The engine is mounted on a special subframe composed of a frame part of the old “Jupiter”, welded to two steel channels with a height of about 70 mm. To the sub-frame the engine is attached using standard fasteners, and the subframe to the vehicle frame through rubber cushions, as shown on the drawings. For mounting the subframe to the frame provides a reference platform, cut from steel sheet 4 mm thick and welded to the tubes of the frame.

Drive wheels, as already mentioned, two — stage chain drive and idler sprockets are arranged on intermediate shafts and on the housing double overrunning clutch. This design of the rear axle provides independent suspension without the use of labor-intensive and low-tech in terms of a handicraft workshop differential with cardan transmission (with a record low weight of the coupling).

Chain wheels — homemade, they are cut from steel sheet blanks with a thickness of 5 mm. their Manufacture was made by a well-known technique using a drill press, hacksaw and files. In the intermediate sprocket cut a hole the diameter of the housing freewheel, and then the sprocket was welded to it. The other two, side, sprocket welded were fixed to a steel sleeve having an internal keyway. A corresponding groove milled and intermediate shafts. Sprocket rear wheel of the motorcycle IZH.

Steering — motorized FDD. Lateral pull split, using steering lever — “triangle” the type of the car “Duet” Vologda designer Alexander Krylov (incidentally, much of “Yauza” is borrowed in the development of this constructor — the cars of small “Camel” (“M-K” No. 6 for 1987) and “Duet” (“M-K” № 8, 1990).

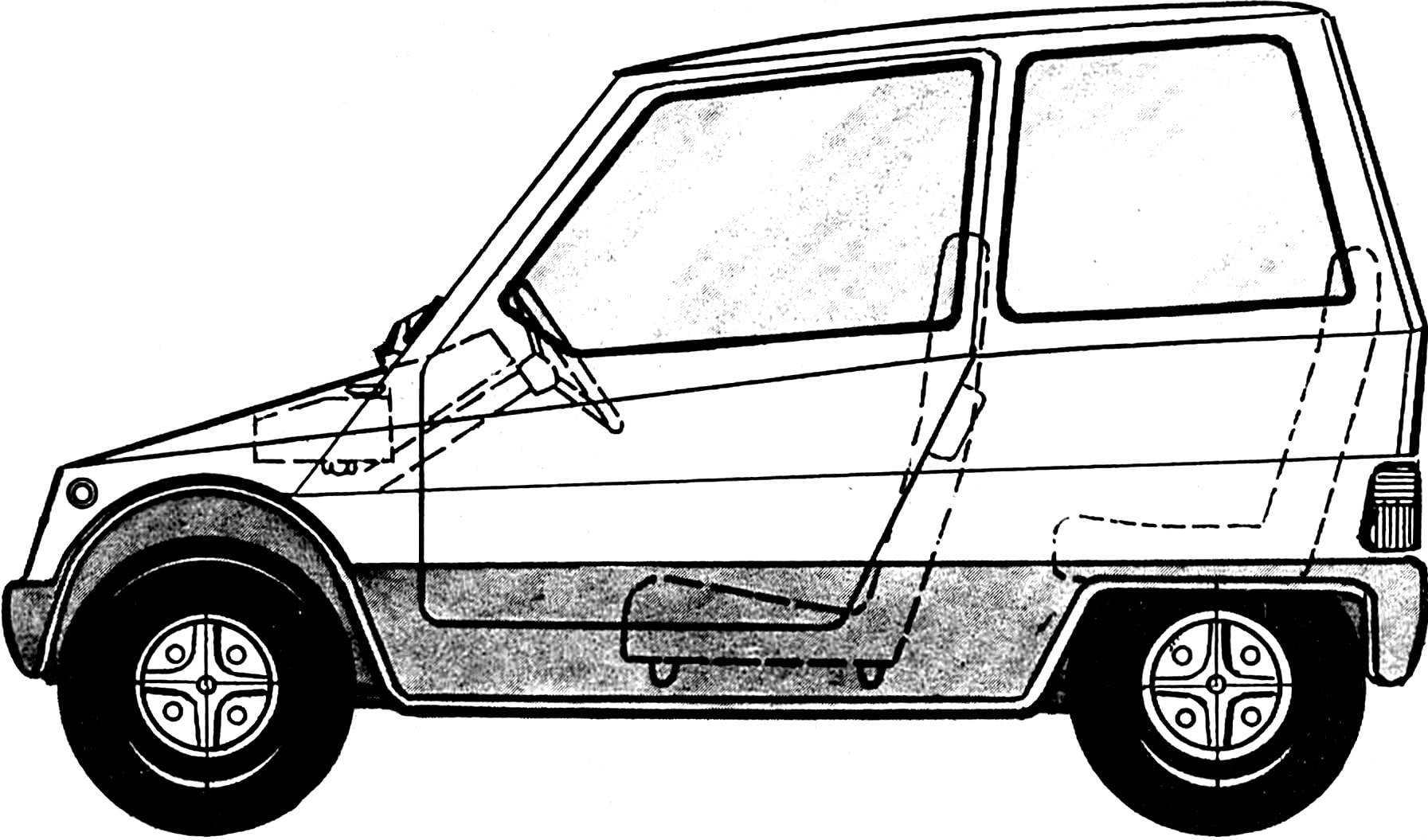

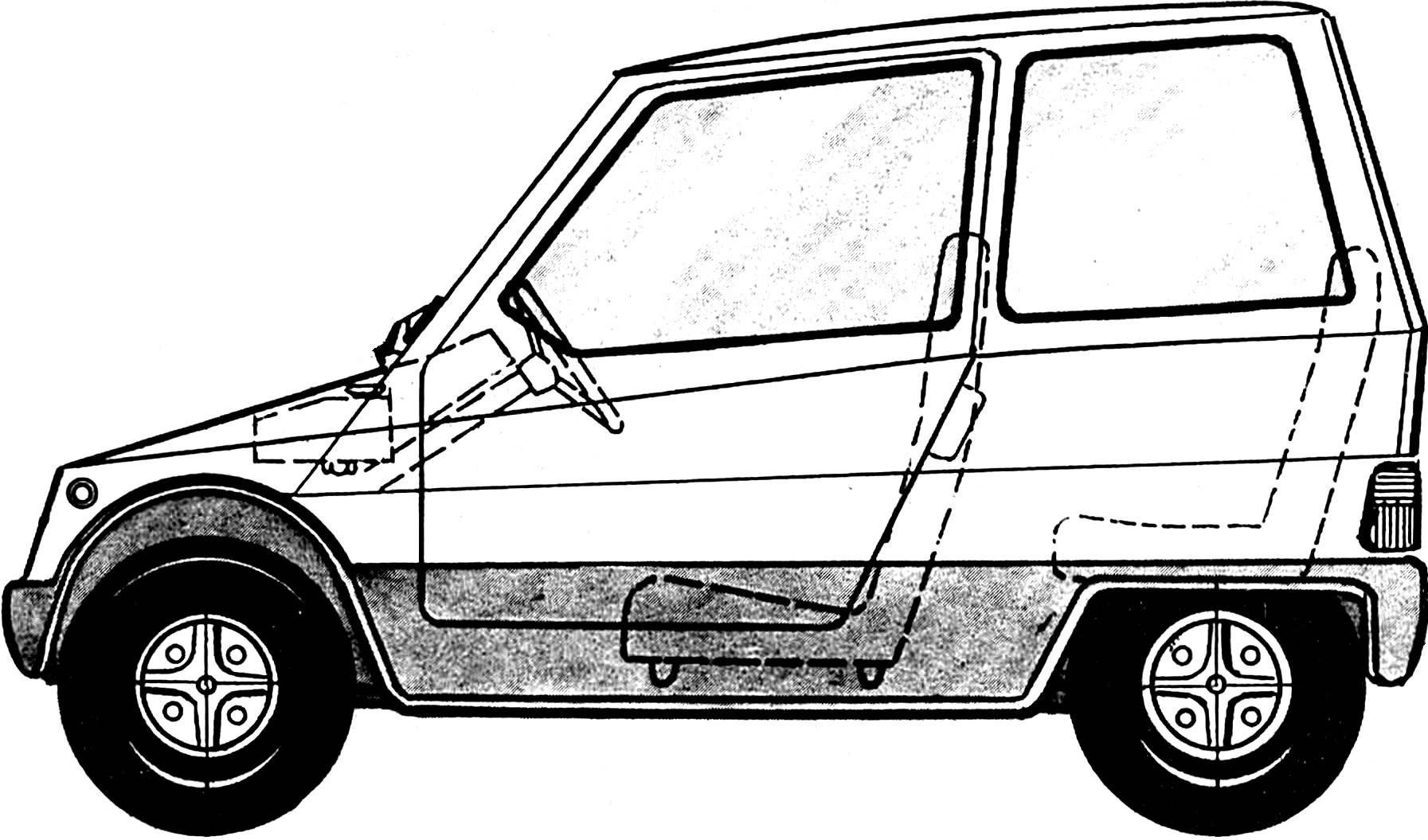

The body of the car “Yauza-035” — with a wooden frame and a covering of hardboard. Work on the production of the body starts with a drawing on a sheet of plywood Plaza in 1:1 scale. Further along the Plaza cut blanks for frames and stringers. Note that the Central frame is glued of five wooden bars and is reinforced inside with plywood gussets.

The door frame is also wood. Glazing doors and rear side and rear Windows of plexiglass. The glass doors tight and are not able to fall, however, the glass slotted round window, closed by a lid made of the same Plexiglas.

The surface of the body formed by the bar (single-curvature) surfaces, however, due to the rather spectacular form the corpus of “Yauza-035” does not seem simplistic, primitive. The fact that the roof, side and bonnet consists of several sheets of hardboard, attached to the frame so that the impression of a single surface with the punch to increase the rigidity. Each of the shell elements is a ruled surface, but the whole lining has the form of a shell with double curvature.

Fig. 5. The body of the car “Yauza-035”:

1 — the elements of the frame of the wheel housing (plywood 20 mm thick), 2, 13 and 14 elements of the front frame (wooden slats with a thickness of 25 mm), 3 — a bridge (rail section 25X40 mm), 4 — bar base body (section 40X40 mm), 5, 11 — elements of the rear bulkhead (wooden slats with a thickness of 25 mm), 6 — longitudinal set of a body (the wooden slats with a thickness of 26 mm), 7 longitudinal side roof elements (Reiki 25X40 mm) 8 — stringers of the roof (slats with 25 mm thick), 9 — roof (strips of hardboard with a thickness of 4…5 mm), 10 — crossmember rear (3 PCs., strips with a thickness of 25 mm), 12 — Central frame (wikiepedia of slats 30X40 mm and plywood), 15, 16 and 17 covering the wheel housing and matousek (plywood thickness 6…8 mm), 18 — trim sides and rear of the body (hardboard thickness 4…5 mm).

As it is, easy to understand, for example, forming the roof. To start, cut two strips of hardboard and they are stuck as shown in the figure, zone B. Further cut the workpiece to the plating zone G and carefully fitted to the frame. Especially pay attention to the fit of the joints with strips of hardboard. The bracket cover small screws and epoxy glue. Also adjusted the strip of hardboard to the Central area of the roof (area B). After mounting the strips of covering in the places of their connections using the epoxy putty is the fillet — the fillet.

Similarly, sheathed the sides and hood. Note that before covering sidewalls of the door is temporarily fixed in the apertures by means of clamps or screws and are integral with the sidewalls. After curing of the resin sheathing between the frame of door the “box” is cut from the inside with a hacksaw, fine teeth. Together with body is sheathed with hardboard and frame of the folding hood of the alligator type, and then in the same way as doors, cut off from the body.

Lined with hardboard, body vysalivaniya, vyshkurivaetsya and glued by one layer of fiberglass in epoxy resin. Then its surface is sanded, primed and painted synthetic (e.g., alkyd) enamels three to four passes with intermediate podsalivanii and Vykurovanie.

Inside the body is glued with strips of packing or construction foam, significantly reducing the noise level in the cabin. Then the foam is aligned to the height of the stringers and glued artificial skin. The inner surface of the door is also filled with foam, then stitched laminate and glued artificial skin.

As the instrument panel it is best to use the power of the motorcycle “IZH-Ю4” containing the ignition switch, speedometer, and warning lamps “neutral” transmission, turn signal, ignition and headlight. Installation this unit is easy to produce in a convenient for the driver area on the panel.

Seat drivers, passenger, and rear (children) sofa — homemade. They are all lightweight tubular frames (from dural pipes Ø 22 mm), covered with nylon cord. Over the cord glued to the foam and then trimmed seat upholstery fabrics.

A few words about the car controls. As you know, a motorcycle engine (including the “IZH-Ю4”) is equipped with a foot kick-starter foot switch gear box, and also has the control cables throttle of the carburettor and fuel corrector and linkage mechanism. All this had to be converted into inherent cars combination of pedals and levers.

Clutch left cable, however, connects it with the pedal, located under the left foot of the driver. Under the right foot pedal is the throttle actuator carburetor (the accelerator), connected by a cable in budenovskoy shell with a carburetor. On the right side of the driver’s seat — gear lever, the connecting rod with a cropped regular pedal shifter engine. Manual lever transmission gear can only move forward and back. Thus from neutral forward turns on the first transmission; the consequent movement of lever back include second, third and fourth gear.

The engine shall be started kick-starter, however, instead of the regular starting pedal shaft is fixed a steel pulley, around which is spanned by two round nylon cord. One of the ends of the cord secured to the pulley, and the second launched under the dashboard and secured to a convenient textolite handle. Motor starting is a dramatic breakthrough for her, after that she is keen on a return spring trigger device under the dashboard.

Interior floor is made of plywood 12 mm thick, impregnated with hot linseed oil (by the way, the same is processed from the inside, all wood and ergalieva of the body), and then — Movil. Between the seats the driver and passenger constructed of trapezoidal cross-section of a box, inside of which passes the drive chain.

And the last one. Engine cooling inputs to directly affect is exactly the same as on the motorcycle, the counter flow of air, especially hot are the cylinders directly behind the intake grille. Indeed, motion does not occur overheating of the motor, however, in the absence of airflow (for example, the long stops at traffic lights, in traffic jams, with a strong tail wind) the temperature increases rapidly, there is a risk of jamming of the pistons in the cylinders. To avoid this, in the engine compartment is the blower motor — dural impeller fixed on the shaft of the motor from wiper motorized FDD. His power is enough in critical situations to provide cooling.

Technical characteristics of the car “Yauza- 0 35″

Dimensions (mm):

length……2520

width…..1320

height……1430

Base (mm): 1800

Track (mm): 1100

Ground clearance (mm): 170

Lots of little micro-car (kg):

dry……400

full……620

Maximum speed (km/h): 80

Engine: IZH-Ю4

Engine power (HP): 27

The transmission from the engine: chain, two-stage

Front suspension — independent, semi-trailing arm with shock absorbers “IZH-Ю4”

Rear suspension — independent, longitudinally swinging control arms with shock absorbers “IZH-Ю4”

Fuel tank capacity (l): 18

YAROSHEVICH M., engineer, Minsk

“I intend to build a car for wide use. It will be large enough so that it will fit the whole family, but small enough that one person could operate it. It is made of best material and designed in the simplest methods possible in modern technology. Despite this, its price will be so low that every person receiving decent content will be able to buy a car to enjoy with your family, relax in the open fresh air.”

“I intend to build a car for wide use. It will be large enough so that it will fit the whole family, but small enough that one person could operate it. It is made of best material and designed in the simplest methods possible in modern technology. Despite this, its price will be so low that every person receiving decent content will be able to buy a car to enjoy with your family, relax in the open fresh air.”