The Modeler, working with paper, it is advisable to understand that a paper like material not only speeds up the process of creating the model and reduces its complexity compared to traditional materials. The material is valuable. The viewer looking at the finished model, mentally or aloud says: “that’s it… out of paper?!1′ the Inclusion of metal and wooden parts immediately turns the paper into a cheap substitute.

For this reason, it is not recommended to rely on the disguise of Assembly defects color, especially the underwater part of the ship. The feel of paper, not only forgiving, but making a kind of dignity some grantest the surface will disappear after the first layer of paint, but to get a really smooth surface is possible only as a result of multiple putties and polishes.

The only exception is the desirability, and even the need to touch-up the ends of the cut out parts with a color of their main surface. It is best suited for this purpose markers.

The model can be done with underwater part and the waterline. Both options have their advantages, the Implementation of the underwater part requires special care and technical skills, but if any here can show you the possibilities of paper as material modeling.

The performance of the model without the underwater part at the waterline, greatly facilitates the Assembly process. In addition, the ship appears to us. as we could see him in reality on the surface of the water.

Legend:

Part numbers are always in rectangular frame, Room no frame marks the spot, which is glued to the item with that number. In the parts kit, splice, with the help of slots, marking the inserted part near the slot.

The letters “R” and “L”‘, complementary to the numerical designation, refer to the membership details accordingly to the right (R) or left side (L). Such items always have a pair

The letter “W indicates a section that should be cut from the part without disturbing its external contour. As a rule, it is easier to do in the first place, before the separation of the part from the sheet.

The asterisk (*), complementary numerical designation, means that the item has accurate dimensions and after mounting, the excess should be cut.

Any bend parts are preferably pre-notched where needed to be done with high precision, the set dash-notch length of 1 mm. mandatory such notches, as well as stroke the rear side supplied with double-sided detail.

Stage 1 Assembly

Straightening the paper clip to disassemble the booklet on the leaves. Divide the sheets in bending place

The sheets with the numbers 1.3, and in case of model creation with an underwater part, and the sheet 2 be pasted on cardboard with a thickness of 1 mm

In the case of use of water-based glue of the PVA should pay special attention to the prevention of deformation of sheets: the adhesive is applied only to the cardboard, glued a pair of cardboard-the paper is immediately sent to the press and kept there until complete disappearance of the feeling of dampness.

From details 001-002 glued the waterline Bonding is performed back to back with the seam reinforcement strips of thin paper. The grey strip on the glue sets 003-012 frames In their slots are inserted into the nasal lump and areas diametrical plane 013 and 014 and stick to the waterline at the contact followed by a longitudinal connection 015 All details should enter into each other with a very light force, the frames remain vertical, but the waterline is flat and tight to the surface, for example, of the table.

Then mounted the lower deck 020. It has details 021-024

Upper deck 025-027 glued butt joint with reinforcement paper strip from the bottom, and then after drying, the seams under pressure is attached to the ends of the frames and longitudinal ties.

Stage 2 build (to create the model without the underwater part -skip)

From the bottom to the waterline just below the surface are bonded underwater parts of frames 050-059.

Immediately after installation, the frames should be assembled keel frame 060-062 (from. extremities to the midsection) and the longitudinal relations 063-065 In places of their contact with the waterline – stick.

Before complete drying, it is important to control the Assembly. The line of the keel should be perfectly straight (but not parallel to the waterline), frames perpendicular to the waterline.

Stage 3 build (to create the model without the underwater part – skip)

Cut out detail trim 130-139. to paint their faces with a red marker and give the necessary form, you Can also paint the ends of the frames are acrylic or gouache paint. The cladding lead in numerical order from the midsection to the extremities

At this stage, it is also desirable to make the stand (details 166-170) and painted it with dark paint.

Small parts on the lower deck it is advisable to start with the mounting facing the outside of the branches of the frames 109. The installation of the other parts at this stage is clear from the graphic part of the user

5 the build stage (when the model is created without the underwater part – skip)

The screws and the wheel that shut down underwater part requires the utmost care and thoroughness of execution. Details 074-076 must have a cross-section of lenticular shape of the Front and rear sides of the paddle blades can simply be glued together, and you can also give them volume, carved arched front side, gluing along the contour to a flat rear side and then cutting along the contour.

6 build stage

Plating freeboard 150-155 is in the order of numbering and can cause problems only in the aft in case of inaccurate execution frames.

At this stage, the glue line 165″, plating, sponsons 156-159, 160 aft balcony. In addition, you need to close portions of the open end of the cardboard around the perimeter of the openings in the upper deck part 149*

A large number of parts that are assembled and mounted on this stage, almost needs no comment. The numbers stamped on the deck (with balanced nodes only along the right side) and the graphical part of the user is sufficient to accurately detect the nature and location of each node.

Chimneys are a combination of two cylinders, the alignment of which is achieved by inserts 376, glued to the inner cylinder (painted black inside) logging first glued the outer cylinder, and inside it is inserted into already assembled combination of the other components 1-I pipe has the sides flat areas, which is achieved by gluing to the inner cylinder of cardboard plates 377 and gluing them to the outer cylinder

Before laying the pipe, it is desirable to pierce the holes for the stretch. The ends of all black color handle black marker, the inner surface of the pipe to be painted black with gouache or acrylic, the inner surface deflecto red.

Relingowe the fence, sometimes there are small tarp, first cut, and then glued together. Its outer side is 0.5 mm more than internal This over the fence and is fixed on the basis of

Details of the mast – stingi, Rhea. the gaff, (all. except masts) have V-shaped cross-section and require very careful bending, and the black steggy – touch-up the ends and back side.

8 build stage

Manufacturer of boats starts with the installation of the strip 390 on the casing (image plating boat inside!). Bending the strip 390 in half, begin to glue it outside to Board the boat from bow to stern When he reached the cut, bent the casing so that the slit disappeared, and I. continuing to glue the strip 390. fix this position. The challenge is to repeat this procedure for the other side for the other boat, creating the same curvature.

Further the process of assembling the boats in the diagram and the complexity is not.

9 the build stage

Rigging is the last stage of the model. The stays and shrouds of each mast, it is better to pull simultaneously in order to prevent its distortion.

Relingowe fence is created with the help of the conductor being assembled from parts z01 and z02. After the tension of the thread impregnated with varnish or glue (e.g., PVA liquid). and after it dries cut and assembled on the main deck, forecastle deck, searchlight platform and outboard ladder.

We wish You a successful Assembly and enjoyment of the result.

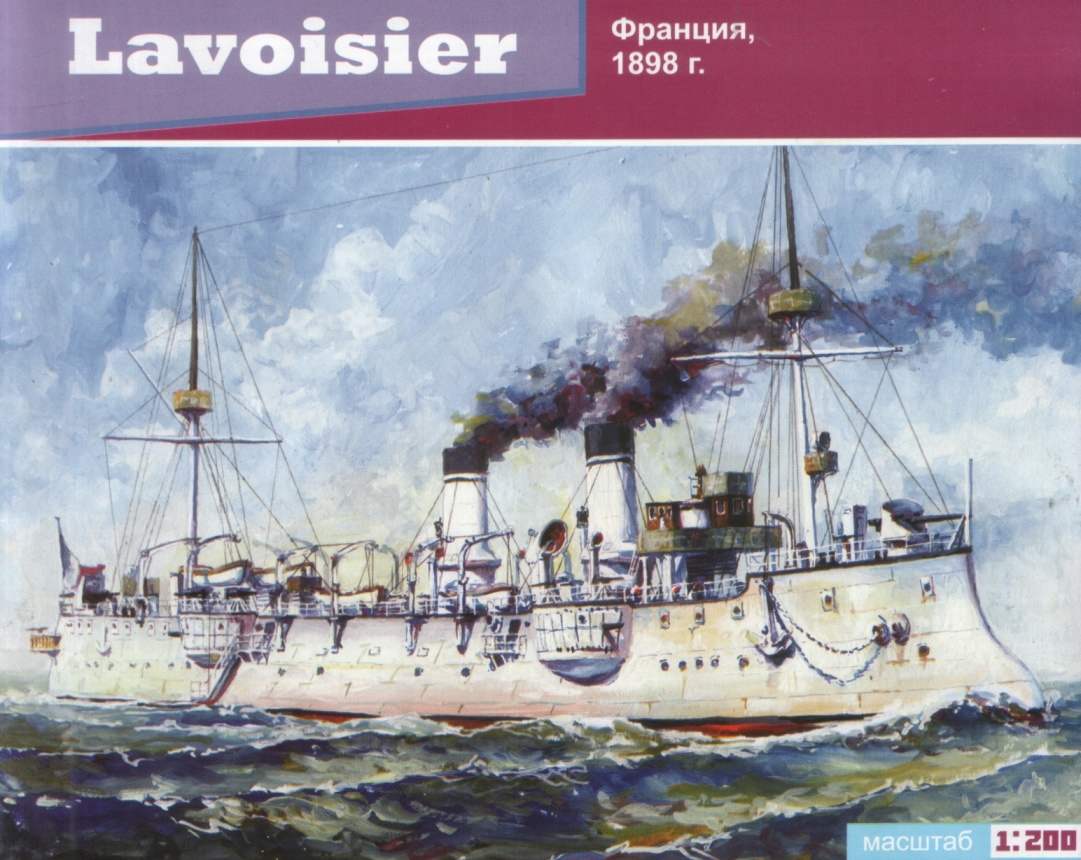

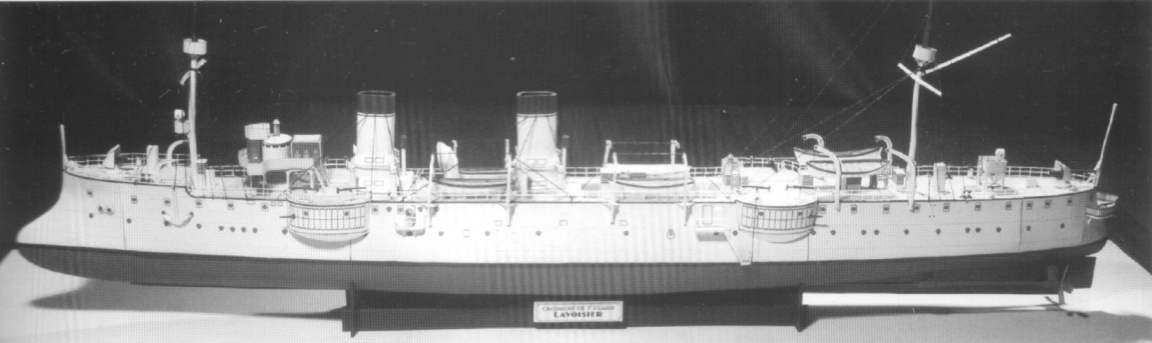

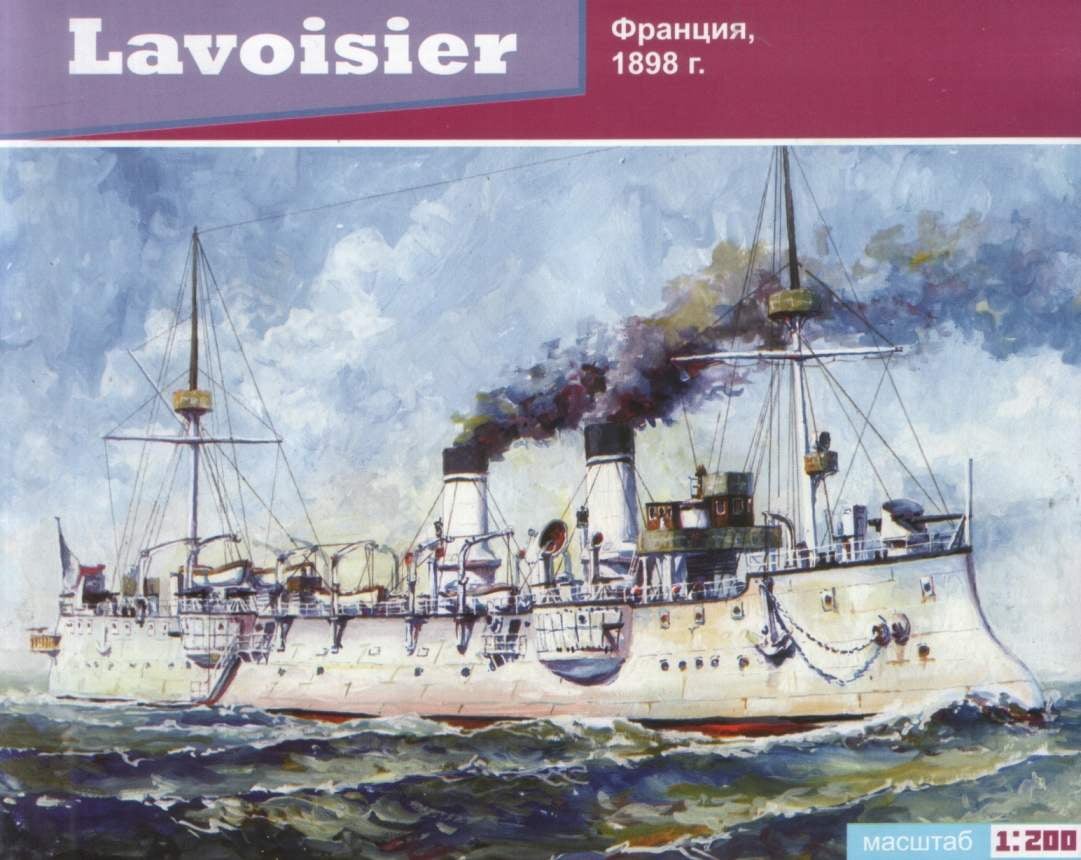

The materials to build a model of the CRUISER 3-CLASS LAVOISER (download )

Recommend to read AST WATER HEATING IN THE SAUNA To obtain hot water in a bathhouse, a tank-register on the stove pipe (or a boiler in the stove itself) and an external tank in the washroom are often used. Water circulation between them... TRIPOD FOR MACRO PHOTOGRAPHY During normal photographing miniature objects - be it coins, insects, or drops of dew on the grass - is the involuntary trembling of the hands, especially with long exposures: they...