It is not difficult to do even the novice hobbyist. And materials needed for this available.

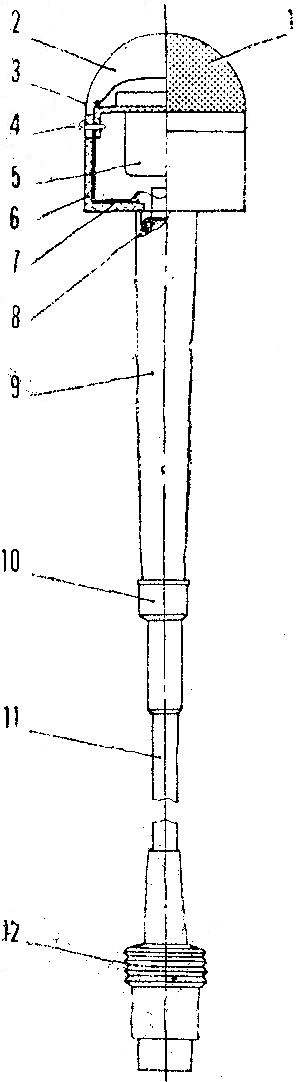

It is not difficult to do even the novice hobbyist. And materials needed for this available. The basis of design — a primer of domestic microphone MD-47. The device consists of a body, handle, cover, rubber sleeves. With amplifier microphone connect a shielded two-wire cable and standardised plug SSHZ.

The body is made of cylindrical packaging from photoprojects up-2 Lviv factory “Reagent”. The microphone capsule is glued to the bulkhead separating the package into two compartments. At the base of the bulkhead and drill hole for cable and air. The membrane of the capsule is closed with silk (it is bonded to the partition).

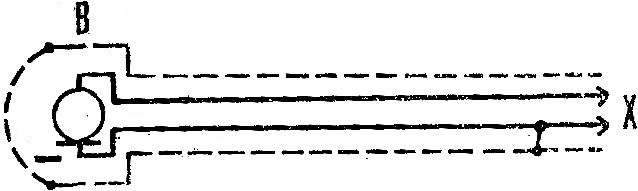

Fig. 1. Microphone design:

1 — mesh, 2 — silk, 3 — baffle, 4 — screw M1,5, 5 — microphone capsule, 6 — housing, 7 — screen, 8 bandage of thread, 9 — stick, 10 cuff, 11 cable, 12 — plug SSHZ.

For decorative mesh is used a tea strainer with a minimum of cells. It is attached to the body with two screws M1,5. The holder serves as a foot from the TV “the ruby”. It is glued to the bottom of the box. Rubber safety cuff — burnt from soldering iron SPE-25. The cable in the housing of the microphone is fastened a brace of threads.

To reduce the background and interference, the microphone capsule shield the glass from permalloy tape, and soldered the braided cable. To it connect and decorative mesh. “Ground” the core of the cable is connected to the braid at the connector. Diagram of the microphone in figure 2.

Fig. 2. The electrical circuit of the microphone.

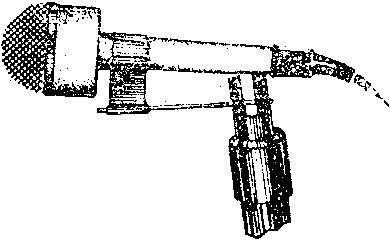

Fig. 3. Mount the microphone.

At the front the microphone can be installed in different ways. One of the ways shown in figure 3.

V. CHUDNOVSKY, G. Odessa