Original wooden snowmobile constructed schoolchildren Gene Vorontsov, Jora of Kochetov, Svetlana Sour, Boris Nasonov, Kohl Utkin and the teacher of the O. D. of the Bars, who for several years headed the technical school circle in the village Lampozhnya Arkhangelsk region. That’s what they tell us about their cars.

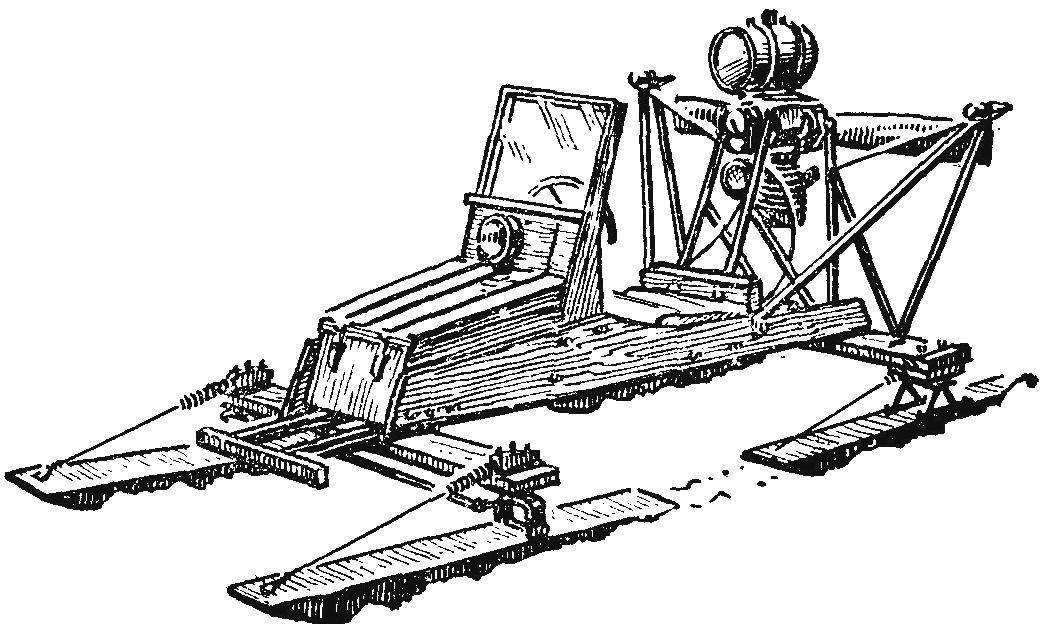

Original wooden snowmobile constructed schoolchildren Gene Vorontsov, Jora of Kochetov, Svetlana Sour, Boris Nasonov, Kohl Utkin and the teacher of the O. D. of the Bars, who for several years headed the technical school circle in the village Lampozhnya Arkhangelsk region. That’s what they tell us about their cars.

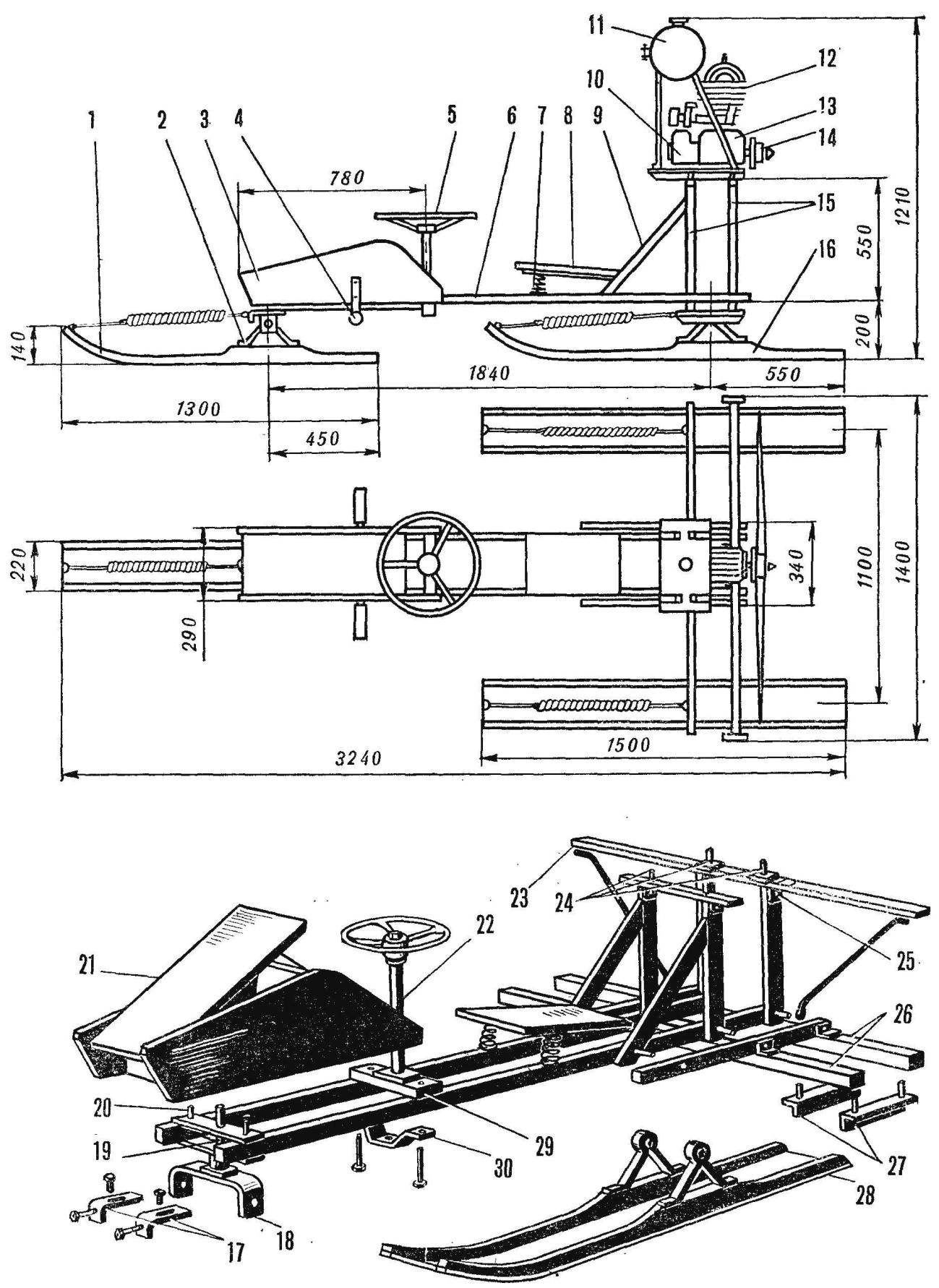

Our first machine was built of wood, called “Start” (Fig. 1). It was a single snowmobile trehmernoi scheme. The longitudinal beam and the transverse housing for the mounting of the rear ski and the sub frame is made from pine bars section 35X40 mm, with mounting bolt M6 (Fig. 1). In connecting nodes installed metal angle brackets and washers a large diameter for preventing the crushing of the wood. In the field installation of swivel of the front skis, engine mounts and suspension the rear of the ski are provided metal plates, angle brackets and brackets. Skis are also wooden. Front housing zakoptelova. On the side of the hood placed metal braces, footpegs, upper part of a Bicycle headlight. The driver seat is made of plywood of 8 mm thickness — the front part is supported by two springs from a Bicycle seat.

Transverse bars, on which is mounted the engine are different lengths: the back — long, and he is supported by tubular uprights and serves as a fence propeller. Its curved ends are fixed to the radius plate screw, painted red.

Wooden sled “Start”

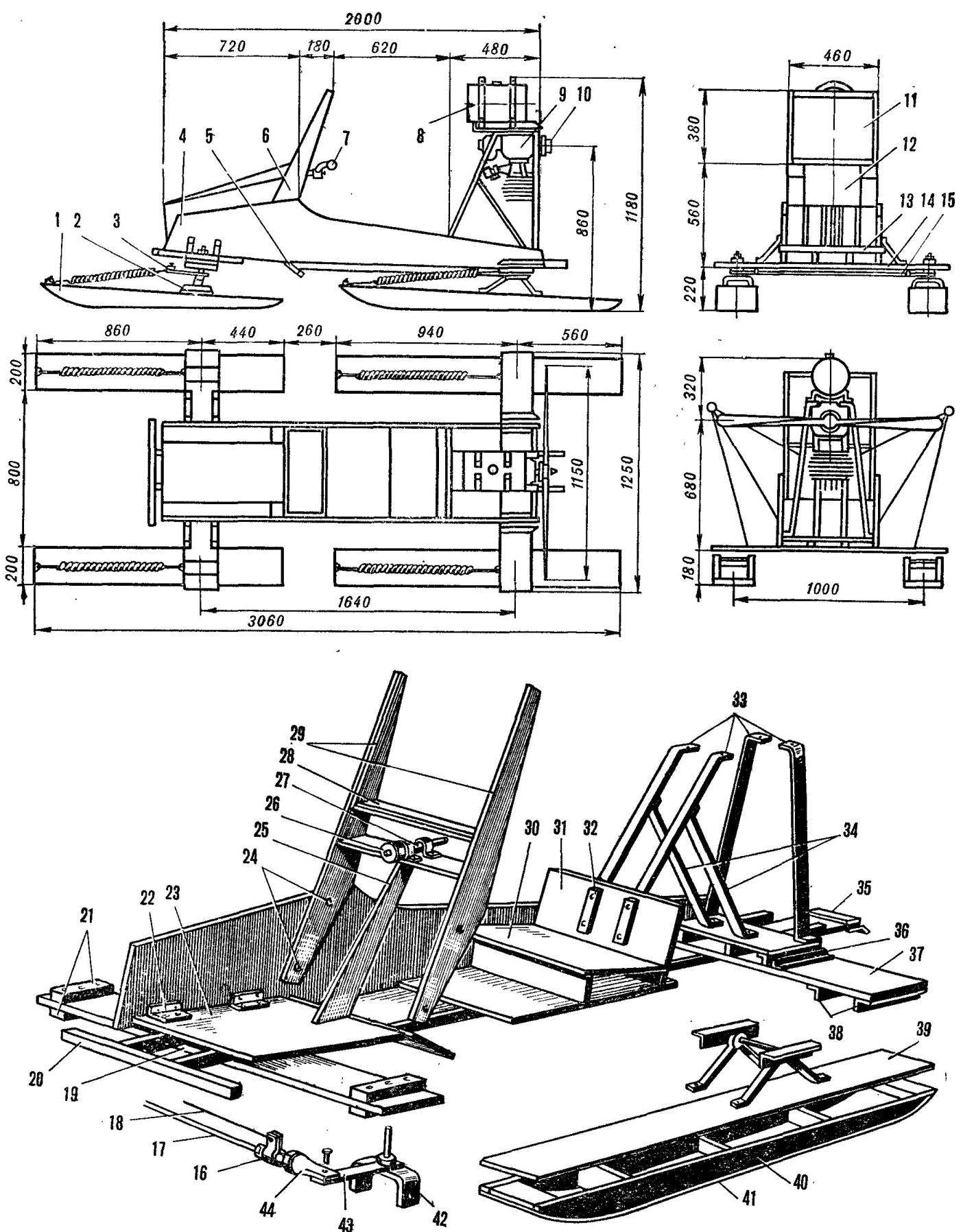

Snowmobile “Comet-70”

The rear skis are staples-hog of flat steel the size of 5X30 mm. With their help, the skis are mounted on the bolts M10 to the corners connecting the bars of the cross beam. Skis are going on a casein glue three plates of plywood 4 mm thick, and the edges are amplified shaped oak bars. The soles of the ski bottom sheet bound in iron and has longitudinal undercuts. To the skis hit the snow when hung, they are dilatory cables with springs.

Control of the snowmobile by turning the front skis. Transmission of the steering column cable. For engine management there are levers gas and advance the ignition, and the wiring is borrowed from a motorcycle, the cable or wire in a flexible sheath.

The engine is tractor of puskach PD-10, which includes a cylinder air cooling motorcycle IZH-56. The fuel tank is located over the engine. Fuel feed is by gravity.

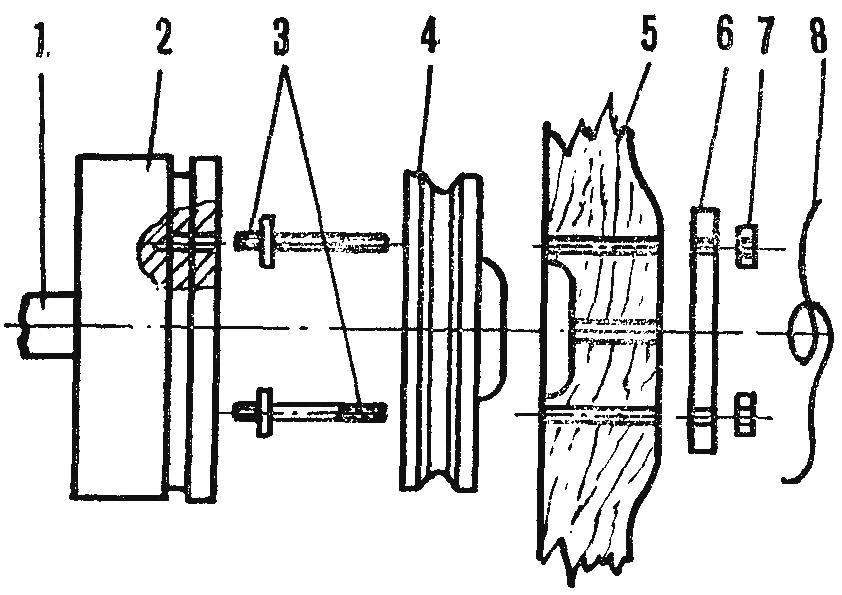

Fig. 1. The design of the snowmobile “Start”:

1 — front ski, 2 — pylon-ski, 3 — side enclosure, 4 — step, 5 — steering wheel, 6 longitudinal bar case, 7 — spring seat, 8 — seat driver, 9 — brace motor, 10 — magneto 11 — fuel tank 12 — cylinder IZH-56, 13 — Carter PD-10, 14 — propeller, 15 — stand motor, 16 — rear ski, 17 — rotation limiter, 18 male, 19 — rotary axis, 20 — mounting plate pivot shaft, 21 front cover, 22 — steering column, 23 — fencing of the propeller 24 and the bolts of the engine, 25 — gon, a 26 — bars, 27 squares, 28 — the sole of the ski, a 29 — lining under the steering column, 30 — clip.

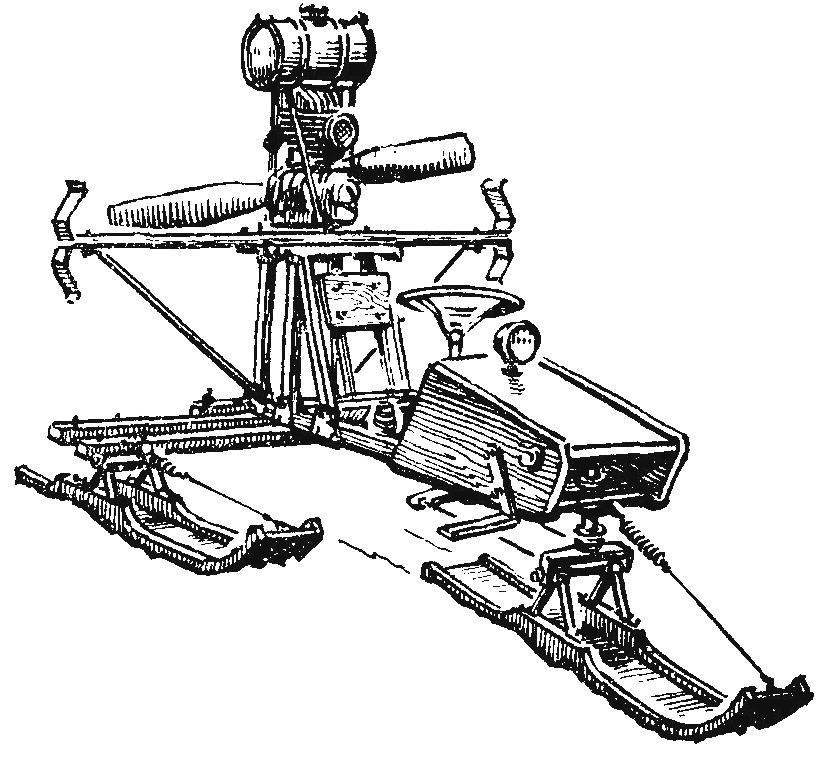

Fig. 2. The design of the snowmobile “Comet-70”:

1 — front ski, 2 — base of the front skis, 3 — pivot arm, 4 — side panel of the case, 5 — step, 6 — front windscreen, 7 — wheel, 8 — fuel tank 9 — engine 10 — propeller 11 — back driver seat, 12 front cover, 13, 20 bumper, 14, 19 — beam suspension front ski, 15, 17 — cross, tie rod, 16 — clamp cable, 18 — steering cable, 21 — lugs, 22 — gon, 23 — floor front, 24 bolts, 25 — medium, 26 — drum steering, 27 — the steering shaft, 28 — cross member, 29 — pillar of the windscreen, a 30 — seat driver, 31—seat, 32 — mount plate brace, 33 — stand motor, 34 — struts, 35 — brake scraper, 36 — triangles, 37 —beam rear suspension ski, 38 — triangles the rear of the ski, a 39 — edging of the skis, a 40 — sidewall skis 41—the sole of the ski, a 42 — swivel bracket, 43 — lever swivel 44 can be threaded tie rod end.

“Comet-70” (Fig. 2) as “Start”, single car, but made for chetyrehstennoy scheme. When you create a “Comet” kept the basic principle of design: use a minimum of scarce and expensive materials with maximum simplicity of manufacture. Special attention was paid to reducing the weight of the machine. And despite the fact that the Comet has not three, as “Start”, and four skis, it is easier to 21 kg (weight of “Comet” — 84 kg, “Start” — 105 kg).

Case “Comet” made of bricks and solid spruce boards with a thickness of 18 mm. Its design is shown in figure 2. Skis are mounted symmetrically to the two cross-section boards. The front ski is controlled. Their brackets they are part of the rotary bracket, which is attached to the M10, which is an axis and providing free rocking of the ski. The control lever combined with a fork. Method of connection of the control levers left and right ski and control cable — rigid transverse rod and clamps. The cable goes through the rollers on the drum of the steering column, where it is fixed by M6 bolt. Transverse thrust has both ends threaded ends for adjusting parallelism of the skis. The axis of the turntable bracket on the front of the Board passes through the bars with cross section 30X30 mm. Back of the ski using the M10 bolt attached to the parts mounted on the transverse Board. The design of the ski — box, as shown in the figure. Running sole made of galvanized roofing iron with a thickness of 1.2 mm. On the sole, there are two podraza steel area size 8X20 mm (at the edges of the skis). With a frame ski they are connected by screws with countersunk heads. As sleigh “Start”, skis have guy ropes attached with springs.

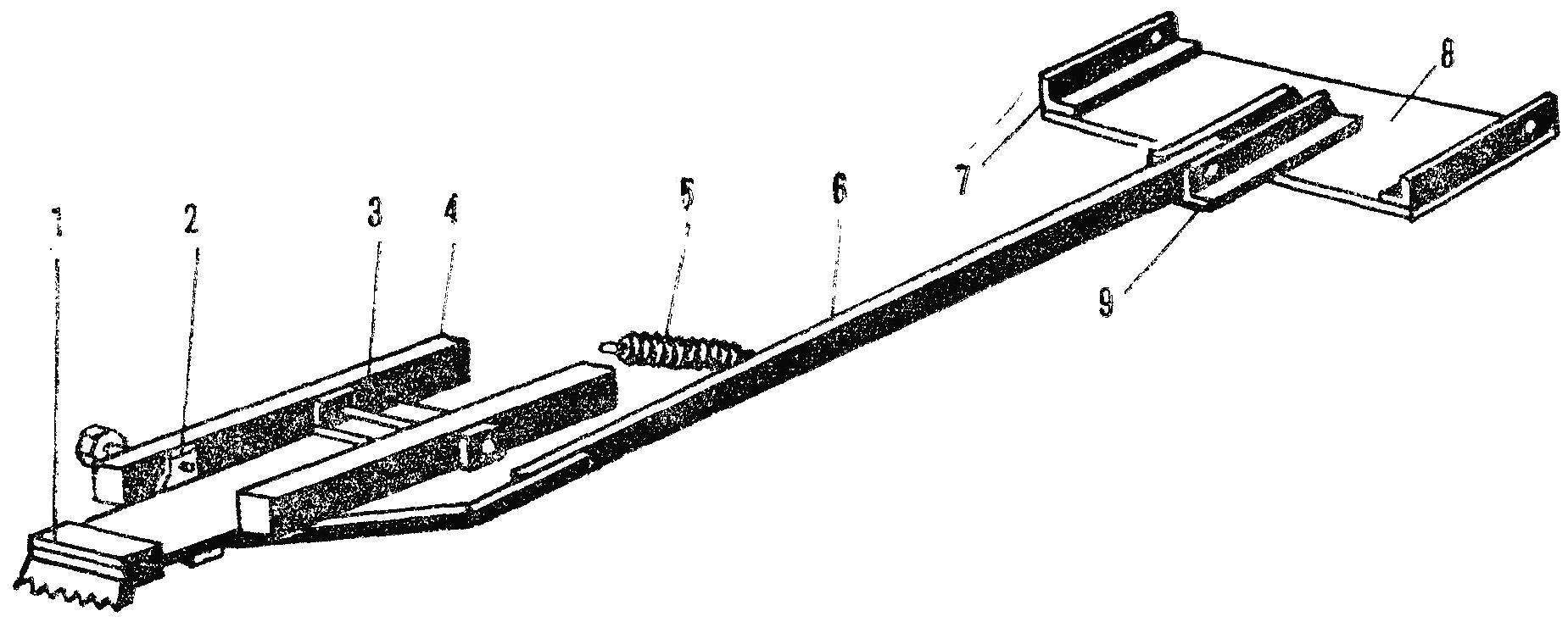

Snowmobile “Comet” is equipped with a brake device of the scraper type (Fig. 3). Serrated steel scraper, mounted on a wooden lever connected by a rod with the brake pedal. When pressed, the lever is lowered, toothed scraper, running in the snow, carries out braking of the car. In the initial position, the brake is returned under the action of a return spring.

Fig. 3. Brake device:

1 — steel serrated scraper, 2 — stop, 3 — axis, 4 — bars of the frame case, 5 return spring, 6 — thrust, 7 — gons hanging pedals, 8 — pedal, 9 — hinge.

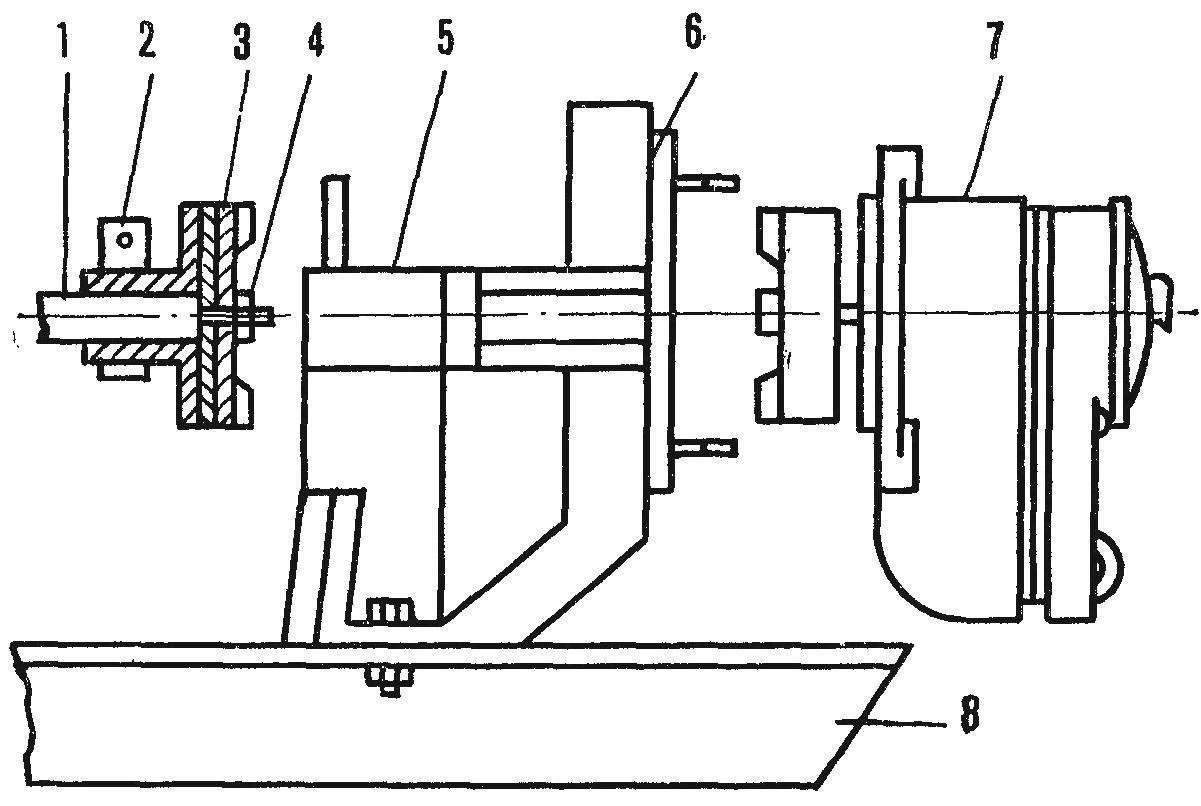

Fig. 4. The node setup of magneto:

1 — shank engine crankshaft, 2 — bolt, 3 — the elastic coupling 4 — mounting nut clutch, 5 — bracket, 6 — stand, 7 — magneto 8 — area of the motor frame.

Fig. 5. Installation of the propeller:

1 — the tail shaft of the motor, 2 — flywheel, 3 — studs, 4 — pulley, 5 — rotor, 6 — flange, 7 — nuts 8 — lock wire.

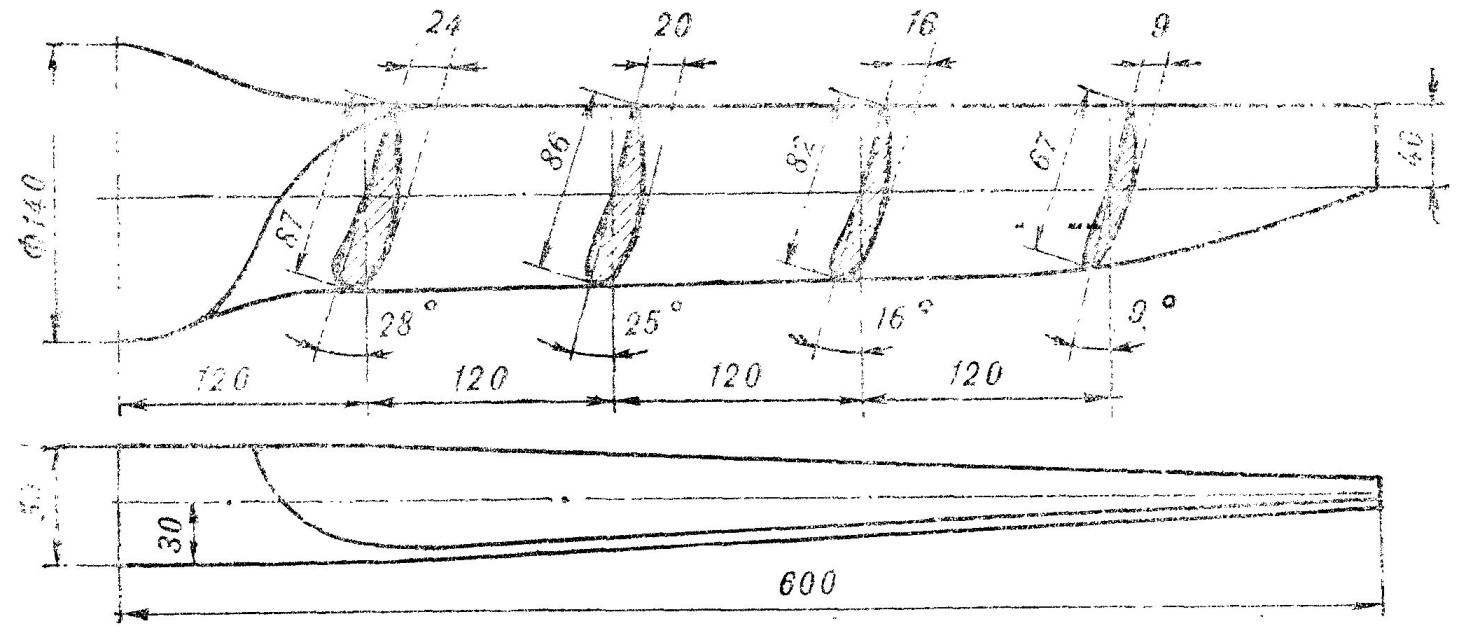

Fig. 6. Propeller planes “Comet”.

Engine similar to that installed on the “Start” button, but placed differently for lower center of gravity and increase stability of the car he put the cylinder down. The sub stand is made of flat steel size 8X30 mm; front lean back in the driver’s seat. The gas tank is above the engine, the fuel supply is by gravity. Ignition from magneto aggregate KATEK driven in rotation directly from the shank of the crankshaft through the elastic coupling (Fig. 4) made of a set of rubber plates. Adjust ignition timing by turning the magneto bracket.

On the carb there is a air intake made from tin cans. Its entrance hole is closed by the filter made up of ten layers of fine metal mesh, allowing the engine’s not afraid of splashing and falling snow.

Propeller — wood, with a diameter of 1.2 m is Attached to the flywheel with four studs (Fig. 5). Between the flywheel and the screws on these studs is placed a pulley from a car fan. It serves for winding the starter rope during starting of the engine. On top of the propeller hub includes a flange made of steel with a thickness of 5 mm, which is tightened by nuts. Making sure there is no runout of the blades, evenly tighten the nut and be sure to counter their round soft binding wire.

Rotor group of the snowmobile has a fence, made in the form of a tubular farm. The fence is painted with red paint to alert others of the danger.

O CHEESE