When the device watering system for garden plot or in the garden many problems arise when it is necessary to bend a metal tube. Meanwhile. not that hard to assemble a simple machine (see picture) for flexible aluminium, copper and thinwalled steel tubes with an outer diameter of 20 mm.

When the device watering system for garden plot or in the garden many problems arise when it is necessary to bend a metal tube. Meanwhile. not that hard to assemble a simple machine (see picture) for flexible aluminium, copper and thinwalled steel tubes with an outer diameter of 20 mm.

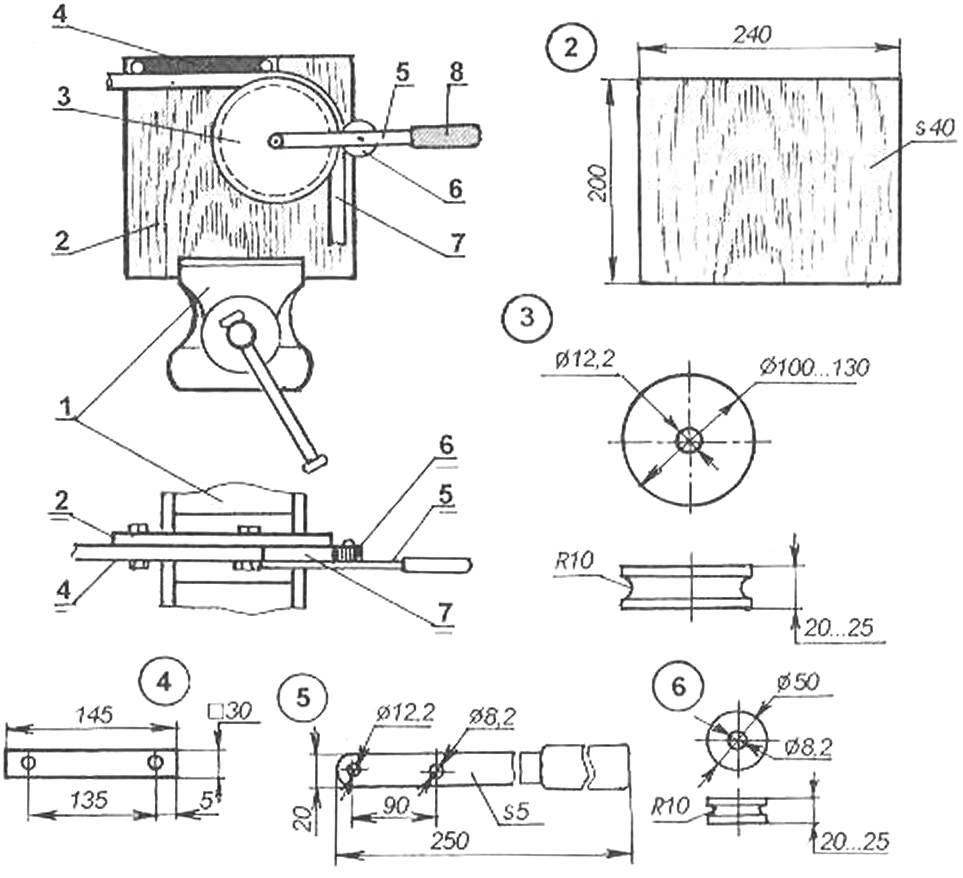

Base (2) such machine is used solid wood of dense wood dimensions 240x200x40 mm. On one of its corners (figure — right) at a distance of 76 mm from the edges on the axis (bolt diameter 12 mm) reinforcing metal roller 3 with a diameter of 100 — 130 mm and thickness 20 — 25 mm. It may be carved and made of thick wood, preferably of oak.

Around the axis of the roller is free to rotate the lever 5 of the steel strip (250x20x5 mm). It mounted a rotating metal roller 6. and in the end impaled arm 8. In the upper left corner of the base 2 using two M6 bolts attached wooden rack focus 4. From the rollers 3 and 6 on the circumference of the machined groove depth of 10 mm.

Pipe bending machine:

1 — bench vise; 2 — the Foundation (Board); 3 — wooden roller; 4 — a rack-focus; 5 — lever; 6 — metal roller; 7 — pipe; 8 — the handle

As in the Amateur practice, the need for bending of the tubes occurs from case to case, there is no need to manufacture durable, and hence relatively bulky base of the machine. The Board firmly enough to clamp in the bench vise 1.

To bend a pipe, you need a 5 lever to divert to the contact roller, with a focus 4, in the groove between the rollers 3 and 6 to insert the tube 7 and turning the lever to bend it to the desired angle.

S. MAXIMOV