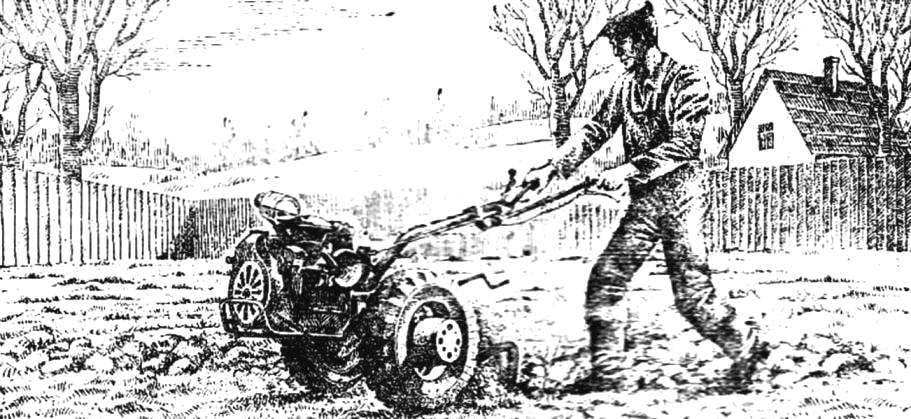

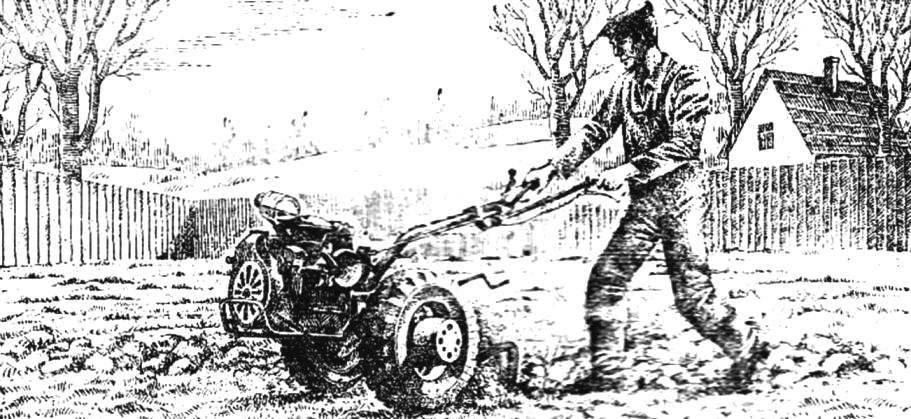

The word “cultivator” has entered our lexicon relatively recently. In principle it is the same tractor only built on the basis of single-axle chassis and designed to actuate a replaceable mounted and trailed agricultural implements, and controlled by the levers behind the operator. In some cases, when the walk-behind articulated to the truck, he becomes the vehicle and the operator does not go and goes.

This definition is consistent with the “Belarus” MTZ-05. It is possible to plow light soil, harrow, hoeing potatoes and beets, mow the grass, to transport cargo.

Its own mass of 135 kg walk-behind tractor towing a Laden trailer weighing up to 500 kg. Suitable for stationary work with the drive from the PTO shaft.

However, to handle different cultures, you need to have a variable track. From MTZ-05 it is set in the range of 450, 600 and 700 mm. And the radius of rotation of the tillers at least 1 m.

Clearance “Belarus” — 300 mm, which allows not to crush the treated plants and, incidentally, to overcome in case of need Ford the same depth.

Design MTZ-05, very original. Cochem with the fact that he has no frame. The frame of cultivator is made up of several buildings of the transmission. First clutch with manual control: it is multi-disc and so-called “wet”. Then, the mechanical speed gearbox with constant-mesh gears. Eye then the transmission bevel gear with helical teeth. Further, the Cam self-locking differential. He wheels go end of transmission — side single-stage reducers with cylindrical gears.

Fig. 1. Walk-behind tractor “Belarus” MTZ-05:

1 — bumper with hinged Parking support, 2 — motor, 3 — exhaust pipe 4 — throttle cable, 5 — fuel tank 6 — pivot axle, 7 — steering column 8 — shift lever, 9 — lever front to back, 10 — the throttle lever, 11 — control handle, 12 — clutch lever, 13 — clutch cable, 14 —tubular coupling, 15 — node sample of agricultural equipment, 16 — lever for engaging the PTO shaft, 17, the starter pedal, 18 — wheel 5,90X13″, 19 — fastening the wheel to the intermediate disk 20 to the mounting of the intermediate disc to the hub, 21 — final drive, 22 — differential case, 23 — PTO, 24 — pull shift lever, 25 — pull lever “back and forth”.

The front docked to the frame of the engine UD-15, diesel, four-stroke, carbureted, single-cylinder, 5 HP and a nominal engine speed of 3000 rpm. it Runs with kick pedal, located on the crankcase on the right. On top of the engine the strengthened exhaust pipe, bottom — folding Parking leg with a spring.

On the lid of the transmission housing equipped with fuel tank capacity of 5 l and the steering column, the handlebars which is placed the levers of the clutch, gas and transmission.

The steering column is also original — it swivel, can be denied the right or left in 15° or even turned 180°. This is done in order to enable the operator to go after work on and side — on virgin soil or when the spacing of the forward movement or after the tillers — reversing. Handles height adjustable for the height of the operator.

Fig. 2. The experimental setup of the gauge.

Now about the gear. Them in MTZ-05 six: four forward (current movement speed 2,1; 3,8; 5.4 and 9.5 km/h) and two (2.5 and 4.5 km/h). Such a large selection is not random: certain types of soil treatment require both your tools and the proper speed.

What is aggregated in small DOLE? Plough PL-1 and Hiller CO 2 produced by the enterprise “Lidselmash”, harrow bn-90 and cultivator KR-70 Volkovysk plant of foundry equipment, semi-trailer PF-0.5 production Association Bobruiskselmash and mower KN-1 of the plant “Gomselmash”, named after the 60 anniversary of Great October.

For coupling to the walking tractor is unit charge, and for the mowers, powered by the PTO shaft, — a tubular coupling. The speed of rotation of the shank of the shaft 1 thousand rpm. the Steering column in this case is rotated by 180°, and the included transfer back.

Plow is recommended for first and second gear with a track 600 and 700 mm. Plow must be adjusted so that at a given depth and width, he is not buried in the ground and not slip out to the surface.

When plowing, cultivating, hoeing and harrowing — in fact, the energy — intensive works to prevent wheel slippage, it is recommended to be Attached to their loads, which included tillers. Four cargo weight of each of them is 17 kg.

The tire pressure should be about 0.8 kgf/cm2.

Fig. 3. Possible positions the steering column and the controls.

During transportation of the trailer when the cargo disc is removed, the pressure increased to 1.2 kgf/cm2.

“Belarus” MTZ-05 in contrast to its predecessors experienced-industrial design. A small batch of tillers not so long ago was implemented in Belarus through the trading network of the Union. Farmers happy: microfracture help them to cultivate potatoes and other vegetables, to harvest and transport the feed.

Although the plant continues to improve MTZ-05, there is no doubt that Amateur designers, owners of private farms — all who intend to mechanize the hard agricultural labour, take into consideration the experience of the Minsk tractor take advantage of original solutions.

Call MTZ is hardly advisable, not everyone can do it. And needs and everyone has different tastes. The idea is that the Amateur design enthusiasts saw what could be the tillers, reacted to his design as an example.

A. ALEXANDROV

Recommend to read MODEL-A COPY OF CHAMPION In the laboratory, missile and space modeling of the Moscow city Palace of children's (youthful) creativity of the work on the creation of models-copies of the booster (PH) "Soyuz" was... “INCONSISTENCY AND UNFINISHED” We have previously described a pretty complicated path of development of the French submarine fleet before the First world war (see "M-K" No. 4 of 2014), consisting in the infinite... Scroll back to top

The word “cultivator” has entered our lexicon relatively recently. In principle it is the same tractor only built on the basis of single-axle chassis and designed to actuate a replaceable mounted and trailed agricultural implements, and controlled by the levers behind the operator. In some cases, when the walk-behind articulated to the truck, he becomes the vehicle and the operator does not go and goes.

The word “cultivator” has entered our lexicon relatively recently. In principle it is the same tractor only built on the basis of single-axle chassis and designed to actuate a replaceable mounted and trailed agricultural implements, and controlled by the levers behind the operator. In some cases, when the walk-behind articulated to the truck, he becomes the vehicle and the operator does not go and goes.