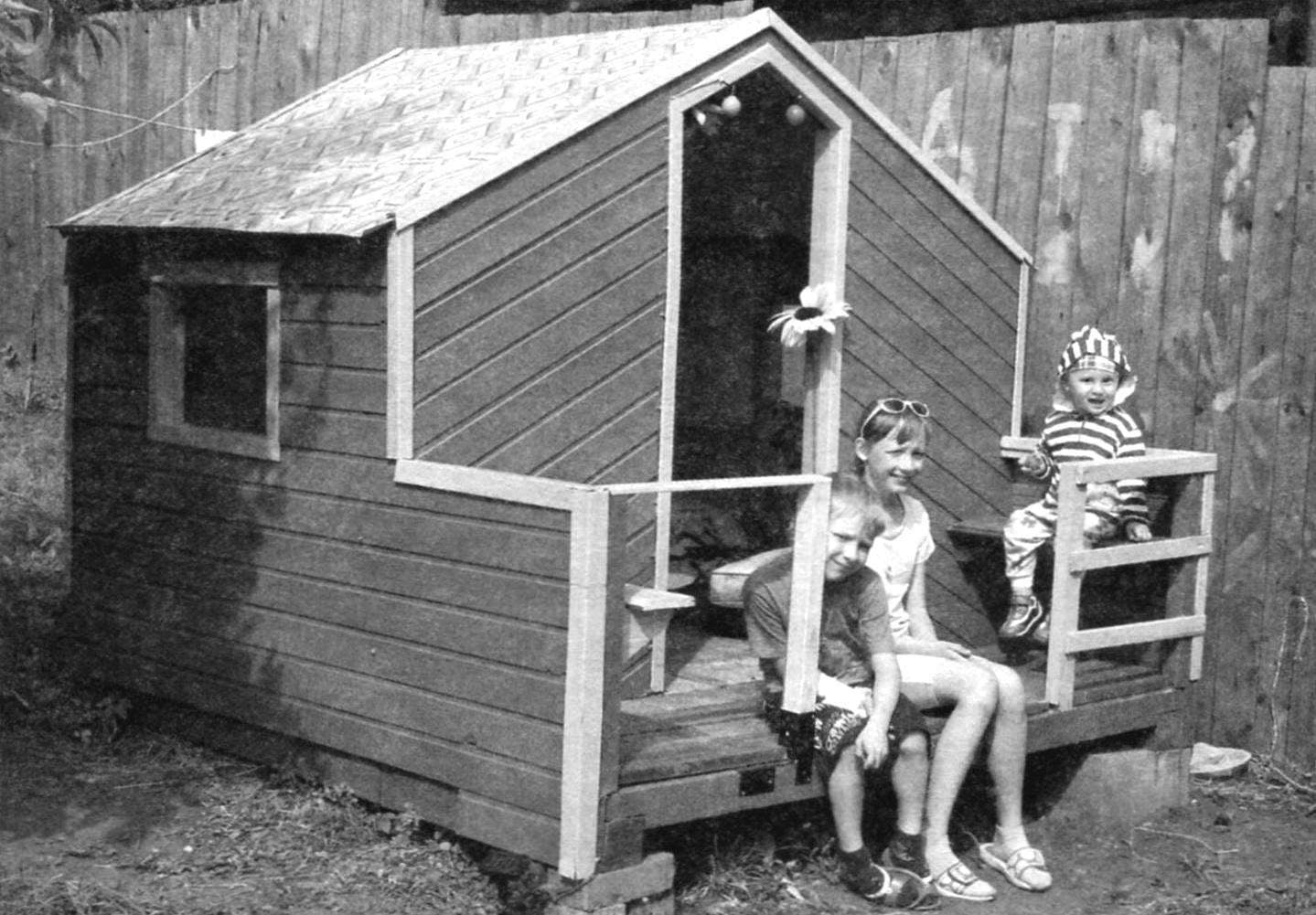

the Desire to build a children’s Playhouse in the garden for the grandchildren (they have three) came about when flipping through a magazine with illustrations on this topic. But none of the published options fit, wanted to make not just a house but sportevenementen area.

the Desire to build a children’s Playhouse in the garden for the grandchildren (they have three) came about when flipping through a magazine with illustrations on this topic. But none of the published options fit, wanted to make not just a house but sportevenementen area.

Working in this direction, provided for the stairway with a platform above the roof and the flagpole, as well as the “climbing frame”. But the reality proved different, as the owner has allocated a building too small a territory to the same closely adjacent to the fence, but next to the sandbox and swings. In the end, it all boiled down to the simplest version of house of size 2×2 m, of which the “living area” had 3 m2.

The Foundation is made of the four corner columns: one was concrete block and the rest of brick.

Grasp the construction, decided to minimize the visit to the hardware store and used scraps left over from the reconstruction of the house. Mounting the lower harness house, placed laterally two-meter beam of cross section 150 ? 150 mm and connected them with a two-meter piece of timber section 50×75 mm. with timber of the same cross-section fabricated transverse and longitudinal strapping jumper. Of course, piping on the Foundation put in “horizon” level.

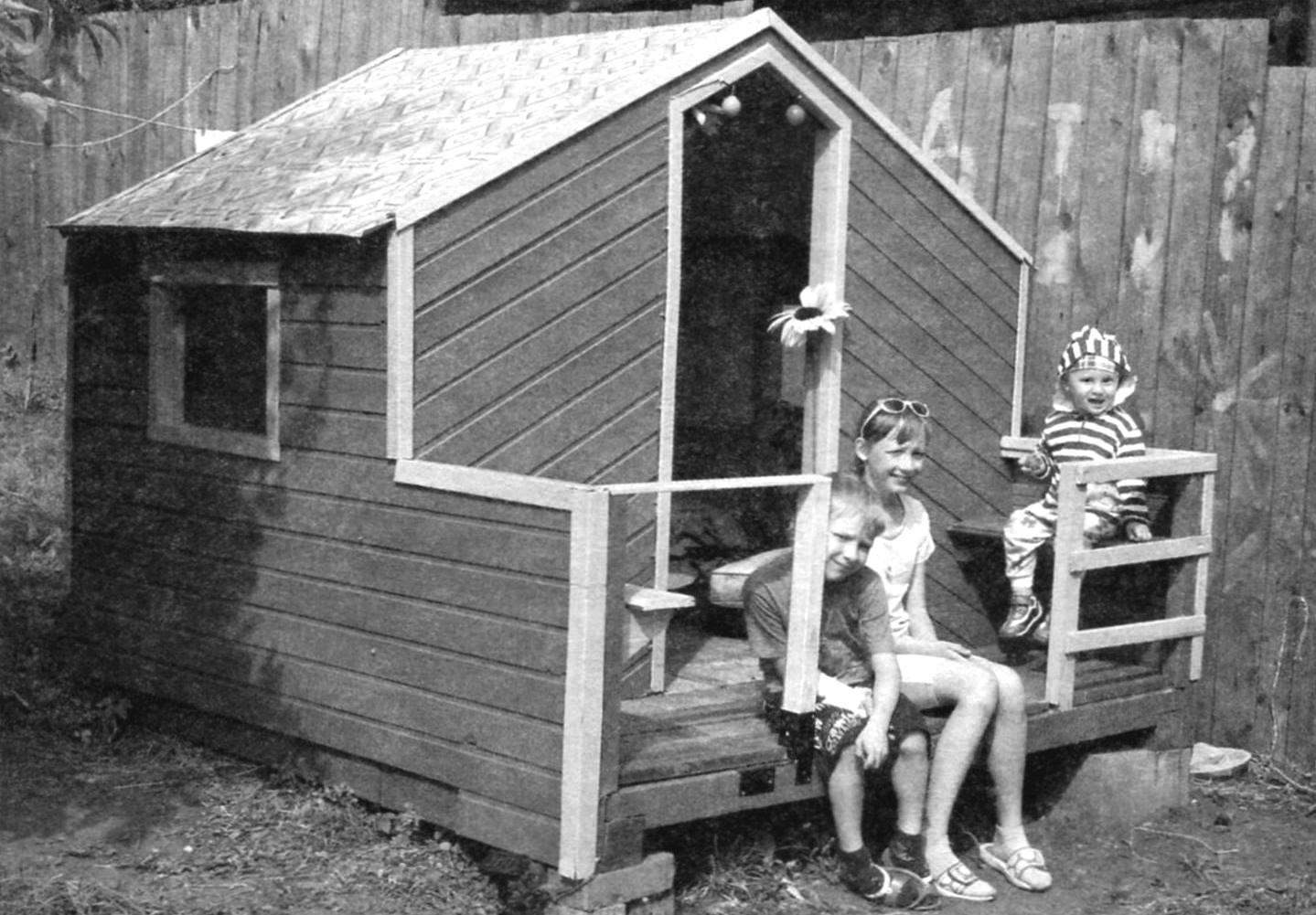

Frame house front view

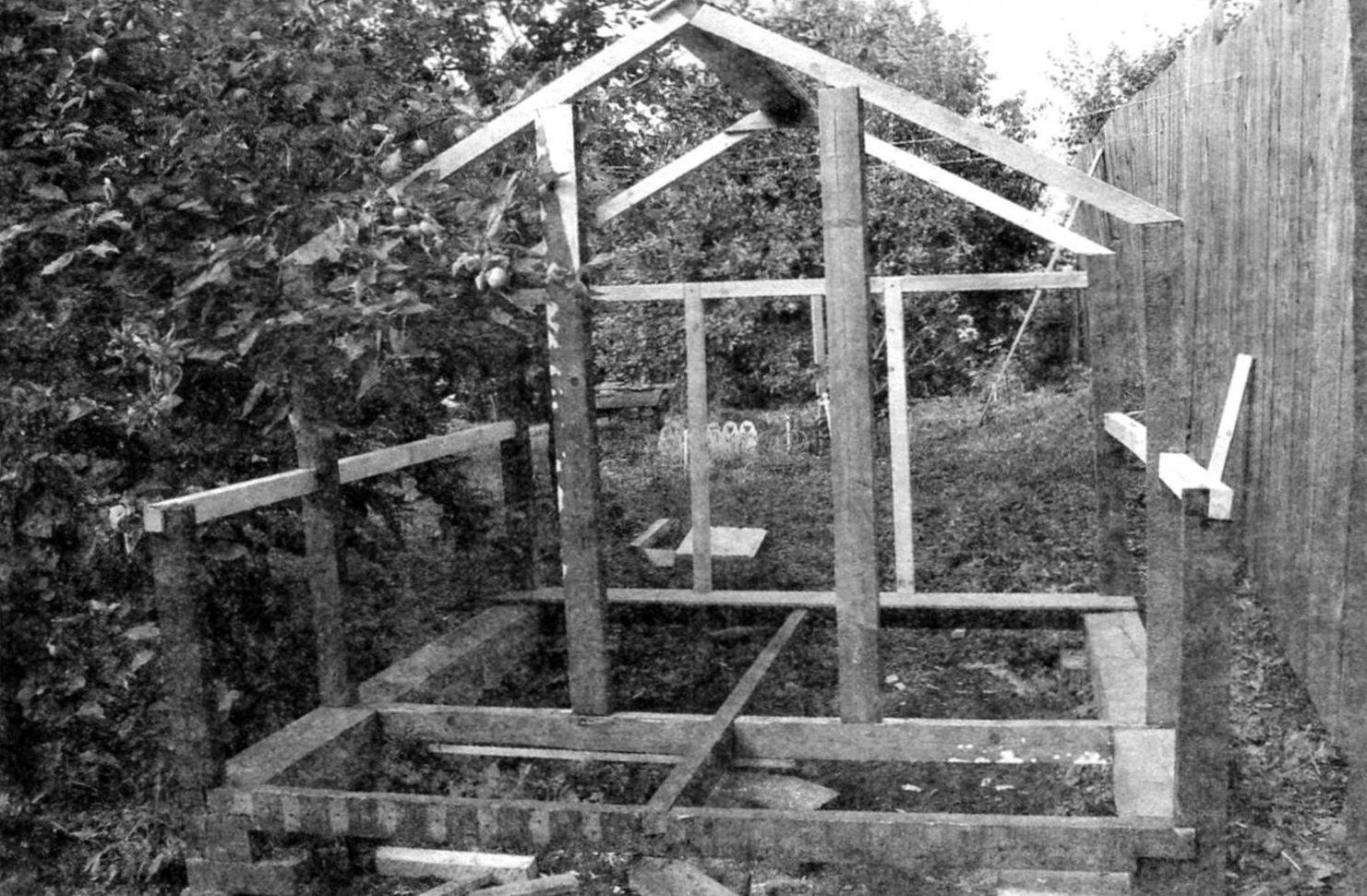

construction Progress. Trim the lining used for facade cladding

Then started erecting the frame for which we used a timber cutting cross-section mm 50×50 and 50×75 mm. The Height of the uprights of the house (section 50×75 mm), fixed on its perimeter, was chosen “by eye” – 1 m, and the porch – 0.6 m. a Vertical support attached with screws to the timber strapping, inserting them into pre-prepared grooves.

A vertical support structure was tied in the middle with a beam size of 50×50 mm, the height of the entrance of the house chose on the growth of the eldest granddaughter, but with a small margin for growth. So the roof had to do gable with ridge. Based on this, stands the access opening made with a height of 1.3 m. since the walls had sheathing lining scraps left over from building a large house, the upper ends of the vertical supports to tie the sides of the lumber did not. The only exception was the back wall, the side stand which was connected by a beam of size 50×50 mm using screws.

The front and back of the house is its vertical support bonded with the rafters of timber with dimensions 50×50 mm, connecting the last ridge beam of the same section. And rear rafters in the center of the ridge was bonded wooden solitaire.

Openings for Windows (three of them) to do until it was decided to first build the roof, as the summer fell a rainy.

The roof began to make with crates-she’s solid-made with scraps of lining, beat them with nails to the rafters. The gap from the top along the ridge until the seal was gone. For strength (in winter it is often snow) the roof in the middle of the reinforced wooden 10-mm strips, with the edges at the ridge beam and the top 15 mm Board cladding to side walls and secure them with screws from the inside to the roof boards.

At the same time the shortest scraps lining sheathed facade.

Then proceeded to window openings. On the top boards of the frame side walls secured by screws, two short vertical bars, and below them are fixed with metal corners on the bars of the median binding.

On the back wall to make a window, had to put two additional vertical bars, attaching them using such metal corners to the bottom rail of the house and the upper horizontal beam. Glass Windows until it was decided to close them from rain at the time the remains of a roll of insulation.

After this, the roofed floor, covering it with linoleum. The outside walls are sheathed with a lining, and the front did it in a herringbone pattern under the angle of the roof. Well aware that it is better to sheathe the outside of the house is vertical boards (less water will flow into the cracks), did the opposite. Since the work was done manually, it was easier and faster, and questionable joints sealed with sealant.

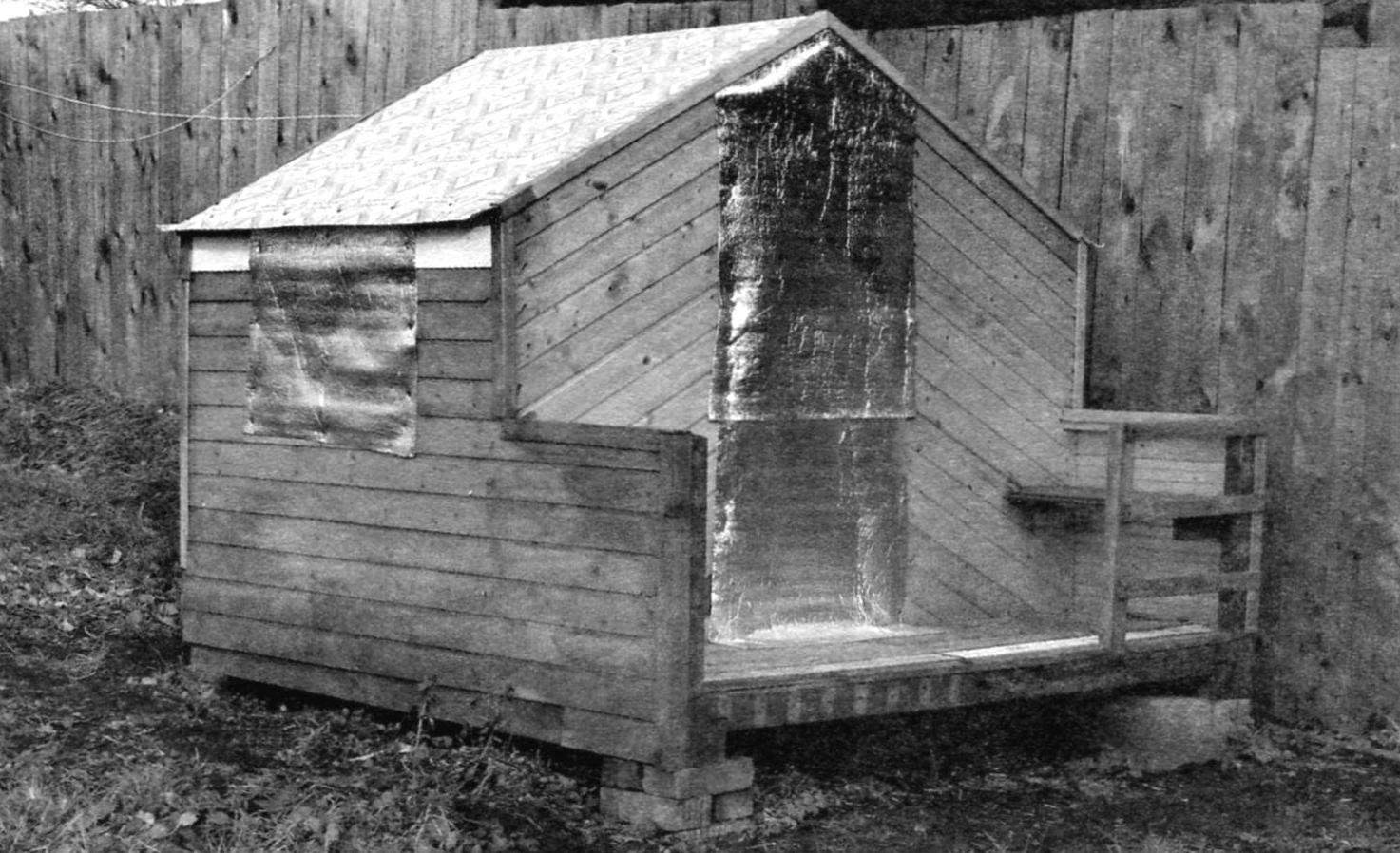

it looks like the house in the back

As the Windows and the front doorway opened to all winds, in winter, “preserve” the house with ISOVER insulation (mineral wool on the fiberglass and covered with aluminum foil), remaining after the construction of the baths

However, waste is still not enough and had to buy more. Inside the Lodge is partially sheathed with plywood and lining, securing around the Windows at the request of future “tenants” small shelf, and on the porch bench. Although next year will have to do another on the opposite side, “residents”, then three, and on the bench only fit two.

As the structure is designed for children, to prevent injury to all “questionable” places closed planed wooden corners and the skirting Board.

It should be noted that the wooden parts before Assembly, the inside was covered with Pinotex, and after final Assembly – and outside. Uncoated left the porch, because next spring will complete the plan, including to make a removable ladder.

It remains to solve the problem with the roof. Leave it like this for the winter do not like and had to cover with a thin linoleum. And laterally linoleum, pressed wood parts dimensions 50×50 mm and when the weather got colder (taking into account the possible compression of the roof in the cold), shot parallel to the decorative furniture nails (wide heads). Turned out beautifully, but as a building for children of winter see the spring.