Most velomobile designs feature a rigid connection between the frame and wheel axles. This places increased demands on the quality of a number of parts that cannot be produced at home. The relatively high seating position of the rider on most velomobiles impairs the stability of the car when cornering. Due to their large dimensions, their storage and transportation are difficult.

We tried to overcome these difficulties to some extent when designing the small-sized collapsible velomobile “Tetra”.

The simplicity of its design is achieved thanks to a rational, in our opinion, design and the maximum use of parts from mass-produced Shkolnik bicycles (wheels, frames, etc.). By the way, they are the lightest and most inexpensive.

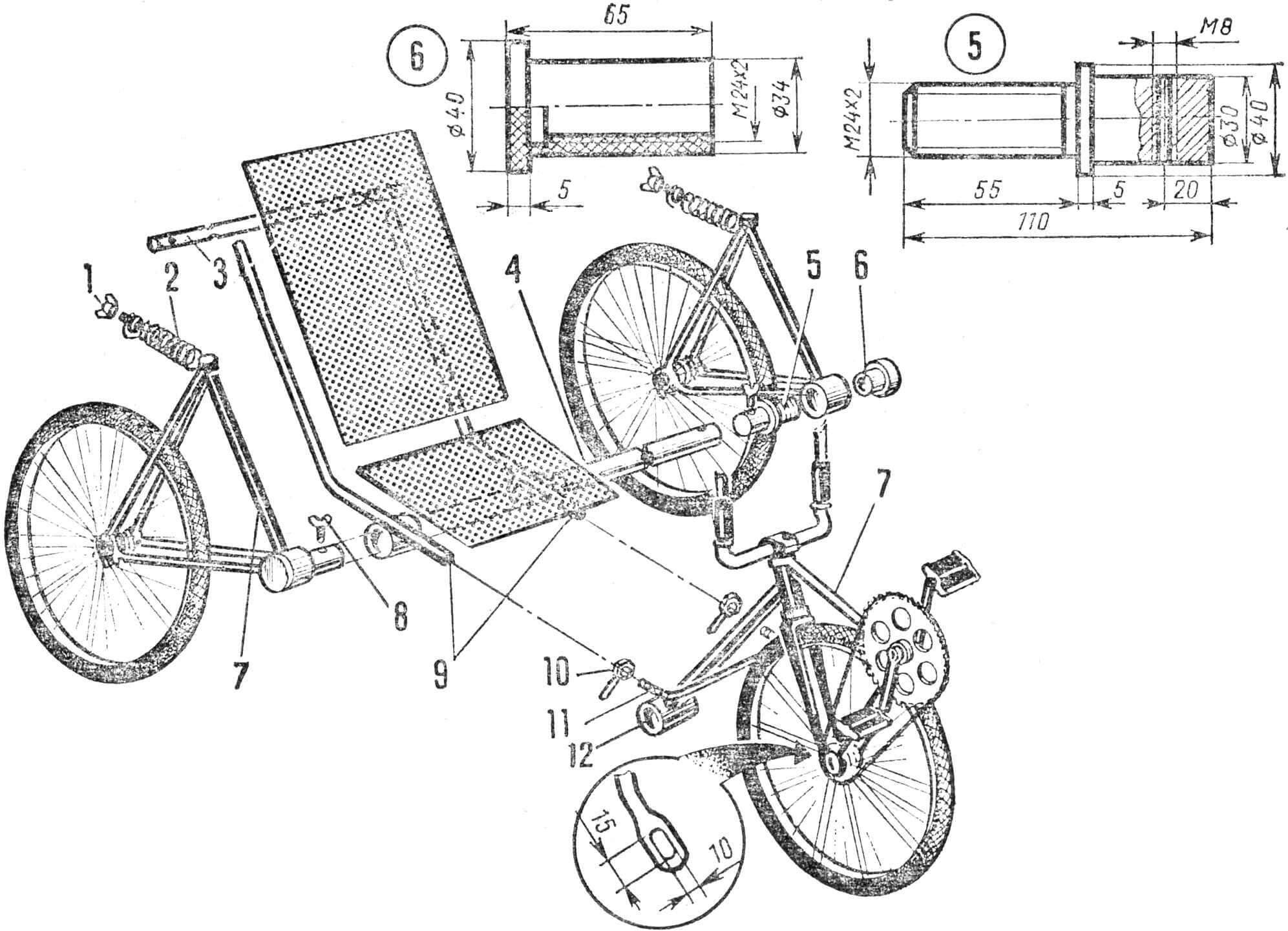

The design features of our velomobile are, first of all, that it has a collapsible frame; the drive is carried out on a rotary wheel; rear wheel suspension is independent, the rear wheels are tilted relative to the vertical to ensure optimal operating conditions when cornering; roof – canopy with adjustable installation angle.

The collapsible welded frame is made of water pipes. It consists of a steering column beam, a rear fork axle, tubes and a seat cross member. When disassembling the frame, the seat cross member is released, to which the shock absorber springs are attached, the wings are loosened, the axle is pulled out and the seat is removed.

The rear wheel mounts are made from the rear of the bicycle frame. To withstand lateral loads on turns, the rear wheels are inclined; it is achieved by deforming the seat tube relative to the former carriage at an angle of 5°-10°. A bushing is pressed into each carriage; a pin is screwed into it, fixed on the axis of the rear forks using a thumbscrew.

1 — shock absorber mounting wing, 2 — shock absorber spring, 3 — seat cross member (pipe or angle), 4 — rear fork axle (pipe Ø 35 mm, L — 600 mm), 5 — M24 pin (D16T), 6 — bushing (caprolon, fiberglass), 7 — seat parts of bicycle frames, 8 — wing screw (M8), 9 — seat bracket tubes (Ø 22 mm and Ø 42 mm), 10 — wing nut (M16), 11 — spacer bracket with threaded shanks (M16), 12 — steering column beam (pipes Ø 33 mm and Ø 42 mm).

The rear wheel assemblies are “sprung”. Motorcycle seat springs are used as shock absorbers. Each of the springs is fixed with one end in the upper part of the rear wheel assembly, and with the other, threaded end with a wing, on the seat cross member.

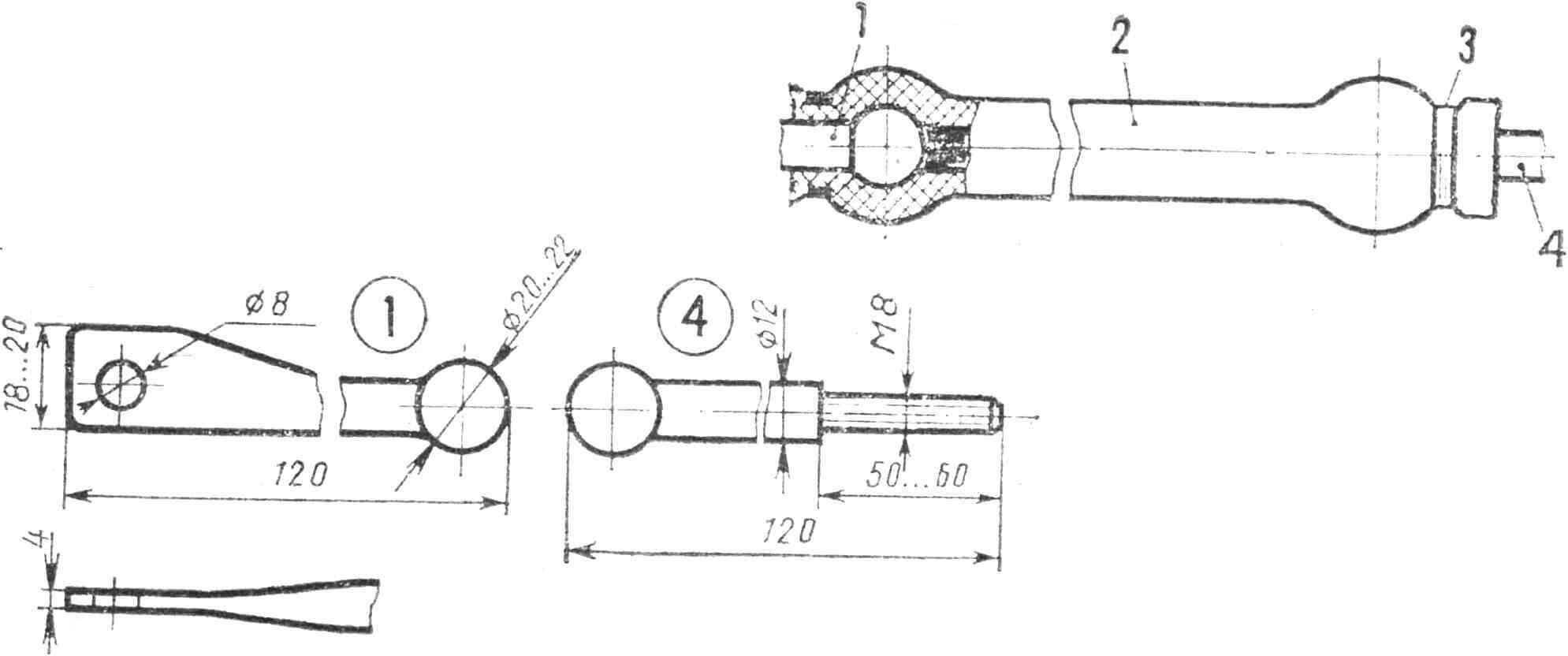

More efficient shock absorbers can be made from sections of vacuum hoses Ø 50…40 mm and length 200…250 mm, into which rods with spherical tips are inserted. The ends of the hoses are crimped with clamps or wire.

To secure the drive, a rear fork with a carriage is also used, mounted on the swivel fork of the front wheel.

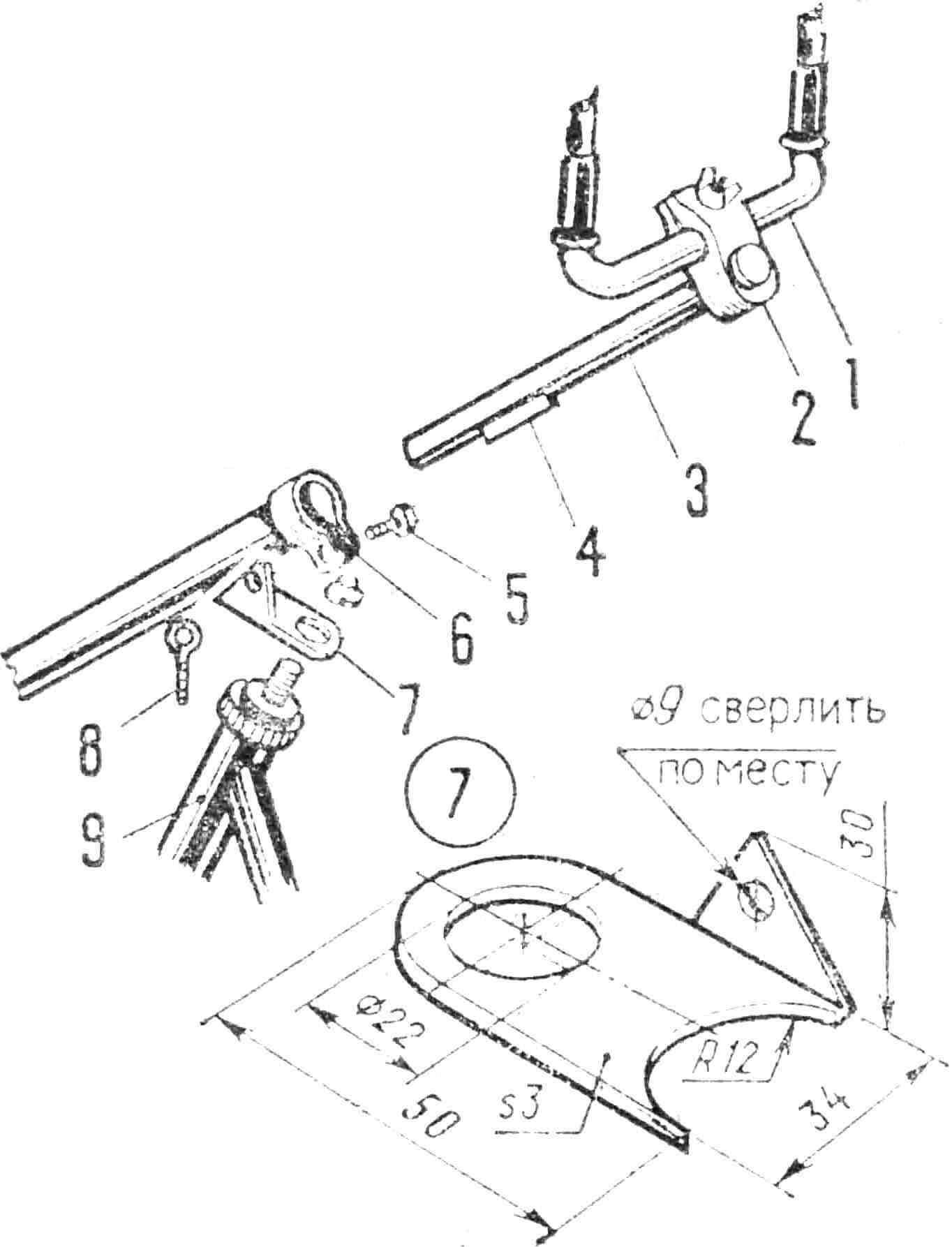

1 – U-shaped steering wheel, 2 – steering wheel clamp, 3 – steering rod, 4 – rib, 5 – bolt (M8), 6 – mounting clamp (from the saddle), 7 – bracket, 8 – wing (M8), 9 – steering column.

Steering wheel assembly. The steering wheel itself has an inclined additional column, which also serves as a bracket for the pedal assembly. It uses a saddle clamp to install the handlebars. The steering rod has a special rib that fits into the groove of the column, making a rigid connection with the rotary unit.

The U-shaped steering wheel is mounted with the handles up: the frame of the visor roof is inserted into these handles. On the steering wheel clamp, the nut is replaced by a wing, which serves to fix the steering wheel in the most convenient position.

1, 4 – rods, 2 – hose, 3 – clamp.

The pedal cranks are taken from an adult bicycle. To reduce energy costs and make pedaling more comfortable, it is useful to increase the length of the connecting rods to 200-220 mm, depending on your height.

For those wishing to make a two-seater model, we recommend lengthening the axle of the rear wheel forks in order to install a second frame on it. The units of the first and additional rudders are connected by a transverse rod.

To transport, carry and store the velomobile when disassembled, it is convenient to use a large (“climbing”) backpack or kayak case.

TECHNICAL CHARACTERISTICS OF THE VELOMOBILE

Machine length, mm … 1500

Width, mm … 800

Height, mm … 900

Height with roof, mm … 1100

Weight, kg … 20

Speed, km/h… up to 30

Dimensions in packaging, mm … 800x700x350

M. ILYIN, A. SHELYAKIN