The boat standing at the dock, nothing attracted attention. Except that instead of a outboard motor on it was a propulsion system with a propeller of relatively small diameter at the gliders it is usually much more. Engine, who worked on small gas gained momentum, howled, n suddenly the plane screw threw himself from a dense foggy cloud. The glider, dramatically picking up speed, reached the redan, and after a couple of minutes disappeared from view, leaving behind a trail of slowly falling.

The boat standing at the dock, nothing attracted attention. Except that instead of a outboard motor on it was a propulsion system with a propeller of relatively small diameter at the gliders it is usually much more. Engine, who worked on small gas gained momentum, howled, n suddenly the plane screw threw himself from a dense foggy cloud. The glider, dramatically picking up speed, reached the redan, and after a couple of minutes disappeared from view, leaving behind a trail of slowly falling.

Such are the trials of a new combined aerohydrophysical created by a group of enthusiasts from the laboratory of technical creativity, vocational school № 33 under the leadership of Alexander Mikhailovich Ivanov. The main difference from existing is that it combines the advantages of known propulsion — jet and air screw, although the similarity with a water cannon obvious at first glance.

Before I talk about the design of the new propulsion, let’s look at the advantages and disadvantages already mentioned.

First in essence is nothing like working in an annular channel of the screw with all its advantages and disadvantages. On the merits can not speak — they are well known, but the disadvantages of… Limited speed of rotation due to the cavitation phenomena, the decrease of efficiency with increasing speed of water flow, the significant complexity of the design.

Not without its faults and the second — a large diameter, and hence increased danger to others, in spite of various kinds of fencing; uneven characteristics: depending on the stop on the screw speed. The fact that the screw is usually calculated under the optimum cruising speed of the vessel, thus on the place (at zero speed), it will not develop maximum traction. To configure it for different modes is possible only in the presence of the device to change the angle of the blades. In addition, the design of VISH (screw pitch) complex.

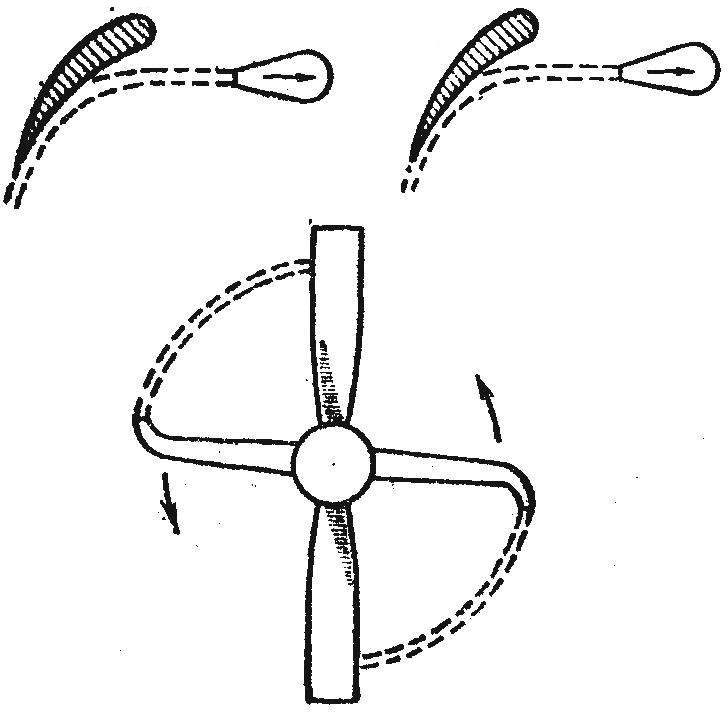

Fig. 1. The principle of operation of aerohydrophysical.

We believe that these contradictions will cease to exist, if we apply the mover developed in our laboratory. He is a regular propeller in the plane of rotation which is injected water. Obviously, this will radically change the physics of operation of the screw. In principle there are three possible. First — when supplied to the screw, the liquid is partially or fully falls on the blades. Blade meeting water drops, throws them in the direction opposite to the direction of movement of the vessel. Since the density of water is approximately 800 times the density of air, that means, and the dimensions of this screw will decrease compared to pure air. But the first case, generally speaking, unlikely, since in practice not all fluid gets on the blade.

The second mode is when the water is injected just behind the plane of the rotor, i.e. the blades don’t get a single drop of liquid. The effect was observed in the atom case, although the physical picture of the operation of the screw is somewhat different. The air flowing around tiny particles of liquid, in the end, carries them away, changing their speed from almost zero up to the speed of the air flow. The liquid particles are in this case as a set of miniature screens. Recall the helicopter near the earth’s surface: it is well known that the thrust developed by the rotor, in these conditions, much higher than the thrust at altitude exceeding the linear dimensions of the rotor.

Finally, the third mode is a combination of the first and second. It is interesting that with the constructive reference of the propeller was the main one.

What is aerohydrophysical, what we imagine? In the ideal case is a propeller with four blades. Each has an internal canal, ending with the nozzle orifices in the trailing edge of the blade. The cavity is fed seawater. At screw rotation the resulting centrifugal force begins to drive the water to the ends of the blades, that is, a screw works like a normal centrifugal pump. Ejected through the nozzles the water partly falls on the blade and is thrown back, and generally forms immediately behind the screw some sort of fog, every bit of it, as we have said, plays the role of the basic screen.

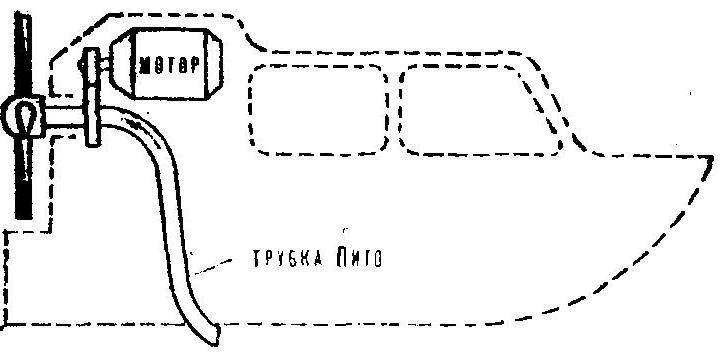

Fig. 2. Schematic diagram of the vessel with aerohydrophysical.

And, as a result of the increase in the mass of ejected particles and the occurrence of ground effect — a slight increase in efficiency of the screw and, importantly, the ability to significantly reduce the length of the blade while maintaining the traction characteristics.

Interestingly, there is a possibility of adjustment of the tractive force on the screw with the flow in the plane of rotation greater or lesser amount of water. To some extent this is equivalent to changing the angle of the blades to the CART.

It may seem that we present here only the theory, not supported by experiment. It is not so; we made a few modifications, one of which — on the basis of the engine PD-10 — was tested on the boat type “Kazanka” and showed good results.

Another promising option is a motor with a screw located on the moving base (for measuring the thrust dynamometer), combined with an annular pipe with holes-nozzles aimed at the inner part of the ring. This design is intended for measuring the thrust of the propeller in the injection fluid in different region of the air stream, and also in the plane located directly in front of the screw.

Difficult to solve issue in the design of the new propulsion is the problem of reducing hydraulic friction losses in the pipeline, the inlet water to the propeller. It seems to us, in addition to conventional methods is the desire to avoid abrupt thickening or contraction of pipes, sharp bends, here could be applied another way of dealing with liquid friction. Reduction of surface tension of water can be achieved by using polymeric additives. They are injected directly at the entrance of water intake pipes. The amount of additives relative to the weight of water is small and the effectiveness is very significant.

The scope of this aerohydrophysical seems quite extensive: hovercraft and hydrofoils, gliders… in short, where there is an air screw. By the way, speaking of courts on an air cushion, we mean the use of our mover not only for main engine but also on the fan, directly creating an air cushion.

A. IVANOV