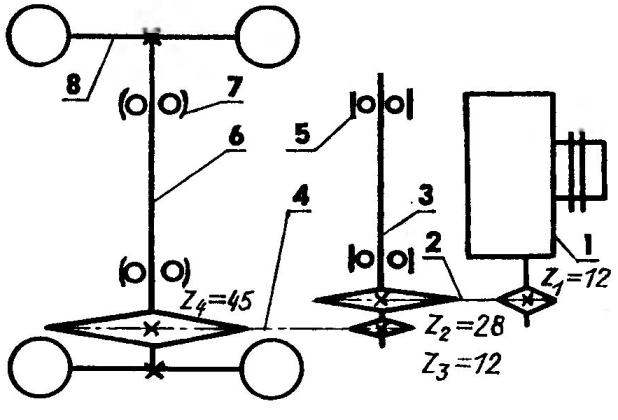

The second stage of transmission — almost a copy of the first, only the number of teeth of the driven sprocket G4 = 45 (luckily managed to find one in Sutov-ing stocks). The result is the gear ratio of intermediate gear increased from 2,Ssdo 3,75. Enter this two-stage chain transmission to the kinematics of tillers possible to reduce the frequency of rotation of the output shaft 8.74 times.

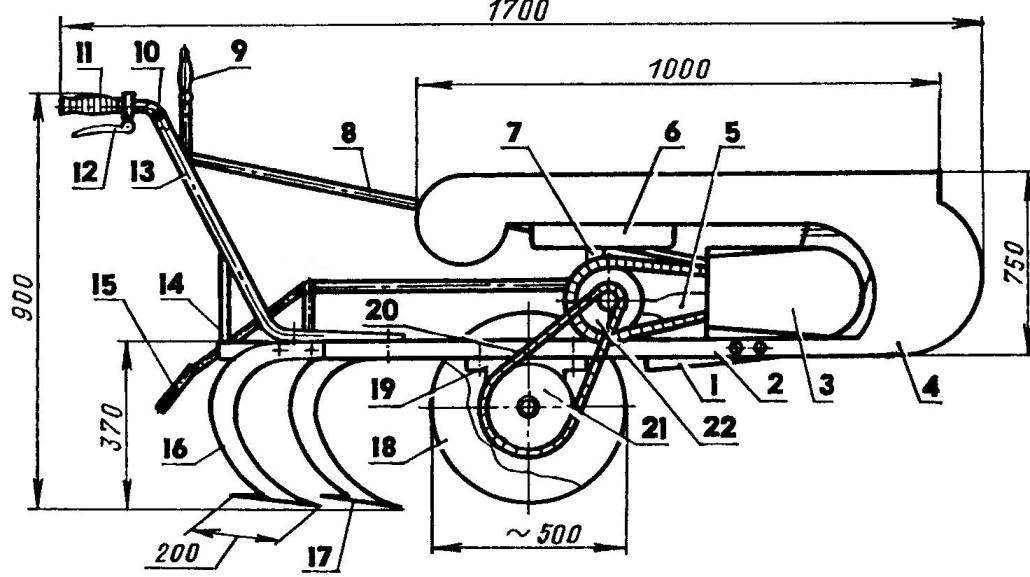

Walk-behind tractor with cultivators:

1 — folding footrest (from a motorcycle “Voskhod”); 2 — frame (steel, pipe 60x50x2); 3 — power unit (from a motorcycle “Minsk”); 4 — hood (steel, sheet s2); 5 — muffler; 6 — gas tank (motorized FDD); 7 — bracket (steel, pipe 60×2,5 with two welded cross bars from the corner 25×25); 8 — thrust of the gear lever (steel, rod d10); 9 — gear lever; 10 — cross bar (steel pipe 25×2, L600); 11 — handle “gas” (from a motorcycle “Java”); 12 — lever clutch (from a motorcycle “Java”); 13 —control handle (steel, pipe 33,5×4,L1200, 2pcs.); 14 — cosina (steel, pipe 25×2, 2 PCs.); 15 — the kick starter lever with the rod (steel rod d10, L700); 16 — bracket-bracket of the cultivator (2 or 3). 17 — paw cultivator (2 or 3). the 18 — wheel Assembly (sidecar FDD, 2 PCs.); 19 — bearing Assembly output shaft (farm equipment, 2 PCs); 20 — circuit PR-19,05 (farm equipment, 2); 21 — sprocket output shaft with the hub; 22 — intermediate shaft Assembly with the two intermediate sprockets

Kinematic scheme of transmission:

1 — power unit (from a motorcycle “Minsk”); 2 — first stage chain transmission (I = 2,33); 3 — intermediate shaft; 4 — the second stage chain transmission (I = 3,75); 5 — node of the intermediate shaft bearing (2 PCs); 6— output shaft; 7 — node samoustraniajutsia bearing of the output shaft (from the straw walkers of the combine harvester “Niva”, 2); 8 — wheel (sidecar FDD, 2 PCs.)

Frame tillers (steel pipe 60x50x2)

Bracket-to-bracket and paw cultivator

Hub (steel 45) and the wheel; b — sprocket intermediate shaft

The output shaft of the motor-block (steel 45)

The frame of the cultivator, welded, made of steel pipe 60x50x2 mm. In terms of this design resembles the sash for glazing of balconies or loggias, but several times reduced. Overall size — 1280×470 mm with 120 mm removal for removable plow or third arms of the cultivator. On top of small longitudinal incisions are attached to the seat fitted(from a scrapped farm equipment) bearing units of the intermediate, and the bottom on the side of the output shaft.

Access to the”heart” of a mechanical assistant is quite simple: raise the hood

The power unit is mounted in front of the frame using two clamps (place), made from steel strips with a thickness of 2 mm. At the base of the clamps drilled two holes for bolts M10.

The transition shaft, sprocket, and chain two-stage transmission of torque from the powertrain output shaft of UMB borrowed, as noted, have worn out (but to be quite acceptable for “Kearney”) cars, motorcycles and agricultural machinery. From straw walkers of the combine harvester “Niva” are fitted and the bearing of the output shaft.

The output shaft and the wheel hubs and sprockets homemade. Machined from steel 45. The technology of manufacturing and Assembly hub with asterisks presented on the pages of “Modeller-designer” (№ 5’91, 3’95, 2’97).

The wheels and fuel tank — motorized FDD. Steering levers are made of steel thick-walled tube. Lever clutch and throttle of the carburetor from a motorcycle “Java” foot — a motorcycle “Rising”. Levers gear shift and kick-starter is made of metal rod with a diameter of 10 mm.

Kickstarter launched back to the operator, which facilitates the process of starting the engine. Fuel from the fuel tank to the engine flows by gravity.

The casing material is a metal sheet 1.5 mm thick.

Despite the fact that the cultivator can perform a few operations guys often use it on school grounds and in the collective garden as a cultivator. Working bodies — cutting feet — stainless steel with a thickness of 3 mm. To the frame of the cultivator they are mounted with three steel brackets, each of which has a thickness of 10 mm, and bolting.

N. KOCHETOV

Recommend to read

“E” CULTIVATOR

“E” CULTIVATOR

The idea of creating a mechanical assistant for the treatment of garden I came up with long ago. Looked appropriate magazines "modelist-Konstruktor" with the description of the... Hello!.. DO YOU HAVE DRILL?

Hello!.. DO YOU HAVE DRILL?

True stories about Vitka-inventor. That day we swam in a rubber boat Vaikinai far. Left behind and the dam, and willow spreading, with lower branches which is so convenient to dive, and...

In gardens and orchards, dachas and school grounds — wherever there is a need to treat a small area of land, widely use universal blocks (UMB). Including homemade, are often created with maximum use of standard components and parts. One of these structures was developed and successfully tested in the case of members Ceadir-Lunga syut under the leadership of Vladimir Konstantinov.

In gardens and orchards, dachas and school grounds — wherever there is a need to treat a small area of land, widely use universal blocks (UMB). Including homemade, are often created with maximum use of standard components and parts. One of these structures was developed and successfully tested in the case of members Ceadir-Lunga syut under the leadership of Vladimir Konstantinov.