Very often for finishing wood products use burning. Even if this operation is performed by a special device — cautery, it is very time consuming, especially when applied to a variety of complex patterns. I want to offer successfully tried mechanized method of burning intricate patterns and various applications. It is much more productive than the traditional method and besides, it was pretty spectacular.

Very often for finishing wood products use burning. Even if this operation is performed by a special device — cautery, it is very time consuming, especially when applied to a variety of complex patterns. I want to offer successfully tried mechanized method of burning intricate patterns and various applications. It is much more productive than the traditional method and besides, it was pretty spectacular.

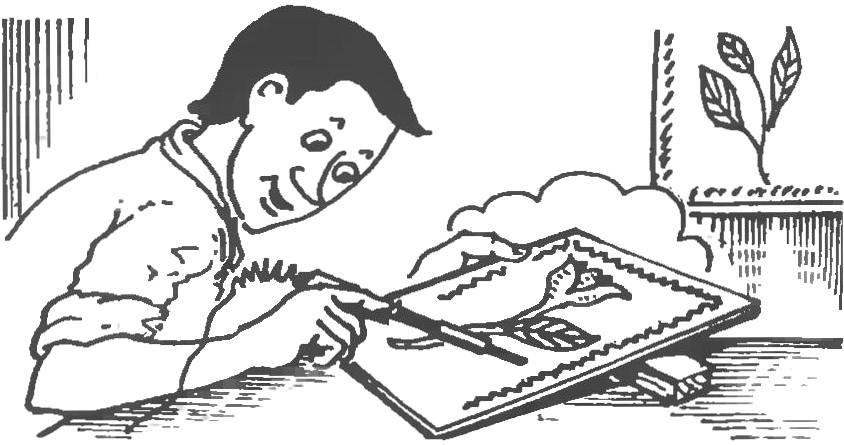

To speed up work using an ordinary electric soldering iron 150 W (however, the results with 100-watt soldering iron is no worse).

The fixture of the soldering iron to burn is that it grinds the copper rod so that its end came the element of the ornament or figure.

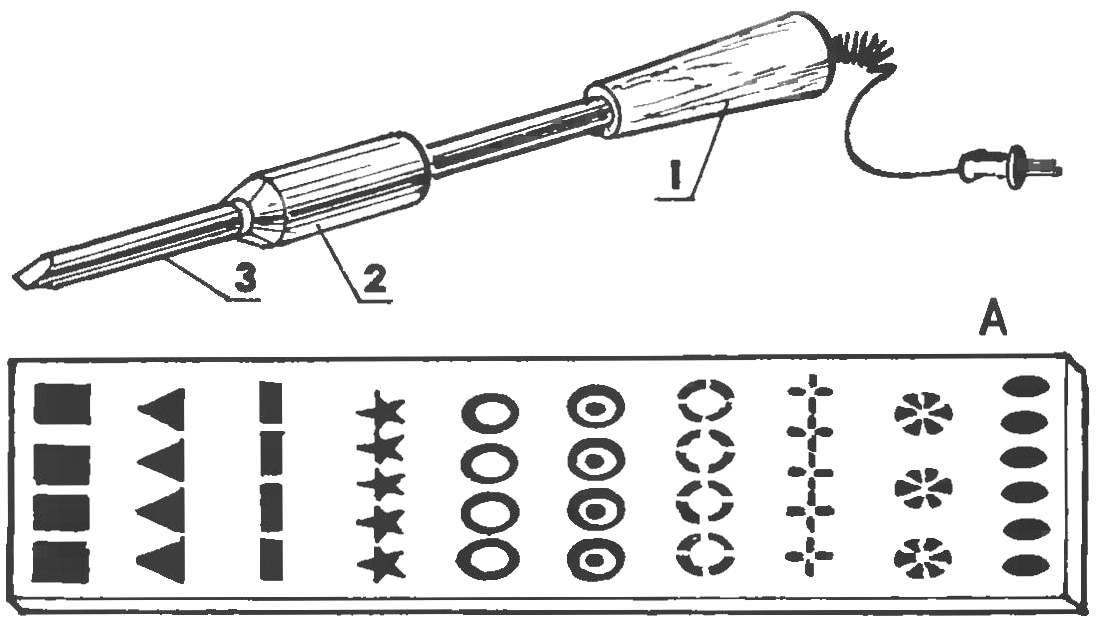

All the elements are performed on a lathe, but for the rest only need a needle file. In addition, to get the curves (and straight) lines, we can manufacture special rollers.

The burning process using such inserts is very simple. The soldering iron is set to one of the replacement rods, and soldering iron included in the network, giving it time to heat up. After the test on the rough piece of wood is burning in the product via pre-applied pattern or lines. The shaft of the soldering iron is pressed against the surface of the wood for 1 — 2 seconds. Depending on the power soldering iron time of contact increases or decreases to the contrary.

The electric soldering iron with replaceable tip for burning:

1 — the handle; 2 — heater; 3 — shaped shaft; And — options for cutting of the picture — depending on the profile of the rod figure

To replace the stem another during work not need to turn off the soldering iron and to wait, when the latter has cooled; it is enough to use pliers. Hot pin is necessary to put on a metal stand or ceramic plate, be sure to protect it from rolling.

The thus obtained prints and drawings have a very neat look, look impressive. In addition, their implementation requires a small amount of time, which is important when finishing products with a large surface or several products with the repeat pattern.

It is desirable to manufacture a set of different execution pins that will significantly increase the variety of pictures. But we must remember that the metal pins must be well to conduct heat, and therefore to use them for copper, aluminum, as, for example, steel pins heat up more.

Insert for burning in the form of a roller (A); B — versions of the picture — depending on the profile of the roller

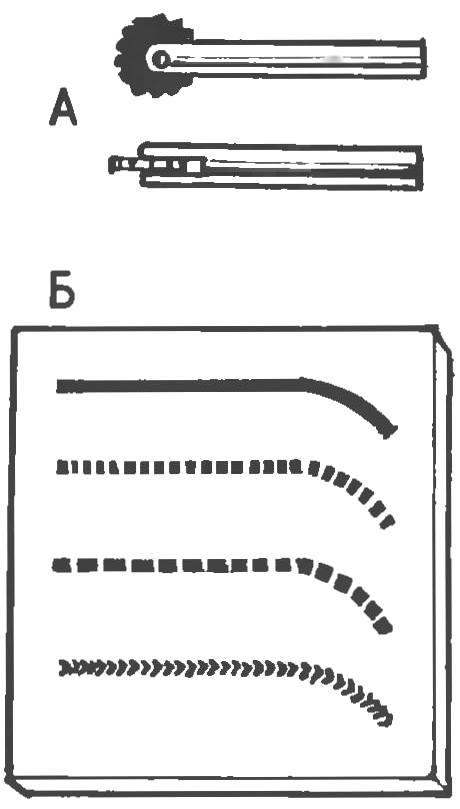

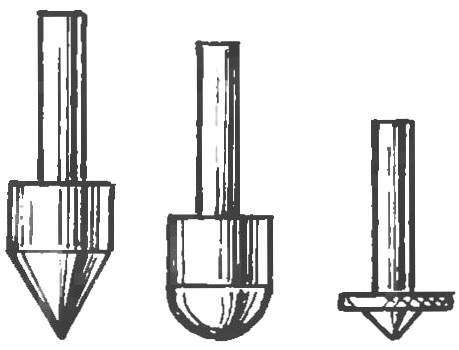

Convex tips for burning friction using a drill

One last thing: the room where you are burning must be frequently ventilated.

Another tool can help you in finishing the surface of wood by burning is a common electric drill or drill press. A method of producing a pattern with them can be called “the burning friction”. Work on here will be specially made convex tips of the metal produced on a lathe. The maximum diameter of the tip shall not exceed 30 mm (tested in practice). A prerequisite for this tip is the presence of the speaker center.

The burning process too simple Tip is secured in the Chuck, the number of revolutions of the drill is set to maximum, the tip gradually fed perpendicular to the planned place. The pressure force is determined experimentally.

Very good looking product, treated cone and spherical tip, after coating them with varnish.

A. LEUSHIN, p. Bazhelka, Kirov region.