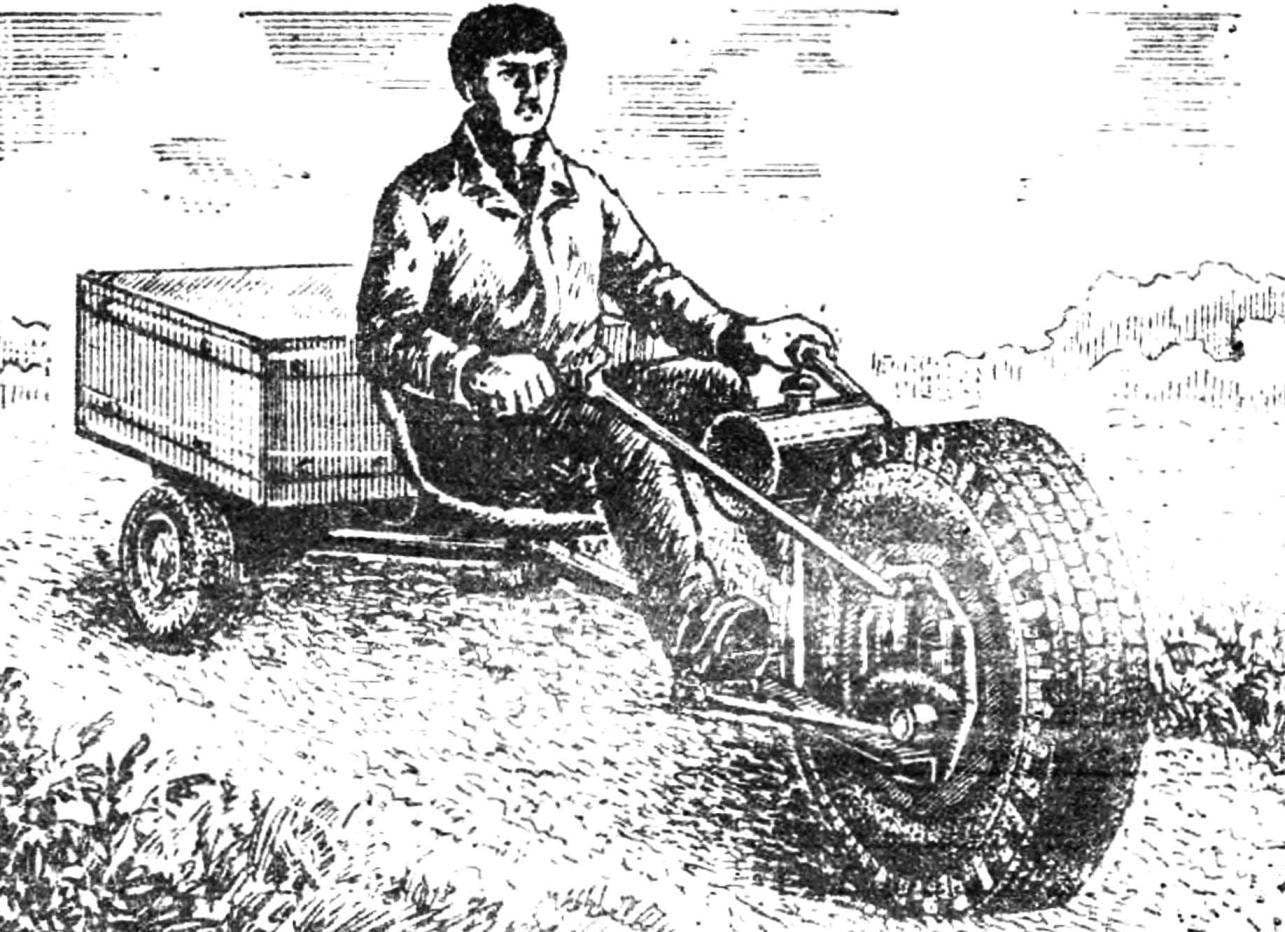

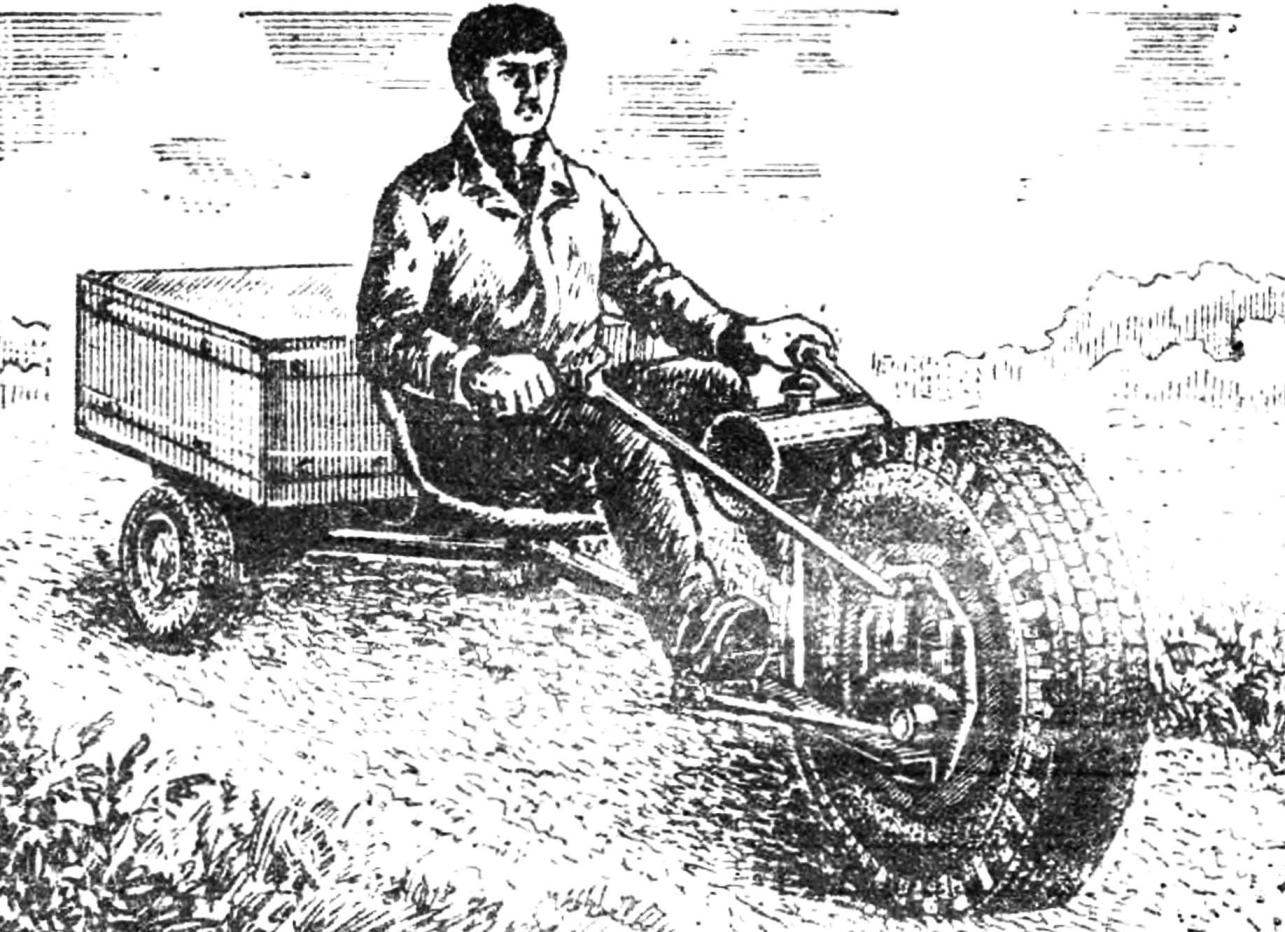

It is no secret that large diameter wheels have better maneuverability. In the case of using them and, by increasing the contact area — they provide good adhesion to the pound. However, when installing the power unit above the wheel or behind tillers obtained is too high or long. Why not use the internal volume of the wheel, placing the engine in the center ring of the disc?

Our truck was used the engine of the scooter T-200. It is mounted on welded tubular frame supported by five rollers on the inner ring of the wheel disc. The output sprocket of the engine are connected by a short circuit with the intermediate shaft, which still fortified sprocket cycloid gear with the drive wheels.

The frame carrying the engine, brackets support-guide rollers and the intermediate shaft, consists of two octagonal rings, made out of identical segments of water pipe 3/4. Both rings are connected in parallel to each other by four transverse tubular struts and bolts. This facilitates Assembly and disassembly of the unit, as the reference guide roller frame — steel rollers, provided with two flanges covering the ring “rail” wheel disc.

Fig. 1. The device is a one-wheeled tractor:

1 — frame, 2 — disc wheels, 3 — tire, 4 — engine. 5 — silencer 6 — steering fork, 7 — fuel tank 8 — the lever of kick starter, 9 — pedal switching speeds, 10 to the lower fork of the frame. 11 — reference-guide roller. 12 — chain drive to an intermediate shaft 13 — sprocket, intermediate shaft 14 — bearing supports the intermediate shaft, 15 — brake pedal 16 — swivel hitch.

Fig. 2. Frame:

1 pipe 3/4″. 2 — brackets oboronpromleasing rollers, 3 — mounting brackets engine 4 — mount plate steering fork, 5 — the bearing housing on the intermediate shaft.

A couple of corners 40X40 mm,-bracing to the lower part of the frame forms a support for the wheel pivotally coupling device and carries brackets pedals shifter and brake control. In the upper part to the frame is connected a tubular steering fork. It can be used fuel tank, handle the clutch and gas. Additional rigidity gives the frame vertical posts connecting the upper and lower racks.

The drive wheel forms a cylindrical rim, welded from steel strip with a thickness of 1,5 mm. on the outer side at a distance of 20 mm from each end by a welded 8 steel eyelets with threaded hole M8. Inside the disk in the middle of its width is set in chain wheel consisting of two steel rings that are connected in Parallel to each other at a distance of 14 mm close cylindrical pins that are machined from steel rod Ø 14 mm and hardened. The inner cylindrical surface of the rings of the wheels serve as support surface for the rollers sub-frame, and the cycloid pins provide engagement with the drive sprocket of the intermediate shaft.

Fig. 3. Disc wheel:

1 — compression ring, 2 — lug, 3 — wheel disc, 4 — pin Ø 14 mm, 5 — pinwheel.

Fig. 4. Reference-guide roller:

1 — roller, 2 bearing No. 203, 3 — axis, 4 — puck.

As the tyre was used to the cut the diameter of the disc outer part of the tubeless tires. It is better to use the diagonal because its a hard side bear the weight of the unit and swap the air is not required. Otherwise, the internal cavity of the tyre during the Assembly tightly to hammer rags, waste rubber or just straw. The disk lid is secured by two steel rings which secure the edges of the sides with bolts through the through holes to the lugs.

The tractor is designed for use with two-wheeled trailer. The stability he provides for pivotally coupling device bottom part of the frame. It has a vertical axis and a horizontal base plate. The drawbar trailer is equipped with a bushing under the vertical axis, and at the end of the video. This arrangement reduces the bending loads of the rotary axis.

The accessory kit allows you to use the truck not only for transportation, but also ploughing, cultivating, harrowing and other operations in the cultivation of the land.

A. MASTRYUKOV, city of Novotroitsk, Orenburg region.

Recommend to read METEOR-CROSS Homemade mikromototsikly built using bicycle parts and children's scooters, gaining among our youth is growing in popularity This is quite natural: a miniature car garage is not needed,... “SNOWFLAKE” WINTER ALL-TERRAIN VEHICLE One or two tracks at the back, two skis at the front, a seat for two passengers - this is what motorcars look like - the machines that are now making a triumphal march around the world....  Compactness, maneuverability and good traction — the undoubted advantages of the one-wheeled tractor created at the station of young technicians in the city of Novotroitsk. They managed to obtain, using the unusual tillers layout of the “wheel — motor”, which provides a minimum unit size, and ease of transmission.

Compactness, maneuverability and good traction — the undoubted advantages of the one-wheeled tractor created at the station of young technicians in the city of Novotroitsk. They managed to obtain, using the unusual tillers layout of the “wheel — motor”, which provides a minimum unit size, and ease of transmission.