Do not rush to dispose of old vacuum cleaner: the motor will serve to drive crusher — indispensable assistant in the preparation of feed for poultry and other domestic animals. The principle of operation of the devices is the same as the electric coffee grinder: swivel high speed metal plate — knife slices through the grain for as long as their value will not be less than the mesh size.

Do not rush to dispose of old vacuum cleaner: the motor will serve to drive crusher — indispensable assistant in the preparation of feed for poultry and other domestic animals. The principle of operation of the devices is the same as the electric coffee grinder: swivel high speed metal plate — knife slices through the grain for as long as their value will not be less than the mesh size.

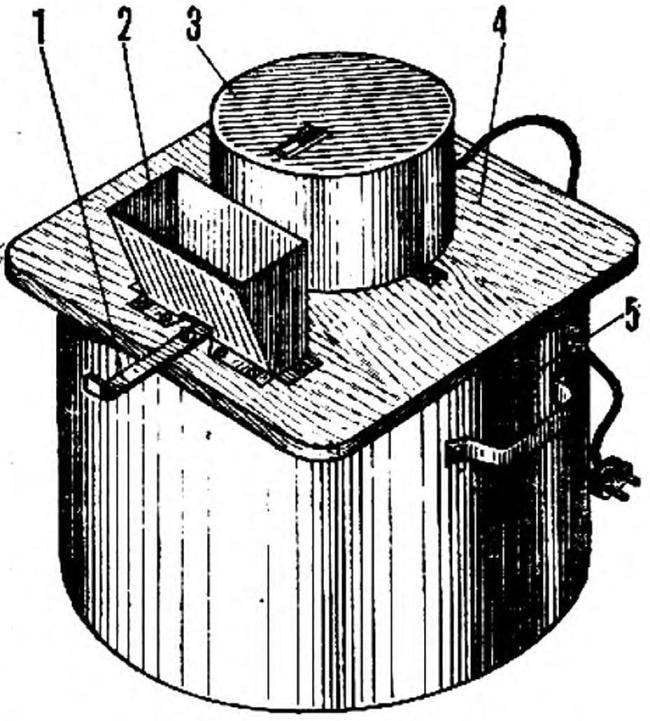

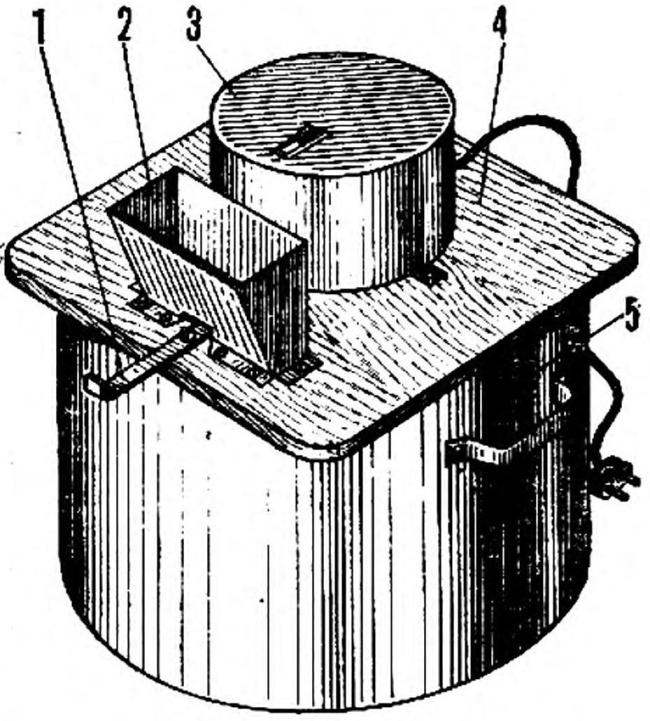

Based on the square sheet of plywood (10X300X300 mm) reinforced top motor so that the shaft went down by 35-40 mm. At its threaded shank with the bushing, washers m and nuts installed the operating element of the crusher — steel plate with a thickness of 1-1,5 mm, dimensions mm. 15X210 Axial bore in it must be fulfilled exactly in the middle of its length, and the edges on both sides of the axis — sharpened.

The working chamber of the crusher forms an annular housing with internal Ø 220 mm and height of 40 mm. It rolled from a metal strip with a length of 705 mm and a width of 60 mm Both edges of the ring are bent around the perimeter outwards, forming a flange width of 10 mm for fixing to the base and attach the sieve.