Led bulb (abbreviated SL) can be seen today in almost every home. And for good reason-they are economical. Energy conservation is that SL, for example, with a declared capacity of 9 watts and current consumption of just from 0.065 A, is the analog of the output light of the incandescent lamp 60 W, which consumes several times more.

Led bulb (abbreviated SL) can be seen today in almost every home. And for good reason-they are economical. Energy conservation is that SL, for example, with a declared capacity of 9 watts and current consumption of just from 0.065 A, is the analog of the output light of the incandescent lamp 60 W, which consumes several times more.

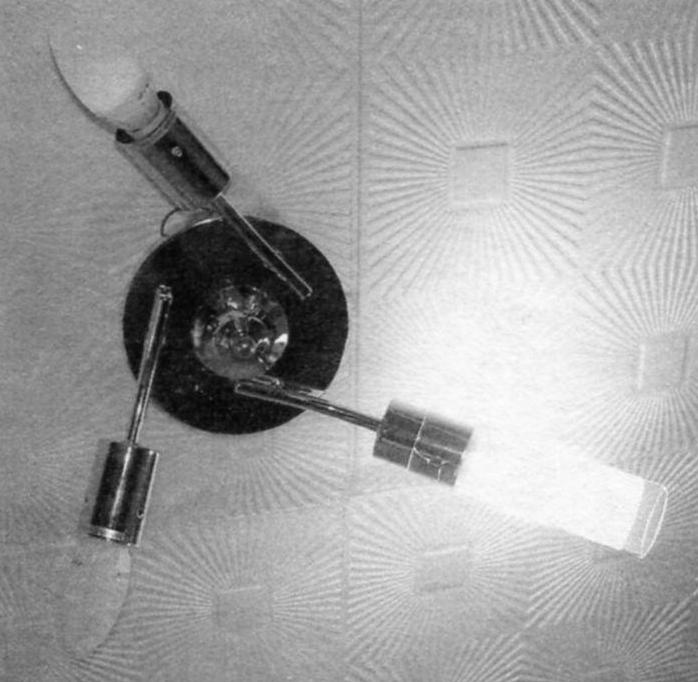

Photo 1 presents a view of the lamp with the three CL size E14.

Buying the lamp, you will read on the packaging as: “a service life of at least 50,000 hours” – more than five and a half years of continuous work. In fact, the lifespan of CL are often not so long (sometimes ten times less than claimed). Why household SL do not produce the estimated (by the manufacturer) lifetime, and can they be fixed?

To do this, let us examine the device of household SL and their typical faults.

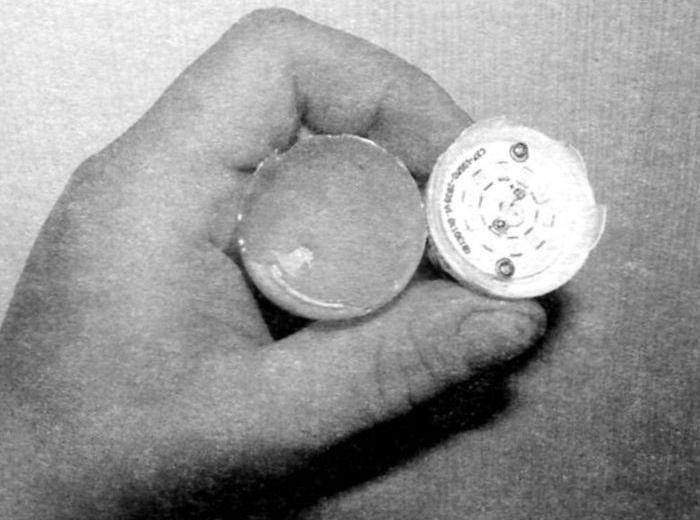

Modern led bulbs are manufactured based on semiconductor sources of white radiation – high-brightness LEDs. If you disassemble the SL size E14 (photo. 2), we can see the heat sink and the Converter input voltage (in the range 170 – 250V) to DC (modulated) voltage is 14 V. Therefore, in the case of SL (bulb) functioning power source: adaptor 220V – 14th Century

Photo 1. The appearance of the ceiling lamp with three same type of CL

Photo 2. SL disassembled: a cooling heat sink is a part of the body and the Board with discrete electronic components that make up the power supply – inverter 220 V – 14

Let’s start with the electronic switching power supply built into base (such as E27, E14); it is sensitive not only to voltage but to its frequency. In my example, the lamp “served” less than a year, to be exact, 116 hours in an enabled state, and the on/off cycles “experienced” no more than 100, as the use of country workshop in this period of time not often. The temperature in the workshop was consistent with the requirements of the manufacturer of SL – the temperature never dropped below +16 °C. the Lamp was also devoid of the harmful effects of precipitation because it is in the house. Supply voltage in the lighting network are controlled via special stabilizer with power output of 10 kW. Thus, the network is protected from overloads (surge). Nevertheless, the next time you turn in the summer of 2015 one SL (three part ceiling light) went out. The next time (after turning off) went out second. The third SL continues to Shine to this day.

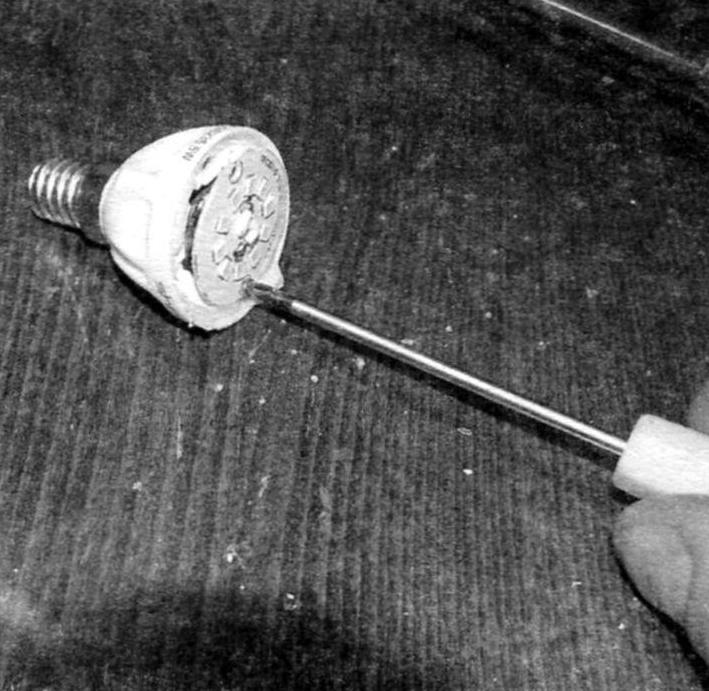

To parse SL, remove it from the holder and work on the table-it’s more convenient and safer (photo 3), then it is necessary to remove the flask (with stress and turn – on glue) and then remove the screws securing the led cluster using a thin Phillips screwdriver.

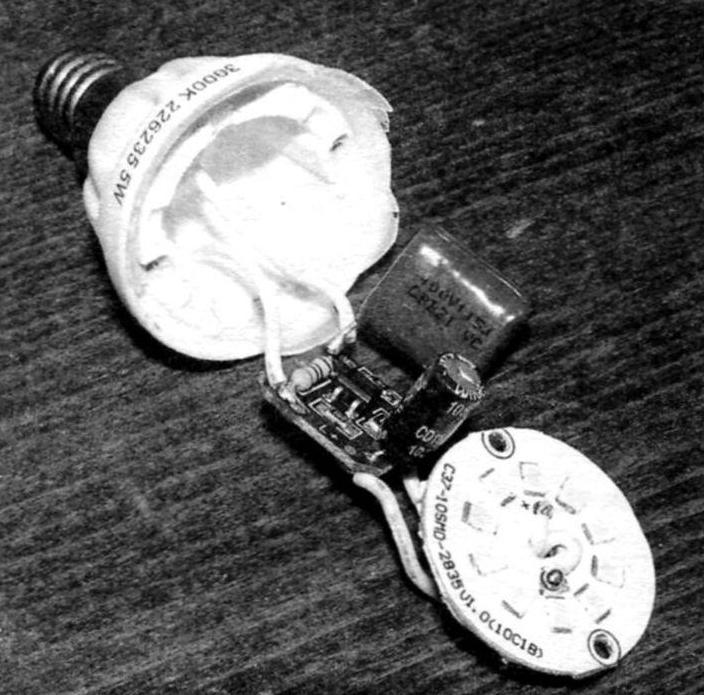

This opens access to the “stuffing” of the cap SL, namely for the PCB of the power supply (photo 4).

Photo 3. Disassembly of SL with E14 socket

Photo 4. View of the PCB of the power supply

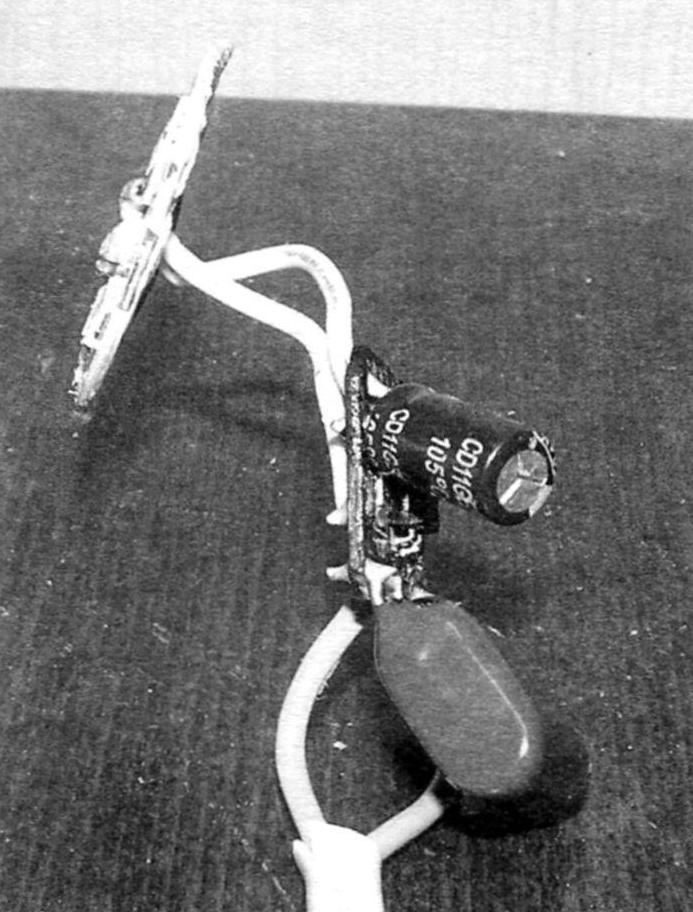

Photo 5. Illustration of the additional propane findings of the elements of the source power

The weakest link tab – oxide capacitor of 2.2 UF at a working voltage of 400 V. If it is even slightly loses capacity and the more completely breaks down, the output voltage of the power supply adapter drops significantly, and the LEDs may not light up at all. The second possible reason, which I was able to establish empirically — contact oxidation on the tracks of the PCB. If the electrical contact on the circuit Board at the connection with her conclusions non-polar capacitor marked C1 on the Board is lost (or becomes unstable), given the low current consumption of the device power supply SL also does not give the rated voltage at the output. Both these potential problems can be solved without much difficulty. First – by checking and replacing the electrolytic capacitor, the second propisanim all tracks on a printed circuit Board (installation work on propane conclusions element power supply Board SL is shown in photo 5). The next step (if SL were faulty) – checking the diode bridge. Then move directly to a led cluster that has 10 LEDs (led cluster charge C37-10SMD-2835V1 is shown in photo 2).

Design and manufacturing technology of SL have a decisive influence not only on the service life and reliability, and the cost of the finished products. Good design is intended to provide heat dissipation from the crystal, which is achieved by quality of installation of the chip and the heat sink material of the base.

The main indicator of the efficiency of led lamp is its light output. It is measured in LM/W, where one LM (lumen) is the unit of luminous flux, and W is the unit consumption of electrical power. Modern powerful SP is able to operate with direct current more than 1 A, however, require constant heat for safety of the crystal. With the growing power SP the effectiveness of the crystal (containing the entire set of parameters) is reduced. This is due to the nonlinear dependence of light output from the direct current of the led chip.

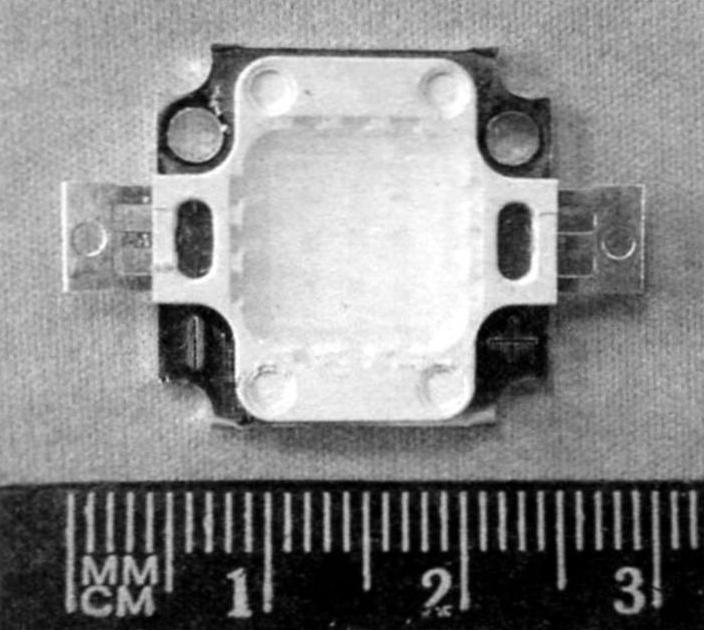

The LEDs are mounted on a special Board with a PCB track, which will be discussed later because of its manufacturing technology and installation is highly dependent on the quality of the SL. The product (PCB) with logo C37-10SMD-2835V1 is a cluster of 10 semiconductor LEDs mounted on a printed circuit Board with aluminum base. View of a single led is shown in photo 6.

Photo 6. The forks on a single led 5 watt Cree’s mounted.

The light source (one of 10) used heavy duty CREE Q5 led; according to the manufacturer, the led – provides a time interval of continuous service of 10 years (time to failure) led 50 000 – 100 000 hours. The luminous flux of such devices depending on power is 270 – 530 LM (lumens). Approximately the same characteristics from other LEDs. So, the led 3 W cold white symbol 270 – 300 lm 6000 – 6500 K (color temperature), 3.2 – 3.4 V (forward voltage), radiation angle is 120°. The most important indicators that you should pay attention when choosing LED bulbs is their color temperature, base and power. Of course, different manufacturers of SL use other types of LEDs.

LEDs in SMD-design are mounted on printed circuit boards with aluminum base and variable may be equipped with secondary optics to receive radiation pattern of the light flux. The Board is made in the form of a circle or a polyhedron with multiple pocket-holes for M3 screws (photo 7). Such and similar Board (for mounting multiple LEDs in SMD housings) can be purchased today, wholesale and retail (apart from lamps), however, repair at its cost and time consumption appears to be unprofitable. But nevertheless, consider this issue.

Photo 7. Printed circuit Board for mounting LEDs (base cluster) for other types of SL

Photo 8. The result of the forced deformation of the circuit Board of the led cluster with the fingers – the LEDs lit up, but not at full capacity

The reason for the failure of SL often hides in cracks or breakage of the contact track on the cluster. Since all the LEDs are connected in serial electrical circuit is open or bad contact in the track of a cluster is quite a significant reason for the lack of brightness on all LEDs. This is the most unpleasant for the installer and the repairman situation – creeping fault. If the cost of the cluster with LEDs slightly deform (fingers), the glow appears (picture 8). the same effect can be achieved by tapping the charge of the cluster on the table, but, of course, all this can’t satisfy the installer.

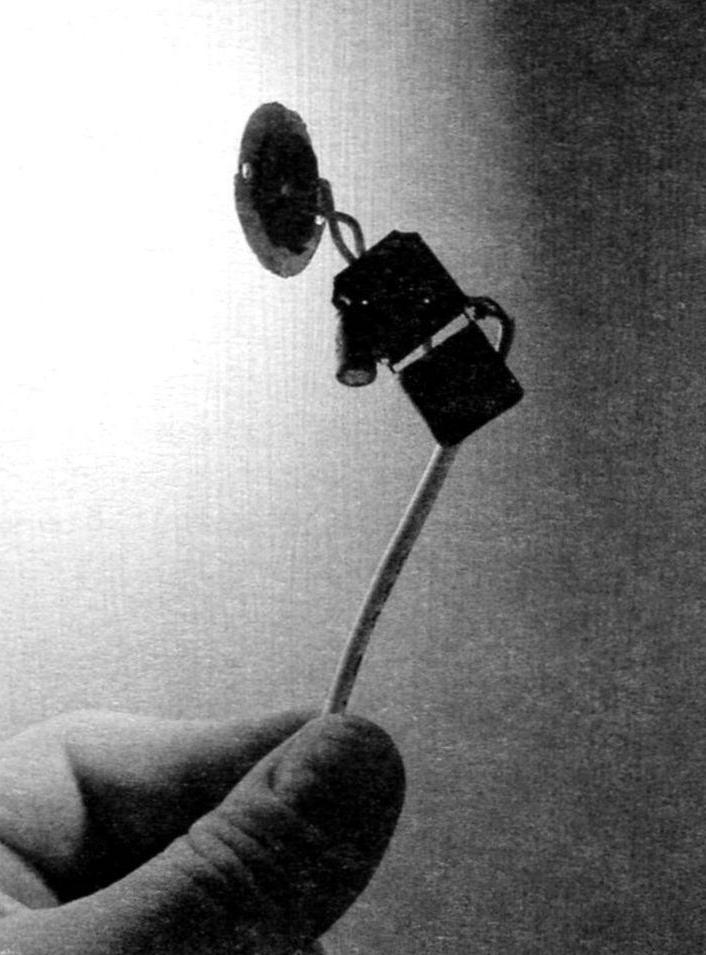

Photo 9 shows a method of connecting the led cluster, and a power source SL for laboratory research, that is, after it is removed from the lamp housing and carrying on a separate (additional) wires for later experiments and repairs.

Photo 9. The method of removal of boards from SL hull SL and connect new wires for subsequent experiments and repair

In this case, you will have to propagate locations of the contact pads of the LEDs and, if necessary, to control the printed tracks on the circuit Board of the cluster with a magnifying glass (for transmission) in search of cracks. The fault is common and often occurs in almost all manufacturers of cluster led lamps.

Leading manufacturers of crystals solve this problem in different ways. For example, some use the copper heat sink base, the other “glue” the crystal to the substrate, and technology firms use eutectic Limileds Lighting* installation. Each method has both positive and negative features. Soldering the crystal on a substrate allows to reduce the thermal resistance between the chip and the case, but there is the diode contact between the heat sink base and the chip, which requires mandatory electrical insulation SL in single or group installation on a circuit Board. This “negative” not only reduces the workability and makes more expensive the production of the finished product, but in the end, increases the thermal resistance between case and heat sink (radiator). The silicon substrate and the copper heat sink base have significantly different coefficients of expansion when heated, what with the “thermo-Cycling” leads to a violation of the eutectic, the damage of the crystal and, consequently, to premature aging or even failure of the light source.

After propane using a low voltage (12V) soldering iron with a fine tip managed to rectify the fault. When working SL operating temperature of the heat sink (heat sink) can reach 80 °C. it is Not recommended to look at illuminated led – can damage the eye, as illustrated by the photo 10.

Photo 10. The restored state of the cluster after repair

After that, the led lamp of the type considered can continue to use as directed. The study was subjected to led bulbs Camelion LED A60 8.5 W, 660 LM, 830, 220, E27 3000K; LED-A60-standard 11 W 160 – 260V E27 3000 K 900 LM (the Russian production company “ASD”); Jazzway PLED-ECO-A60 7W etc.

INSIGHTS

Warranty period of led lamp is counted from the date of acquisition through the retail network and is usually three years. And in the box with the product is often a warranty card with the serial number and stamp of the manufacturer that distinguishes SL from energy saving lamps (which have no serial number and is secured by a guarantee by check of the organization-seller).

Today, manufacturers are trying to reduce the cost of production of led lamps and go with aluminum radiators for heat-conductive ceramics. In practice there are cases when after the next turn on, after about 10 – 20 minutes, the light output from such a “cheap” bulb is reduced by 10 – 20%. This process is directly linked with the heating of the lamp housing, and after turning off and cooling the bulb to room temperature, re-enabling, it repeated. In addition, when “weak” manufacturing technology of SL over time the operation occurs the flaking of the tracks in the led cluster, which leads to poor contact and off of SL (illustrated above).

However, the described fault is eliminated in a relatively straightforward manner. This is true for those who can handle a soldering iron and knows something about the principles of operation of LEDs and power supplies. All other consumers today not to be envied. At an average cost of SL capacity of 6 watts to 140 rubles, taking into account frequently occurring failures, they have to “lighten your wallet”. The alternative, however, also have. It is not necessary to pursue cheapness and “shares” of lower prices and to purchase SL trusted manufacturer, even with a higher cost. Thus, it is possible to protect yourself from constant repairs of lamps, one-day. Folk wisdom – “Miser pays twice” is still relevant. Yet I give advice to those who sometimes travels abroad to Europe. Buy lights there. Here is an example. 10 SL, I bought the case in Finland (by the way, on a seasonal sale, and therefore inexpensive) for four years, not one has failed. The lamps provided the country-manufacturer – China. Under other equal conditions acquired in St. Petersburg domestic “cheap” SL has been repeatedly robbed of my time for repair, causing a fair amount of discontent in the Russian industry (it is in some places still are). In addition, our manufacturers are frequently disingenuous: for example, the specified characteristics color rendering index CRI over 80. And the packaging he modestly doesn’t say. Official website of the manufacturer (for example, ASD, Russia) the characteristics of the lamp indicates CRI >70 (a measure of comfort perception of lighting). This means that the cheapness of the lamp is achieved by using LEDs with a mediocre performance. This lamp may fit for technical lighting, but not for comfort. This lamp can be compared by putting a number of slightly more expensive (10 – 20% of the cost) lamps and indicator CRI 80 – 90. Besides, if you connect the SL in the circuit in series with the switch illuminated (neon lamp), it will blink. The controller of the electric power load (dimmer) that is designed to adjust the illumination (intensity, brightness) of the lamps in this case apply generally useless.

To ensure home comfort when you purchase 1 room apartment in Krasnodar – http://www.usi23.ru/kvartiry/odnokomnatnye/ suggest to install led lamps.

Closest competitors of LEDs, halogen lamps have efficiency (light output) of about 25 LM/W. SL has long surpassed this figure, and one should expect a further increase in their efficiency and the significant reduction in prices. If, for example, the apartment is equipped with 10-15 bulbs, the savings are quite substantial. But it is necessary to consider all given in the article “dangers” of purchasing “cheap” led bulbs or in another case to be ready to take on the most in their recovery. Although SL is not designed to repair, taking into account expressed in the article recommendation, it is quite possible.

A. KASHKAROV, St. Petersburg