Wood burning is very often used for finishing wooden items. Even when this operation is done with a special tool—a pyrograph—it is very labor-intensive, especially when applying various complex ornaments.

I would like to suggest a successfully tried mechanized method of burning complex patterns and various appliqués. It is much more productive than the traditional method and also quite effective.

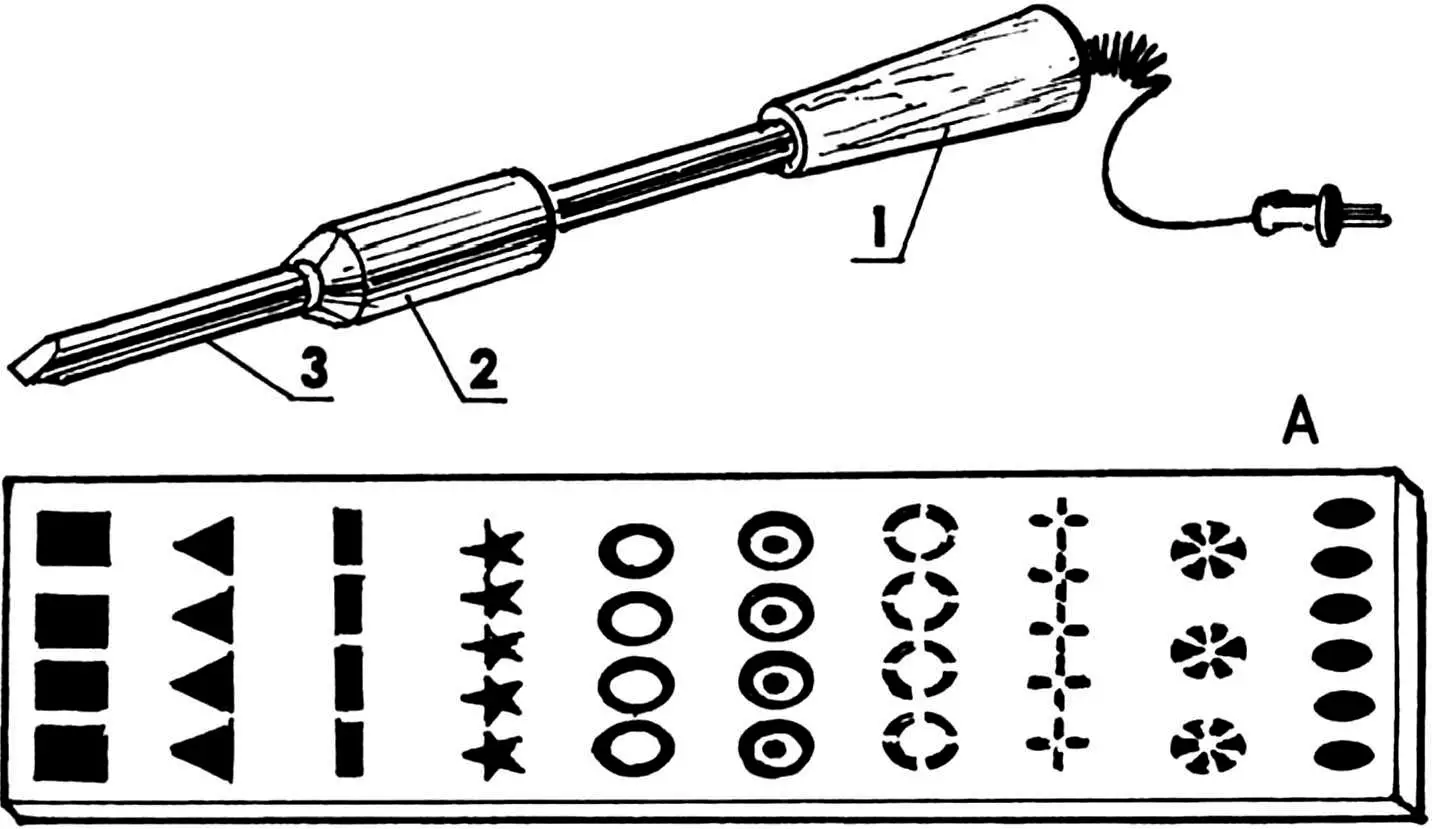

To speed up the work, an ordinary electric soldering iron of 150 W is used (though results with a 100-watt soldering iron are no worse).

Adapting the soldering iron for burning comes down to grinding its copper rod so that an ornament or design element appears at its tip.

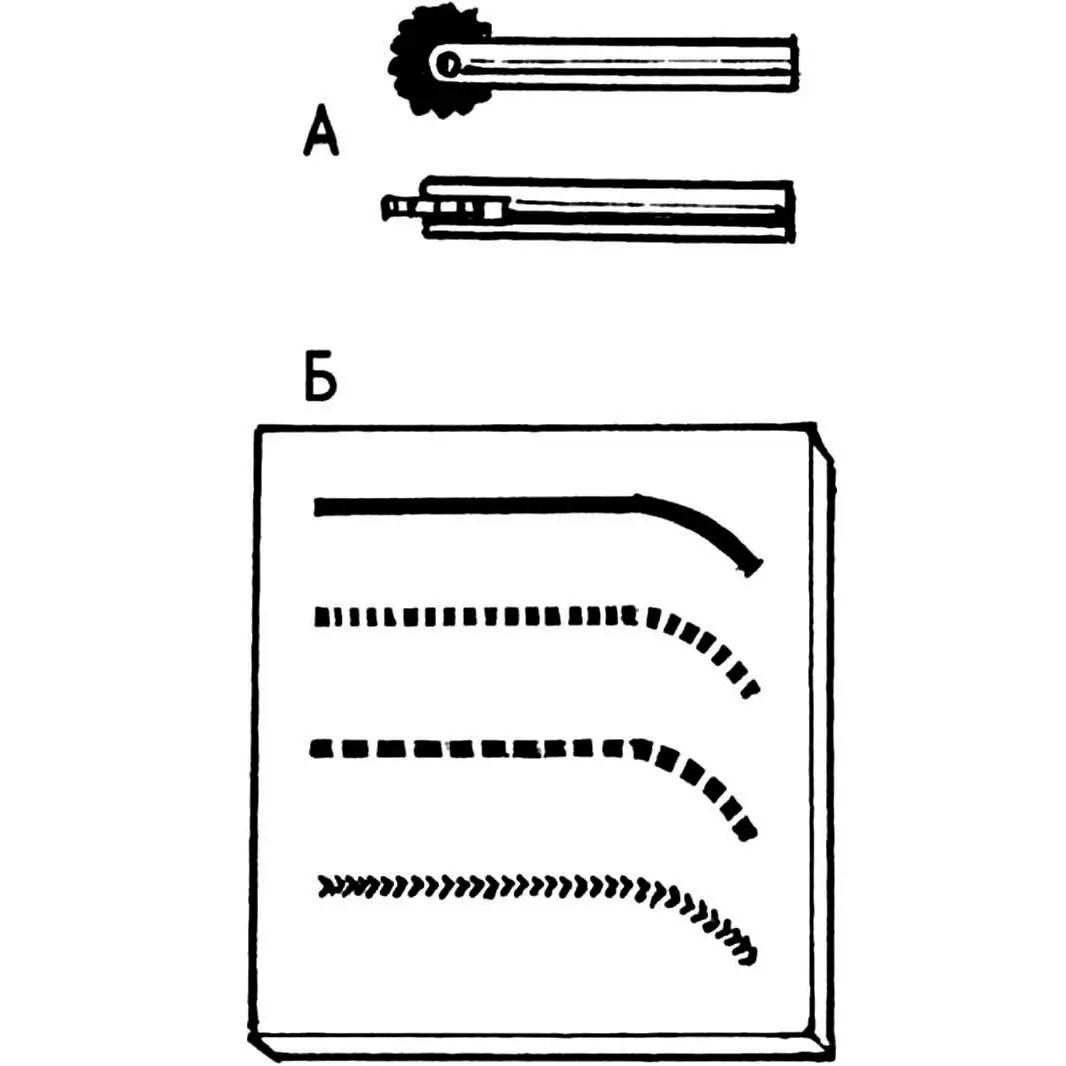

1 — handle; 2 — heater; 3 — shaped rod; A — variants of burned design — depending on the profile of the shaped rod

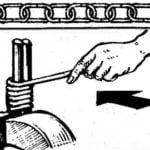

Round elements are made on a lathe, and for the rest only needle files are needed. In addition, special rollers can be made to obtain curved (as well as straight) lines.

The burning process with such inserts is very simple. One of the interchangeable rods is fitted into the soldering iron, the iron is plugged in and given time to heat up. After a test on a scrap piece of wood, burning is done on the workpiece along the pre-applied design or lines. The soldering iron rod is pressed against the wood surface for 1–2 seconds. Depending on the iron’s power, the contact time is increased or decreased.

To replace the rod with another during work, there is no need to switch off the iron and wait for it to cool; pliers are enough. The hot rod should be placed on a metal stand or ceramic plate, and kept from rolling away.

Ornaments and designs made in this way look very neat and effective. Moreover, they take little time to produce, which matters when finishing a piece with a large surface or several pieces with a repeated pattern.

It is advisable to make a set of rods of different shapes—this will greatly increase the variety of designs. But remember that the metal of the rods must conduct heat well, so use copper or aluminum; for example, steel pins heat up more slowly.

One more thing: the room where burning is done should be well ventilated.

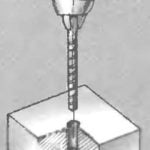

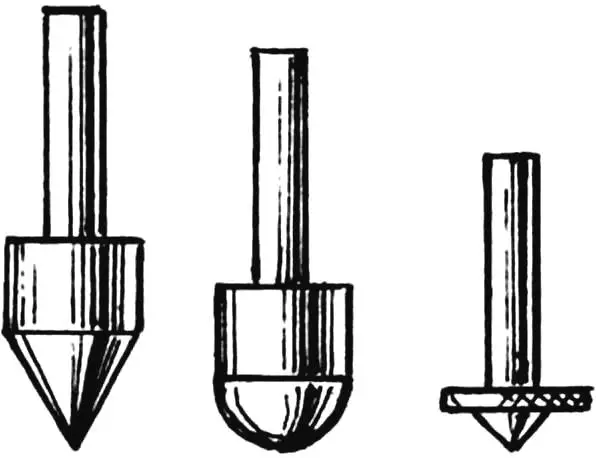

Another tool that can help you finish wood surfaces by burning is an ordinary electric drill or drill press. The way of obtaining a design with it can be called “friction burning.” The working part here is specially made convex metal tips produced on a lathe. The maximum diameter of such a tip should not exceed 30 mm (verified in practice). A necessary condition for such a tip is a protruding center.

The burning process is simple too. The tip is fixed in the drill chuck, the drill speed is set to maximum, and the tip is gradually fed perpendicular to the marked spot. The pressure is determined experimentally.

Pieces finished with conical and spherical tips look very good after being coated with clear varnish.

«Modelist-Konstruktor» No. 5’2006, A. LEUSHIN