The All-Union Competition “Small Mechanization”, held by the editors of the magazine “Modelist-Constructor”, has gained wide popularity among the creators of small-sized agricultural machinery. Many of the designs presented by its participants were awarded (see “M-K” No. 4 for 1987), and a number of developments were recommended by the editors for display at the Central Exhibition-Fair NTTM-87, where their authors became laureates and were awarded diplomas and medals.

Today we introduce readers to the universal motor plow “Sokol”, which brought its designer one of the highest awards – the silver medal of the USSR Exhibition of Economic Achievements.

The author himself, winner of NTTM-87, engineer from the Moscow region B.V. Sokolov, talks about its structure.

Homemade motorized plow – in four days. Is it conceivable? And yet, for several years now, a small machine, built in such a short period of time, has been helping me cultivate the land on my plot. The “high-speed” assembly of the motor-plough is explained by the fact that its design includes a maximum of serial components and parts. The engine and wheels are motor scooters, the plow and control handles are from a horse plow, the intermediate gearbox is from a 2-ton manual hoist.

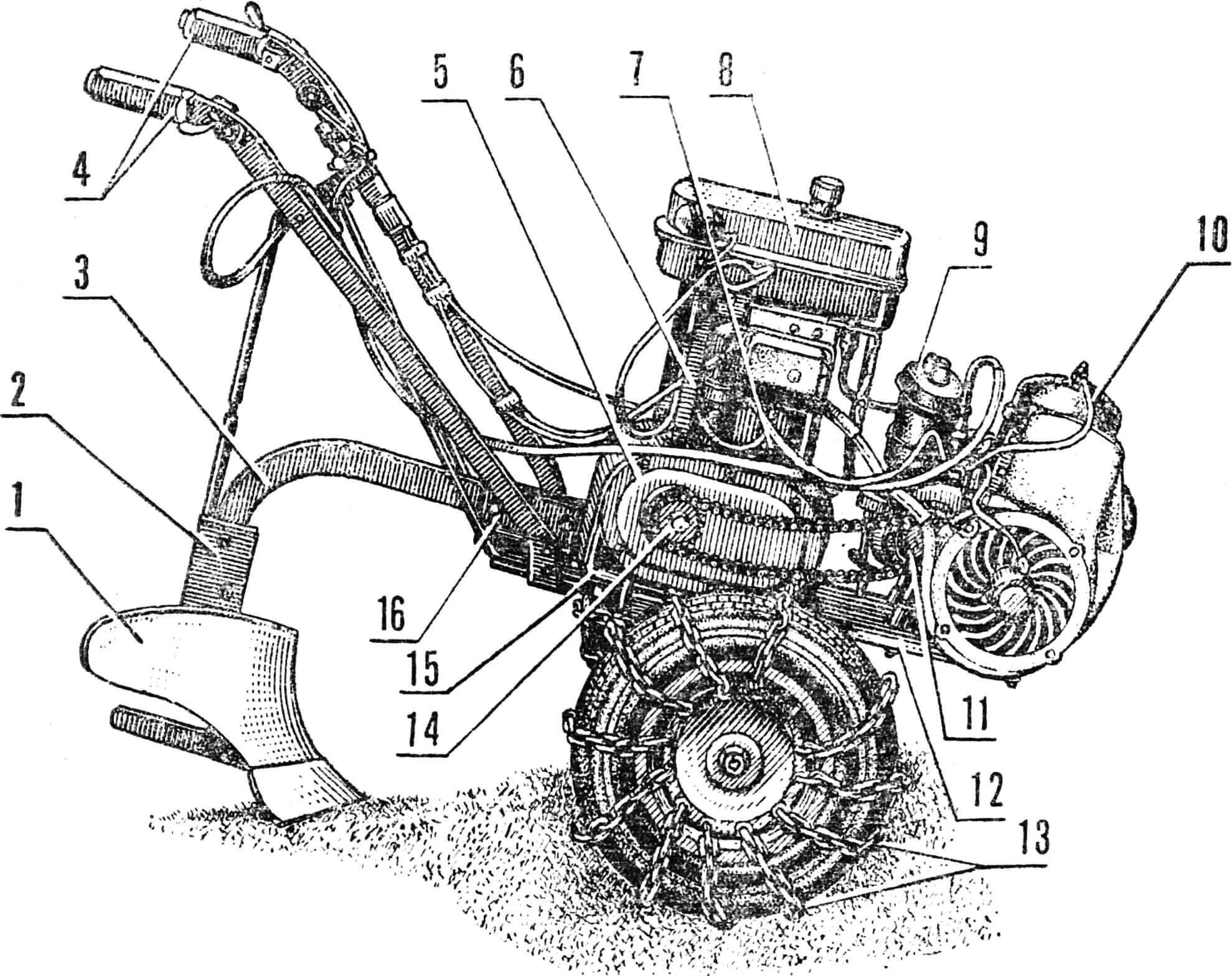

1 – share, 2 – adjusting plate, 3 – drawbar, 4 – control handles, 5 – intermediate gearbox, 6 – U-shaped stand (assembled), 7 – battery, 8 – fuel tank, 9 – filter, 10 – T-200 engine, 11 – engine output shaft sprocket, 12 – base platform, 13 – chain lugs, 14 — gear sprocket, 15 — gearbox mounting angle, 16 — plow mounting angle.

All fastenings of the units are bolted, which made it possible to do without welding work, carry out the entire assembly at home, and make adjustments in the field. The motor plow is reliable in operation. Plowing ten acres of land takes about 1 hour, and 5-6 liters of gasoline are consumed.

The total cost of the main components and assemblies purchased in the store is 270 rubles.

The motor plow is a single-axle two-wheeled self-propelled machine weighing 65 kg, equipped with a two-stroke T-200 engine, capable of moving at speeds from 3 to 12 km/h.

An important design component is the intermediate gearbox, the purpose of which is not only to reduce the speed of the motor-plough to 3 km/h, but also to transmit maximum forces to the wheels at stable engine speeds. I used a gearbox with a gear ratio of 11, but others with a gear ratio of 10-20 are also practically suitable; for example, worms. In this case, the wheels must be equipped with overrunning clutches located in the wheel brake drums.

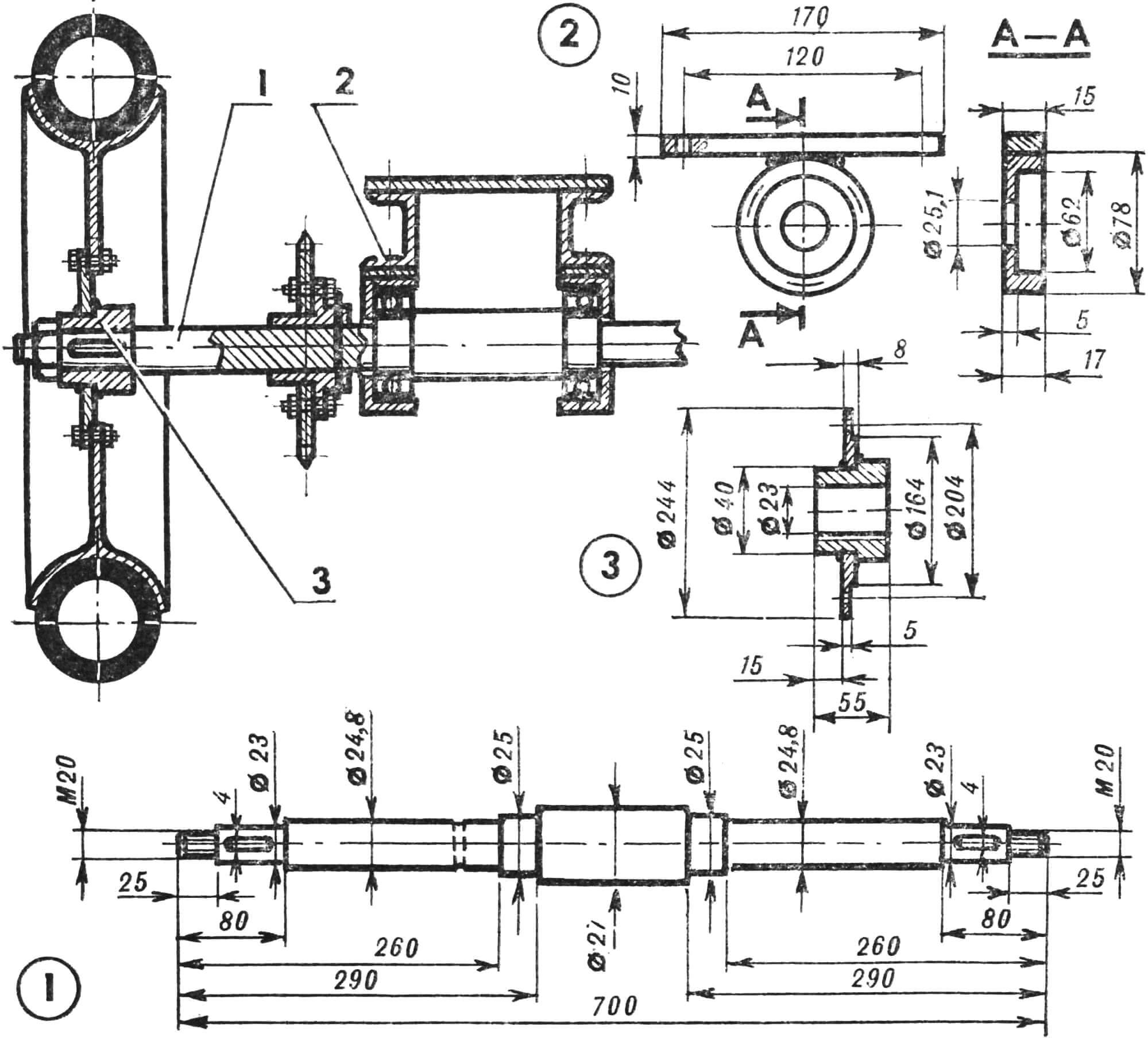

Torque from the engine output sprocket is transmitted to the intermediate gearbox, and from the output shaft sprocket to the sprocket of the drive axle of the wheels. All parts (sprockets and chains) are scooter parts. Along the transmission, the engine output shaft and gearbox sprockets each have 17 teeth, and the wheel axles have 40 teeth.

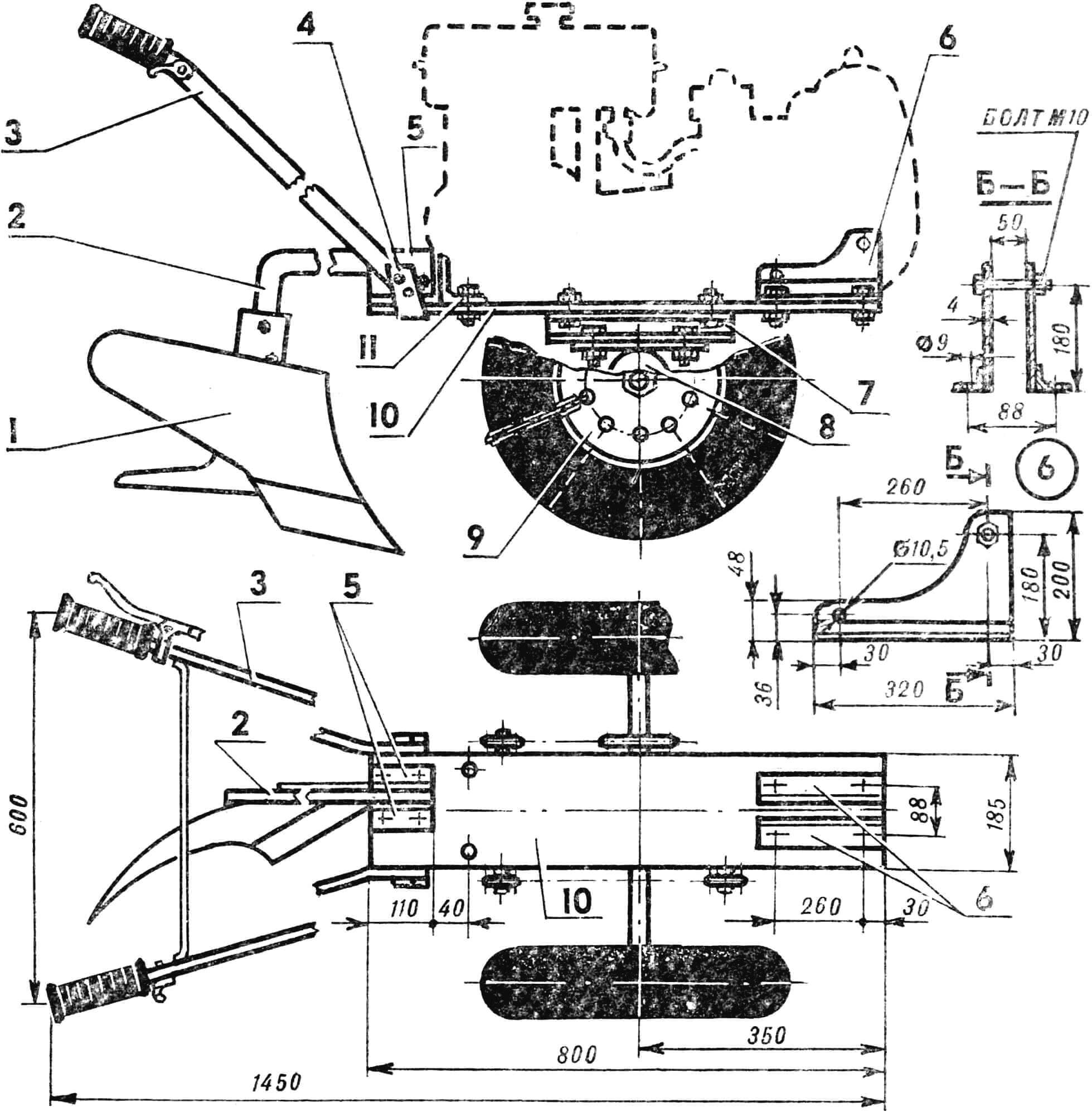

1 – ploughshare, 2 – drawbar, 3 – control handle, 4 – handle bracket, 5 – plow mounting angles, 6 – brackets, 7 – channel, 8 – support bearing housing, 9 – wheel disk, 10 – base platform, 11 – gearbox mounting angle.

For better traction with the soil, the wheels are reinforced with chains, each 400 mm long. They cover the tire and are secured by the outer links on opposite sides of the disk with an M6X35 mm bolt.

The basis for installing the engine, intermediate gearbox, battery, fuel tank, plow and control handles is a steel platform measuring 800X185X4 mm. A drive axle made of steel rod Ø40 mm is attached to it from below through side channels No. 6 and support bearings on M8 bolts. The track size of 650 mm is dictated by the need to move the unit over the bed during hilling.

The T-200 engine has not been modified. It is installed in the front part of the platform on two 4 mm thick rack plates, which are secured to the base through 30×30 mm corners welded to them with M8 bolts. Before installing the intermediate gearbox, its output shaft is ground to the size of the sprocket welded to it. The gearbox is attached to the base using two corners with M8 bolts. The battery and fuel tank, located above the gearbox, are secured with two U-shaped steel stands and M8 bolts. The tank is slightly raised above the engine, since the fuel enters the carburetor by gravity.

In the rear part, the base plates are fixed to the 70X70X5 mm corners of the control handle and the plow drawbar, fixed with M12 bolts between two 95X45X6 mm corners. This ensures the rigidity of the connection and at the same time allows you to widely adjust the plowing depth and working width by moving two bolts into additional holes in the platform and corners.

1 — axle, 2 — axle mounting unit, 3 — wheel hub.

Installation and fastening of the plow are very important, since if the balance of the acting forces is disturbed, the working body will begin to bury itself or come out of the soil.

I offer a simple and reliable way to adjust the position of the plow. On a flat surface, we lift the entire structure onto bars with a thickness equal to the required plowing depth, for example 250 mm; Having fixed the base platform with the units in a horizontal position, we adjust the installation of the plow. The most stable position is along the center line of the site with a turn of 2°-3° counterclockwise. To prevent the walk-behind tractor from tipping forward when moving, the center of gravity of the entire structure relative to the axis of the wheels must be shifted 50 mm towards the plow.

In the transport position, a two-wheeled trolley is put on the plow slider, lifting the ploughshare above the surface.

B. SOKOLOV, engineer