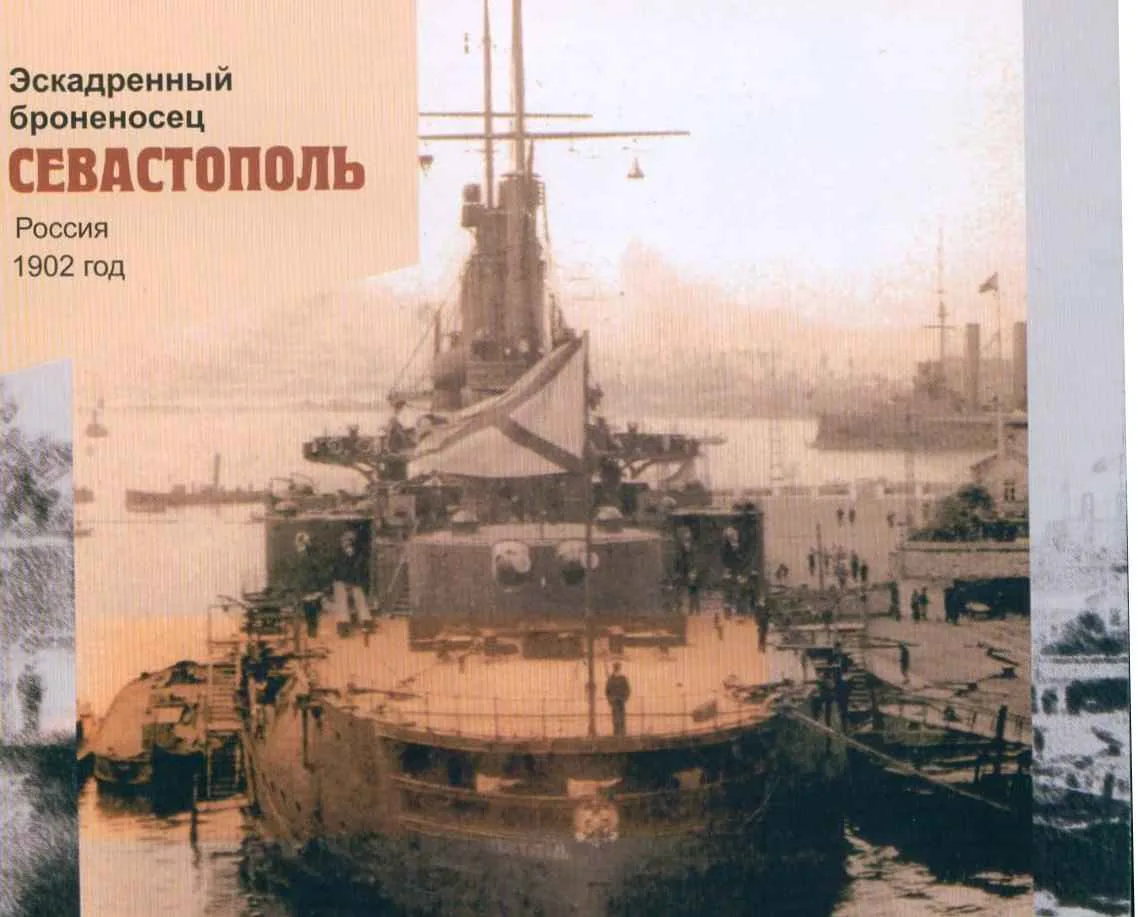

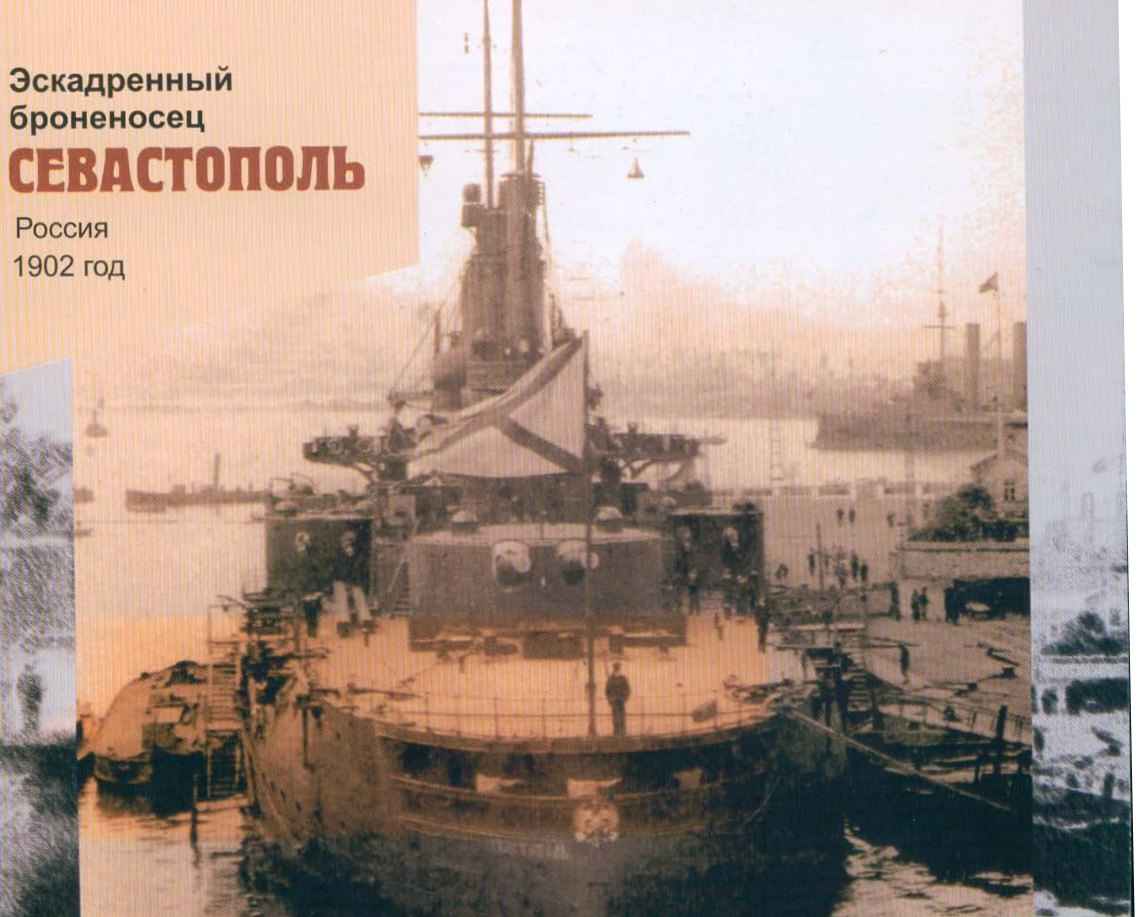

THE SQUADRON BRONENOSEC SEVASTOPOL. Scale model 1:200.

THE SQUADRON BRONENOSEC SEVASTOPOL. Scale model 1:200.

A plan to strengthen the Baltic fleet in 1891-1895 he was provided, among others, the construction of five armored ships seaworthy. The experience of the leading naval powers persuaded the Russian government of the need for a strong Navy, able to operate in open seas. Its basis was supposed to be armadillos, named according to the classification 1892 squadron.

In November 1890 the Manager of the Marine Ministry Vice-Admiral N. M. Chikhachev was ordered to work in MTK sketches of battleships of the first and second classes. For the prototype ship of the first class were encouraged to take “Emperor Nicholas I”, by increasing the displacement up to 10,500 t and installing aft, “if you let the weight”, the second tower of the main fire. Required combination of seaworthiness “Nicholas I”, artillery, booking and speed (17 km) of the British battleship “San Pareil”; the cruising range was set at 7 thousand miles, the deepening was limited to 7.9 m and width of body width of Constantine the dock in Kronstadt. As a prototype of a battleship of the second class with a displacement of 8,400 tons (future “Sisoy Great”) N.M. Chikhachev suggested the battleship “Gangut”.

In January 1891 the first draft design of the battleship, developed in the drawing of the MTC. received approval at the meeting of the admirals. Made on the basis of preliminary design theoretical and practical drawings, and the model presented to Alexander III, who “deigned not to make any comments against this project.” The normal design displacement 10960 t consists of the following articles load: case 3862 t (35,2%), booking 2997 (27,4%), weapons 1131 (10,3), mechanisms 1640 (15), the normal fuel capacity 900 (8,2), crew and supply 420 (3,8), stock displacement 10 t (0,1%). Placement of coal provided even on a residential deck, which increased the fuel capacity to 1310 T. But in this case, the estimated cruising range of economic speed (10 KTS) was significantly less specified and not exceed 5600 miles. The maximum length and width were, respectively, of 114.3 and 21.3, the normal sediment nose – 7.62 and stern – of 7.93 m.

The project involved four 305-mm guns, 35 calibres in two and eight 203-mm in four towers, ten 47 – and eight 37-mm guns. The location of towers on medium caliber and aft could shoot two 305 – and four 203-mm guns. Mine armament consisted of six 381-mm mine machines (four surface, two traps) and 50 min. boom. A vital part of the ship was protected by armor thickness as possible, able to withstand the shells of Minich opoly Topshina main bonavigo belt height 2.3 m

offices accounted for 406 and forth (bow and stern) 305 mm. of the longitudinal of the fire was protected at the ends of the armor belt bow (229 mm) and aft (203) traverse, from which the extremities were carapana deck (64 – 76 mm). On top of the waist armor was 51 mm armour deck and 127-mm casemate (height 2.3 m) with traverse; vertical armor of the towers of the main caliber and pipe the filing of the charges was 254, and medium caliber -127 mm. When choosing the power mechanisms focused on the black sea battleship “Georgy Pobedonosets” -10600 HP at natural draft.

After approval of the detailed specification of employees of the towing tank, the Denny in Dumbarton (England) has received an order for test models developed in MTK theoretical design. Held in September 1891, the tests showed that when the chosen capacity mechanisms battleship will be able to develop only 16 uz. N. M. Chikhachev ordered the contours to change and begin the breakdown of the hull at the Plaza on the already developed project. In this situation once again confirmed the necessity of its own towing tank, which at that time was being built. In February 1892 in a newly built stone boathouse New Admiralty began construction of “Poltava”. Elling (internal dimensions 125×26,8×21,6 m) was created specifically for the construction of battleships with a displacement of up to 14 thousand tons In March at the shipyard “Galerny Islet” began construction the same type of “Petropavlovsk” (the new stone shed) and Sevastopol (in the old large wooden shed), and 7 held their official bookmark.

Insufficient production capacities of domestic plants for the production of marine engines has forced the Marine Department to order arrangements for the first two ironclads in England. Contracts with firms “hamfris Tenant” and “Hawthorne Leslie” concluded respectively on February 29 and September 3, 1892, provided for the fabrication and erection of machine and boiler plants “Poltava” (1,27 million roubles) and “Petropavlovsk” (of 1.13) by October 1894, the composition of each installation weight 1570 t consisted of two vertical steam-engines triple expansion total display capacity of 10600 L. E., 14 agnetron boilers with a steam pressure of 8.8 al, desalination plants, two auxiliary boiler, propeller shafts, screws etc the Main mechanisms for Sevastopol, was to make Franco-Russian plant (contract dated 14 July 1892, 1.96 million RUB). From the mechanisms of the first two battleships they differed only in the number of boilers (16). In just built in St. Petersburg (December 1893) the first domestic pool testing tank are proposed (though not yet officially open) tested the model with a length of 4.35 m; the results of these tests were conducted close to the pool, Danny.

Launching of the “Poltava” and “Petropavlovsk” was held respectively on 25 and 28 October 1894, By the time the mechanisms are already delivered to St. Petersburg, however, the decrease in payment more than doubled (from 183 to 71 rubles per ton of displacement) led to a shortage of artisans and delay construction. After the descent of the “Petropavlovsk” work stopped for seven months artisans were transferred to the “Sevastopol” (launched 25 may 1895). Not without its oddities – the same mechanisms weight of machine foundations on the “Petropavlovsk” was twice more than in Poltava.

The project involved the installation storerelease armor, but in the late 80’s-early 90-ies abroad, she was widely replaced by solid steel and then studentlevel. In 1894-1895 the Izhora plant also started production of studentlevel armor, but the production of plates of the greatest thickness I. sized plant not yet mastered, so they had to order abroad. In the competition for the supply of armor took part English, French, German and American firms, preference is given to American “Betleem iron company.” 16 December 1894, the naval Ministry has signed her contract for the supply of 406-mm salenikovich plates armor belt “Petropavlovsk” and 368-mm Gruevski for Sevastopol; the use of armor, cemented by way of the American Garvey. reduced thickness and weight (50 tons) armor belt “Sevastopol” Interesting facts of this order have been preserved, the petition of the Russian naval agent (attache) in the United States, Etc .T. Mertvago in the name of performing the works of the chief GMS p. P. Tyrtov about the payment of the remuneration is $ 750 to a certain N. In. Maximov, a former Russian citizen, retired Lieutenant worked as clerk in the newspaper “new York Herald”. Betliemsky plant could not learn at what price the English company offered the armor of the Russian Maritime Ministry. Maximov, who had spent several months before this in England, knew – 80 f. tbsp. per ton, but reported that 60. The Americans slowed down by 15% and offered at $ 249 per ton. Thus, Betliemsky the plant supplied the Russian armor at the price twice smaller than for the U.S. Navy, and less noise in the Congress, adopted a resolution to reduce the price of bronhodilatirutm plants. Savings for the Navy Department amounted to 386 thousand RUB When Nicholas II was told about this, he Majesty commanded to give Maximov $ 750.

It was assumed that talenacademie plate for FC Poltava will put Izhora factory, but it soon became clear that the firm Krupp developed a new way of cementation and hardening armor, superior resistance geroevskoe. In proof by Krupp test plate shooting at a speed of projectiles a half times larger than it was intended to do by other firms (865 563 against m/s). In January 1896 for “Poltava” hull armor ordered the firm “Krupp”, and the tower and barbato (280 and 254 mm) main fire – company “Gelingen” (technology of Krupp); “Poltava” received the most advanced protection, besides 368-mm thickness.

The construction of battleships coincided with the adoption of the Russian Navy guns of a new type, differing from the former the greater length of the barrel, and hence the initial velocity of the shells. Changes to the project were the following: instead of 305-mm guns with a barrel length of 35 calibers mounted 40-caliber, eight 203-mm guns were replaced by twelve 152-mm guns, more rapid, mass production of the Obukhov plant started without working prototypes. The first test of the guns of the main caliber was held in may 1895, and in October there was a detachment of the ninth breech of the gun; after the necessary alterations, the work was resumed, but by early 1897 the battleships type “Poltava” never received a single gun. In the competition for the best project of the towers of the main caliber was attended by Russian factories – Metal. Putilov. and a number of foreign firms – Armstrong, “Whitworth”, “kayl”, “Paris”, “Kane”. “In view of the technical merits” of the project and lower cost preference is given to Metal works, which ordered the installation of “Poltava” and “Petropavlovsk”; “Sevastopol” they were instructed to make drawings Obukhov Metal plant.

After the death of the battleship “Gangut” there was a question about a more thorough testing of watertight bulkheads. At the initiative of Vice-Admiral S. O. Makarov in the navigation of 1897 on “Poltava”, “Petropavlovsk” and “Sevastopol” watertight bulkheads were first tested by water pressure to the level of the upper edges; boiler feed compartment was filled with water after installation of boilers, steam pipes, ventilation and other mechanisms. Stepan Osipovich noted “horrible complication” bilge system “Poltava” as a result of the introduction of a large number of watertight bulkheads. It happened that during the consideration of the drawings experts and Builder of the ship could not solve the question of the drainage of a compartment; I had to go into the hold and look all over the place. “If it is the construction of the vessel, wrote Makarov – what’s gonna happen when all the former during the construction of the face will be and when during the accident will have no time to lay out the drawings and collectively to discuss…”.

Completed all three ships in Kronstadt, however, the start of testing was delayed due to the lack of guns, turrets, armor. Firms – builders of machine and boiler plants waiting for the official acceptance mechanisms Finally 1895 21 Oct 1897 “Petropavlovsk” was released on a continuous 12-hour sample. The first car has developed a power less than the contract, and the selection Committee has postponed trials, limiting them to four runs on four mile measuring line; 14 Oct 1898 ship with a displacement of 10 890 t and indicator power machines 11213 HP showed an average rate of 16.38 bonds. Final testing of the machines “Poltava” 3 Sep 1898 due to the outbreak of the storm, the Commission has restricted nine hours (indicator 11 power L. E. 223, the average speed of 16 kt.) During the official tests of mechanisms of Sevastopol on 16 October 1899 at full speed and broke the steering actuator, and to return to Kronstadt had by maneuvering of machinery. Additional three-hour test on 11 July next year went well (11 a displacement of 249 m, the average speed of 16.41 km), however, instead of the required 10600 HP machine developed only 9368. For the shortage of power the contract provided for significant penalties, but only if it shows “George”, according to the drawings of which were built machines Sevastopol. In fact, it turned out that machines of this black sea battleship did not fulfill the contract capacity, and MTC did not require it and from Sevastopol.

When tested in the summer of 1898 artillery “Petropavlovsk” was discovered subsidence of the towers of the main fire. After reinforcement of the bases of the firing settings on the “Poltava” and “Petropavlovsk” was completed in August of the following year blagopoluchno. However, when volley firing full charges flew from the shaking glass deckhouses, skylights, lights, broken sinks, dishes, hundreds of light bulbs, broken doors and even damaged wooden bow decorations (the eagles); the same pattern povtorilas and when tested artillery

“Sevastopol” in July 1900, the selection Committee took this kind of damage to the “inevitable accident”; however, the chief Hukic V. P. Verkhovsky, turning to the MTC. did not agree with such statement:”… it is necessary and quite possibly, to the courts do not subject to destruction from its own firing.” Tests of the artillery of medium caliber has shown that the rate of 152 mm turret guns (two to three shots per minute) is less than that of the guns mounted on the battery deck. Rapid-fire small-caliber artillery in its final form consisted of twelve (“Petropavlovsk” -ten) 47-mm and twenty-eight 37-mm guns Combat Mars on the fore-mast with ten 37-mm guns in the late XIX century was already an anachronism, as well as a huge (6.5 t) Admiralty anchor, cleaning which the experience of navigation of 1897 required over an hour. “Poltava” and “Sevastopol” became the first karabali the Russian fleet with a stationary radio stations: selecting a location for the radio room and equipment deployment systems Popova – Ducrete zanimatsja in Kronstadt (end of September 1900) A. C. Popov personally.

5 Oct 1899 “Petropavlovsk” USA from Kronstadt to the far East to reinforce the Pacific squadron. The transition of the Bay of Biscay in stormy time of year has become a serious challenge. When moving against the wind (eight to nine bappo) and vapni a large quantity of water was taken at the tank, so I had to reduce speed to 5 KTS, it was noted a slight voshojdenie on the wave, smooth (10-12 min) the magnitude of roll (up to 20°). not restricting the action of artillery and not causing discomfort. Among the shortcomings highlighted at the bow and stern watertight bulkheads (32 and 60 FR.) in the battery deck during a storm was squeaky “like the old wooden vessels”; 28 APR 1900 “Petropavlovsk” dropped anchor in Port Arthur. Departed from Kronstadt October 3, “Poltava” and “Sevastopol” go to the far East, made separately, only occasionally meeting up in foreign ports. In the Suez canapés had to unload the coal, ballast, some of the ammunition, spare anchor, etc. – the precipitate of the battleship dostigao of 8.4 m and exceeded the maximum allowable of 0.6 m. “Poplava” and “Sevastopol” came to Port Arthur, respectively 30 and 31 March 1901 Head of the squadron of the Pacific, Vice Admiral N. I. Skrydlov informed the commander-in-chief in the far East, Admiral E. I. Alekseev, the second of them came in a “distressed state mechanisms”, immediately needed repairs. The company conducted exercises and shooting showed the lack of training and little familiarity gunners with turret installations. “Military organization and opravenie artillery in its infancy,” said Skrydlov.

Before the start of the Russo-Japanese war battleships made pavonia between Port Arthur, the Vladivostok-ports of Japan, Korea and China. In 1901, after the equipment of the premises for the Admiral and his staff “Petropavlovsk” became flagship of the Pacific squadron; in the following year established the radio system Popov – Ducrete (practical communication distance of 90-100 miles). All three of the battleship participated in the Russian-Japanese war. FERPA 27, 1904, “Petropavlovsk” raised the flag of Vice-Admiral S. O. Makarov. During the exit of the squadron on 31 March, the battleship two miles from the coast struck a mine, quickly banked to starboard and sinking by the nose, in two minutes disappeared under the water, killing 650 people, among them Stepan Osipovich and well-known artist V. V. Vereschagin. Meeting mine officers, prispa to the conclusion that the mine explosion of prosop detonation of ammunition cellars and mine fields. Several previously injured and “Sevastopol”: March 13, due to errors in maneuvering a battleship “Peresvet” hit him in the stern and bent the blades. The absence of Port Arthur dry dock capable of taking such large, corapi, turned into problem solving even such a minor damage. The DPJ change the blades “Sevastopola” Pavo had to make a special caisson-bell, which by mid-may managed to finish the job.

The war has revealed some of the negative side of the Russian naval artillery. Contract speed loader 305-mm guns was 1.5 min in battle it was spent for 4.8 min, which is significantly below the rate of fire of the guns of the main caliber of the Japanese ships. 305-mm turret installation of battleships type “Poltava” did not allow the increase of elevation angle of more than 15 predaina dalnosti of strappy ogranichivat seven miles. April 2, 1904, during the bombardment of Port Arthur by the Japanese ships from a distance of 80 cables “Sevastopol” began the reply from the guns of the main caliber at maximum elevation, but pouches nedobity; at the third shot broke down the machine is one of 305-mm guns, but to fix the damage to the shops of the port are unable, later, the gun was transferred to Poltava.

“Sevastopol” twice exploding mines (10 June and 10 August). To repair the ship afloat used caisson, made previously to seal the holes of the battleship “Retvizan”; it was a wooden box (larger holes), one of the sides which corresponded exactly to the contours of the vehicle in place of the holes; adjacent to the Board edge had a cushion of oakum, and lined with canvas. Interestingly, for the trimming of twisted sheets and designs of the holes were widely used by the voltaic arc constant current (900 A).

From 18 September 1904 port city and ships began to be subjected to bombardment by the Japanese heavy siege guns (280-mm howitzer); 22 Nov sank “Poltava” – 280-mm shell struck the deck and exploded in the ammunition cellar; a powerful explosion shook the battleship, he sat down on the bottom. immersed in water up to the level of the top paruby. By the evening of 25 November the Sevastopol was the only serviceable big ship squadron: the night he at the initiative of the commander captain 1st rank N. O. Essen came to the outer Harbor and anchored in the Bay of the White Wolf.

In the torpedo attacks on Sevastopol, which lasted for six nights, were attended by up to 30 Japanese destroyers (of which perish N8 53 and 42). released on the battleship over 80 torpedoes. On the night of 3 December one of the torpedoes in the pop-up when PC is not protected networks the stern of Sevastopol, the ship sat on the ground and tilted. A week and a half of hard work roll managed to equalize. The surrender of the fortress did not allow to complete the repair of damages, which prevented the planned Essen to break out of Port Arthur; at dawn on 20 December corapi prespeci flood 50-m depth.

Lying at the bottom of the inner harbour “Poltava”, the Japanese lifted on 8 July 1905, repaired and introduced in the composition of its fleet under the name “tango”; in 1909, the ship was used as a battleship of coastal defense and training ship. On 22 March 1916 the Russian government priobretu ship, which was renamed the “Chesma”; he headed for the Dardanelles, which tried to force the Anglo-French fleet. However, it soon became clear that the allies had failed and refused to force the Strait, and “Chesma” was sent to the replenishment of the fleet of the Arctic ocean. 3 January 1917, the ship came to Aleksandrovsk. June 16, 1921, he was deposited in the port of Arkhangelsk, on July 3, 1924-to be scrapped.

Battleships type “Poltava” – a stage in the development of a class of squadron of battleships of the Russian fleet, and the creation of such complex engineering structures has become a serious test for the Russian shipbuilding industry.

Assembly recommendations

Before Assembly of the model suggest to carefully read the description, drawings, parts and their location on the leaves. The model is not complicated to make, but requires great accuracy in the manufacture of some parts. Special attention in the Assembly must be given to the Board. From the accuracy of the implementation of the “blockage” of the sides would largely depend on the appearance of the model. The bottom after Assembly it is recommended to primed and painted, screw cover bronze paint. In the manufacture of the rigging instead of traditional threads, it is better to use a thin fishing line with a diameter of 0.1 mm black. When assembling non-ferrous parts to improve their aesthetics, it is recommended to do the retouching of the edges and maximize use of the medium. To cut out all the pieces better in the internal contour cutting off the black lines of the stroke.

The patterns in the model (denoted as A1, A2, etc.) must be painted in the appropriate color. The paint scheme shown on the template, it required color – either white or black. Mast (A14-A19) and vapor pipe (A4) have a combination of two colors.

Assembly model is in the order of the numbering of parts. Part numbers 44C. 51, 57, 61Ь, 63-65, 105, 108Ь and templates A5-A6 are absent. These omissions are not an issue, as it should be.

The description of the Assembly

Assembly begins with the manufacture of the frame of the case (det. R1-RZ, /1-/3, W1-W13. S1-S4), all details of which be pasted on cardboard with a thickness of 1 mm. the Frame model is going by the traditional scheme. Before assembling the frame in these locations det. P1 and /3, you have to grind the form. In the ready frame glue children. 1-2.

Prior to installation of the deck (det. 3-5) must be pricked with a needle hole under templates, lifelines and rigging (marked by dots). In

the lower part of the det. 5 stick det 5A-5b. as shown in the figure.

Before gluing the plating of the bottom (det. 6-18) on the edges of the frames should stick strips of thick paper with a width of 4-6 mm Ready bottom plate after Assembly is recommended proshpaklevat and paint.

The Assembly of the boards begins with gluing children. 20-20A and 21-21A (see figure). Build a niche anchor (det. 23a-23C) are shown. Note: to level the sheathing Board (det. 23-25) should be on the risks to the children. 1. Because after gluing children. 20A these risks are not visible, they are kindly requested to draw on the edges of det 1.

Bilge keel (det. 28) glue the folded halves, the inside of the upper edge of the paste of children. 28a. to across the keel was triangular in shape. Assembly screws and steering (det. 29-30) are shown in the figures. Hub screws and blades (det. 29-29A) can be covered in bronze paint.

Assembly aft balcony (det. 32) shown in the figure.

The add-in Assembly of sparteca (det. 33-35) begins with the manufacture of the frame (det. ZZ-ЗЗd). Before gluing children. 33d cardboard on the front part to bend and glue, and then glued to cardboard to limiting the scratches so that it remains apocleinae (see figure). In the finished det. ЗЗd to pierce holes pillers bridge (pattern A1). Ready to glue the add-in det. 34-34b, and top edge glued det. 35-35b.

Assembly det. 36, 39, 43 shown in the figure. Det. 37 can be glued on the appropriate place on the deck and superstructure in accordance with the General drawing. Covers chimneys collected from children. 41-41d, vent mast from the children. 44-44f To the searchlight platform on the mast (det. 44b) from the bottom to stick children. 45-45A.

Bridge (det. 46) glued to cardboard, glue the bottom to det. 46a, and Pope installation installation (det. 46b). Pillars to carry on the pattern A1, pillers the wings of the bridge to glue knize (det. 48). Stick running cabin (det. 49-50). Assembly of the elements of the equipment of the bridge and sparteca shown in the figure. Parking lights (det. 58) painted in green (DPJ left side) and red (right) color.

Chimneys collected from children. 59-61 as illustrated. The upper part (det. 61-61 C) and internal popoy part of the pipe posi the Assembly can be coated with black paint, but not with ink (ink deformity cardboard!). To finished pipes sticking vapor tube (pattern A4) that need to be painted the color of the pipe with a black stripe on top.

The Assembly of baffles (det. 66) shown in the figure. Hole in children. 66c cut after gluing the parts. The finished bells can be luted and painted to hide the joints. The inner portion (as anapolina children. 54, 68. 70) may be colored red.

The compass platform (det. 67) going on the drawing and glued to its place, as shown on General drawing. After the installation of the fittings of sparteca to priceit ladders (det. 74).

The Assembly of the towers of the main caliber (det. 75-79) shown in the figure. Trunks to collect from children. 79-79с, front part of which (with the exception of det. 79с) should round out the tweezers, as seen in the figure.

Build towers 152-mm guns (det. 81-86) are shown in the figures. Barbet (det. 81) glue as shown on the drawing, observing the asymmetry. Det. 84A to turn on a cone and glue.

Assembly of small detailing (det. 87.89,90,91,109,120,126.128) shown in the drawings. The black parts can be completely covered with ink.

Build boats (det. 94. 96, 98,135, 138) and boats (det. 100-101) shown in the figure, and the location of keel blocks (det. 95. 97, 99, 102) – on a General drawing. The letter A represents always the first keel blocks from the nose.

To combat Mars (det. 103) stick 37-mm guns, as shown in the figure. Location flood (det. 106. 108) and masts (templates A14-A17) shown in the diagram Saponov. Themselves the spotlight (det. 109) going in pattern. The boat boom (det. 111-113) are going on drawing and glued as shown in the diagram templates. In det. 112A can be cut out marked hole, det. 114 can be glued or run separately according to the pattern A19.

Chain Clusaz is collected from children. 117, 117b, 117d, podmienkach cardboard. Baye the edges of these datapa to paste poposki (det. 117a, 117C, 117е). Yarn covers Clusaz to strengthen Papua (det. 3). as shown on the General drawing.

Anchor is collected from children. 120-120t as illustrated. Ready to anchor the insert inside the niches (det. 23) and strengthen twisted thread or fine chain, a sample of which is shown in the diagram templates.

When gluing side 152 mm guns (det. 127) it should be done so that det. 127a protrudes from the Board for not more than 1 mm.

At the final stage of work on modalu should be installed on the sides of mine westray (templates A25) and davits (templates A26-A27) with boats (det. 98, 135, 138), and perform backstage (stretch) tubing, rigging and guard rails.

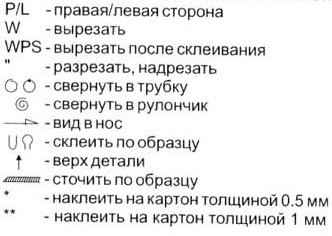

Legend:

The materials to build a model SQUADRON BRONENOSEC SEVASTOPOL (download)