Anyone who has been in Yalta, remember, of course, the town’s waterfront, a huge concrete boulders, piled in the sea in front of her, furious roar of the waves in them in stormy weather: the man protected the shore from erosion by such “pyramids” that have no wave to move. But what kind of giant they have raised, brought down to this place? Even dvadtsatipyatiletnih truck compared to one with such a stone — a child’s toy.

Anyone who has been in Yalta, remember, of course, the town’s waterfront, a huge concrete boulders, piled in the sea in front of her, furious roar of the waves in them in stormy weather: the man protected the shore from erosion by such “pyramids” that have no wave to move. But what kind of giant they have raised, brought down to this place? Even dvadtsatipyatiletnih truck compared to one with such a stone — a child’s toy.

In our country each year we build breakwaters, groynes, retaining Seiki, other structures, does not allow waves to break the sea shore. The weight of each stone array, as it is called experts — now is 80-100 ton, and in the future will be 300. For any kind of land transport — freight unthinkable. But find a “strongman”, the question would remain unsolved, very often to the place of proposed engineering works no access roads.

The same problems and needs of builders sea ports. Piers, walls, overpasses will be built of large and heavy concrete structures with the length up to 20 meters and weighing up to 300 t

And in the country’s ports in recent years dramatically increased the number of goods, weighing more than 100 tons

To cope with all these tasks can only sea floating cranes, which are a lot more powerful than their land counterparts.

The first such crane with a lifting capacity of 50 t was built in the Soviet Union in 1955 (previously they were brought from abroad).

Fig. 1. Floating crane “Bogatyr”.

However, before the designers task was more complex: to create not one, not two new developments, and an industry with certain specific design principles. It was more difficult that foreign models of analogy was not good nor by appointment (only for loading and unloading operations) or manufacturing technology (high labor costs, metal content, etc.).

However, by 1971, the domestic industry has fully ensured the demand of the national economy in such structures. In less than two decades, the country held a rapid path from inception to create unique designs — a new, independent branch of the shipbuilding industry — the construction of heavy offshore floating cranes. With this amount of marine engineering works in 1975, will increase by 12 times compared to 1955.

Shipbuilding and heavy machinery until then had never had anything in common. The design principles, characteristic for this or that industry are completely different. Newly created valves had to synthesize in himself the achievements of both industries.

Work on sea-giants were included in the study operating conditions in the basins of the USSR. Examined the characteristics of wind and water, distances between ports-stops and their location, working conditions at unequipped shores and in shallow water, dynamic loads, emergency situations, the necessary degree of stability and much more.

First of all, marine crane must be able to swim on their own, as the work — at least to strengthen the coast — being in many different places. If we consider the average velocity of the crane and the location of the network of special shelters along the coastline — it will be understood that the tap may take up to five hours to shelter from the weather. So he should have good sea keeping qualities.

Protection from the wind. She and on land represents a major problem. Designers try to reduce the overall windage of the design, coming up with all sorts of devices to ensure that the crane is not moved, not pushed by the wind on rails, not overturned. Much harder to defend against much stronger winds swaying on the waves of the sea crane. In addition to the minimum sail, he’s the center of gravity of the upper structure should be as low as possible. And another problem: fast for ten or fifteen minutes, lay the boom in the stowed position when pitching. The operation should be automated, that it was able to handle himself a crane operator, because the team at this time is busy preparing for the transfer and removal of anchors.

But crane goes to the shelter only in stormy weather, in rest conditions, even in strong winds, the works. Therefore, the upper part of the structure must be very strong, otherwise it will not withstand inertial forces, additional loads from load-swing and jerks. Floating loader need to be able to maneuver to avoid the pitfalls and not run aground. And yet — at the tap not less than 25% of the area of the upper deck needs to take a load platform.

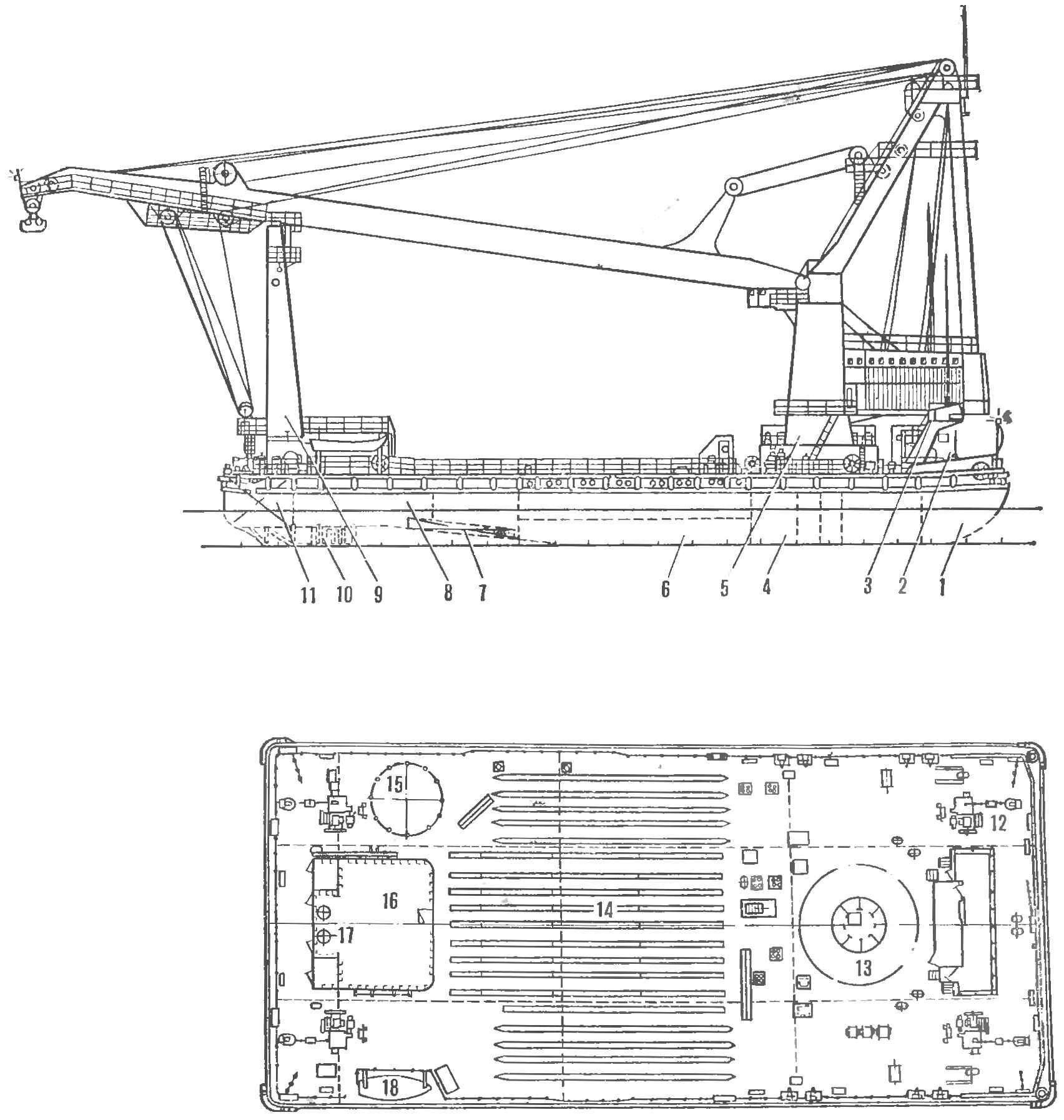

Fig. 2. Scheme of the crane “Bogatyr” (top — side view, below — deck plan):

1 — free compartment; 2 — way cabin; 3 — onboard control; 4 — skipper, 5 — superstructure; 6 — unit residential buildings; 7 — fuel tank; 8 — engine room 9 — the support for stowing the boom in its stowed position; 10 — vane propellers; 11 — ballast tank; 12 — anchor-mooring winch; 13 — zone of the rotating part of the top structure; 14 is a cargo area; 15 — platform slings; 16 — cap machine and boiler Department; 17 reservoir gas exhaust; 18 — working boat.

This, of course, only a rough set of tasks were taken into consideration by designers when designing a new lifting device. The manufacture of floating cranes was commissioned Sevastopol marine plant named after S. Ordzhonikidze. In the beginning there were made of only the pontoon and the steel structure of the boom, a turning mechanism and winch trucks supplied by other companies. But as time went on. From the design and construction of cranes with lifting capacity of 50 MT Sebastopol experts went to the manufacture of more powerful structures, and 1965, the factory became a base of domestic pleskrestore.

Already when you create the first designs were worked out the overall layout, the shape of the bow of the body, the mutual position of the crane and vessel elements selected optimal propulsion and steering complex.

High maneuverability at a low speed, handling and stability on the course at full speed with the wind and the excitement is best provided special vane propeller. It consists of several vertical blades attached to a single disc which rotates around a vertical axis. The plane of the disk is flush with the bottom of the vessel. Rotating, the blades are repelled by the water, playing thus the role of the mover. They can be installed at different angles — this is changing the direction of movement of the ship. So they serve both as rudders.

Until that time, cycloidal propulsion, our country was not made, and that the construction of the offshore floating cranes, brought to life their serial production.

All foreign lifting constructions departure upper arm was changed with a screw mechanism — that is tough. However, this device does not allow fast travelling to lay the boom, and to produce this screw is very difficult. Domestic designers came to the conclusion that the boom should be changed using a flexible cable system. And such original solutions to a lot on account of domestic placentae.

To be the most perfect designs are “Chernomorets” — with a capacity of 100 tons and “hero” is 300 t “Chernomorets” works with four-point winds and waves up to three points in the ports and in the open sea, at a distance of up to 20 miles from shore. In addition to the main hook, the ship has an auxiliary; its capacity is 25 tons.

Lifting height of main hook reaches 27 m, the departure from the axis of rotation — also 27 m. load platform designed ia the transportation of 300 tons of cargo. The length of the pontoon — 46.5 m, width 20 m, height — 3.4 m.

Source of energy on the ship are two diesel generators with capacity of 300 kW and one auxiliary output of 50 kW. Two cycloidal propulsion allow “Chernomorets” to move through calm water at speeds up to 6 knots. Each diesel generator powers the electric motor of one of cycloidal-propeller, rated at 300 HP thrusters are Controlled with remotes, located in the chassis cabin and on the bridge.

“Hero” — with head floating crane was commissioned in late 1971. This marine self-propelled vessel of the pontoon type with vane drivers can exceed a speed of 6 knots, is not afraid of a seven-point wind and waves up to six points. In the Arsenal of “Heroes” unit for underwater cutting and welding metal, the grab capacity 15 m3 and a diving station. Its cargo area can carry cargo weighing up to 900 tons.

In contrast to the “Chernomorets” in the stern of the crane installed not two, but three vane propeller with motors with a capacity of 435 HP each. The motors are more simple and reliable; if one of powering their generators fail, the other two will ensure ticking.

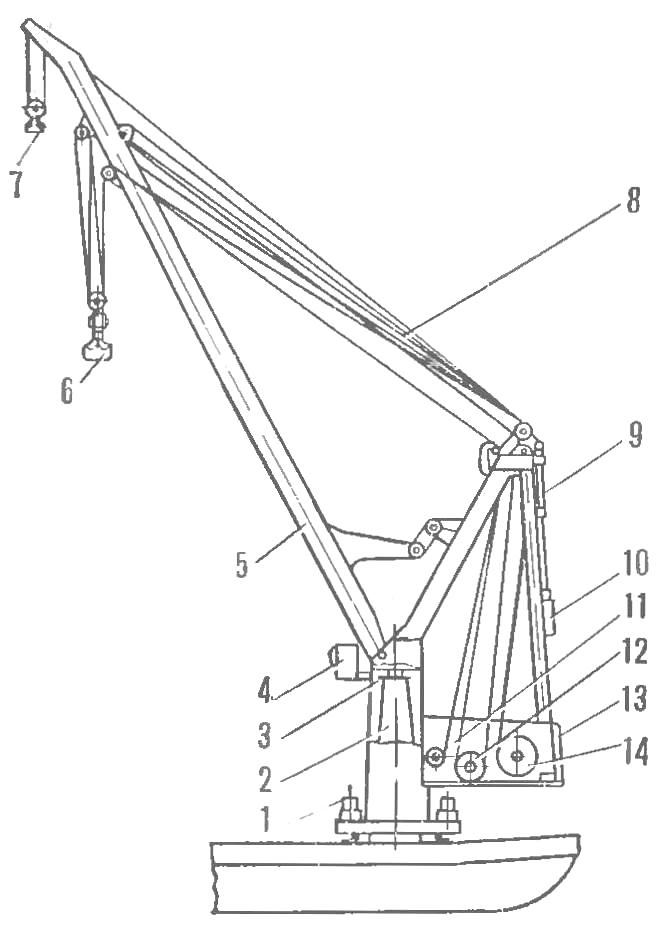

Fig. 3. Scheme of the rotating part of the crane “Bogatyr”:

1 — rotation mechanism; 2 — column; 3 — upper support; 4 — cab, 5—cargo boom; 6 —the main hook; 7 — auxiliary hook; 8 — cable; 9 — boom shock absorber; 10 — opposed double-acting; 11—hoist auxiliary hoist; 12 —hoist mechanism the luffing; 13 — counterweight stationary; 14 —hoist main hoist.

To check seaworthy and maneuverable qualities of the “Heroes” of its stability and structural strength of the crane parts had to spend, in addition to the calculations, the tests on the models. In the end, was realized the most important principle layout of such vessels: crane part is placed on the nose, engine and wing thrusters in the stern.

Cargo boom in the stowed position is inclined to the nose of the ship, which gives the General silhouette of the swiftness and ease, despite the rectangular, as in “Chernomorets”, the shape of the hull. The correct choice of these contours proved ocean stretch of floating crane “Chernomorets” from Sevastopol to the far East to Nakhodka. Swimming it was a unique case because usually before a long stretch of the top structure thereon is removed. “Chernomorets” nothing is dismantled, however, the ship in transit without any damage and endured storms and even a hurricane with waves as high as 10 m.

Pontoon “Hercules” — all-welded, steel. Relatively shallow draft hull with a large width ensures good driving performance.

The body is divided into compartments by watertight bulkheads: five transverse and three longitudinal. Most of the rooms are located inside. On deck only the pilothouse, the lantern light of the engine room, the support for laying the boom in the stowed position and the vestibule for the entrance to the residential block and sanitary facilities.

The support boom is both housing for exhaust manifolds and engine-room ventilators. It is also a very good design solution, because the exhaust gases do not fall to the deck and the engine room is better ventilated.

“Hero” has two the stem of an anchor with a mass of 200 kg and two anchors Hall (aft) weighing 1,500 lbs., they Rise four winches in the corners of the pontoon. When wave and wind anchors securely hold the valve in place without the aid of propulsion.

In running the cockpit mounted control panels cycloidal propulsion and control over signal lights n an emergency alarm. Machinery installation operated by one person from the Central office.

Fig. 4. New powerful crane “Vityaz”.

All devices and mechanisms of the top structure “Heroes” are arranged very conveniently, so it takes up relatively little space, weighs little and has a small windage.

Full-revolving electric crane, variable boom is equipped with two lifting mechanisms with a primary-plus 300 tonnes and an auxiliary 100 t video release gear carries a single cargo boom with a flexible tightening system. This means that the mechanism of change of departure consists of cables and pulley. Flexible tightening reduced the weight of the top structure 250 tonnes — almost 30%.

A group of specialists of the Sevastopol marine plant named after S. Ordzhonikidze headed by chief engineer Nikolai Dmitrievich Velikosel recently was awarded the State prize of the USSR in 1974 for his work called “the Creation of domestic heavy marine pleskrestore on the basis of a family of highly efficient self-propelled floating crane “Chernomorets” and “Hercules” multi-purpose”.

Strong “hero” — five electric locomotives can be accommodated on the deck, and the ship is five times stronger than his: factory is already working on a new design — fixed the floating crane “Vityaz”, the capacity of which will amount to 1,600 tons

In the territorial waters of our country lies on the seabed over 500 warships and merchant ships sunk during the second world war. Hundreds of thousands of tons of high-quality metal. And to get it, no need to mine ore, smelt iron, make steel. Only have to “bend over” ^ to raise from the seabed.

“Vityaz” and is designed to lift sunken vessels with a depth up to 50 m, and also for removal of vessels from the shoal. In addition, with the “Vityaz” maybe a new solution to the overload of work, which quite recently it was impossible to imagine.

That it is profitable to haul cargo in containers, transferring them from the car body or platform of the trailer in the freight car, and then into the hold of the vessel, now known quite well. But this progressive method is being further developed. For example, from Leningrad to Petrozavodsk it is necessary to deliver a uniquely oversized cargo. In Leningrad it is set on the river lighters, taken to Murmansk and using the mighty “knight” raised directly with the lighters on the ocean the ship to the mouth of the Yenisei. And there again, the floating crane Bogatyr: he takes the lighters, and they sail under its own power on the river.

R. YAROV