Conveyor under the open sky could rightly be called a complex of the most diverse and unusual cars, created in our country in recent years for laying pipelines in any geographical conditions. The novelties of this amazing technology are annually demonstrated at the Exhibition of achievements of national economy of the USSR. Here, in the pavilion “Gas industry”, a series of exhibitions dedicated to special design Bureau Gazstroymashina, where high-performance mechanisms for gas and oil routes.

Conveyor under the open sky could rightly be called a complex of the most diverse and unusual cars, created in our country in recent years for laying pipelines in any geographical conditions. The novelties of this amazing technology are annually demonstrated at the Exhibition of achievements of national economy of the USSR. Here, in the pavilion “Gas industry”, a series of exhibitions dedicated to special design Bureau Gazstroymashina, where high-performance mechanisms for gas and oil routes.

We invite modelers interested in the economical technique, make a short journey, therefore, the address prompted by the exhibition. So, the Exhibitor ENEA-74 — SKV Gazstroymashina.

CHANNEL OIL RIVERS

USSR — the country of the man-made rivers of oil, the largest oil and gas pipelines. According to the directives of the XXIV Congress of the CPSU length of trunk gas pipelines by the end of the ninth five-year plan will reach 100 thousand.

Last year saw the commissioning of one of the most important objects: the oil pipeline Samotlor — Ust-Balyk — Kurgan — Ufa — Almetyevsk. Only twenty years ago was opened the richest oil fields in the North of the Tyumen region, and recently there has been produced dvuhsotmetrovyj ton of oil. The new pipeline passed through the territory of the Tyumen, Kurgan, Chelyabinsk oblasts, the Bashkir and Tatar Autonomous republics.

Moving through the wild, remote places, swamps, taiga, mountain passes of the Urals, the builders put more than 700 thousand tons of steel pipes, has fulfilled more than 12 million m3 of earthworks. This oil pipe is the largest in the world.

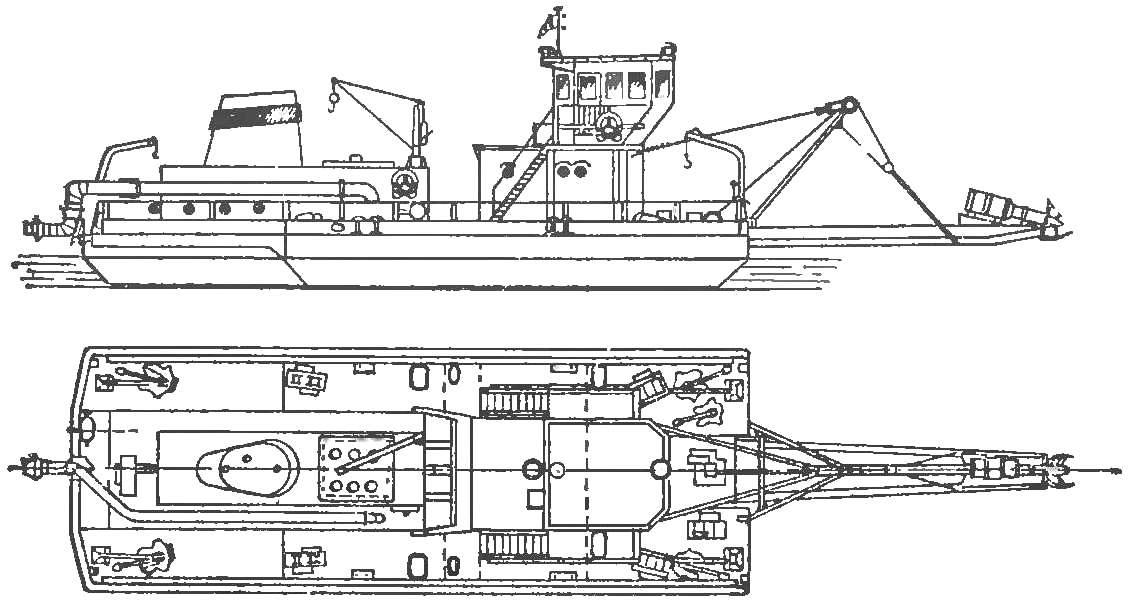

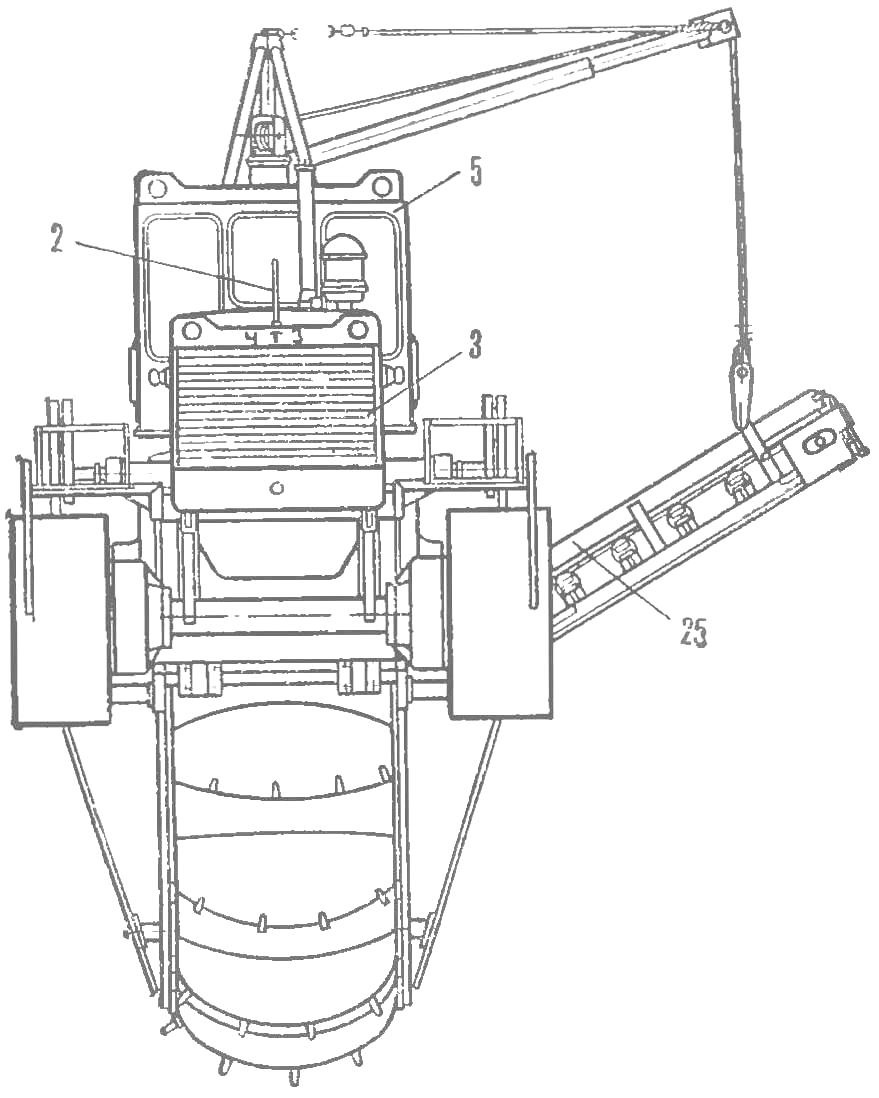

Fig. 1. Trench dredger ТЗР12М (side view and top).

And fills its wide network of smaller pipelines in Tyumen swamps. Their total length is several thousand kilometers. The highway goes to two thousand kilometers to Almetyevsk, and from there along the previously constructed pipeline goes to refineries in Gorky, Yaroslavl, Ryazan, Moscow. Siberian oil river approached the city on the Neva river, it joined the system of the oil pipeline “Friendship” and comes to Poland, GDR, Czechoslovakia.

The route of the pipeline Central Asia — Center has a total length of 10 thousand km, and by the end of the five-year plan it will continue for another 2 thousand km; in the ground will form pipe with a diameter of 1420 mm. On the Taimyr Peninsula at the temperature of 50° build a gas pipeline messoyakha — Norilsk, as several thousand kilometers to the South, at a temperature of + 50°, the gas pipeline Nairi — Khiva. On the North of the European part of the country the builders of the pipeline to overcome a wide Pechora, in the South mountain passes of the Carpathians. In Siberia, the builders of the highway Anzhero-Sudzhensk — Krasnoyarsk has laid more than 800 km of pipes with diameter of 1220 mm. Work of such magnitude the world practice did not know.

THE “HANDS” OF MACHINES-GIANTS

Nowadays, the construction of pipelines is one of the most mechanized industries. Almost every third worker of the industry is controlled by the machine, the mechanization level sometimes reaches 99,4%. Designs all these cars, sometimes quite exotic in appearance, special design Bureau Gazstroymashina. It is a large organization with branches in Leningrad and Kiev, with a large production base and a scientific testing ground. Here “born” machine for pipeline construction from the smallest — diameter of 89 mm, to the large — diameter 1420 mm. For the five-year period SKB Gazstroymashina should develop around 120 new types of machines. They will use the latest achievements of electrical engineering, hydraulics, Pneumatics, widely applied new domestic brand cars and tractors on the basis of which a special equipment for pipeline construction.

Earthmoving machinery — rotary trench excavators and drilling rigs. It may seem strange: why drill? Because the pipelines are located horizontally, not vertically. These units are designed for tunneling under railroads and highways. Shallow underground works, and on top of safely moving cars or trains.

Machines for construction of underwater crossings. It is known that new oil and gas find, as a rule, in places uninhabited, wild, deaf, fenced off from the usual places of human habitation of the mighty rivers, or marshy swamps. Therefore required when laying the pipeline trench dredges that could dig a ditch in the bottom of the river; winch — for pulling of the pipeline through the waters; accessories.

Lifting and transport machines. The cars that carry pipes, named very similarly: “pletevozy”. The image became the term: long pipe actually looks like a whip. And the whisky is, in essence, cranes of a special type.

Further there are machines for cold bending of pipes, welding, cleaning and isolation “whips” and other.

Modelers who are interested in this modern technology and want to have play her in a nutshell, you should first pay attention to a rotary trench excavators. Carried them is now unthinkable pipeline construction; in addition, in the design of these machines embodied a kind of very original technical ideas. Finally, the demonstration of the working model of the rotary trench excavator will always cause admiration for the power of modern technology and, as a consequence, an increased interest in her. Put the good of the model to the ground, turn on the mechanism of rotation of the rotor with buckets and should soon be available commensurate with the scale model of the “trench.” Isn’t it interesting to build such machines-laborers, machine-workers?

TIRELESS WORKERS

Rotary trenchers, as is evident from the name itself, differs from the conventional in that instead of one bucket, placed on the boom, there a lot of them. They are mounted on the circumference of the rotating rotor. Buckets one by one to draw the ground, it is served on a conveyor belt, which throws the earth aside, and after continuously digging machine reaches the ready-made trench. What a sharp contrast to the conventional dredge, the only bucket which together with an arrow to turn, descend, gain ground, rise again to turn empty land. Of the many movements, only one working. And rotary all operations workers, support no. That’s why the performance of the excavator is much higher than the productivity of the shovel and that is the main rotary digging machine during construction of pipelines.

Now Chelyabinsk tractor plant goes to the issue of new powerful (160 HP) the machine T-130. On the basis of the tractor SLE Gazstroymashina developed a design of a rotary trench excavators ЭТР204 and ЭТР223, prototypes of which have already released Bryansk and Moscow experimental mechanical plant.

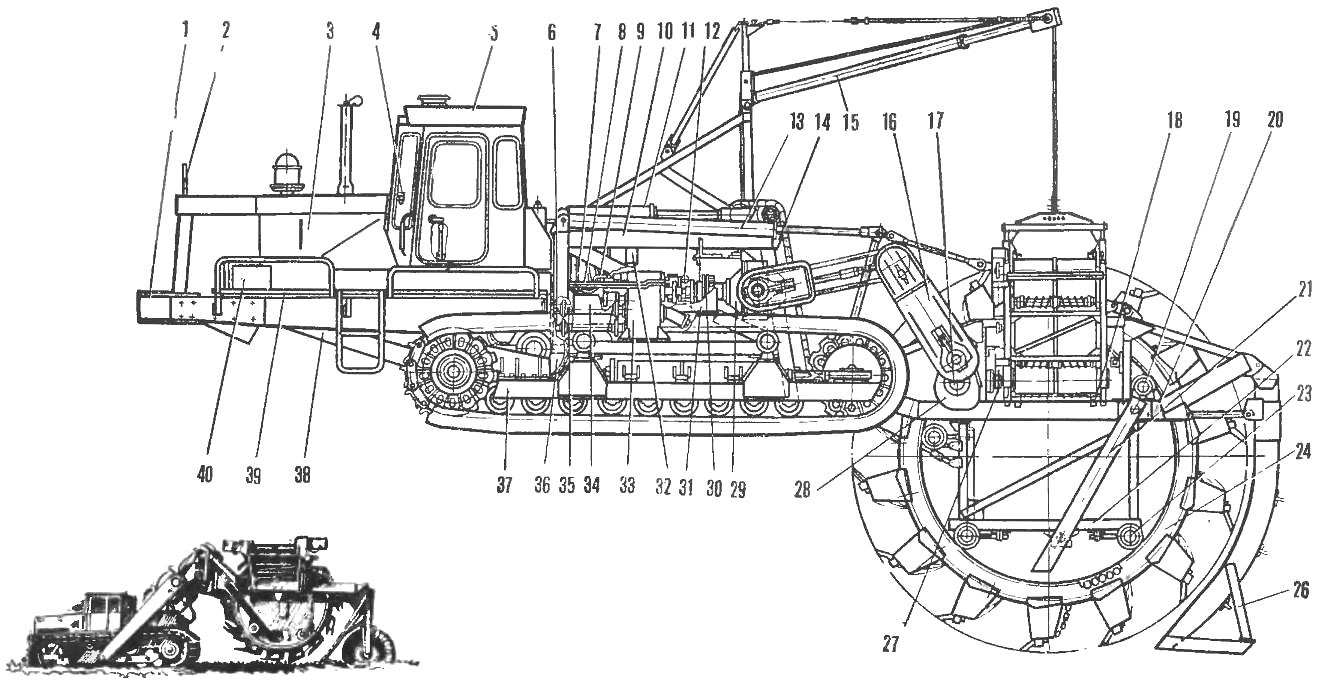

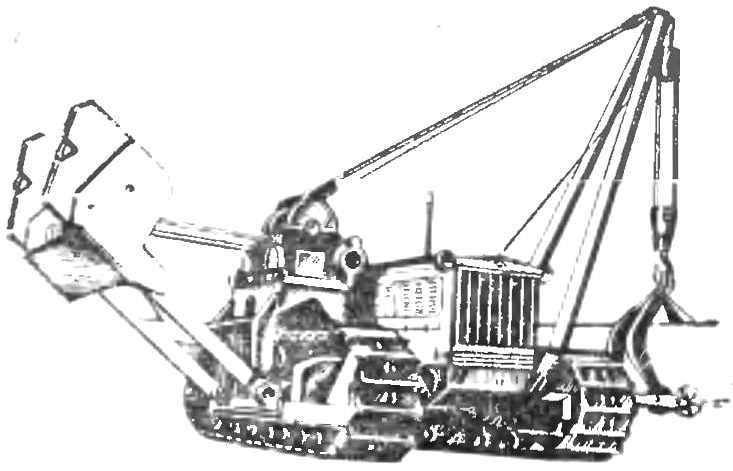

Fig. 2. The trench rotary ЭТР253.

Fig. 5. The trench rotary ЭТР223 (side view to the front):

1 — opposed, 2 — sight, 3 — engine, 4 — instrument panel, 5 — cabin, 6 — shaft intermediate, 7 — hydraulic system for lifting and working on conveyor, 8 — control arms transfer case gear. 9 — the lever of inclusion of the pump 10 to the frame of the tractor 11 –hoist the front of the rotor 12 device upravlennya hydraulic drive stroke, 13 — raising mechanism for the rear part of the rotor 14, the latch mechanism for lifting the front of the rotor 15, the lifting mechanism of the folding part of the conveyor 16, the chain drive of a rotor, 17 — shaft rotor drive, 18 — mount conveyor, a 19 — roller support 20 to the frame of the rotor top, 21 — otkazniki, 22 — frame of the lower rotor, the 23 commercials rails, 21 — rotor, 25 — Transporter, a 26 — bearing rear, 27 — chain drive conveyor 28 and the motor drive shaft of the rotor, 29 is the gearbox chain drive rotor 30 to the slipping clutch, 31 — cover, 32 — hydraulic drive stroke, the 33 — gear transfer case, 34 — housing of the propeller shaft, 35 — shaft, 30 gear on-Board, 37 — Rama of track, 38 — bearing sub-frame, 39 — service platform, 40 — tool box.

ЭТР204 can develop trenches for pipelines with diameter up to 820 mm, excavator ЭТР223 — for pipes with diameter of 1020 mm. And since the machine is designed to work in very harsh conditions, they can pave the trench in the rock and frozen ground with a frost depth up to one meter.

New excavators are very stable. This property is achieved due to the fact that the mechanism underlying the tracked tractor introduced four additional carrier roller and the length of the track increased. The designers have provided also larger than the basic tractor, tracks, and enhanced track. This is to ensure that the machine can work on slopes of hills and ravines.

When 14 rotary excavator buckets bite into the ground, the load per a machine, so big that simply tilting it back. To balance the whole tractor power unit — engine, transmission with clutch and gearbox, and rear axle, cab with controls — rendered compared to the base machine far ahead. To increase traction to the normal side of tractor motors added, with a gear ratio of 1 : 2.

Imagine that the excavator is moved from one area to another. He goes his way, and a special mechanism hydraulically lifts the rotor and keeps it above the ground. But we need to get to work. The rotor is lowered and rests on the dedicated rack. The rack is welded at the bottom of the Shoe which can slide on the bottom of the trench when the excavator is moving ahead. Turn on the engine; special shaft “takes away” the power and actuates the hydraulic system in which force is transmitted to the rotor. Hydraulics allows Plaz-but to change the speed of rotation of the rotor, which is very important.

Each bucket has teeth that you can change: if the ground is soft, install a steel; if frozen solid, apply the teeth with solid carbide tips.

Cab new excavator has heat and sound insulation, equipped with ventilation and heating. Excavator and protected it from frost and from the heat. The estimated productivity of these machines — 650 m3/h. For all techno-economic parameters — engine power, weight, size, performance, degree of utilization of the hydraulic drive — they are not inferior to the best world samples.

As for the ability to develop the frozen ground, as well as provided for an excavator, the new machine is the best in its class.

Even more powerful machines — the new excavators of the type ЭТР231 and ЭТР253. The first paving of trenches for pipelines of up to 1220 mm in diameter, and the second for pipes with a maximum diameter up to 1420 mm.

Vase excavator ЭТР231 is a special diesel-electric tractor power of 250 HP Diesel drives the generator that supplies electric current to separate motors. They cause the car to move, it rotates the rotor, power conveyor, casting the land. The rear rotor is based on the pneumatic wheel. The use of electric drive allows to regulate workers and transportation modes over a wide range.

Base excavator ЭТР253 is commercially available diesel-electric tractor DET-250. Its design has been significantly revised: the machine is used and an Electromechanical actuator (rotor and conveyor) and purely mechanical (transport movements) and hydromechanical (stepless regulation stroke). During the summer testing a prototype of the excavator was digging the day trench length 1200 m maximum depth and width. A new car can work in different climatic conditions.

RELAY MECHANISMS

Slowly, but incessantly moving wheel excavator. And behind him — whether in the marshes, the Sands, permafrost — remains smooth wide trench. But ahead of the river. It comes in different machine — a suction dredger. Most productive and modern of machines of this class — trench dismountable dredger ТЗР12. The figure here means that the machine can dig and fill the trench at the bottom of reservoirs at a depth of 12 m from the surface of the water, And dismountable dredger called because his body consists of individual pontoons that can easily be disassembled and transported on a railway platform or in the vehicle.

The figure shows that tool to develop a soil is a Ripper, located on the end of groundsare frame that is lowered and reaches the bottom. Ripper placed in a waterproof capsule, equipped with electric drive. The loosened soil is sucked and is fed to the shore grunteneem, which is driven by a diesel engine. Management of all mechanisms of remote. Here is a brief technical specification of machine: capacity — up to 180 m3/h, power — 300 HP, the estimated length is 18.8 m, the estimated width—6.3 m, the amidships — 1.5 m.

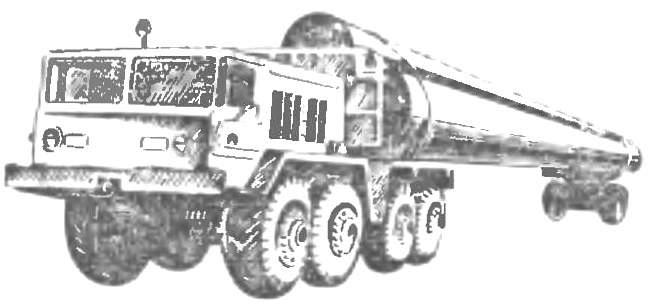

Fig. 3. Placebos ПВ481.

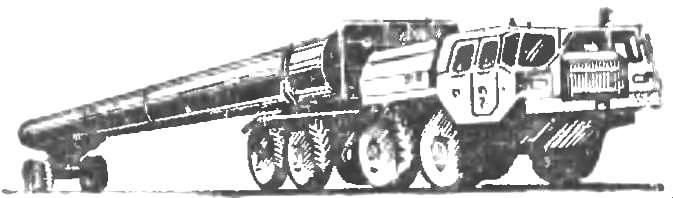

Fig. 4. Pipelay Т3560А.

Fig. 6. Placebos ПВ301.

The trench is dug, it is necessary to lay the pipe. It is clear that conventional lifting crane here the. The action takes a special machine—the pipe layer. In the construction of pipelines with a diameter of 1220 mm is used pipelayer Т3560А (Fig. 4). From figure it is visible, how much different this design is from the tractor Д804М on the basis of which it is made. Overturning moment from the tube (max weight — 35 tons) is opposed on the other side of the car powerful counterbalance. Boom length — 7.7 m, the distance between the tracks — 2500 mm, between the axes of the leading and idler wheels—3800 mm width caterpillars — 700 mm, length, width and height of the machine — 5400, 4260 and 7860 mm.

Think of the number: on the pipelines transported during the year more than half a million tons of pipes. The volume is huge, but when you consider that the goods of a special kind in the body not to put, roads as a rule, no, the climate is severe, then it becomes clear that for this purpose is needed and the design is very special.

On the basis of a powerful tractor with the wheel formula 8X8 MAZ SKB Gazstroymashina designed the pletevozy ПВ481. These powerful machines can carry the pipe diameter of 1420 mm with a total weight of 55 tons on paved roads and even dirt if they are not very soaked. And to transport the same pipe (weighing up to 30 tons), but in the complete off-road designed another placebos ПВ301 on the basis of the car “MAZ-543”. Wheel formula and a variable pressure in the tires allow ПВ301 to overcome the dunes, Sands, and swamps.

R. YAROV