It happens that some of the most common types of fastening parts — bolt weakened, cannot withstand the load: the bolt is cut, the remaining upper portion in one part and lower in another. And if the top part of it to extract just enough to work the key, to turn the lower is usually the problem. For this you have to drill a hole in it, then tap to cut a left hand thread to screw in there another bolt or pin and then use that to Unscrew the stuck “stub”.

It happens that some of the most common types of fastening parts — bolt weakened, cannot withstand the load: the bolt is cut, the remaining upper portion in one part and lower in another. And if the top part of it to extract just enough to work the key, to turn the lower is usually the problem. For this you have to drill a hole in it, then tap to cut a left hand thread to screw in there another bolt or pin and then use that to Unscrew the stuck “stub”.

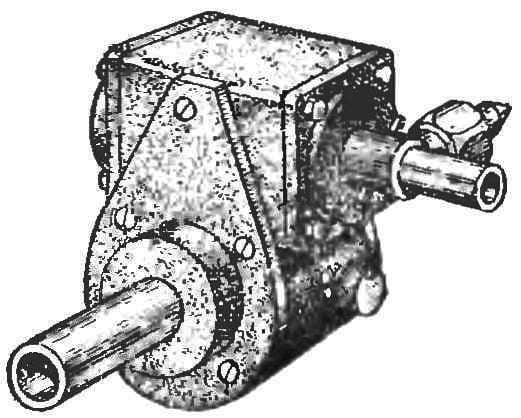

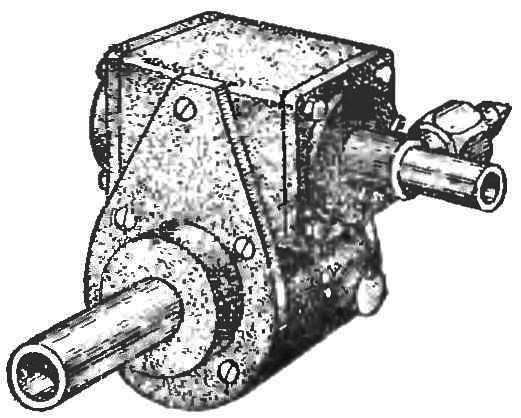

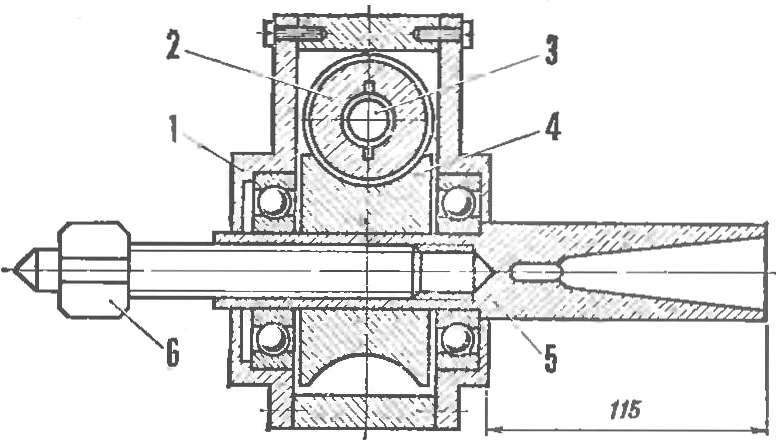

This is often the drilling has to be done manually, using the so-called “ratchet”. Innovator of the mine office Voroshilovgradsky N. Seagull has found a way to mechanize this operation, the developing device on the basis of the drill. The device consists of a worm gear whose worm wheel shaft has a form that allows to insert it into the Chuck of a drill. The torque is transmitted to the second worm mounted on a shaft with a cone, designed for mounting in the drill of the required diameter. The required force for axial feed of a drill in the cone is achieved by mechanical means: unscrewing screw M24 abutting any nearest ledge. This attachment to the drill increases production, reduces labor intensity of the operation and accelerate the repair works.

Attachment to the drill:

1 — reducer, 2 — worm wheel, 3 shaft, is inserted in the drill, a 4 second worm, 5 — Wai with cone, 6 — stop screw.