All these deficiencies deprived of a designed me a belt sander, working on the principle of counter milling. It was made (except welding) in terms of aeromodelling laboratory. In its construction there are no deficient items and materials.

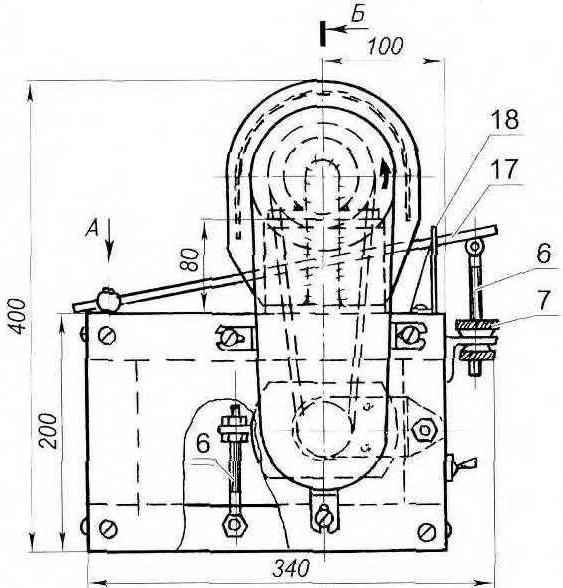

All subassemblies are mounted on the base, which is a parallelepiped with dimensions 200x265x340 mm, welded steel angles 40x40x4 mm. are welded To the base, in addition, two mounting bracket, made of channel No. 8 for fastening the bearing housings of a drum.

Drum (the main working body) and its pulley — cast. The material used the aluminum alloy AL-25, which is made from the pistons of automobile engines. Pistons melted in a muffle furnace, and then cast in a sand form. The holes in the drum at a rotary bolt-clip skins and counterbalance bolt should be drilled symmetrically about its axis. By the way, the mass of the first (along with the dog-lock) and the second mass should be equal. Otherwise, as a result of the imbalance will occur vibration which will lead to premature bearing wear and affect the machine’s performance.

The bearing housings are made of welded. The final size of the bearings in the housings rastaquouere after welding. The drum is driven in rotation by V-belt drive transmission from the electric motor of a power not less than 300 W, with the number of revolutions per minute from three to five thousand, with a large enough starting torque, since the drum has a pretty decent mass, despite the fact that it is made of aluminum alloy. This requirement meet the collector motors. I used the machine motor household electric floor-polisher.

Grinding machine:

1—drum; 2 — swivel bolt clip-skins; 3 —axis; 4 — pulley drum; 5 — a pulley of the engine; 6—adjustment bolts; 7 – knurled nut; 8 — a nut of the fan; 9 — hinge; 10 —the bearing housing; And—”dog”-hexagon; 12 belt; 13—a cover belt; 14 — casing of the drum; 15 — fan wheel; 16 suction nozzle; 17—table; 18 ruler; 19 — bearing No. 204; 20—motor; 21 —bracket motor; 22 — a bag for collecting sawdust; 23 — base 24—fan housing; 25 — counterbalance bolt; 26 sheathing base; 27 — sandpaper

Fundamentally important in my proposed design of a grinding machine is a system of suction of contaminated sawdust and wood dust air. This system makes the machine environmentally friendly and more “comfortable” at work, as it allows to do without a respirator. For suction of sawdust used centrifugal fan-blower systems of heating of salon of the car, which is installed on the threaded end of the shaft of the drum. A “cleaner” performance is not inferior to the household unit.

The fan shroud is attached to the bearing bracket with screws-lambs to quickly withdraw it when the need arises to replace the worn skin. On the discharge pipe shall be fitted with the pouch made of thick cloth to collect sawdust. The suction hole of the fan housing is connected with the cavity of the casing of the drum with a pipe. Pipe wikiepedia of fiberglass on the foam block which is then melted with acetone. The cavity of the casing of the drum formed by two concentric shells welded to the end plates to the flanges. The internal ones can be intermittent welded seam, and outer — necessarily continuous, in order to avoid pressure losses. The distance between the membranes is chosen from the condition of equality of the area of the suction inlet of the fan casing area of the two gaps formed by the shells. The front slit is absorbed by the sawdust thrown by the drum when grinding, and in the rear — chips, which are captured by the skin and thrown by centrifugal force of the drum.

Filling (I) and loosely (II) skins:

1 — skin; 2— swivel bolt-clamp; 3—retainer

The housings of the drum and belt transfer and covering of the machine base made of steel sheet 1.5 mm thick. the axis of the drum machined from steel 30, and the rest of the details — of steel 10.

The operation of dressing skins is simple and amply illustrated. Stretch the skins is carried out using the lever-“dog”, put on the square part of the swivel bolt clip skins and fixed in one of five positions.

The table is made of steel sheet 10 mm thick and has dimensions of mm. 180×350 Its working surface must be smooth , possibly polished on surface grinding machine. Table, hinged to the base, raised and lowered using the adjustment bolt, which gives the opportunity to veneer with thickness from 0,3 to 30 mm. desired size is installed on the line, screwed to the base. The line is calibrated by measuring the bars, pinched between the drum and table.

Good performance of the machine is eloquent testimony to the fact that in one pass it is possible to remove the “chips” with thickness up to 1.5 mm.

Recommend to read TRACTOR “WORLD ON A STRING” To make myself a mini-tractor (MT) is a dream of many. But they sometimes stop because of the difficulties in acquiring scarce nowadays powertrains, gearboxes with the right gear... THE LACES FROM THE HATS… Sometimes it is difficult for the elderly person to tie a shoelace. To help out maybe round hat elastic, forever laced and tied. After this improvement, the boots are easy to put on with...

During the construction of the models is often necessary to apply a veneer of varying thickness. Typically the desired thickness is obtained by grinding with fungus with glued on end cloth, is inserted in the Chuck of the drilling machine. This method is most affordable, but it has several drawbacks: poor performance, inability to process veneer with thickness less than 0.5 mm, because of the rotation of the fungus veneer escapes from the hands and broken, and finally, the main drawback is the large air pollution wood dust. To handle more than three or four plates is not possible even a respirator.

During the construction of the models is often necessary to apply a veneer of varying thickness. Typically the desired thickness is obtained by grinding with fungus with glued on end cloth, is inserted in the Chuck of the drilling machine. This method is most affordable, but it has several drawbacks: poor performance, inability to process veneer with thickness less than 0.5 mm, because of the rotation of the fungus veneer escapes from the hands and broken, and finally, the main drawback is the large air pollution wood dust. To handle more than three or four plates is not possible even a respirator.