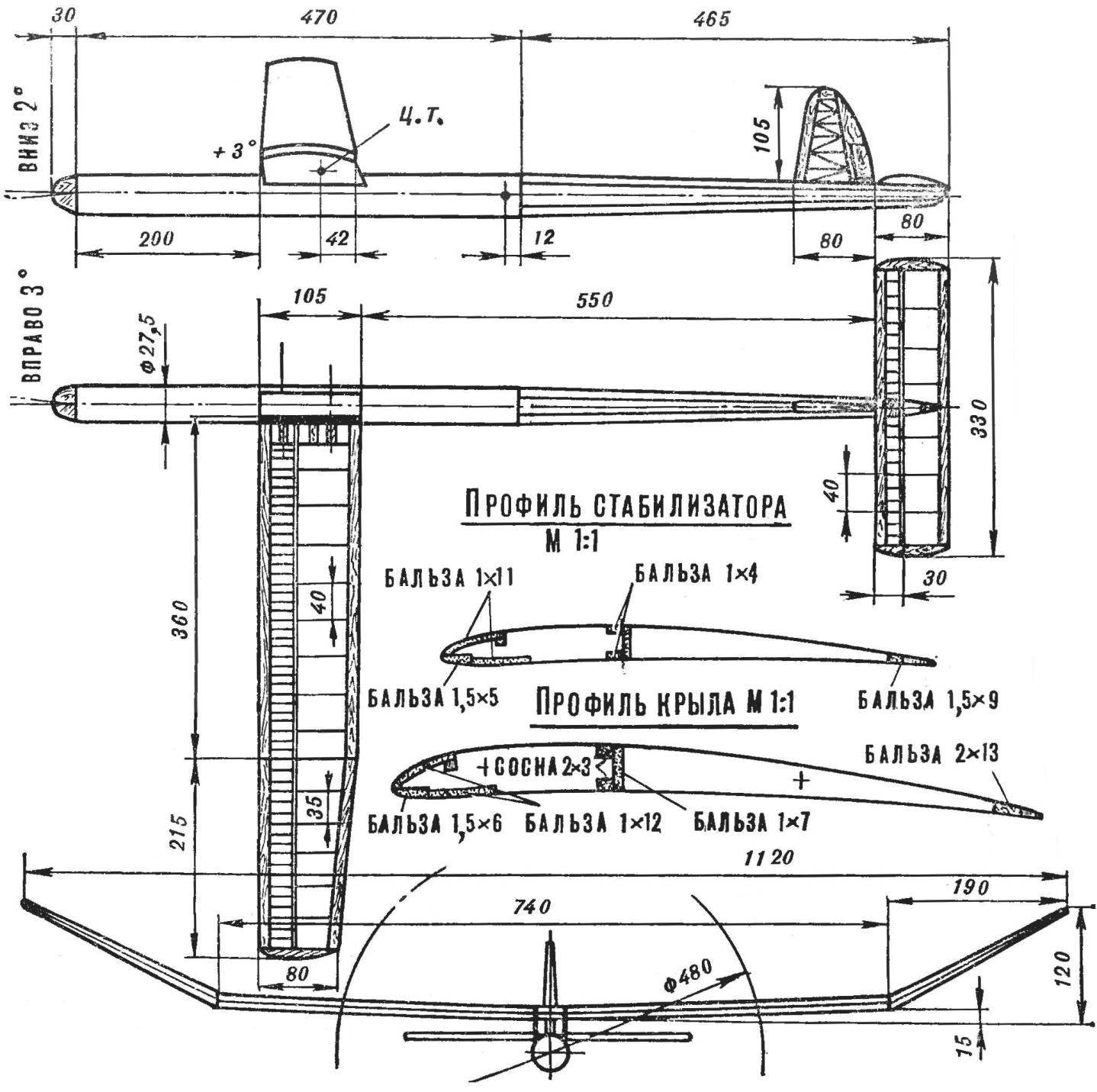

The model is built in accordance with the new technical requirements for this class: load-carrying surface is not more than 14 DM2, the minimum weight without motor 100 g, maximum weight of the lubricated motor — ‘ 25

The FUSELAGE is detachable and consists of two parts. Power made of fiberglass epoxy glue. Metal polished bar Ø 27 mm (having a slight taper), covered with a thin film separator (wax floor wax), is wound six layers of fiberglass with a thickness of 0.06 mm, promazyvaya each layer of epoxy glue. Then the workpiece is tightly wrapped with PTFE tape (for extrusion of excess resin). After the glue dries the tube removed from the mandrel and smooth out the bumps. Finished up the paint Amalita, mixed with aluminum powder, causing the markings and cover parquet lacquer. The weight of the tube 23 g.

The TAIL boom is in the form of an octahedron shaped balsa plates 2 mm thick on a wooden frame. Composite keel with rudder balsa also. The tail and fin are covered with metalized Mylar film with a thickness of 0.01 mm. Weight of the tail boom with a keel — ‘ 10

PYLON — two balsa plates with a thickness of 3 mm. In he glued two steel pin Ø 1.5 and 2 mm for mounting the wings. The upper part of the pylon has the shape of a wing, are located in the timer / clock mechanism is programmed to supply commands to the rudder and the deviation of the stabilizer to enter the parachuting mode

The WING split. Rib is made of basswood variable section from 1 to 0.5 mm (to front edge). Force the ribs out of plywood with a thickness of 1 mm pine Spars, balsa shelf, their front and rear edges are made of dense balsa. Console attached to the center section of the aluminum parts with a thickness of 0.5 mm covered with lime. Polosochki between the ribs from balsa. The weight of the wing without the stitched — 21

The wing is covered with Mylar film with thickness of 0.01 mm: the wing is transparent, and the console is metallic. Film glued with glue BF-2 with subsequent thermal drying. Final wing weight is 24 g. the wing Area of 11.3 DM2.

Fig. 1. Model aircraft-class-1.

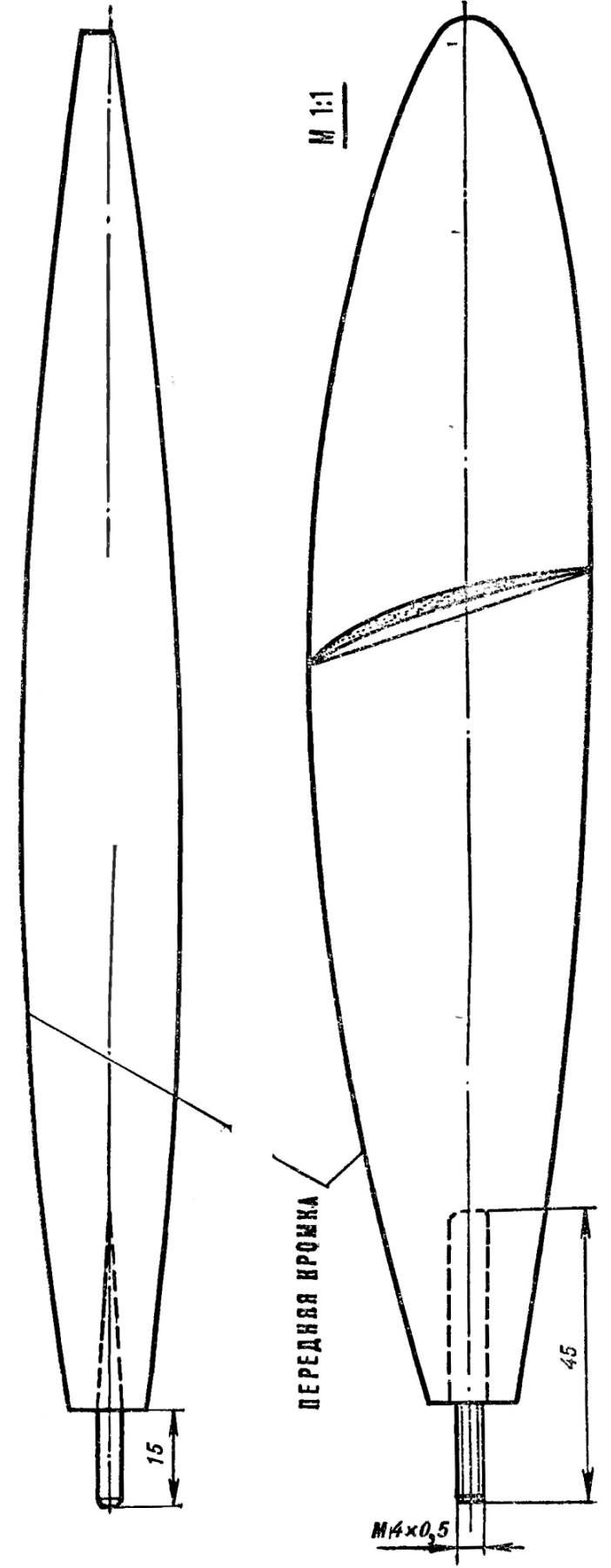

Fig. 2. Patterns of propeller blades.

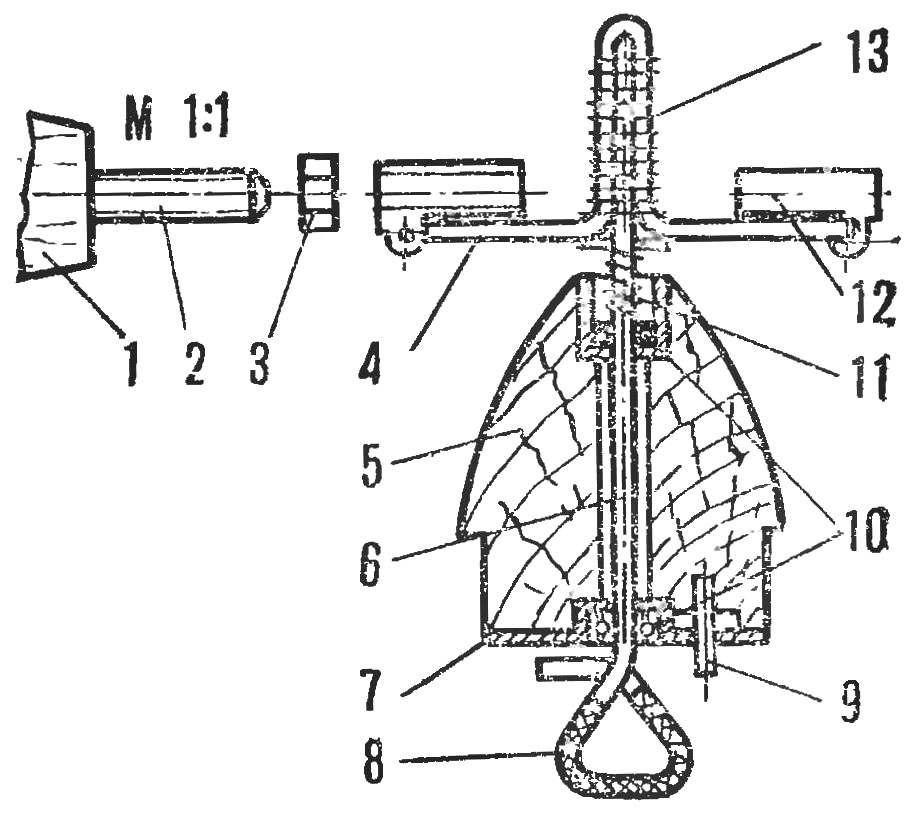

Fig. 3. The propeller hub:

1 — blade, 2 — threaded rod, 3 — nut, fixing the installation angle of the blade, 4 — post (OBC Ø 1.5 mm), 5 — boss (Linden), shaft (OBC Ø 2 mm) 7 — washer (duralumin D-16), 8 — vinyl chloride tube, 9 — the stopper (screw M2), 10 — bearings (2Х6Х3), 11 — spring, 12 — Cup for fastening blades, 13 — copper wire, OPANA soft solder.

The design of the stabilizer the same. All of his rib edges and spars from balsa to 4.5 g. the surface of the stabilizer is 2,6 DM2.

It should be borne in mind that the use of the Mylar film provides a number of advantages compared to mcalenney paper: three times reduces the weight of stitched, the film does not tear during failed landing, the model does not get wet in the rain, not warped from the sun. Finally, a Mylar film fireproof.

Markings marked with a red nitro stencils.

ROTOR GROUP. Boss carved from basswood, glued it in the dural sleeves for fastening bearings. The screw shaft of the wire OVS Ø 2 mm, hub — wire OVS Ø 1,5 mm. Stopper is screw M2, which is twisted in a nut secured in the boss. Spring steel wire Ø 0,5 mm.

The PROPELLER BLADES each weighing 3.5 g balsa, hollowed out the plate on a special mandrel with a thickness of 5-7 mm, which is laminated of fiberglass on the bottom surface of the blade Plate treated with the form of the blade, with a thickness of 4 mm (from butt) to 1.5 mm, is heated in hot water and privinchivayut to the mandrel. After drying, the blade is cleaned, paste over the outer contour of celluloid, tight comly fiberglass thickness of 0.03 mm and coated with a thin layer of epoxy glue. In the root part of the blade is glued dural pin with thread M4X0,5 for connecting the Cup of the hub. For the fixation step is the nut. The design allows you to change the angle of the blades and quickly replace them, the same technology can be used to produce blades and plates of lime.

The rubber motor consists of 14 strands of rubber Pirelli with section of 4X1 mm. Its length is 440 mm, weight 23 g. rubber motor a twisted at 450-480 rpm. The spin-up time of 45-50 C. At the zonal competition model was run for resinator of round rubber Ø 1 mm When the twist at 420 rpm screw worked 35, and the model during this time gained height of 45-55 m.

The model takes off and plans right around.

Its total weight without rubber motor — 105 g flying weight — 129 g.

V. IVANOV, head of the aeromodelling circle, Sverdlovsk