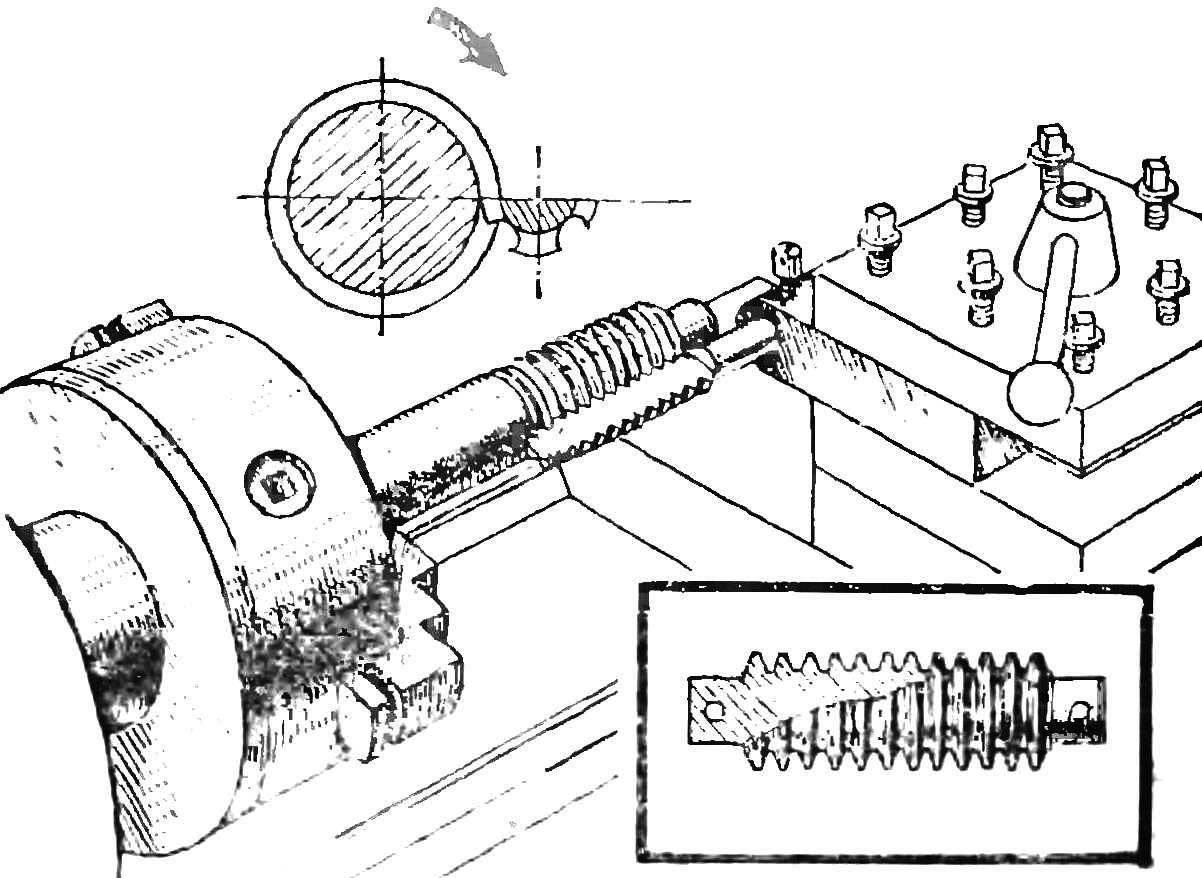

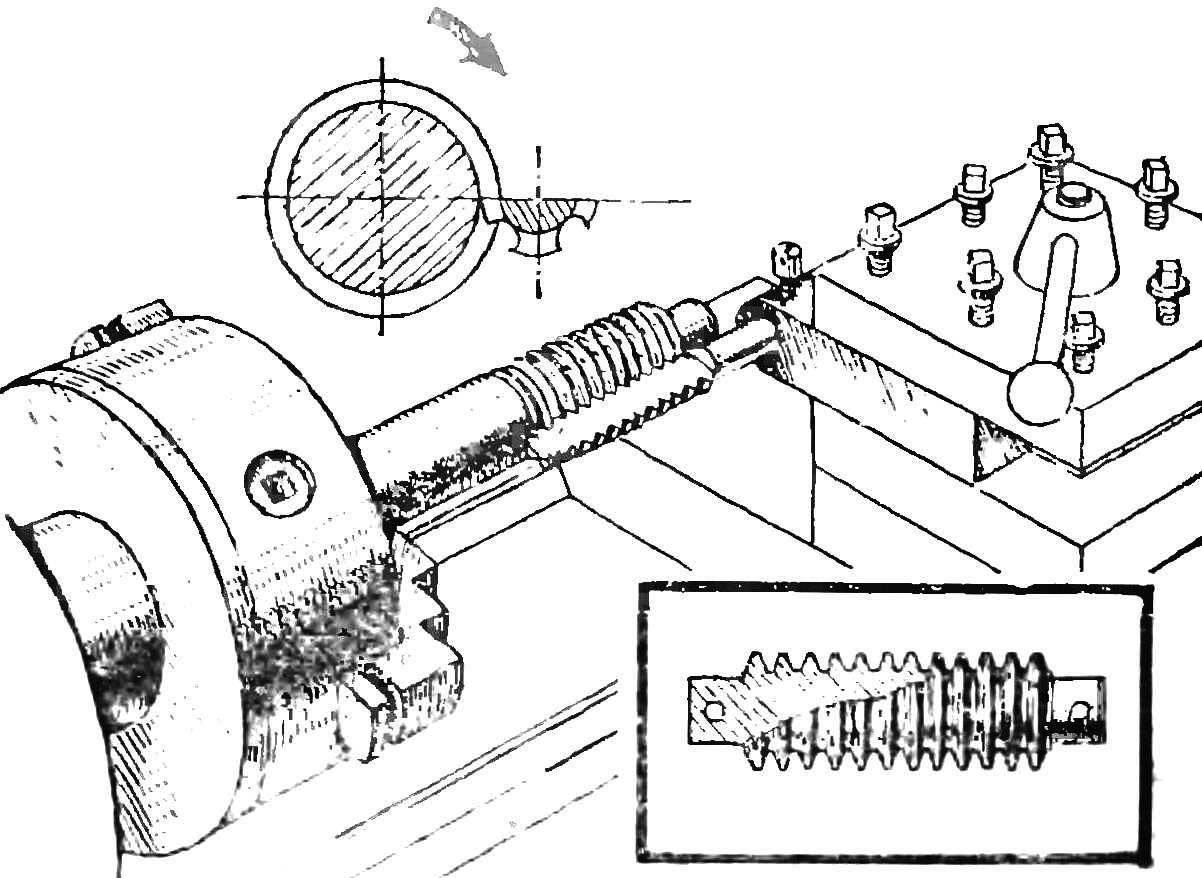

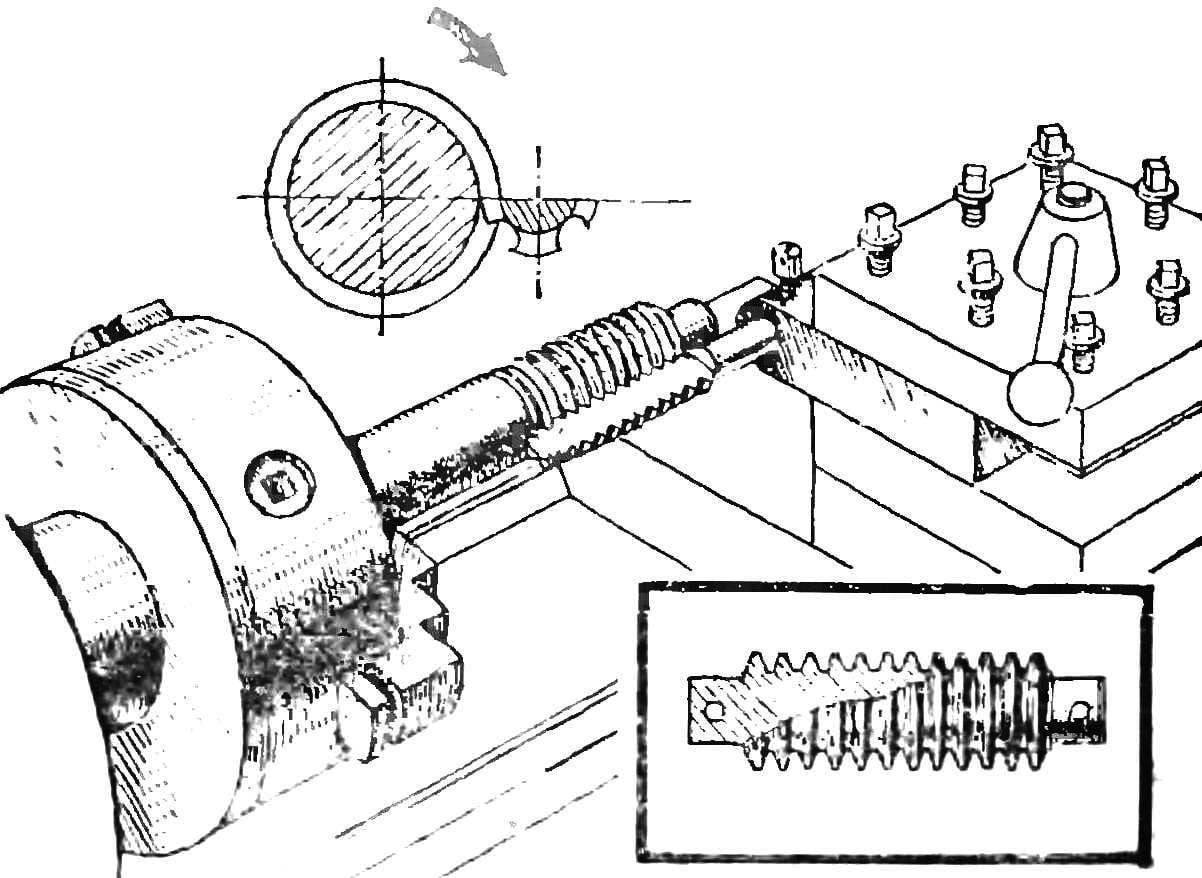

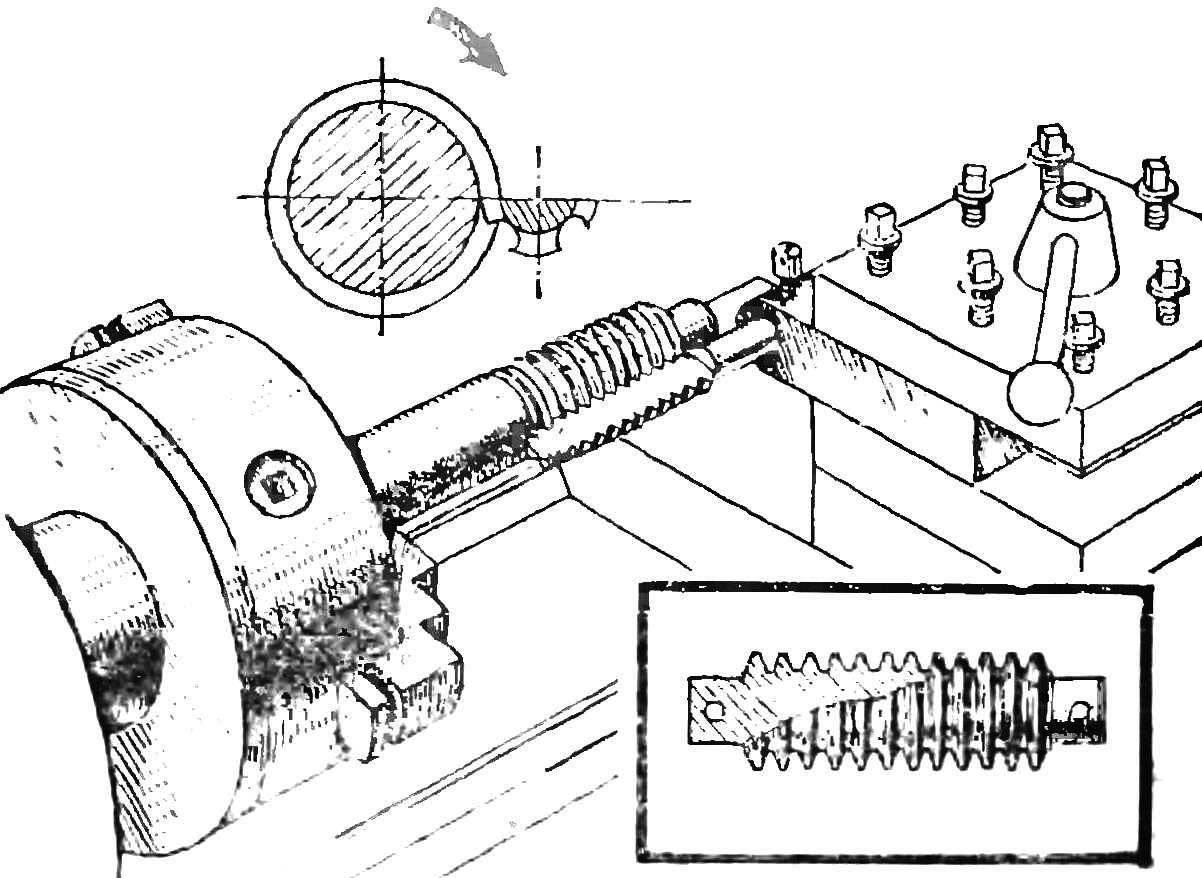

We offer you a simplified method of manufacturing a cylindrical gear rack. It can be done with a conventional tap, picking up the thread profile in accordance with your existing gear. Before working make a simple mandrel is a steel bar with a hole, which is inserted into the tap. The tap should be to grind on the sandpaper by about half. Processing is done in the following way. Dressed in the machine workpiece is a cylindrical rod, turn on the machine, and improvised cutter is applied to a rotating workpiece. The rod is cut a full thread profile (this requires to remember the division of the nonius cross-feed), the cutter is given a longitudinal feed handwheel moves to the left (cone!). Operation recess is repeated.

Recommend to read

The intricacies of opening a padlock

The intricacies of opening a padlock

Today in various spheres of our life are widely used padlocks of different nature. For example, they can be seen on garages, sheds. In addition, they meet and in the case of summer... FOR STUKELEY SCHEME

FOR STUKELEY SCHEME

The search for new solutions before the next sports season has led our members to very unusual for present-day design. In a subclass of HH-0.2 is now dominated by specialized yacht...

We offer you a simplified method of manufacturing a cylindrical gear rack. It can be done with a conventional tap, picking up the thread profile in accordance with your existing gear. Before working make a simple mandrel is a steel bar with a hole, which is inserted into the tap. The tap should be to grind on the sandpaper by about half. Processing is done in the following way. Dressed in the machine workpiece is a cylindrical rod, turn on the machine, and improvised cutter is applied to a rotating workpiece. The rod is cut a full thread profile (this requires to remember the division of the nonius cross-feed), the cutter is given a longitudinal feed handwheel moves to the left (cone!). Operation recess is repeated.

We offer you a simplified method of manufacturing a cylindrical gear rack. It can be done with a conventional tap, picking up the thread profile in accordance with your existing gear. Before working make a simple mandrel is a steel bar with a hole, which is inserted into the tap. The tap should be to grind on the sandpaper by about half. Processing is done in the following way. Dressed in the machine workpiece is a cylindrical rod, turn on the machine, and improvised cutter is applied to a rotating workpiece. The rod is cut a full thread profile (this requires to remember the division of the nonius cross-feed), the cutter is given a longitudinal feed handwheel moves to the left (cone!). Operation recess is repeated.

We offer you a simplified method of manufacturing a cylindrical gear rack. It can be done with a conventional tap, picking up the thread profile in accordance with your existing gear. Before working make a simple mandrel is a steel bar with a hole, which is inserted into the tap. The tap should be to grind on the sandpaper by about half. Processing is done in the following way. Dressed in the machine workpiece is a cylindrical rod, turn on the machine, and improvised cutter is applied to a rotating workpiece. The rod is cut a full thread profile (this requires to remember the division of the nonius cross-feed), the cutter is given a longitudinal feed handwheel moves to the left (cone!). Operation recess is repeated.

We offer you a simplified method of manufacturing a cylindrical gear rack. It can be done with a conventional tap, picking up the thread profile in accordance with your existing gear. Before working make a simple mandrel is a steel bar with a hole, which is inserted into the tap. The tap should be to grind on the sandpaper by about half. Processing is done in the following way. Dressed in the machine workpiece is a cylindrical rod, turn on the machine, and improvised cutter is applied to a rotating workpiece. The rod is cut a full thread profile (this requires to remember the division of the nonius cross-feed), the cutter is given a longitudinal feed handwheel moves to the left (cone!). Operation recess is repeated.