The method of circular broaching increasingly used for cutting the teeth of bevel gears, such as differential drive axle of the vehicle. The essence of the method of machining the workpiece cutting tool of a large diameter with radially arranged cutters. This technology is one of the most productive methods of manufacturing straight bevel.

The method of circular broaching increasingly used for cutting the teeth of bevel gears, such as differential drive axle of the vehicle. The essence of the method of machining the workpiece cutting tool of a large diameter with radially arranged cutters. This technology is one of the most productive methods of manufacturing straight bevel.

However, circular broaches are among the most complex and expensive instruments. So the innovators are constantly pay great attention to improve their design and increase durability. This has been achieved by using a modified tool, implemented at the Ryazan plant of automobile units and KAMAZ.

The existing tool for cutting the teeth with a module of 5 mm and above provides two serial operations — roughing and finishing. The last one only performs the profiling cavities of teeth with minor removal of surplus metal. But for rough subprocedure in which the cutters remove up to 80% of the metal, the characteristic maximum load on the cutting tool. Particularly large voltage is necessary to experience the first 15-20 cutters, ripping up “virgin” in the initial passages from the sock to the heel of the tooth. This removes the wide and short chips and the level of vibration reaches a maximum, causing the impact in the kinematic chain of the machine. Such a regime leads to the formation of cracks and chipping on the cutting edge of cutters is that they are easily damaged.

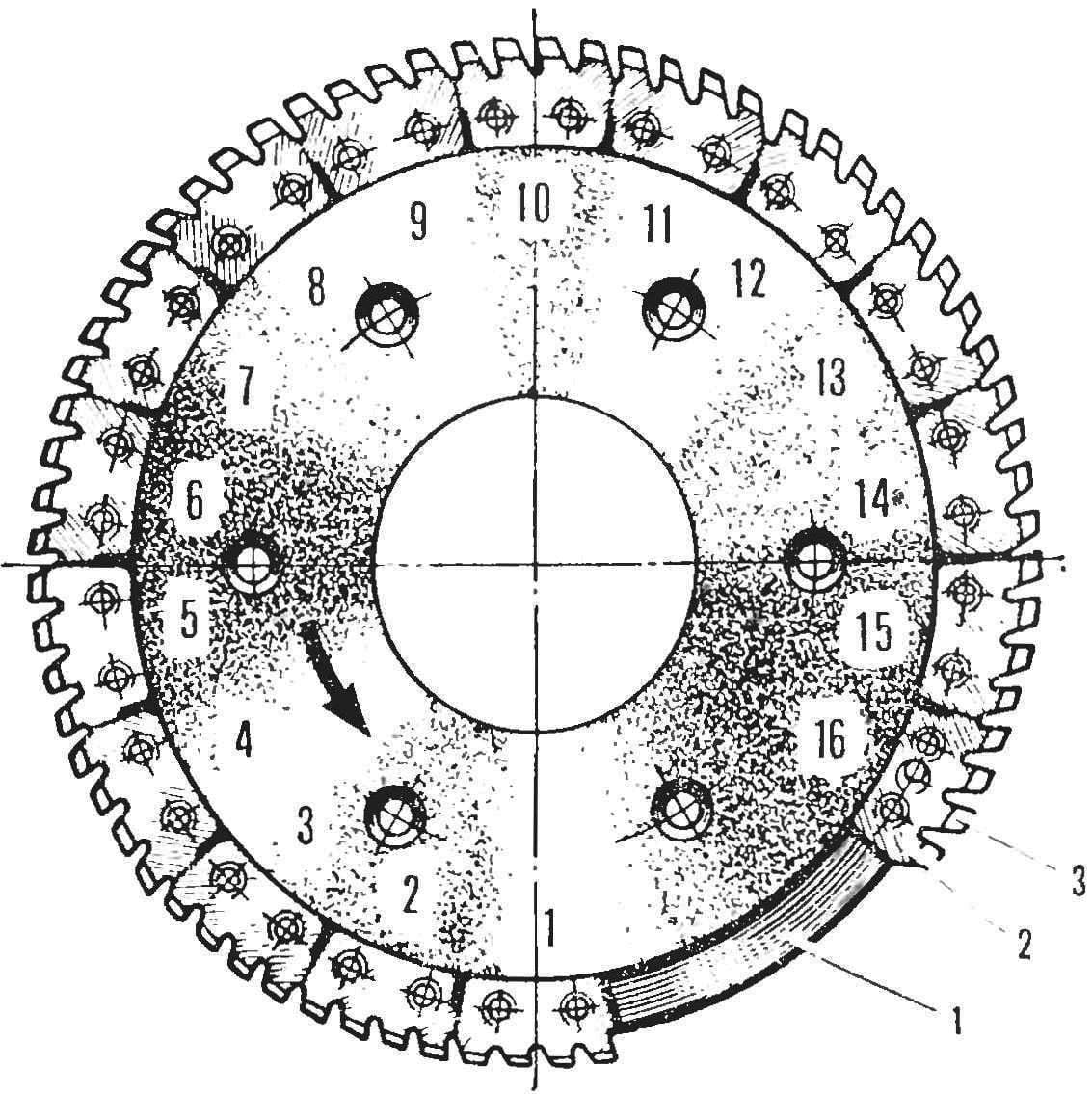

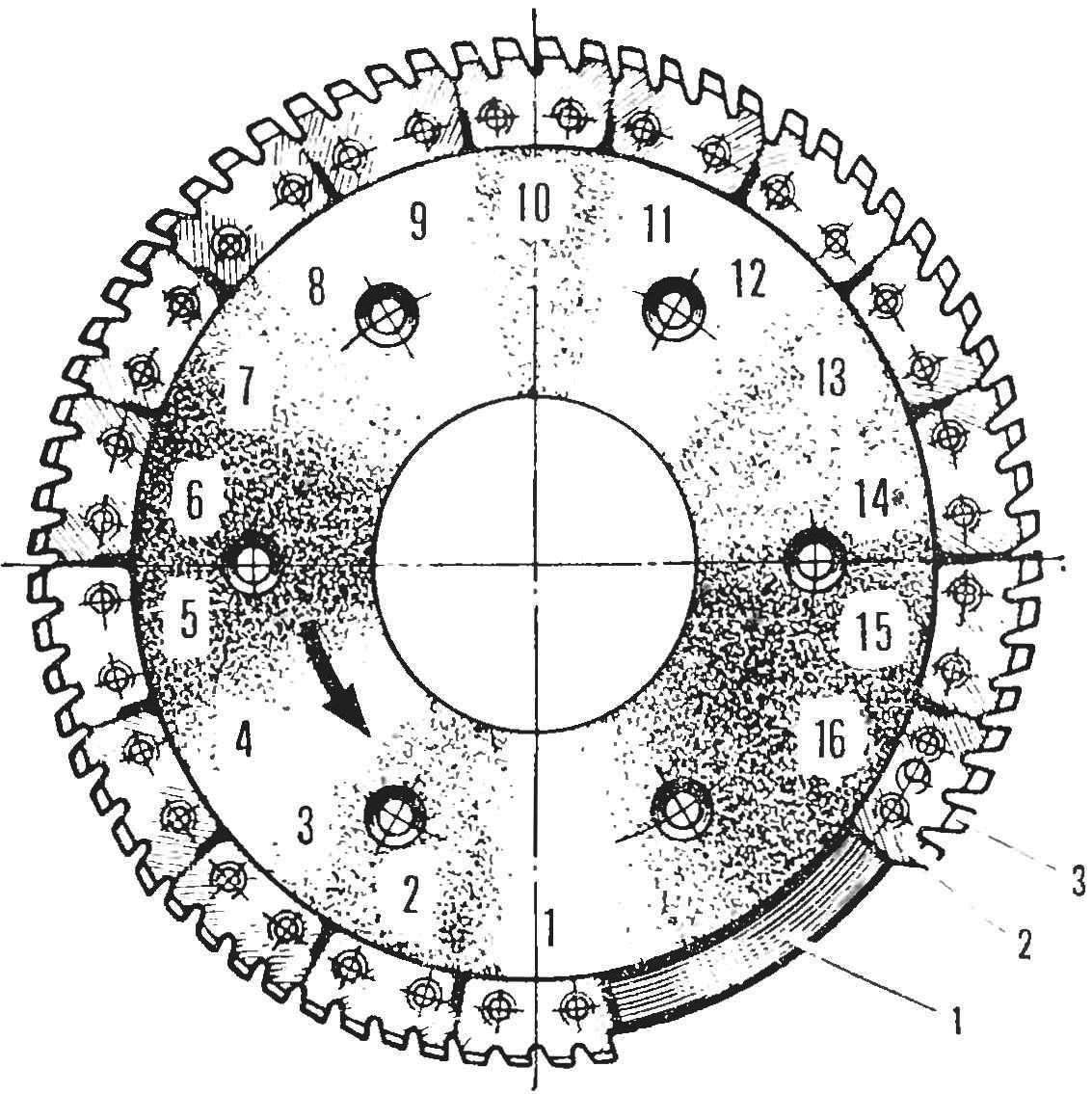

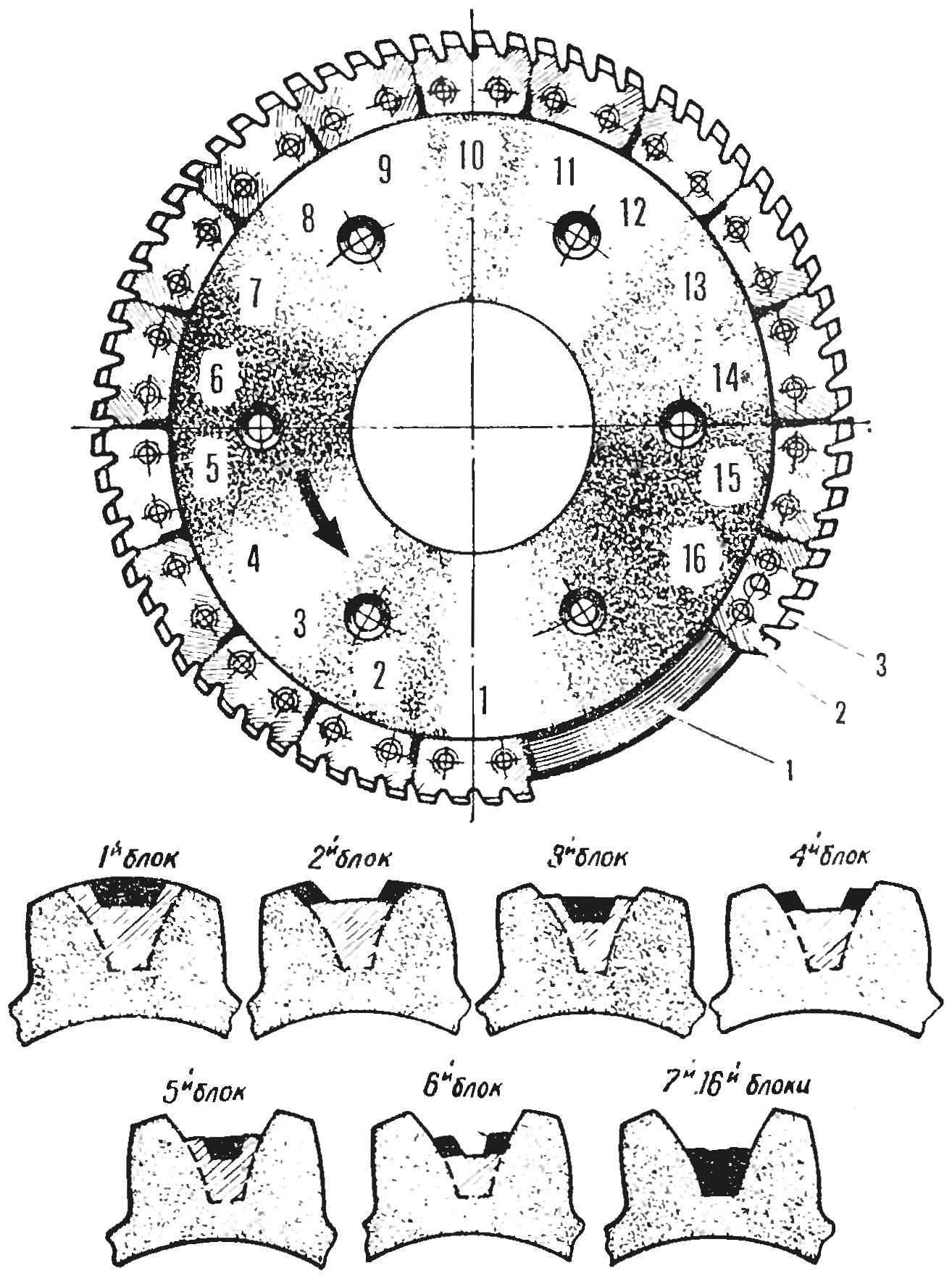

Circular broach:

1 — ROM-base, 2 — blocks cutters, 3 — cutting edges; bottom — diagram of the step of cutting the blocks.

In the new tool all tools are divided into three groups that comprise the “specialized” units. The cutters of the first group, which consists of the blocks 1, 3 and 5, have a relatively narrow width of the cutting edge and cut only the middle upper part of the basin. Blocks 2, 4, 6 combine cutters of the second group: with its broad edges, they are removed from the first passages of the sidewall of the upper part of the basin. After that wide strip of metal is selected, enter the working tools of the third group, grouped in blocks 7 through 16. They are easy to finish processing the trench to full depth.

Due to the fact that the tools perform part of the General operation alternately, the load on them is distributed evenly, the treatment goes smoothly, without bumps, greatly reduced vibration, eliminates cracks and chips of the cutting edge.

The durability of the cutting heads increases 1.5 times. The transition to such a tool gives up to 50 thousand rubles in savings per year.