A modern city dweller cannot be intimidated by long trips: all types of public transport are at his service. Another thing is short everyday routes: to a kindergarten, a store, a workshop, a laundry… A rural resident, owner of a summer house or garden plot has to make short trips with cargo even more often.

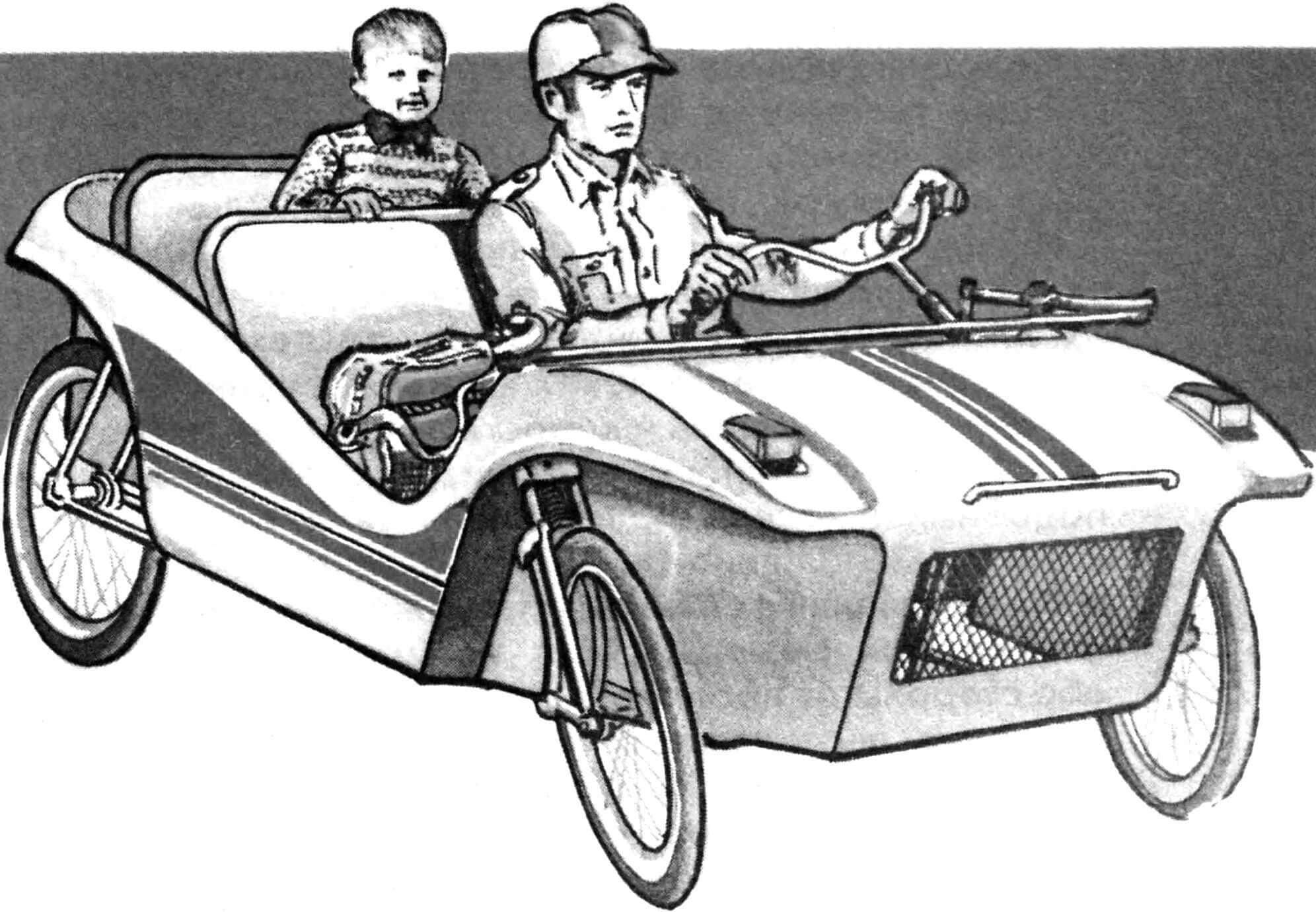

In all of the above cases, the Troll velomobile, created specifically for these purposes, serves me well.

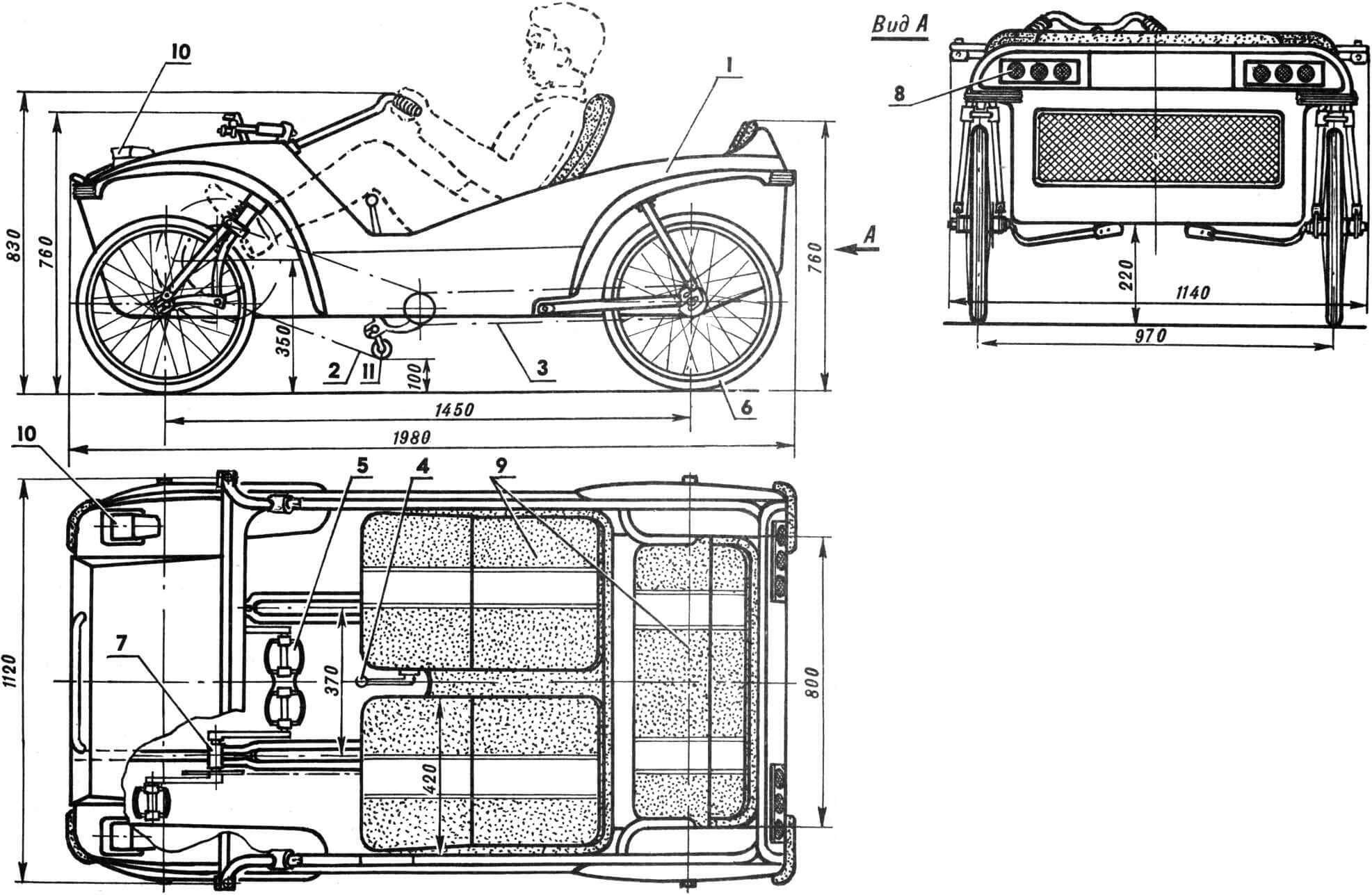

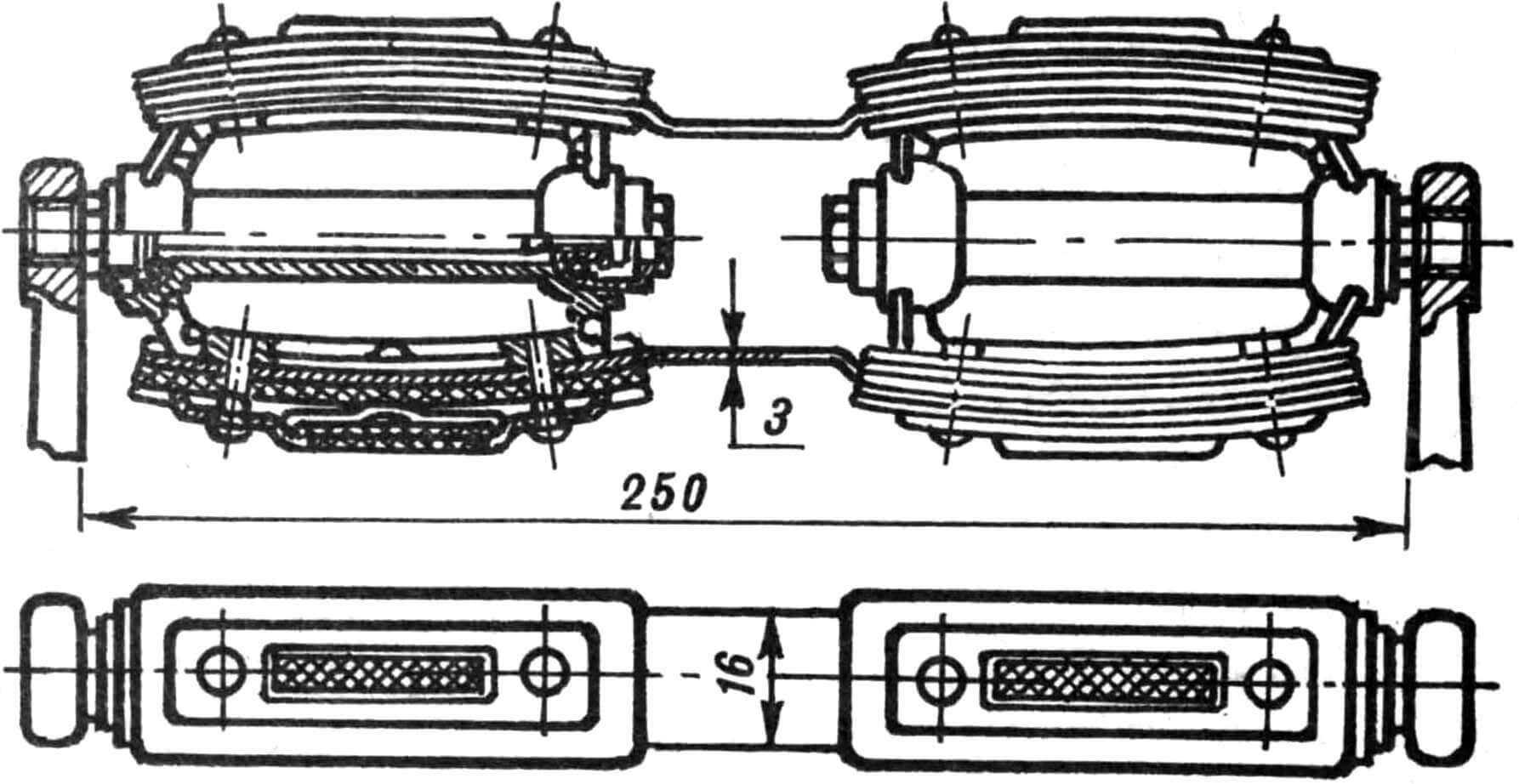

The machine is four-wheeled, with one driven rear wheel. This scheme is justified in this case, since it allows you to evenly distribute the load on all wheels. Compact and durable, with a small diameter, they have shock absorbers that not only make the velomobile more comfortable, but also significantly relieve body elements from dynamic loads when moving.

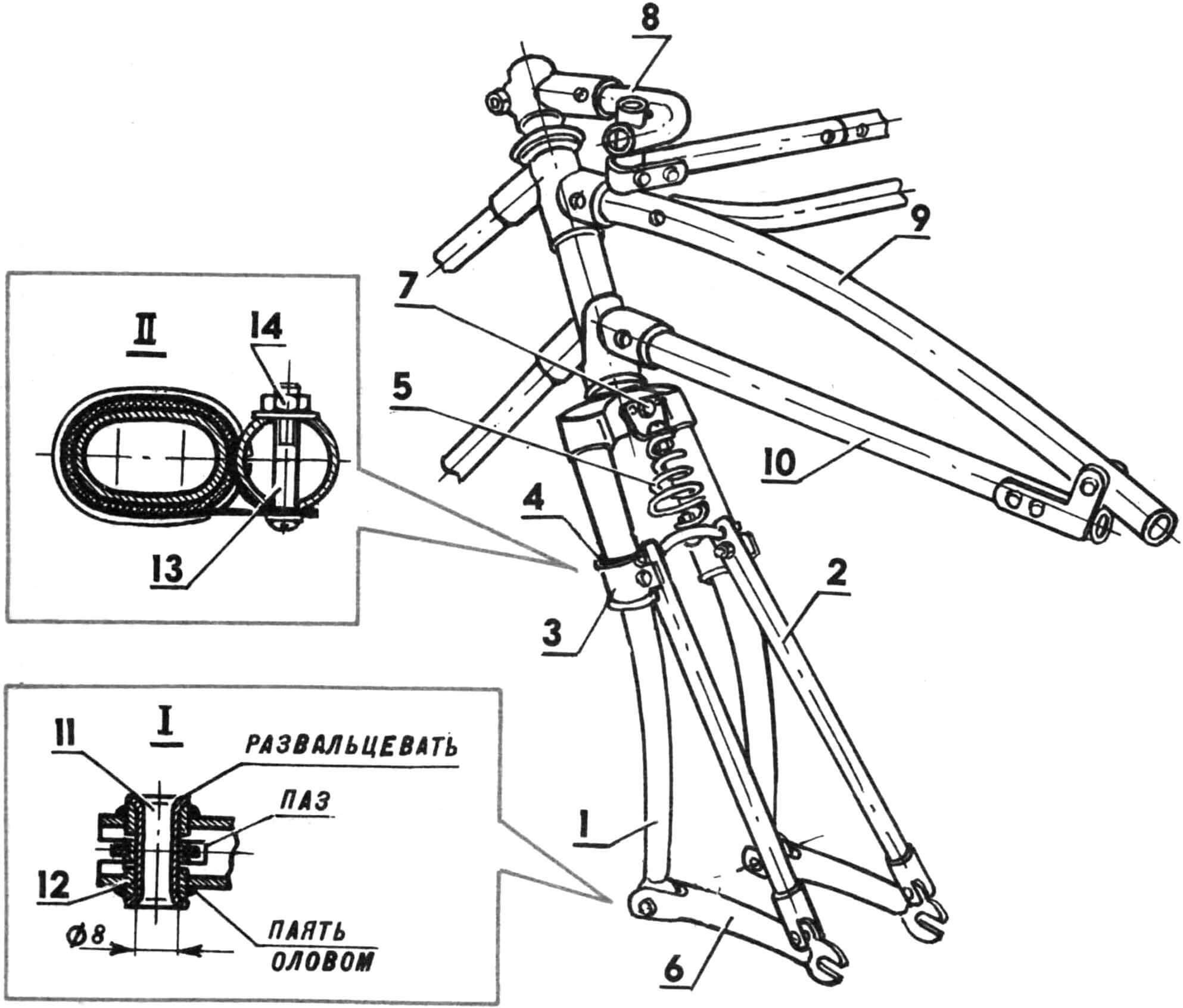

1 – supporting body, 2 – first stage of chain transmission, 3 – second stage of chain transmission, 4 – gear shift lever, 5 – double pedal, 6 – drive wheel, 7 – carriage assembly, 8 – rear light block, 9 – seats, 10 — headlights, 11 — chain tension mechanism (not shown in view A).

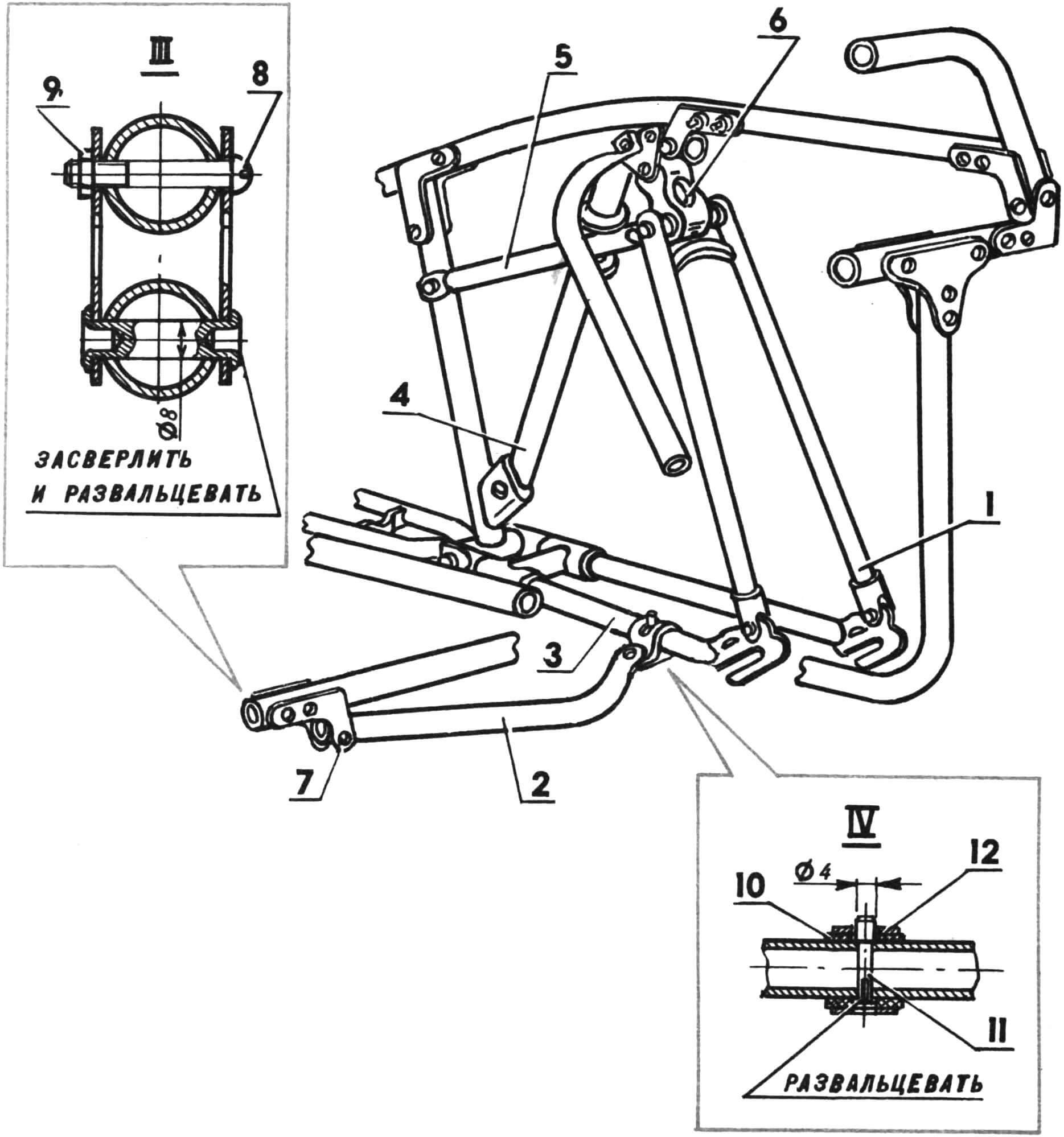

The supporting body of the velomobile has a frame made of duralumin tubes. The frame is based on two homemade bicycle frames connected to each other by transverse pipe ties. The Ø20 mm pipe passing in the area of the carriage units (let’s call it central) is gas and steel. Textolite bushings with an outer diameter equal to the inner diameter of the carriage units are put on it. All other ties are made from pipes from folding beds.

The frame is assembled with M5 screws using overlays and gussets. After assembly, the connections are wrapped in fabric glued with epoxy resin. The space between the pipes is filled with foam plastic and also covered with two layers of calico. The inside of the body is trimmed with leatherette on a paper basis. The seat frames are included in the power structure of the body. A nylon mesh is sewn to them. The seat position is adjusted to the height of the driver and passenger and is not adjustable.

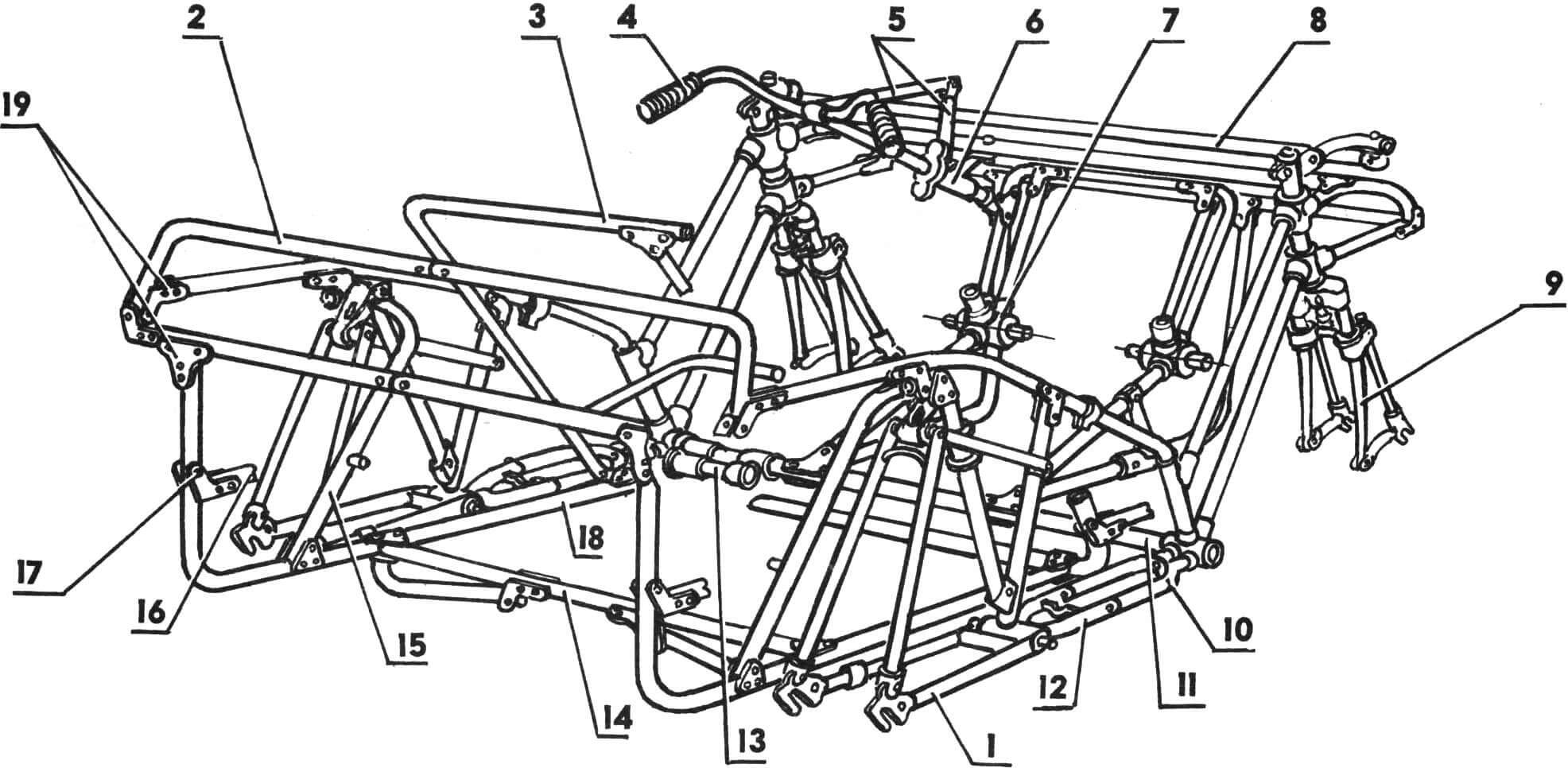

1 – rear suspension, 2 – transverse link, 3 – front seat frame, 4 – steering wheel, 5 – steering arms, 6 – steering wheel support, 7 – carriage assembly, 8 – steering rod, 9 – front suspension, 10 – frame assembly from bicycle “Schoolboy”, 11 – central pipe, 12 – part of the frame of the bicycle “Krokha”, 13 – intermediate shaft, 14 — lower rear cross member (pipe), 15 — strut, 16 — rear seat frame pipe, 17 — M5 screw, 18 — longitudinal pipe, 19 — lining.

The suspension of all wheels of the velomobile is independent. The front suspension assembly consists of a fork from a Shkolnik bicycle, rotated 180°. The upper fork is attached to it with clamps with polyvinyl chloride bushings, designed to transmit force to the spring and ensure rigidity of the suspension in the transverse direction. The lower ends of the stays of these forks are hingedly connected using levers. The axes of the hinge joints are copper tubes Ø 8 mm inserted into steel bushings. The springs are used from a road bike saddle. They are good because they have variable stiffness, which allows for a smooth ride of the velomobile under different loads. The maximum suspension travel is 50 mm.

1 – main fork, 2 – upper fork, 3 – clamp, 4 – polyvinyl chloride bushing, 5 – spring, 6 – lever, 7 – M6X50 mm screw, 8 – steering linkage lever, 9 – upper frame tube, 10 – strut, 11 – hinge axis, 12 – bushing, 13 – M5 screw, 14 – M5 nut.

1 – upper rear fork, 2 – wishbone – connection with the frame, 3 – lower rear fork, 4 – strut, 5 – rear suspension arm, 6 – shock absorber from a Eureka bicycle, 7 – axle, 8 – M5 screw, 9 – M5 nut, 10 – PVC bushing, 11 – pin, 12 – clamp.

Unlike the front, the rear suspension units are equipped with a rubber shock absorber from the Eureka bicycle. The lower fork is made similarly to a motorcycle one, but has a transverse link-lever with the body frame. The upper rear fork transfers force from the lower to the shock absorber. Rear suspension travel up to 20 mm; the hinge joints are the same as the front ones.

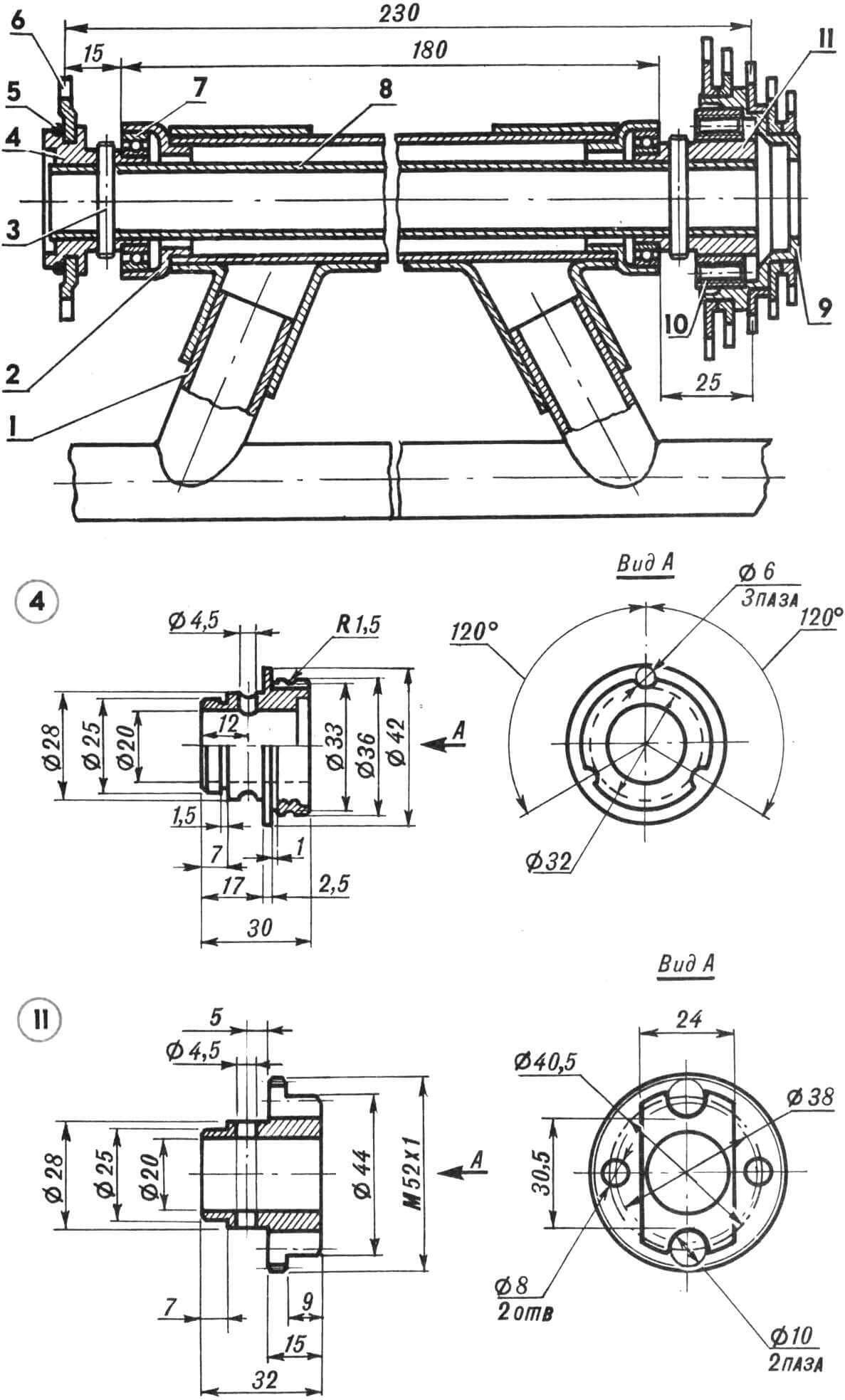

The velomobile’s transmission is a two-stage bicycle-type chain drive. The choice of this design is based on the use of standard parts. The drive is made on two separate carriage units with a common double pedal. This design allows the driver and passenger to work synchronously, which makes it possible to reduce peak loads per pedal for each person. The Z=48 sprocket from a road bike is used as a drive. It is made thinner, to match the chain from the “Tourist”. At one end of the intermediate shaft there are five sprockets from a sports bicycle with a number of teeth of 13, 15, 17, 19 and 21, and at the other there is a sprocket of the second stage of the chain drive. The gear ratio of the second stage is 1. The sprockets have 15 or 19 teeth.

1 – bracket, 2 – bearing housing, 3 – pin Ø 4.5 mm, 4 – bushing, 5 – spring ring, 6 – side gear sprocket, 7 – bearing, 8 – shaft (Ø 20 mm), 9 – sprocket block , 10 – cylindrical key with a threaded hole for pressing out, 11 – bushing.

The first stage of the chain drive is complemented by a gear shifter that operates similarly to a standard sports bike shifter. The functions of a “parallelogram” are performed by an axis 150 mm long. It moves in the bushings parallel to the central tube of the frame (together with the chain tension mechanism attached to it) using a cable drive and a compression spring. The second end of the cable is routed to the gear shift lever located between the front seats. In the chain tensioning mechanism, the function of rollers is performed by rolling bearings with an outer Ø 32 mm.

The steering linkage has universal joints, since to reduce the height of the front hood, the steering arm is made parallel to the road. When turning the wheels, the verticality of the steering joint axes is disrupted, while the cardan shafts ensure the movement and rotation of the axes in all planes. The force from the steering wheel is transmitted through two articulated levers. The hinges are made of copper tubes. The minimum turning radius is 3.5 m (following the track of the outer wheel).

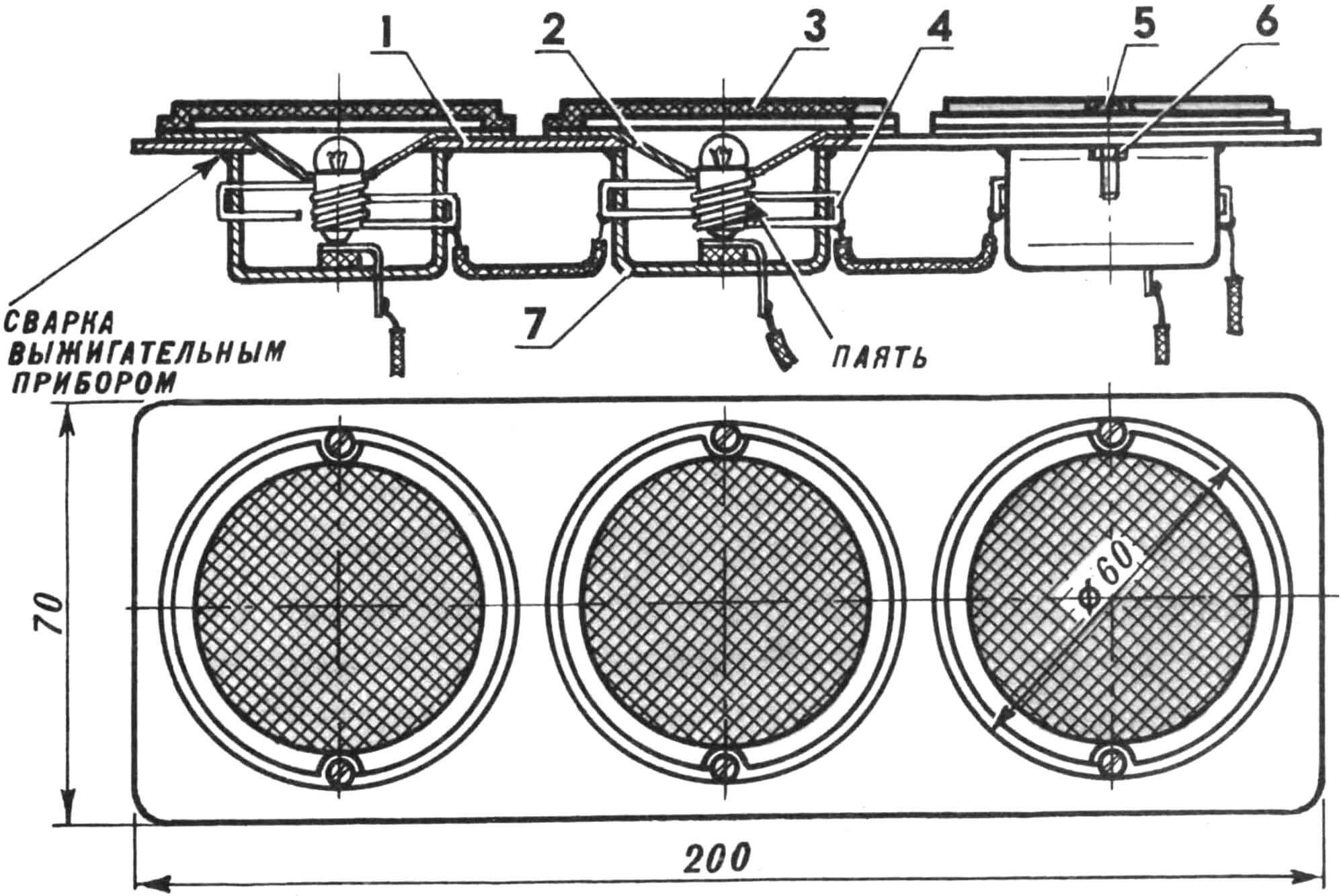

1 – base, 2 – reflector, 3 – reflector, 4 – lamp holder, 5 – M3 screw, 6 – M3 nut, 7 – casing (measuring spoon from Bona baby food).

For the rear light blocks, two yellow and four red reflectors from the Desna bicycle were used. They are secured with screws on a base consisting of a polyvinyl chloride rectangle, to which light bulb casings – plastic measuring spoons from Bona baby food – are welded. Lamp holders are made of copper wire. 3.5 V light bulbs are used. The velomobile is equipped with the Veloelectronics system, the headlights are powered by a bicycle generator.

“Troll” is planned to be equipped with a folding cap made of transparent film. Such a roof will allow you to take walks, business trips even in bad weather, and will make the velomobile an “all-weather” transport.

TECHNICAL CHARACTERISTICS OF THE VELOMOBILE

Weight, kg 48

Capacity, person: 2 adults and 2 children under 7 years old

Speed, km/h up to 25

Overall dimensions, mm 1980X1140X830

Base, mm 1450

Track, mm 970

Ground clearance, mm 100

A. EGOROV, engineer