In the “M-K” № 12 in 2014 was the publication of the tillers “Voskhod-1”, built in the circle of “Technical creativity” under the direction of Vasily Yurevich Skarina in Yakovlevskoe Polytechnic College of the Belgorod region. Today the circle and introduce you to other created by them design.

In the “M-K” № 12 in 2014 was the publication of the tillers “Voskhod-1”, built in the circle of “Technical creativity” under the direction of Vasily Yurevich Skarina in Yakovlevskoe Polytechnic College of the Belgorod region. Today the circle and introduce you to other created by them design.

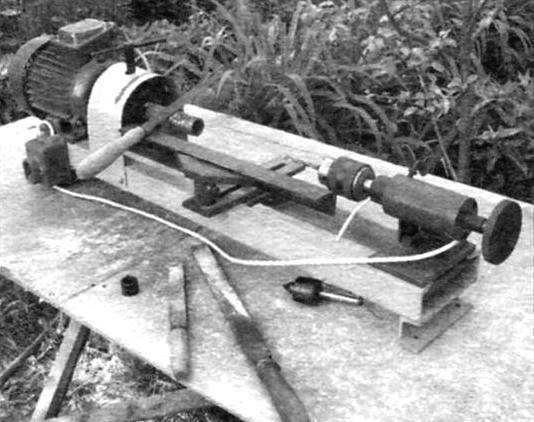

LATHE, TABLE

The basis of the machine – frame rectangular-shaped, welded steel area No. 5. The longitudinal elements serve as guides for the tool post and tailstock. The motor is three-phase, asynchronous, with a capacity of 2.2 kW and is powered from the mains.

The basis of the machine – frame rectangular-shaped, welded steel area No. 5. The longitudinal elements serve as guides for the tool post and tailstock. The motor is three-phase, asynchronous, with a capacity of 2.2 kW and is powered from the mains. The electric motor is switched on by pressing the “start” button. When the motor reaches full speed, push button release. If the selected capacitor engine is very hot, pick the best option, increasing or decreasing capacity.

This machine differs from the standard fact that it is additionally equipped with a lathe spindle (closed casing) and a tailstock, which is the center to insert the drill Chuck. Therefore, the machine can be used for grinding of shaped parts from wood for home decoration, furniture, etc., and for some operations on metal.

For processing on the machine select dry harvesting of hardwoods (preferably without knots).

ELEKTROFOREZA

Electrofresh designed for soil garden and garden plots, hilling potatoes. Given the difficult operational conditions: long continuous work (up to 4 hours), the constant overload, dirt – preference was given to more difficult (24,5 kg) three-phase motor-reducer is totally enclosed with a ratio of 32.

Electrofresh designed for soil garden and garden plots, hilling potatoes. Given the difficult operational conditions: long continuous work (up to 4 hours), the constant overload, dirt – preference was given to more difficult (24,5 kg) three-phase motor-reducer is totally enclosed with a ratio of 32. It can work as under the scheme of three-phase and single-phase power capacitor (coupling star).

The shaft of the cutter is driven in rotation by a chain transmission (step – 18,25 mm, number of links 52). Stars: g has 13 or 15 teeth, and z2 – 15. The speed of the cutter shaft are 38 or 44 min.

Motor-reducer mounted on the frame by means of two transverse plates of thickness 10 mm, which can be offset for tension control circuit.

The frame is made of pipes in 3/4″. The basis of the layout of the mill laid the equilibrium condition in the working position with the aim of reducing the strain on the handles control.

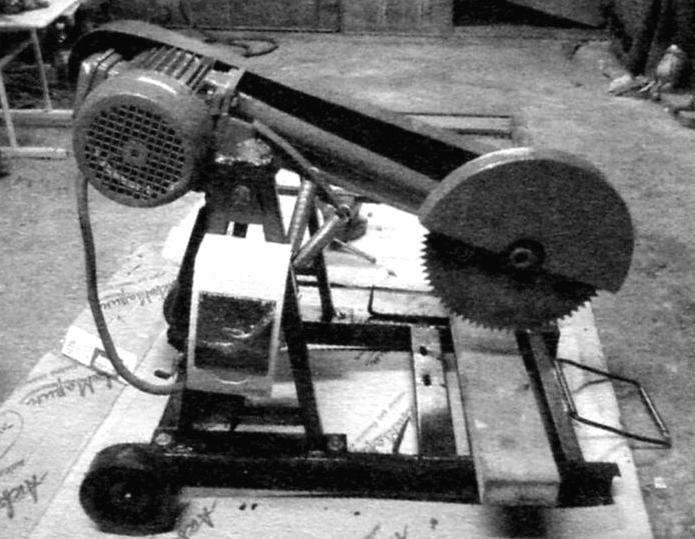

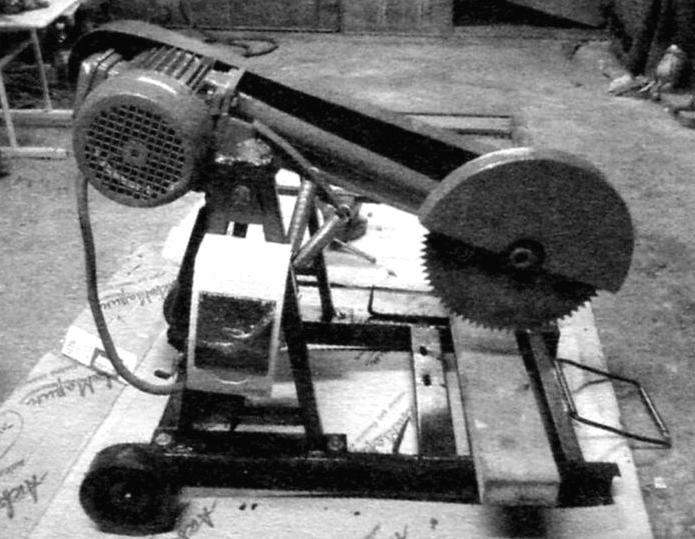

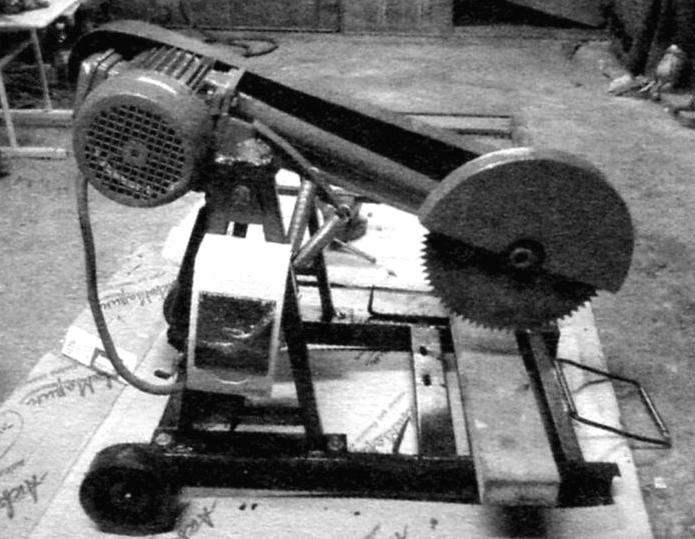

CUTTING MACHINE

Designed for cutting most types of metals and their alloys with an abrasive. Replacing the grinding wheel on a circular saw with a diameter of 400 mm, the machine can be used for transverse cutting of wood with a thickness up to 185 mm. Solid cast iron table provides the work with a massive workpieces, and the rotary vises allow you to perform the cuts specified under (45°) angle.

Designed for cutting most types of metals and their alloys with an abrasive. Replacing the grinding wheel on a circular saw with a diameter of 400 mm, the machine can be used for transverse cutting of wood with a thickness up to 185 mm. Solid cast iron table provides the work with a massive workpieces, and the rotary vises allow you to perform the cuts specified under (45°) angle. The machine is equipped with asynchronous motor power 2.2 kW at a speed of 2670 per minute, is rated for continuous operation from household electrical outlet.

Belt drive from engine to shaft makes the machine low noise and protects the motor from overload. Magnetic starter eliminates start-up after temporary disconnection of supply. The protective cover makes the machine safe. Machine overall dimensions: 750х440х 620 mm, weight-about 75 kg. For transport the machine is equipped with wheels and handle, this cutting unit is fixed in the lower position.

FLORAL CAROUSEL

Light is a necessary factor for the development of most green plants. With this in mind we developed the adjustable rotating stand wheel for flowers, where plants receive necessary and the same luminous flux, which is controlled via relay.

Light is a necessary factor for the development of most green plants. With this in mind we developed the adjustable rotating stand wheel for flowers, where plants receive necessary and the same luminous flux, which is controlled via relay. Design for six plants. The frame is made of pipe cross-section 25×50 mm and 30×30 mm. Wheel bent from a rod of square section with a side of 10 mm. as used in the drive motor-reducer wiper of the car “GAS”, sprocket, and drive chain for Cycling, the number of revolutions of wheel 2 in a minute. For power used a step-down transformer 220/12 In with the rectifier.