Turning in work is always the most difficult was considered the manufacture of spherical components. Understandable why the interest, which called on NTTM-78 offer young innovators of the Kherson combine plant Basarab, V. A. and cotia. They are brought to the exhibition a device for handling cross-spherical holes at the screw-cutting lathe.

Turning in work is always the most difficult was considered the manufacture of spherical components. Understandable why the interest, which called on NTTM-78 offer young innovators of the Kherson combine plant Basarab, V. A. and cotia. They are brought to the exhibition a device for handling cross-spherical holes at the screw-cutting lathe.

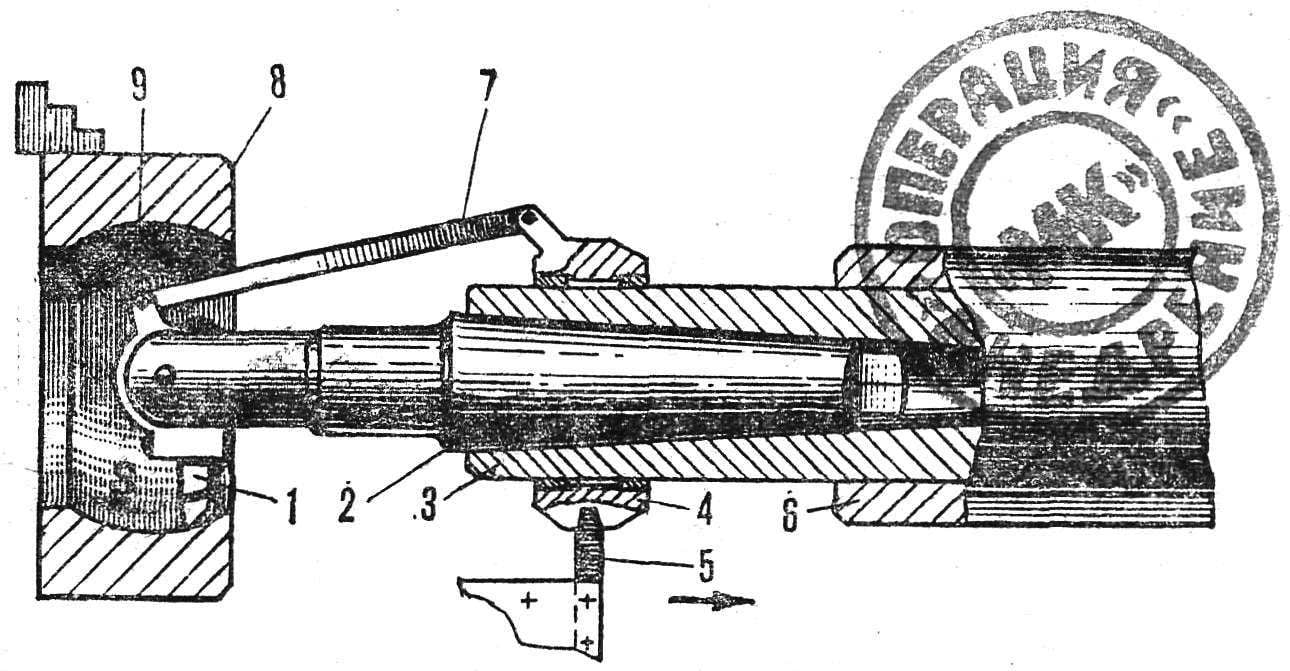

They developed the device consists of a mandrel, tool holder and the control slide. A mandrel mounted in the tailstock quill of the machine. In the groove set the toolholder, which allows in the process of using the slide lever to change the position of the cutter relative to the workpiece.

“Spherical” cutter:

1 — cutter, 2 — shank, 3 — pinol, 4 — slide, 5 — finger in the tool holder of the machine, 6 — tailstock, 7 — lever, 8 — workpiece, 9 — rotary tool holder of the cutter.

Having a change of such special holders and by varying the length of the output of a conventional cutter, you can handle spherical diameters from 62 mm and above.