The functions of the boring machine can run, and milling. Of course, at a lower level of precision, but for many works this is not essential. For such conversion we recommend you to use developed in Valuyskiy young technicians universal boring head: it impresses manufacturability and simplicity.

The functions of the boring machine can run, and milling. Of course, at a lower level of precision, but for many works this is not essential. For such conversion we recommend you to use developed in Valuyskiy young technicians universal boring head: it impresses manufacturability and simplicity.

The device consists of the following elements: tapered shank, hub and tailstock. Hub is planted on a shaft with four screws, two of which are parallel to the clamped and the tailstock. The cutter is fixed in the slider moving in two quill located inside the cylindrical guide. The movement of the slide with lead screw.

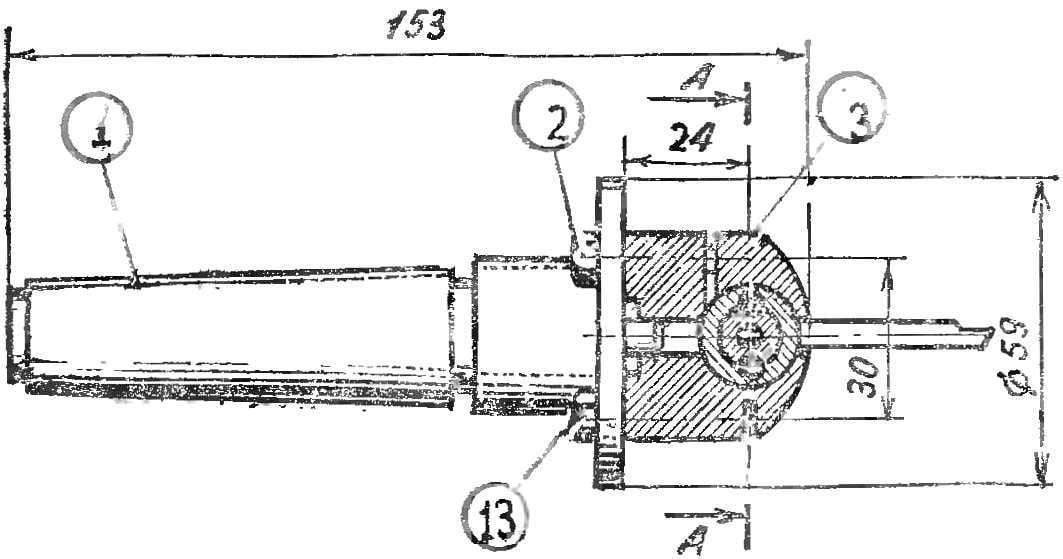

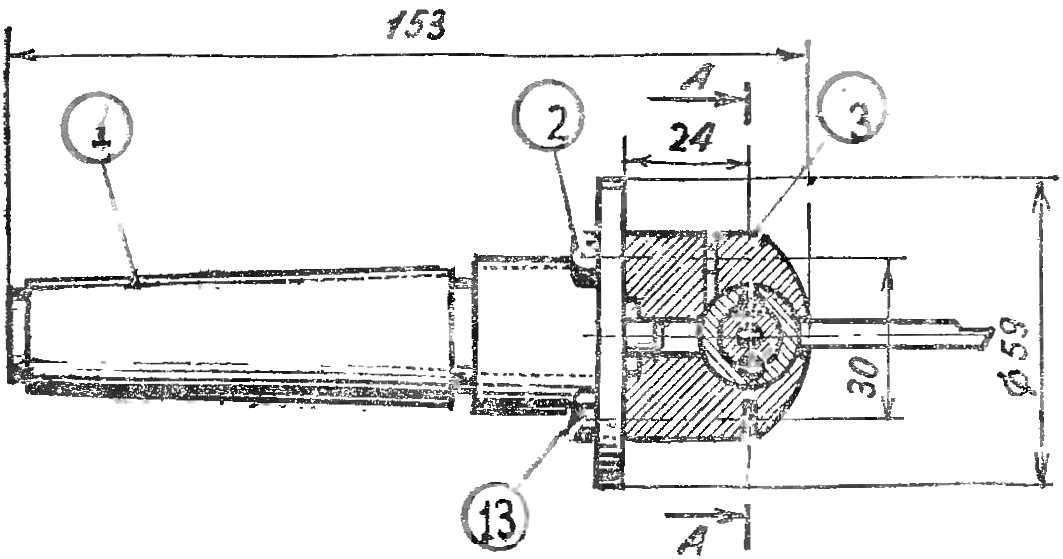

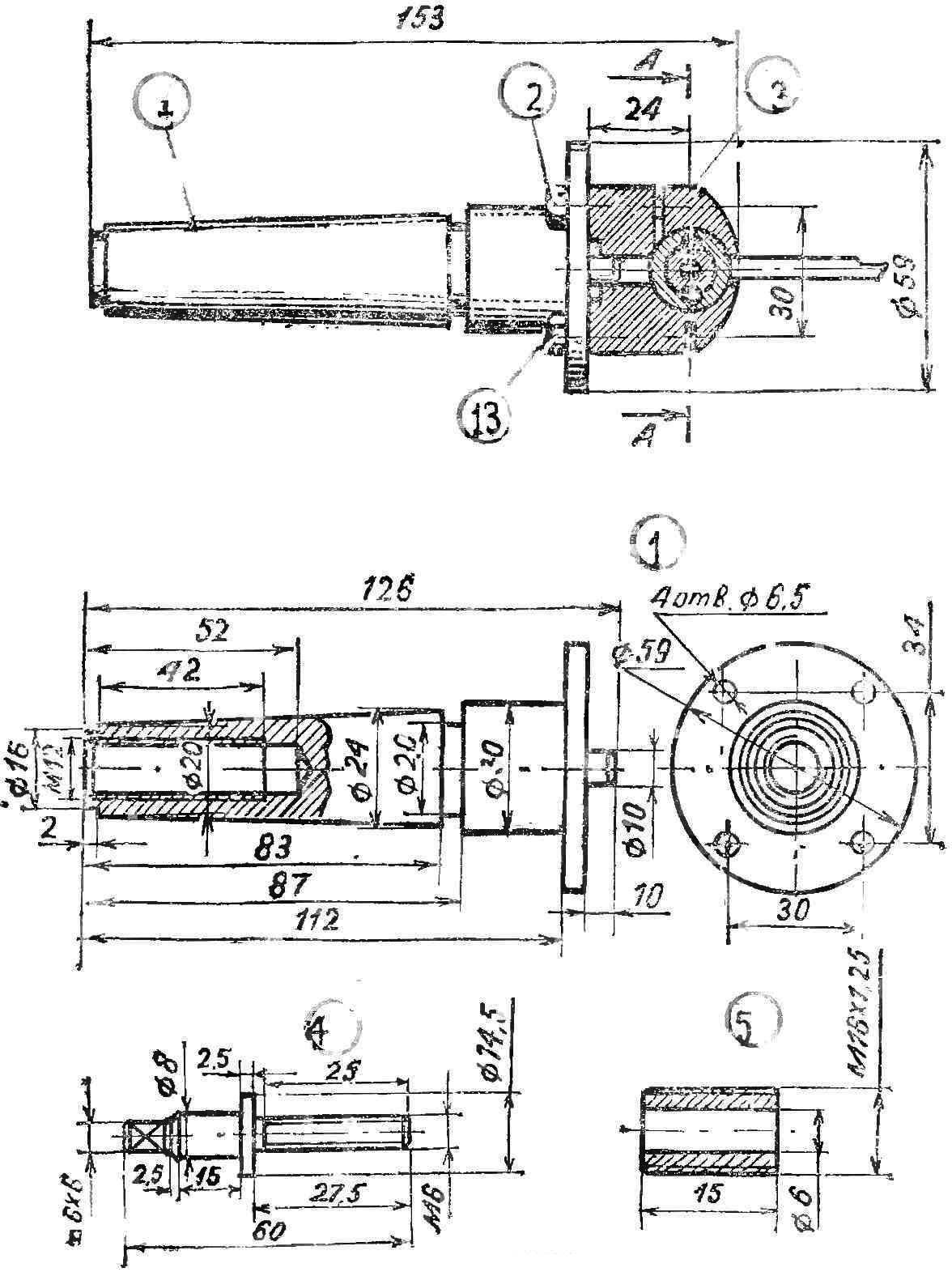

Boring head for milling machine:

1—a shank with a Morse taper (steel 45), 2 — screw M6, 3 — hub (steel 45), 4 — spindle (steel 45), 5 — Bush (Bris-4-4-17), 6 — locknut (steel 20), 7 — the slider (steel 45), 8 — M6 screws, 9 — track (steel 45), 10 — tube (Bris-4-4-17), 11 — the tailstock (steel 45), 12 — washer, 13 — M6 screws, 14 — boss (steel 45), 15 — arm (steel 20).

Boring head operates as follows. The tail part is inserted into the spindle of milling machine is fixed and regular clamping screw. The workpiece is clamped in a vise or machine table. When boring holes up to 40mm diameter adjustment of the cutter position relative to the center of the hole is only. due to the extension of the RAM. Boring of holes with diameter up to 85 mm can be carried out in two steps. First, as described above, then the slider should move to its original position, loosen the clamping screws and move the tailstock all the way into the hub.

Control of hole diameter — on a scale marked on the end surface of the sleeve (POS. 5). The set of fixtures also includes a handle for driving screws and clamping screws.

Yuri KUTEPOV, Valuyki