I probably won’t surprise anyone by saying that preparing firewood for the winter is one of the most labor-intensive tasks for a rural resident. Of course, it’s not at all easy to cut several cubic meters of wood! Is it possible to turn my old motorcycle into an assistant? The idea seemed tempting, and I implemented it quite quickly.

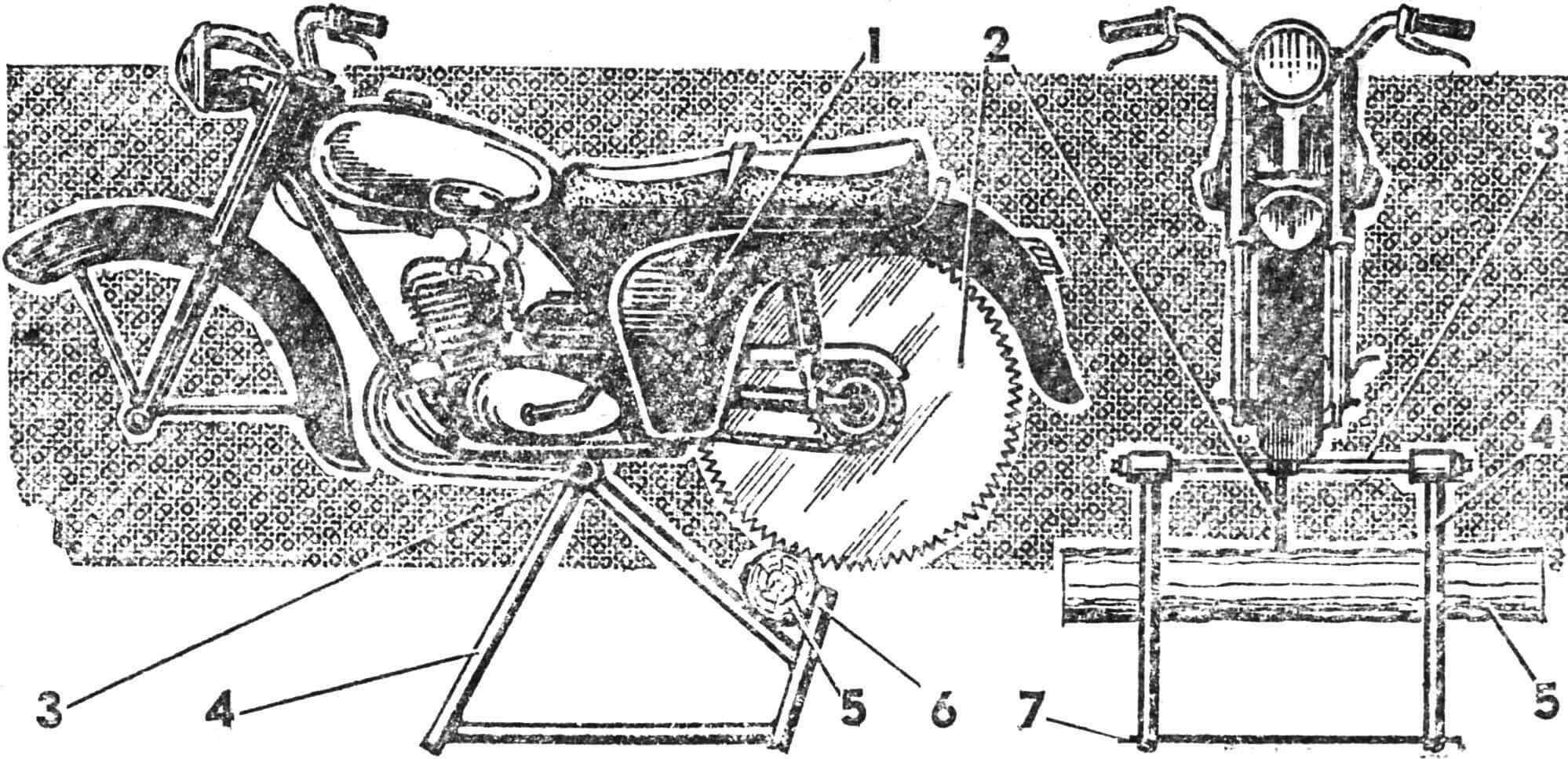

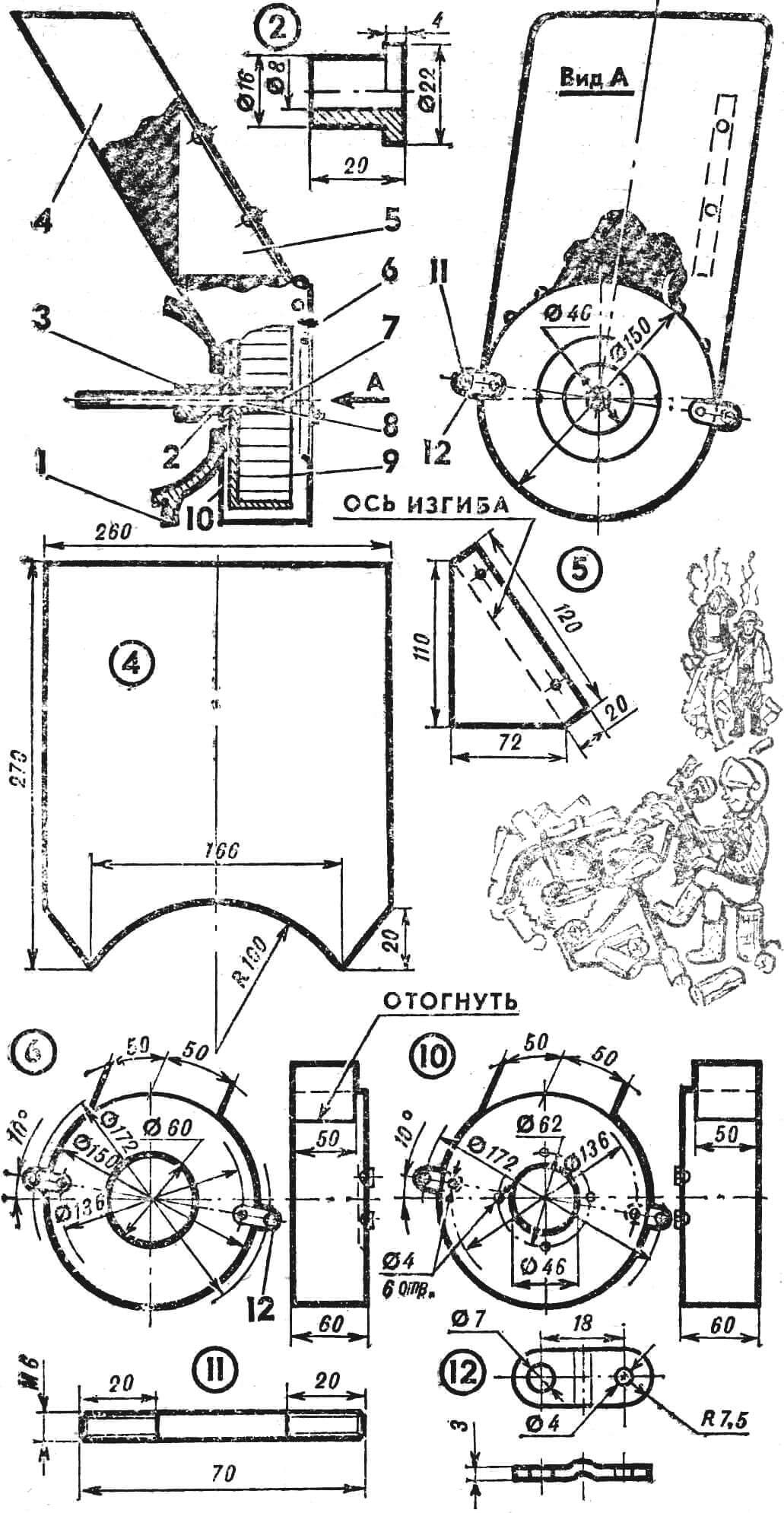

How the resulting “chain saw” is structured is clear from the given figures. Instead of the rear wheel, I installed a circular disk, assembled the base of the machine from two old bicycle frames, and moved the swing axis of the motorcycle to the place of the footpegs.

1 — motorcycle, 2 — circular saw, 3 — swing axis, 4 — machine base (bicycle frames), 5 — log, 6 — log stop, 7 — tie (M8 hairpin).

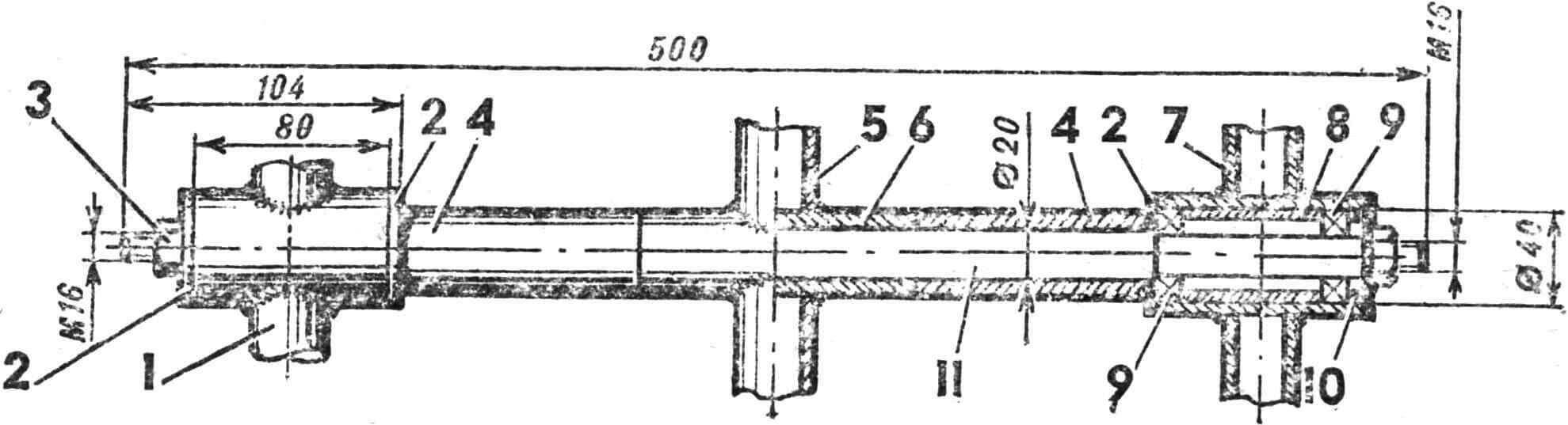

The results of the first tests exceeded all expectations: the log was sawn in a matter of seconds. True, the engine overheated greatly, so we had to take care of forced cooling. The fan impeller was used from a car heater, and ordinary paint cans were used for the casings.

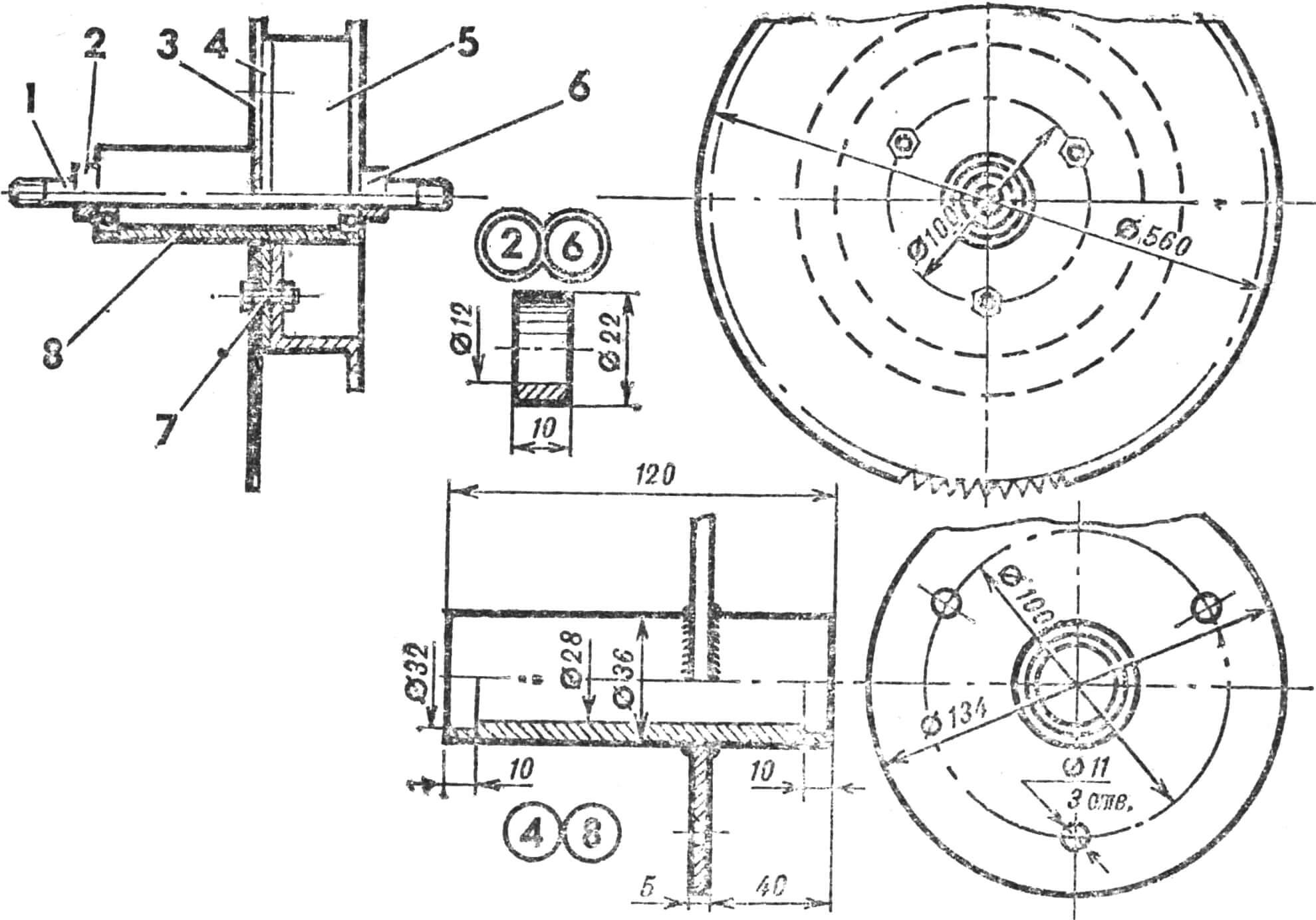

1 – rear wheel shaft, 2 – left bushing, 3 – saw, 4 – flange, 5 – motorcycle sprocket, 6 – right bushing, 7 – M10 bolt (3 pcs.), 8 – hub with bearings.

The sequence of motorcycle conversion is as follows. First, the rubber pad of the footrest is removed, the pins are knocked out and the tube of the footrest is removed, and in its place the swing axis is installed and spacers are put on. The motorcycle is then raised, the bike frames are put on the base and secured with a tie. The inspection hatch of the right crankcase cover is removed, and instead of the generator mounting bolt, the cylinder fixing pin is screwed in. After this, the left fan cover, bushing, fan itself and the right cover with the guide casing are mounted. (The engine head can be rotated 90° for better airflow.) Finally, the wheels are removed from the motorcycle, and a circular saw takes the place of the rear one.

1, 7 – machine base frame, 2 – washers (4 pcs.), 3 – M16 nut (2 pcs.), 4 – bushing (2 pcs.), 5 – motorcycle frame, 6 – footrest bracket, 8 – spacer sleeve (2 pcs.), 9 – bearings No. 203 (4 pcs.), 10 – ring (2 pcs.), 11 – axle rocking.

My motorcycle is old, brand M-103, but a similar machine can be attached to any other car. I’m sawing in third gear. To prevent the saw from accidentally going into the ground, you can make safety stops on the strut and base.

1 – right engine cover, 2 – bushing, 3 – breaker cam, 4 – fan guide casing, 5 – ejector, 6 – right fan casing, 7 – stud nut with lock nut, 8 – stud, 9 – fan impeller, 10 – left fan casing, 11 – tie rod (2 pcs.), 12 – eye (4 pcs.). In view A, the fan impeller is not shown.

Briefly about operation. It is most convenient for three people to work with such a machine: one operates the saw, and two lay the logs on the frame. The significant number of “crew” is compensated by the performance of the mechanism, which surprises even experienced “chainsaw operators”. And more than three years of experience in operating the chainsaw has confirmed its efficiency and reliability.

K. PRIGODICH, Lyshcha village, Brest region.