Cut “petals” are placed in the water, using a saucer or tray. After wetting take out and put the “petal” on the paper, soak it on the mandrel and smooth with your fingers. So put one layer. The width of the sticker one “petal” on the other 3-5 mm. Giving a little dry one layer and put glue on the rest of the mandrel for drying the battery.

After drying of the processed workpieces obtained their seams with a file to remove bumps. Next, hold each in the lathe Chuck and centres. At low speed (70 – 100 rpm) sharpened cutter the workpiece to the desired size and vasculum. If there are irregularities – shpaklyuem and re-processed. Then covered with two layers of paint, bright colors, mark up the location of the riveted joints and rolled (the gear of the clock in increments of 1.2 — 1.5 mm) simulated them. To use gear with smaller increments does not make sense. Further painting parts of these seams will become numb paint and the desired effect will not work.

Having allowed to dry out paint, billet torches to the desired size – the bottom – up to 145 mm, top – to 156 mm. the latter is cut into two parts: the nose – length of 72 mm and ogive -84 mm. In future, the cut will be a plane of separation model. After this operation, the workpiece is lightly heated, and holding the mandrel in the machine, remove the part.

The next stage – making the Central body of the model. Its glued together on a mandrel with a diameter of 65 mm of the three layers of paper “patronka”. Its thickness is 0.3 mm. can Still recommend the wrapping paper. It is light brown, it is Packed with books in printing houses. When gluing, apply glue Stolyar, adding a little water in it. After drying, the workpiece is processed by sand paper and pasted over with a layer of paper, after inflicting on her markings riveted joints known knurling. On a lathe torches to size – 294 mm.

Fairing length 77 mm machined from basswood on a lathe, slightly ease inside and covered with two layers of nitrocellulose lacquer. In the upper part of the insert tip with a length of 23.4 mm, made of fiberglass, and the bottom (wide) part protecive small “skirt” width 5 – 6 mm and insert fairing in the bow of the hull. Then at the bottom fasten the coupling boss, made of basswood.

In the ogive portion of the housing length 84 mm inside the insert, two coupling sleeves. One (top) with a diameter of 53 mm is used for coupling lugs of the head fairing, or rather for the connection of the entire head portion with the body. The other (bottom) with a diameter of 65 mm and a width of 20 mm for bonding with a cylindrical portion of the housing. The exact same bushing used to connect the lower end of the body with the tail section.

U-models R-2 – a large length of the housing, and to improve its stiffness applied three frame and tube-ognevoj. Frames thickness 4 – 5 mm is made of balsa plywood of veneer thickness of 1 mm. Inside, they drilled the hole for the tubular ognevoj, which is glued on a mandrel with a diameter of 20.5 mm. Lower frame -clip – has a thickness of 7 mm.

The order of Assembly of a model like this. In the rear compartment insert two bulkhead: bottom 7 mm, and the upper edge – of a thickness of 5 mm and the splice sleeve. They fixed up ognevoj. Then he “put” two frames (see figure 3) and fasten the housing with inserted connecting sleeve.

Stabilizers cut balsa veneer with a thickness of 4 – 5mm and akantovye at the edges with strips of basswood the same thickness. After that, three adhesive dots to be connected in a package and processed according to the loop. Then dismantle the package, give the profile of each stabilizer and pasted over writing paper with printed markings riveted seams. Cover them with nitro lacquer and primed with paint of bright colors. Processing the convex side, driven by each stabilizer to the tail compartment. The attachment reinforcing paper strips, mimicking the fairings of the rocket prototype.

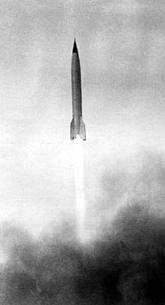

Ballistic missile long-range R-2 (product 8Ж38)

Model-a copy of the R-2:

1 – tip; 2 – heat shield; 3 – the bow of the hull; 4 – lug (connection); 5 – connecting bushing; 6 – end cap bosses; 7 – ogive part of the (upper) housing; 8 – strand suspension parachute – FAL; 9 – chute; 10 – connecting bushing; 11 – body; 12 – frame; 13 – tube-ognevoj; 14 – bulkhead (centering); 15 – the stabilizer; 16 – steering wheel; 17 – gas wheel; 18-MRD

Mandrel for the manufacture of elements of the shell model of the R-2:

I – for the bow; II – for housing; III tail section

After assembling the whole model conduct a “filling” of the outer surface of all outer elements (manholes, pads, etc.), and on the inside, fasten the thread (halyards) to connect the parts of the copy with recovery system – parachutes. In this model there are two. One with a diameter of 400 mm for the salvation of the head portion, the second diameter of 500 mm for the salvation of the main body.

Assembled model lightly sanded. If there are irregularities, roughness is eliminated. Paint the model according to the available documentation (photographs).

Flight weight-models R-2 and about 180 g. it Starts the engine 10-10-3 MRD or MRD 20-10-4 with a special starting installation.

V. ROZHKOV

Model-a copy of the ballistic missile R-2

Model-a copy of the ballistic missile R-2