To get such a cable to the radio Amateur from the rural hinterland — it is quite troublesome and expensive. To make a little bit more affordable ersatz is also no easy task. The thin winding wires, even if they are enclosed in rubber or cumbriabuy insulating sheath, mikrokabel no substitute: when to pull harder for a bundle, the shell a little stretched, all the force will be applied to one (the shortest) “gilet” which, of course, will not stand and will break.

I have also developed a special technology on which the core mikrokabel will be able to make it at home even a novice homebrew. On the strength and reliability of the resulting products can be judged by the fact that the resistance to tearing of the effort here is shifted onto insulation — polyflor-vinyl tube which is much stronger than thin wire, even though its stretching.

The secret lies in the features of the PVC. This material, in addition to the plastic (residual) deformation, changing the length and diameter of the tube after removal of the tensile stress, and elastic (which disappears with the termination of mechanical stresses) is an intermediate elastic deformation. Characteristically, the latter disappears immediately with the removal of the stretch, but gradually.

While stretched polyflor-vinyl tube will slowly reduce its length, you can slowly push inside thin wires, which after the disappearance of the intermediate form of deformation will be located at the shortening tube zigzag (accordion). This will provide an improvised stranded “hybrid” of copper and insulating sheath for additional protection. When pulling this cable, PVC tube as the shortest element will take all the effort, not the wires, having the ability to move inside the tube with a low friction against the wall. Elastic deformation, is inevitable in any stretch of the tube will allow the tendons-wires only slightly to straighten.

Thus, mikrokabel made at home on the basis of PVC pipe (with, say, inner diameter 1.5 mm) and wires (e.g., PELCO-0,1) turns out to be quite convenient and reliable to connect the remote units with the main equipment. In particular, it turns out so soft, flexible and lightweight, does not interfere with during computer games using joystick.

A method of making at home such a stranded cable is pretty simple. At six-foot segment of PVC pipe must first pass copper winding wire conductor diameter of 0.6 mm. However, push it with one hand, and the specified length there was increasing friction about the walls of the tube. As shown, even oiling machine oil here bad help.

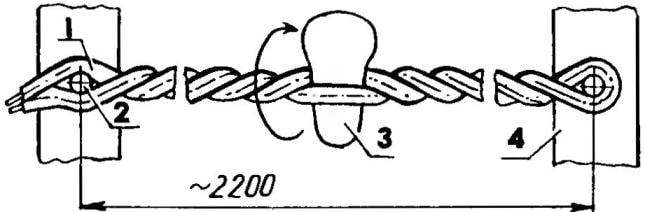

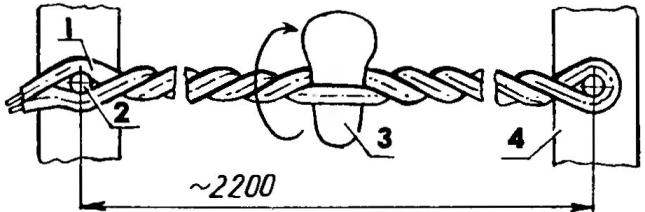

The technology of manufacturing of wiring harness for home-made microcubes (number of strands conventionally low up to two):

1 — wire (wire PALCO 0.1 and a number — as required); 2— pin. (a nail without a hat); 3 — rolled blade (accessory item of arbitrary shape and size, after winding is removed from the harness); 4 — support

Move inside the conductor to a depth of 0.8 m is possible only through periodic stretching of the tube. For this end of the conductor (the location it is easy to see against the light, or to clarify to the touch) should be fixed, sharply bent along with the tube. Then, stretching traversed sheath (within the limits of its elastic deformation), should be overcome in the next section. Next, without removing the tensile stress on the tube, it is necessary to fix (bend) the beginning of it, crawling on the wrapping wire.

Now you can remove the tensile stress, straightening previously done the bend at the end of the conductor, and to see how will move the wire inside the tube when it is shortening due to the disappearance of elastic deformation. Repeating the process several times with successive stretching of PVC pipe and its weakening, it is possible to hold the conductor through the entire length of the insulating sheath.

Tied to the protruding end of the wiring of the eight pigtails PEPSO-0,1 with a length of 2.2 m each (if this is for the joystick, which six wires have to be working and two spare), it is necessary to extend the wires through the tube. Moreover, to exclude any congestion and minimize friction to bend the hook end of the wire conductor, and after putting on his harness hard to squeeze such a coupling Assembly with pliers and grind with a file.

The wiring can be made (manually, as it is simplistically shown in the figure, or by using special equipment and tools), is wound four turns, PELCO-0,1 between two nails hammered in the distance, slightly in excess of 2.2 m, followed by twisting in several places that when drawing up such veins have not broken up and confused. Smooth retraction (and low friction) also contributes to fine silk insulation of the wires, the use of which allows also to reduce the parasitic capacitance of the cable while increasing the security of the varnish insulation of conductors.

When the wiring is finally sucked into a PVC tube, it is necessary to solder one side to pins of the peripheral device (joystick) and the other to the electrical connection. This is done so that is not torn veins in places of soldering.

Homemade cable of great length:

1 — tail harness (conductive core); 2— protective limit (wrapped copper winding wire d0,6); 3 — insulating sheath (PVC pipe with holes); 4— head harness; 5— insulating coupling (number of place); 6 conductor (copper winding wire, d0,6); sizes L and l — in place

Their integrity to provide protective end caps. Each represents a 4-6 turns of wire with a diameter of 0.6 mm, the ends of which are soldered to two free one working contact of the lever or connector. When heated during soldering and coupled with the shell almost ready microcubes, protective end caps are pressed into a bit of PVC pipe as a reinforcing elements give it some extra strength. Now the force that occurs when pulling on the joystick will be applied not to thin veins in place of the soldering, and more durable cable sheath.

And again. If you need a cable of great length, it is made in several stages. To do this, the tube billet is divided into plots of 2 m with the cutting of technological holes. Then take the wiring harness, line, whose length should exceed the length of the tube, and sucked for the guard: first, in the section from the beginning of the tube to the first hole, then in the area between the first and second holes, and so on for the previously considered technologies.

Of course, when using a tube or wire conductor of a different diameter and material cable length or area between the holes will be different.

SOLONIN, G. K o n o t o n, Ukraine

Recommend to read IN THE NAME OF SPEED Middle bomber BB-22 has left its mark in the domestic aviakonstruktorov. About him was legendary. Indeed, this plane was far ahead at the speed of modern bombers, and some fighters. ... VASE-IMPROMPTU Now on sale a lot of different liquids, for example mineral water in large plastic bottles, including a beautiful corrugated walls not only round but also square shapes. If they do ask...

Stranded microcable widely used in modern equipment, in particular for the connection of input devices of a type well-known joysticks and other peripherals to computers. With all the variety of requirements such microcables, even desirable, to be thin and flexible, does not cause inconvenience and noise during the work, was not torn and did not break from repeated bending. The latter is especially characteristic of cable lines with a miniature push-button joysticks that are holding.

Stranded microcable widely used in modern equipment, in particular for the connection of input devices of a type well-known joysticks and other peripherals to computers. With all the variety of requirements such microcables, even desirable, to be thin and flexible, does not cause inconvenience and noise during the work, was not torn and did not break from repeated bending. The latter is especially characteristic of cable lines with a miniature push-button joysticks that are holding.