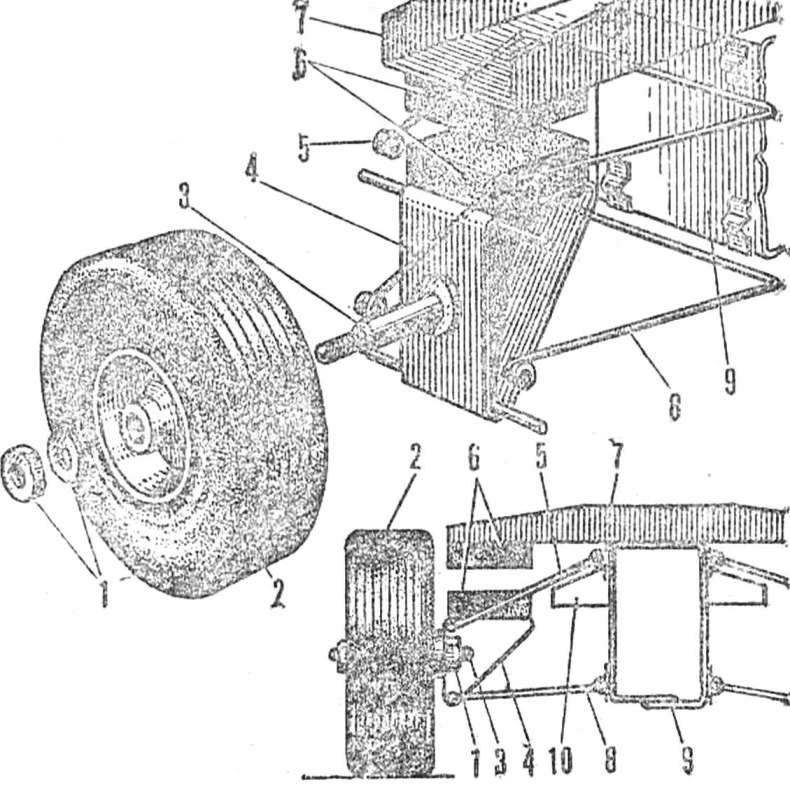

The one who had the opportunity to disassemble a conventional magnetic latch for a door, must have noticed how strong the magnet used in it. This leads us to the idea to use magnets instead of springs in the front suspension trace model. This is done as shown in the figure. Frame our model — box, welded from sheet metal, rigid and light. Front suspension — oscillating arm transversely of the wire. Axle nuts attached to the fists, bent in the shape of a triangle made of tin. The wheel turned, the tires of sponge rubber.

The one who had the opportunity to disassemble a conventional magnetic latch for a door, must have noticed how strong the magnet used in it. This leads us to the idea to use magnets instead of springs in the front suspension trace model. This is done as shown in the figure. Frame our model — box, welded from sheet metal, rigid and light. Front suspension — oscillating arm transversely of the wire. Axle nuts attached to the fists, bent in the shape of a triangle made of tin. The wheel turned, the tires of sponge rubber.

Two magnets glued with glue BF-2 the reliability of the taped threads. Be sure to Orient them so that they were facing each other like poles. One magnet is fixed on the fist, the second to the transverse traverse. The bottom is fixed by soldering the tin bump that restricts the wheel travel.

The suspension device performance magnetic dampers:

1 — nut and washer securing the wheel, 2 — wheel, 3 — axis, 4 — fist (tin), 5 —.upper control arms (OBC, d1,5 mm), 6 — magnets, 7 — upper traverse (tin), 8 — lower control arms, 9 — frame box (tin), 10 — chipper — stopper.

As shown by the practice, suspension elastic, ensures a smooth motion and good stability of the model on the track.

V. TOKAREV, the head of the circle EN-route modeling