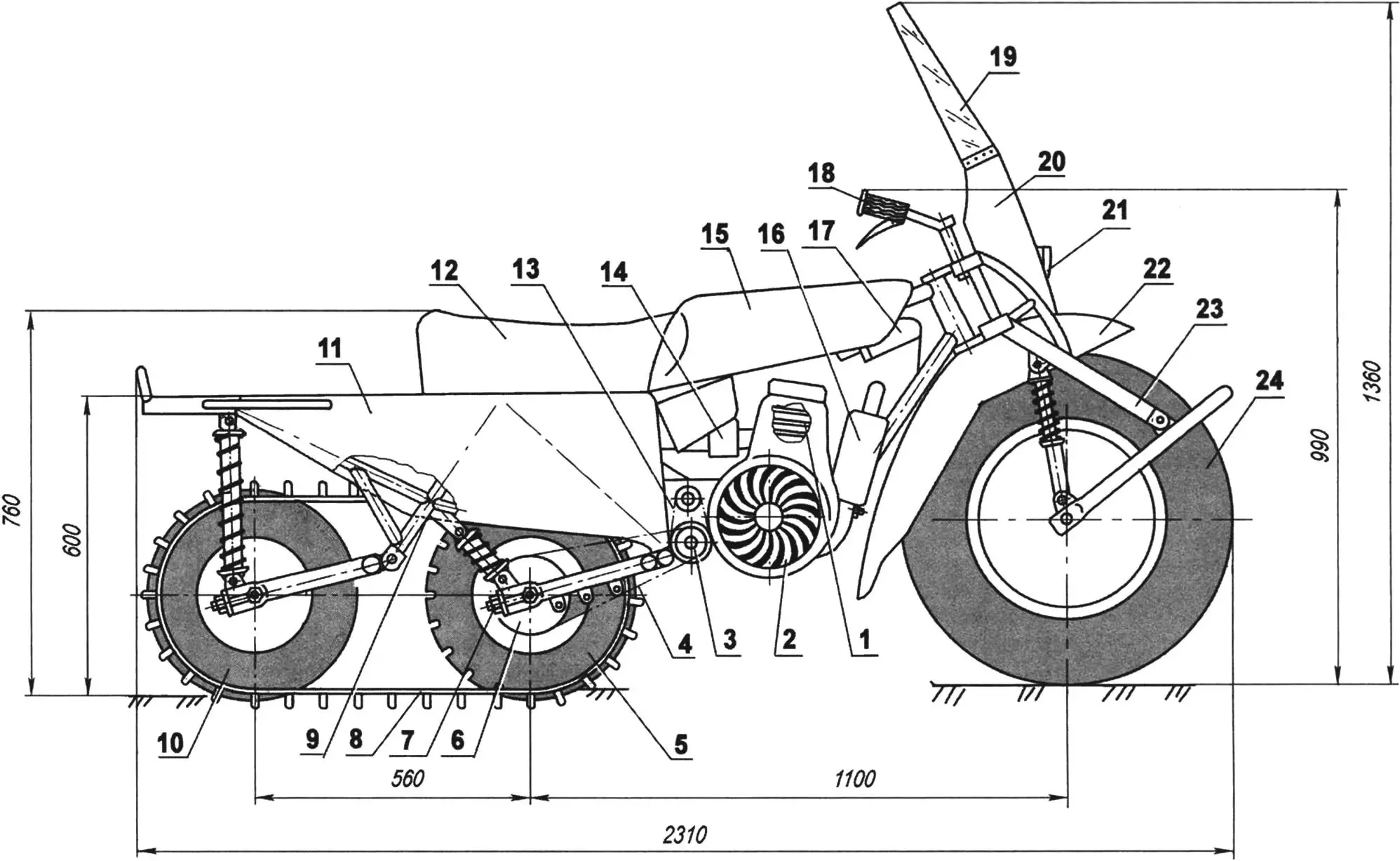

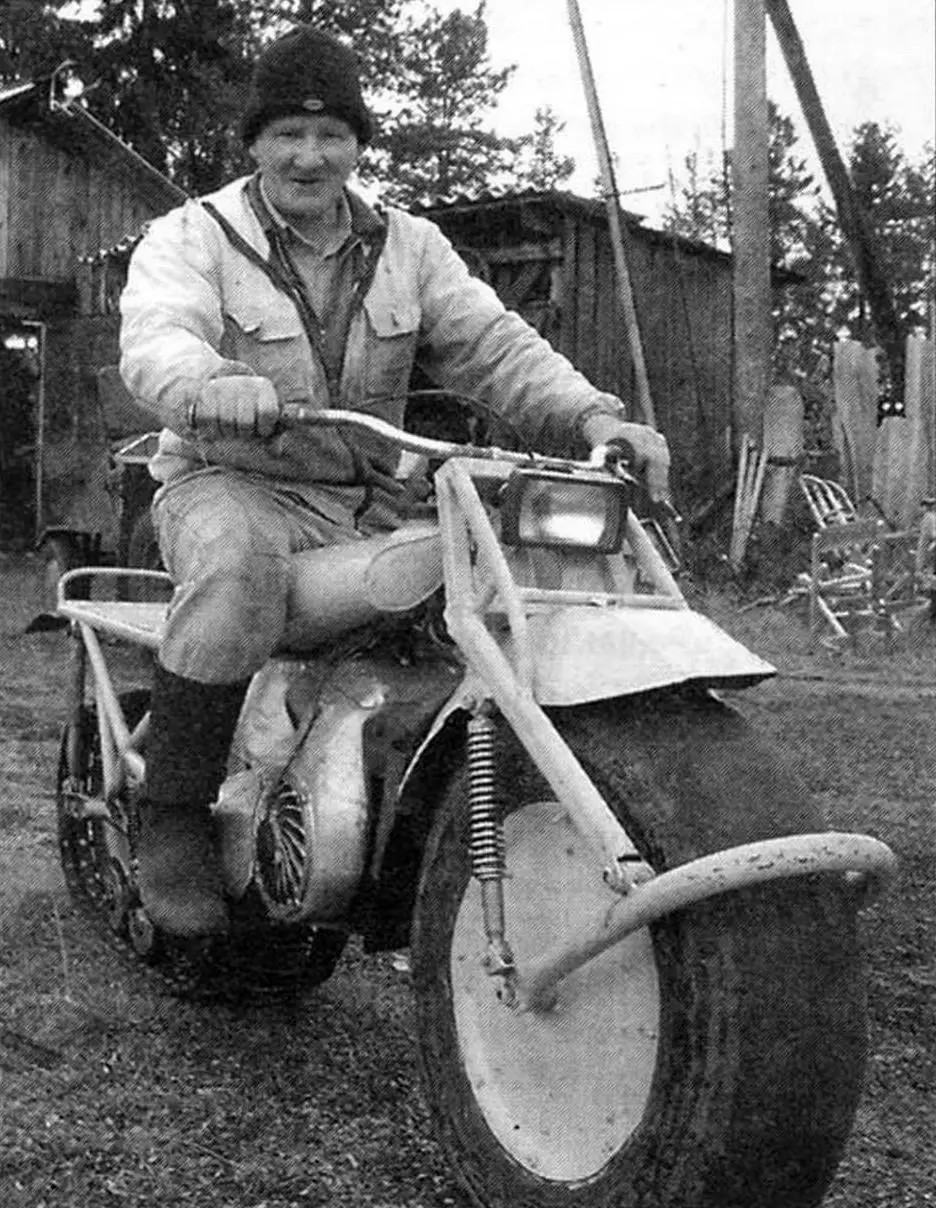

The design presented here is a half-track motorcycle with a steering front wheel on a low-pressure tire and a driven track, intended for off-road travel—mainly in summer and in the off-season, in winter on snow (cover up to 25 cm thick), and also on ice and hard crust. The motorcycle’s capability is, in effect, “go anywhere.” Exceptions are only water obstacles deeper than 30 cm (floods the ignition system) and bog where a person sinks in up to the knee. The motorcycle can carry up to 30 kg of cargo, and a trailer up to 80 kg: in summer on a wheeled trailer (with wide-profile tires), in winter on a sledge.

Similar motorcycles have been described in “Modelist-Konstruktor,” but they were mostly designed for snow travel, had many small-diameter rollers, and as a result suffered significant power loss and clogging of the track drive with moss and mud on bog, and in winter with “slush” on ice. Before this I had various homebuilt wheeled motorcycles: with large-diameter tubed wheels, with “UAZ” lightweight tires, with auxiliary drive to a sidecar, but achieving high off-road capability never quite worked—either ground pressure was too high or dimensions were too big. With a sidecar you lose the ability to follow any path or go straight through the forest, and its mass exceeds 140–150 kg, which is unacceptable for a motorcycle (for reference—the design presented here has a mass of 110 kg).

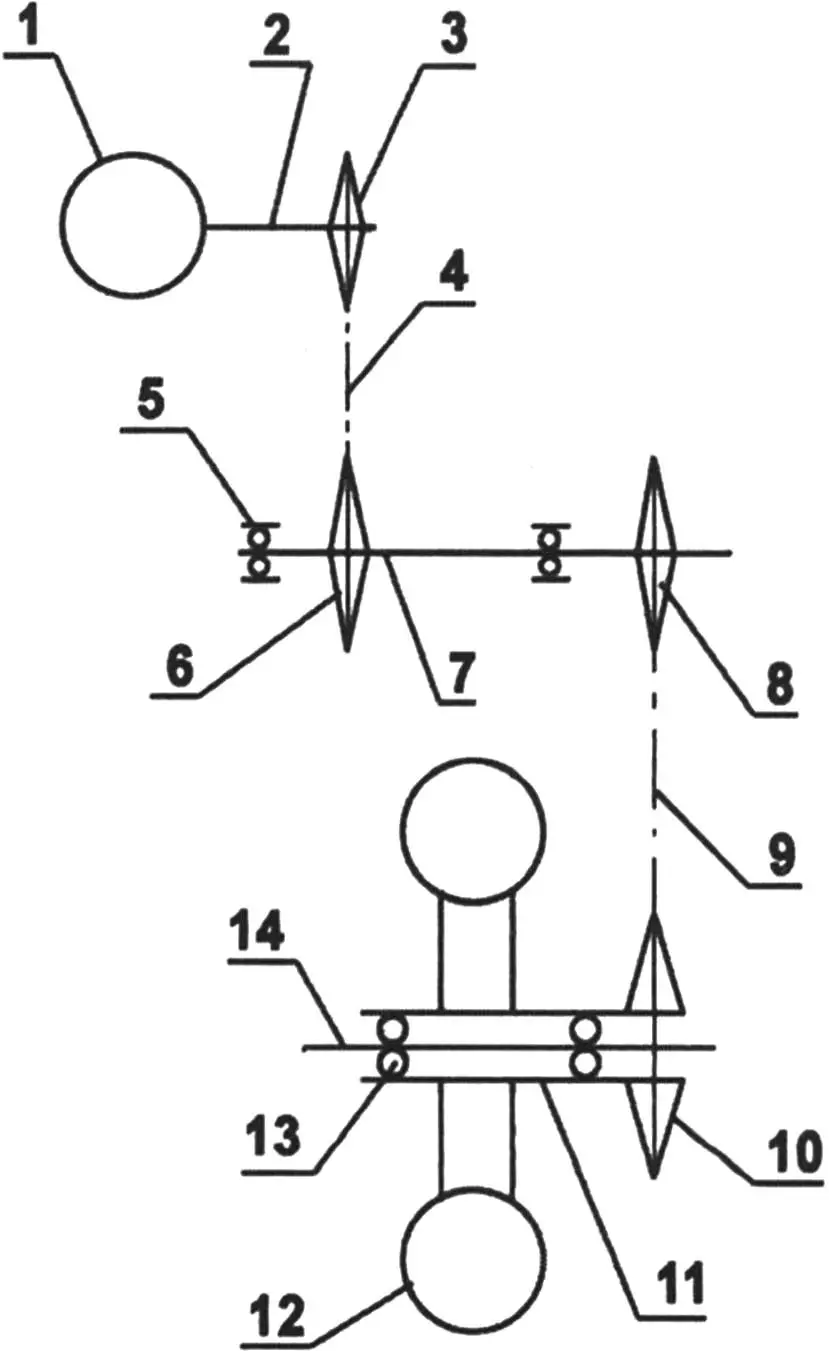

1 — engine (from “Muravey” cargo scooter); 2 — forced air cooling (from “Muravey” cargo scooter); 3 — intermediate chain reducer; 4 — second-stage chain drive (t=15.785); 5 — drive wheel of track unit; 6 — drive sprocket of drive wheel; 7 — chain tension mechanism for track drive wheel (4 pcs.); 8 — track; 9 — frame; 10 — idler wheel of track unit; 11 — guard (AMG-2, sheet s1.5); 12 — seat; 13 — first-stage chain drive (chain t=12.7); 14 — carburetor; 15 — fuel tank V=12 L (AMG-2, sheet s1); 16 — exhaust muffler (stainless steel, sheet s1); 17 — ignition coil (from “Muravey” scooter); 18 — handlebar (from “Voskhod” motorcycle, widened); 19 — windscreen (plexiglass); 20 — wind deflector (AMG-2, sheet s1.5); 21 — headlight (off-the-shelf); 22 — front fender (AMG-2, sheet s1.5); 23 — front fork; 24 — front wheel

Unfortunately, the lack of a light engine forced the use of a relatively heavy one—from the “Muravey” cargo scooter, with air cooling. Engines from “Minsk” or “Voskhod” have low torque, are high-revving, lack forced cooling, and are therefore poorly suited for use with a track drive. The power unit is used unchanged; only the fan intake is additionally covered with a perforated cap (to keep out leaves and grass) and a magneto is fitted, though replacement with a contactless system from the “Vyatka” scooter is planned. That setup has been tried on a snowmobile and works very well. Besides reliable starting it is much lighter, needs no voltage regulator, and does not stick out to the side, so it does not get in the way off-road.

The track-drive motorcycle handles little differently from a normal road bike; its top speed is about 60 km/h, though that figure is not very important when riding on dirt roads or forest paths.

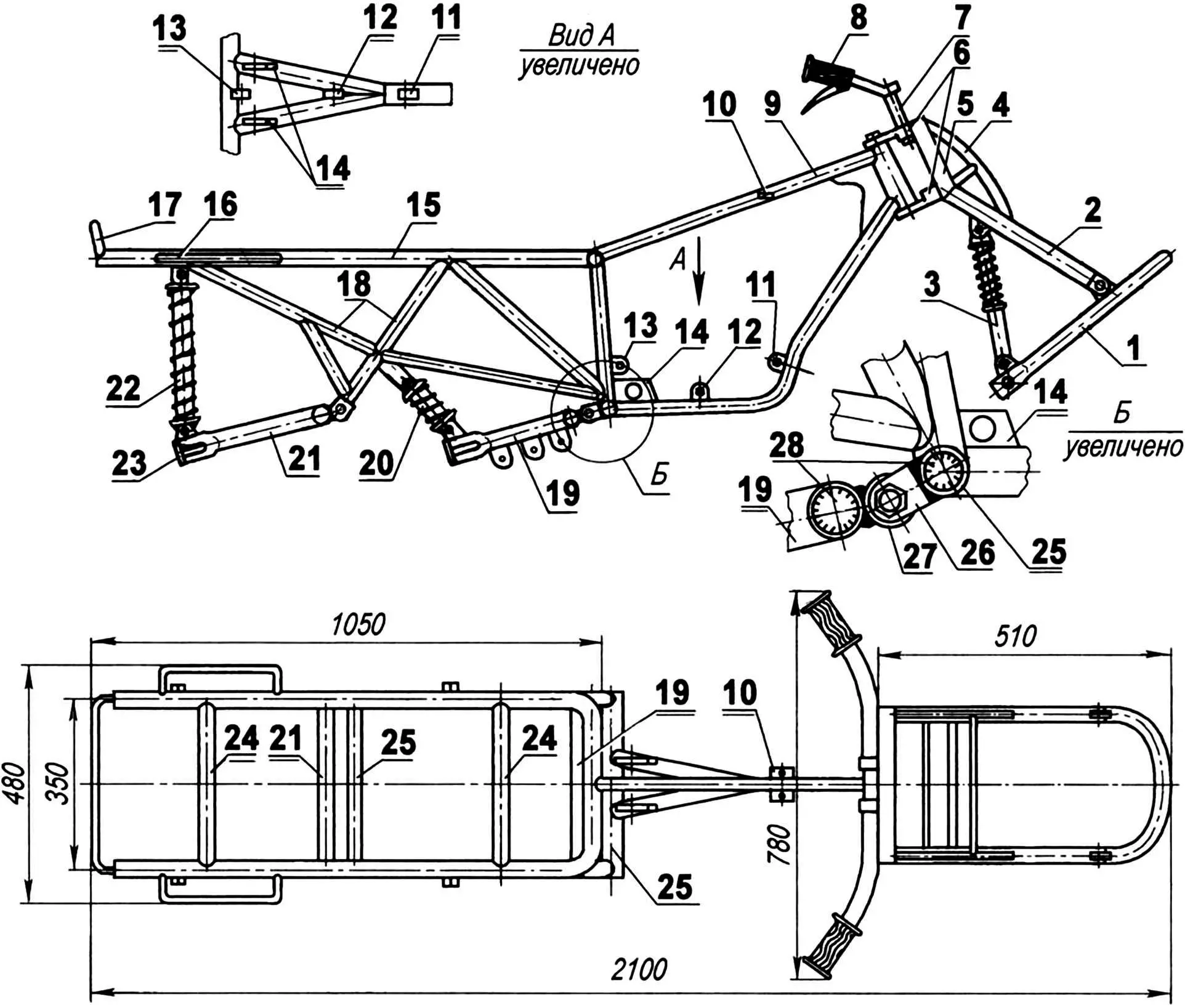

1 — front fork arch; 2 — front fork; 3 — front suspension shock absorber (from “Voskhod” motorcycle, 2 pcs.); 4 — front fork reinforcement (strut, post and crossmember); 5 — bridge tie (2 pcs.); 6 — upper and lower steering yokes; 7 — steering column (2 pcs.); 8 — handlebar; 9 — frame backbone (from “Voskhod” motorcycle); 10 — fuel tank bracket (2 pcs.); 11 — front power unit bracket; 12 — lower power unit bracket; 13 — rear power unit bracket; 14 — intermediate chain drive shaft bracket (2 pcs.); 15 — longeron; 16 — side bracket (2 pcs.); 17 — rear bracket; 18 — track unit suspension grid (2 sets); 19 — drive wheel swingarm of track unit; 20 — drive wheel suspension shock absorber; 21 — idler wheel swingarm of track unit; 22 — idler wheel suspension shock absorber; 23 — tension device (4 pcs.); 24 — longeron crossmembers (2 pcs.); 25 — track unit suspension grid crossmember (3 pcs.); 26 — fork mounting lug; 27 — fork suspension silent block; 28 — plug

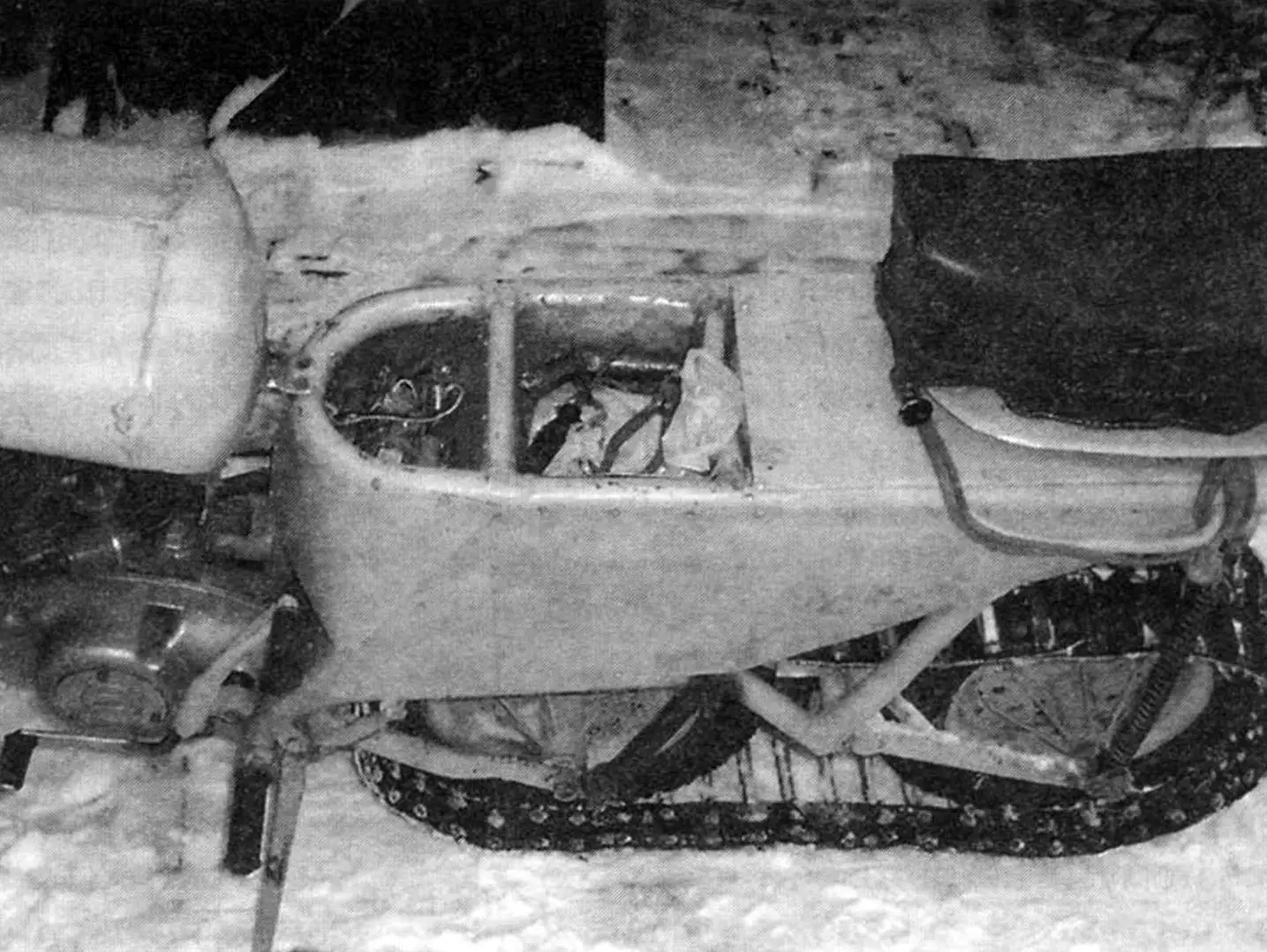

Now about the off-road motorcycle’s construction. The frame is from a “Voskhod” motorcycle with brackets adapted for the “Muravey” engine and a lengthened rear section. To simplify engine installation the front bracket is attached to the frame with two bolts rather than welded like the other two.

The forks are newly made; from the “Voskhod” front fork only the upper and lower bridges and the steering stem with bearings are used. Rectangular thin-wall tube segments are welded to the bridges to form the upper and lower yokes, and the front fork legs with their struts and ties are welded to those. The front (lower) ends of the legs have lugs for silent blocks, through which the swinging front-wheel arch is suspended; it is made from thin-wall chrome-silicon (30KhGSA steel) tube. The fork arch is oriented “toward the rider” (as is common, for example, in aviation). This layout together with a fairly soft wide-profile lightweight wheel—a pneumatic (0.2–0.3 atm pressure)—gives good bump absorption and makes it easy to cross even fallen trees.

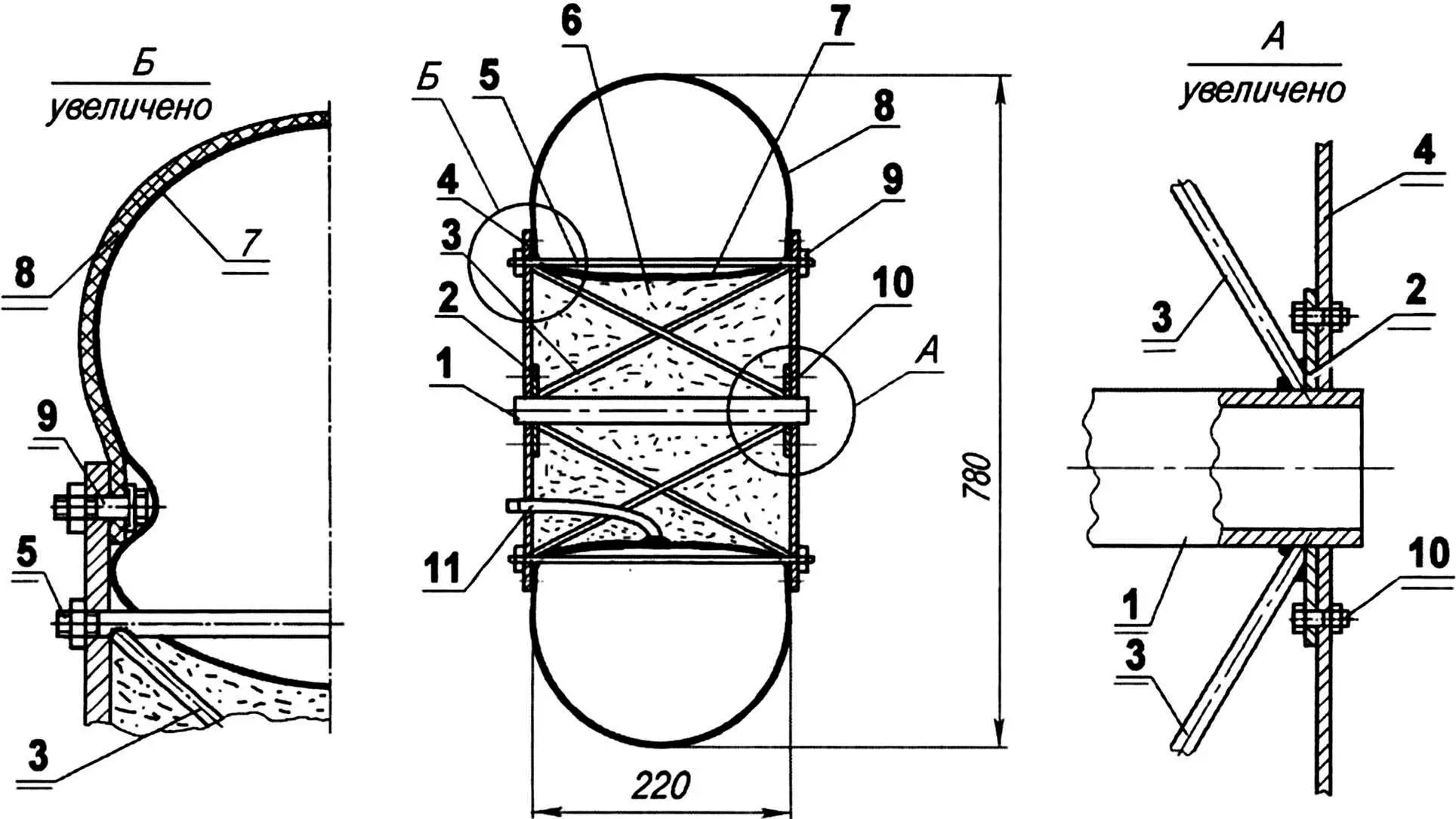

1 — hub sleeve (body of car hand tire pump); 2 — hub flange (steel sheet s3, 2 pcs.); 3 — spoke struts (5 mm wire, 4 pairs); 4 — disc (AMG-2, sheet s3, 2 pcs.); 5 — tie (M6 stud, 8 pcs.); 6 — filler (foam); 7 — inner tube; 8 — tire; 9 — tire-to-disc attachment (M6 bolt with “eared” washer, 16 pcs.); 10 — disc-to-flange attachment (M6 bolt, 4 pcs.); 11 — tube valve (elongated)

The wheel is homebuilt. The rim is 6 mm wire, the discs are AMG-5 sheet 3 mm thick, the struts are 5 mm wire, the hub is from the tubular body of a car hand pump, the axle is also tubular and lightened. One disc has a hatch through which the tube valve is brought out via an extension. The tire beads are bolted to the disc side edges.

The front (and rear) shock absorbers from a moped are admittedly “old school,” but funds do not allow modern ones (from scooters or snowmobiles). Together with the shock absorbers and wheel axle the fork forms a closed structure that resists bending and torsion well. In general, a lot of attention was paid to the best balance of strength and adequate lightness: off-road loads are much higher than on a road motorcycle, and if it breaks down in the back of beyond, getting it home is difficult!

I will describe the rear fork later, when we come to the track drive.

1 — power unit; 2 — power unit output shaft; 3 — engine output shaft sprocket (z=13); 4 — first-stage PR-12.7 chain; 5 — intermediate shaft support (rolling bearing 80204, 2 pcs.); 6 — intermediate reducer drive sprocket (z=21); 7 — intermediate shaft; 8 — intermediate reducer driven sprocket (z=18); 9 — second-stage PR-15.875 chain; 10 — track drive wheel sprocket (z=27, t=15.875); 11 — drive wheel hub; 12 — track drive wheel; 13 — hub bearing (2 pcs.); 14 — drive wheel axle

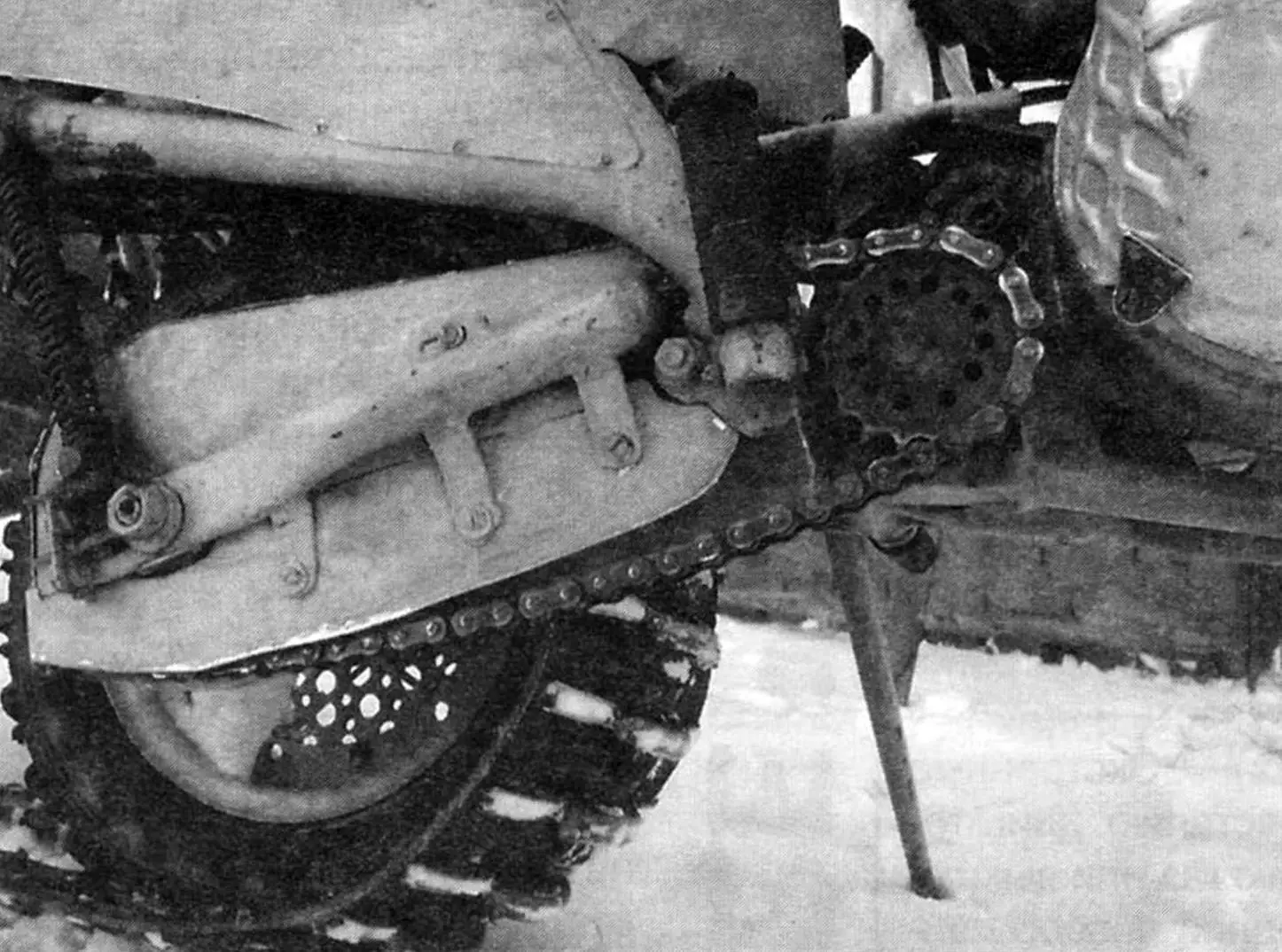

The need for adequate ground clearance and for optimal (fairly low) track drive wheel speed led to using an intermediate chain reducer in the transmission; the frame has matching brackets with slots to tension the first-stage chain (12.7 mm pitch). Drive from the reducer to the track drive roller is also by agricultural chain (15.785 mm pitch). This chain has a longer life in dirty conditions than motorcycle chain.

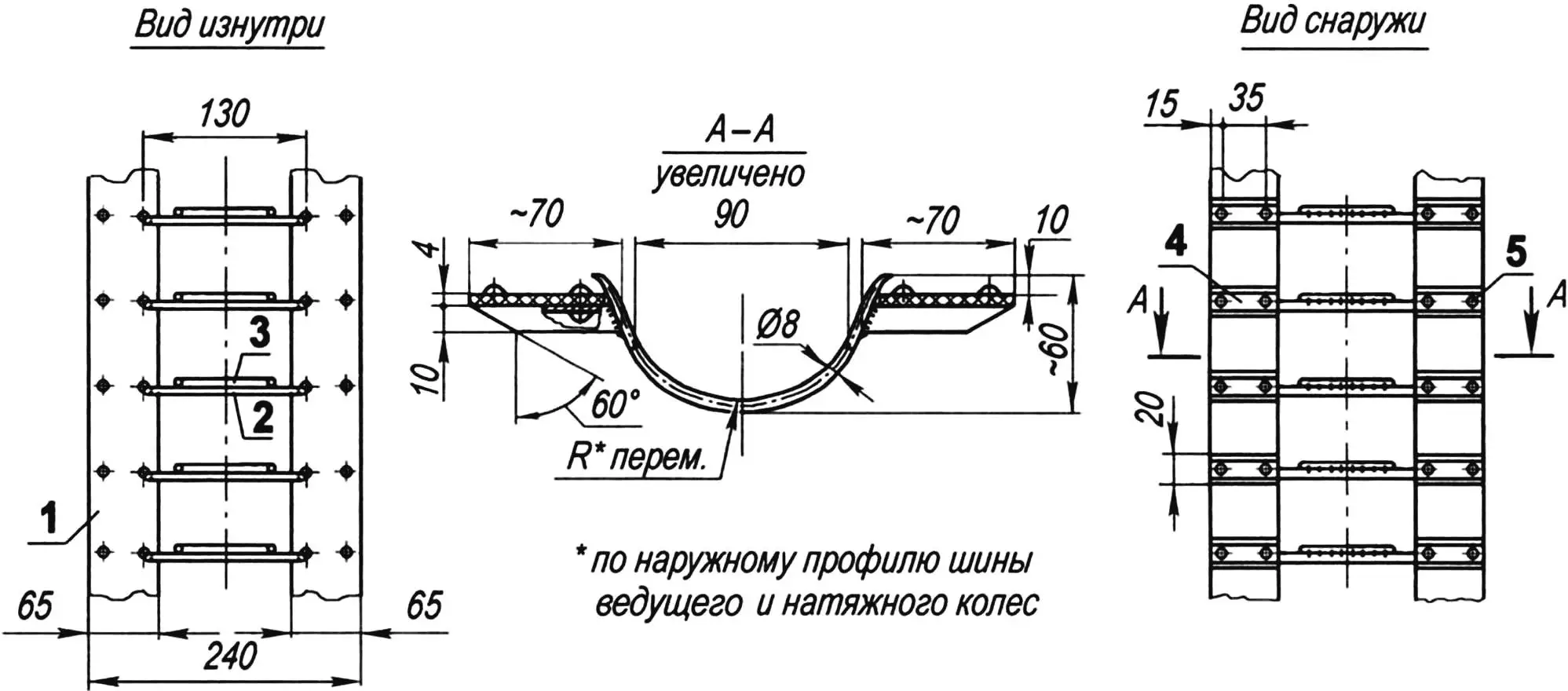

1 — belt (rubber-cord strip s4, 2 pcs.); 2 — clip (8 mm steel wire, as needed); 3 — clip reinforcement (8 mm steel wire, as needed); 4 — cleat (steel sheet s4 — U-profile 10x20x10, as needed); 5 — fastener (5 mm steel rivet with widened head, as needed)

As already clear, the track drive consists of the track and two roller-wheels: drive and idler. Previously there were two small support rollers on each track belt between the wheels (see header photo). But use showed that a well-tensioned track with such a short distance between wheels works fine without idlers.

The track drive and idler wheels are the same, from the “Tulitsa” scooter (or similar); the drive tire has transverse grooves (without cutting the cord) to engage the track cleats. Both wheels have independent suspension. Each is in its own swingarm, linked to the frame via silent blocks (from “Voskhod” motorcycle).

The swingarm ends have slots to move the wheels for track tension; they bear on the frame through simple shock absorbers (tube-in-tube, with springs from “Voskhod” front fork), which keeps weight down. There is no rocking because load is shared between the track wheels. The wheel discs are stock but lightened by drilling. The hubs are inserted in the disc center holes and fixed with welded wire struts (5 mm). The hubs use the cylindrical body of a car hand pump; its bore fits the 202 bearing, and to keep the two bearings from dropping through, rings of smaller-diameter tube are inserted inside and fixed through hub holes with pop rivets. Because the hub flange is flat and thin, it is reinforced on both sides with 5 mm wire struts that spread load to the hub edges. The front (drive) track wheel shaft and the rear (idler) axle are 16×2.5 mm tube with the middle section lightened (turned). Snow and mud pack between the struts, so it is better to seal them with “Macroflex” and paint. All cavities and voids, including the front (steered) pneumatic wheel, are also filled with foam.

Bearing protection needs special attention—they work in heavy contamination, so they must be well shielded with covers or use bearings with seal washers. The track drive wheel has two bearings on the sprocket side for reliability, and the hub tube has extra pads on top to spread load.

The track is made from two strips of nylon cord belt and cleats of 8 mm rod reinforced in the middle with another piece of the same wire. To join the belt strips, channel sections bent from 4 mm sheet are welded to the cleats, and the track belts are bolted to them. Note the cleat shape—it follows the tire profile. The rod ends should be chamfered so the drive wheel enters freely, and welds must be cleaned well. The oval cleat shape has drawbacks—track slip on packed snow and side slip on ice—but that is minor; more important is easy handling in turns, which this cleat shape provides. With a straight (flat) cleat, balance would be hard to keep, especially in turns (tested!). The track block drive and idler wheels have newly made hubs because the stock ones are too heavy.

Now the “secondary” units. The 12-liter fuel tank is TIG-welded from 1 mm aluminum sheet (AMG-2) and has internal baffles (otherwise with great length and low height fuel sloshes into the drain). All “cladding” (side panels) and the front fender are also AMG-2. The headlight is plastic, mounted for protection between the front fork struts. The wind deflector is also AMG-2, removable, held by four thumb screws. The rider seat is removable (its base is AMG-5 sheet 2.5 mm thick); underneath are two compartments whose walls are also light-alloy sheet. One holds the voltage regulator, the other the tools. When switching to thyristor ignition the regulator compartment is planned for use as an air cleaner.

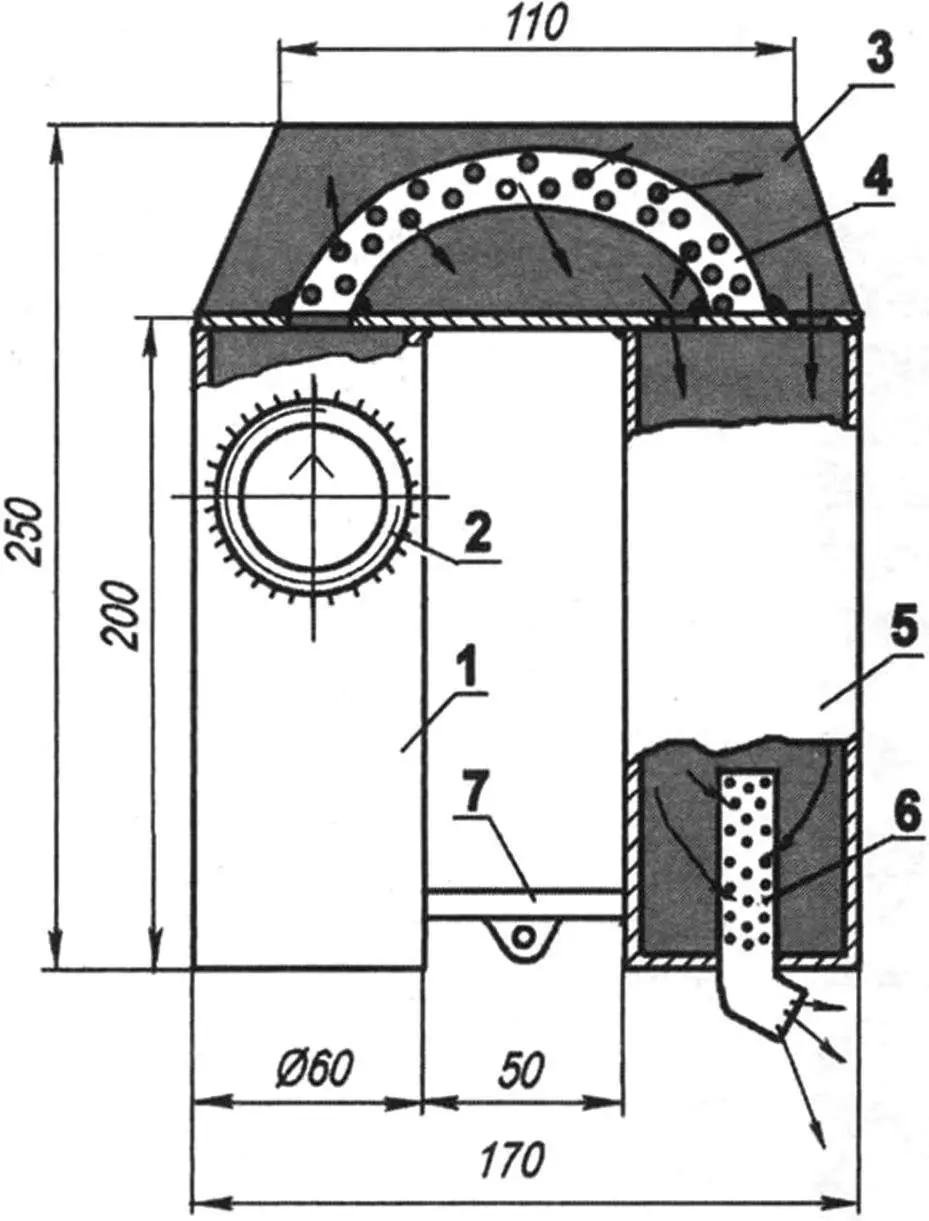

1 — primary chamber (60×1 mm tube); 2 — inlet pipe nipple; 3 — intermediate chamber; 4 — primary-to-secondary connecting pipe (32×1 mm tube) with 5 mm holes; 5 — secondary chamber (60×1 mm tube); 6 — outlet pipe (25×1 mm tube); 7 — mounting lug with tie (steel sheet s3)

The exhaust muffler is made as compact as possible from 1 mm steel, non-demountable; noise level is comparable to road motorcycles. About twice a year it has to be burned out from coked motor oil. All electrical equipment (generator, voltage regulator) is stock, as is the K-36G carburetor. Fitting a valve block (per “Modelist-Konstruktor” articles) is planned. The footrests are tubular, fold back and up. The handlebar is from “Voskhod” but widened with a 150 mm insert; controls are the same as on road motorcycles. Behind the rider seat is a cargo platform with handles on three sides for pulling the motorcycle out of a bog (it happens!), and they also serve as cargo tie-down points. Under the luggage rack is the coupling. It was added later and is not ideal (so it is not shown in the drawing). It should be covered with a mudguard so it does not get packed with dirt. Raising the coupling too high is not advisable (would require a long trailer drawbar). As mentioned, the voids under the seat (behind the tool compartment) and under the luggage rack are filled with foam; together with the front wheel they provide buoyancy, which is useful in recent mild winters. Agreed, that is better than retrieving the motorcycle from the bottom of a pond. The front wheel uses a low-pressure tire made from a lightweight UAZ tire. The method is described in “Modelist-Konstruktor”; note that a “lug” pattern is not necessary—traction is enough with a shallow “chevron” cut with an angle grinder. All transmission chains are covered with AMTs-2 guards to reduce contamination and protect the rider. The drive wheel chain guard is demountable to simplify wheel removal and guard repair when it breaks (which can happen in blowdown). The guard is left open at the bottom so snow and mud do not collect, and the chain sag at speed does not hit the bottom.

Because the half-track motorcycle is an off-road vehicle, brakes were not fitted to keep the design simpler, and they are not really needed. Normal stops are by gradual speed reduction through transmission friction (you can also brake with your foot—speed is low). Emergency braking is by engine—snap the throttle shut or kill the ignition (the latter was only used for practice).

«Modelist-Konstruktor» No. 10’2008, A. KOKSHAROV