Present Board milling machine come in handy craftsmen who love to work with wood to get the blanks embossed surfaces, various geometric patterns, as well as cutting slots, grooves, sockets (both simple and shaped), etc. the Machine consists of two main parts: a base attached to it the guide posts and spring-loaded platform on which is mounted an electric motor.

The base is made of plywood 20 mm thick. In the middle of the drilled through hole with a diameter of 60 mm, and on the sides, a pair of diametrically opposed slots for rails in the rack. The rack I have is brass, but it is quite possible to do this from any ordinary steel.

To the base are fastened with M4 screws and plain washers widened. In order that the washers have sunk into the ground, in this coaxial jacks Pro-milled a shallow cylindrical recess. In those same holes countersink washers under the countersunk screw heads.

The platform is made of duralumin sheet thickness of 8 mm. In it is drilled a series of through-holes: a Central diameter slightly larger diameter of the motor shaft; on opposite sides (on the sides) — a pair of threaded holes M12 under guides and four smooth with a diameter of 5.2 mm in the corners under the bolts to ground the motor.

The guides and the rack I have is made from brass, which, however, is not necessary. Simply and those and others were available and suitable for milling work hard with minimal revision. By the way, the photo of the front view even without eyestrain, you may notice that the bushings are slightly different from each other. But performance is not affected. Sleeve, too it is possible (and even desirable) to produce steel. In one of the bushings has performed side M6 threaded hole for the locking screw. This screw ensures a stationary position of the platform with the motor in the non-working or transport condition, and sets the limit depth of cut during operation.

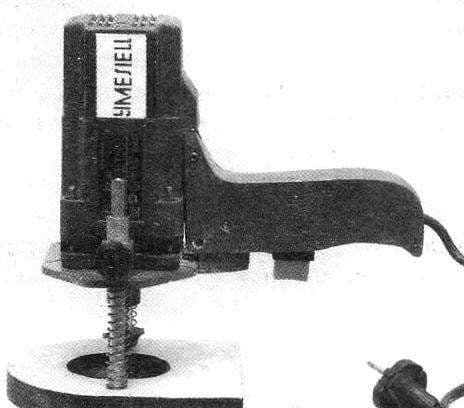

The view from the front of the machine

To assemble machine is easy, the main thing is to select the appropriate engine — compact, high-speed, powerful enough, powered by household mains voltage of 220 V. so I managed to find — from an old hand planer — small, in a plastic housing. Its power is 600 W, and the speed is 10,000 per minute. Engines with rpm of more than 15,000 per minute should not be used — requires higher alignment tool, and the chips fly away.

The engine had yet to make a handle. Cut it out of thick plywood (the same of what made the platform), so to speak, at the place or, more accurately, your hand. So bring only its overall dimensions. In the handle with one hand hollowed recess of the switch of the electric motor and a longitudinal groove for the mains supply cable and lead to the motor wires. After the installation of the switch and cabling with the wires in the handle recess and the groove covered cheek-pad of 4mm plywood, cut to the configuration of the handle, and privernuli it screws with countersunk heads. Handle is attached by screws to the motor frame and rivet through the bracket-plate priklepyvayut to the platform.

Desktop electric hand milling machine:

1—motor U = 220V, N = 600W, n = 10 000 Rev/min (from the plane); 2—arm (plywood s20 and s4); 3—the start button of the switch of the electric motor; 4—power supply cable with plug; 5 — collet Chuck; 6—wood cutting tool (milling cutter); 7 — base (plywood s20); 8 — guiding strut (steel, round 12, 2); 9 — spring (twisted grip, 2 PCs); 10—platform (made of anodized aluminum, sheet s8); 11 —guide Bush (steel, circle 25,2 PCs); 12—clamp platform (screw M6); 13 — mounting the rack rail to the base (M4 screw with countersunk head, 4 pieces); 14 — broadened washer (4 PCs); 15—fastening the motor to the platform (M5 screw, 4 PCs); 16—mount of cheek-pads to the handle (screw 5 PCs.)

Spring — coiled compression (normally stretched), it is desirable to select the same, hard to measure — if only they kept the weight of the platform with the motor.

On the motor shaft end tapped M8 for mounting a collet Chuck in which is inserted and tightened you need to change the cutting tool (milling cutter).

To avoid personal injury and damage to the machine should not use it for machining metal workpieces, and you must work in protective glasses.

A. ALIBEKOV, the city of Derbent, Dagestan

Recommend to read THE GYM IN YOUR BEDROOM "Lack of exercise, old age, and shortness of breath..." — sung in the famous song. Indeed, in our time, the widespread mechanization and computerization of society, the preservation of... CORROSION THREADED CONNECTIONS During repair works of structures with steel threaded connections of the work items that have to deal with the complexity of their separation due to corrosion of the thread. These...  Present Board milling machine come in handy craftsmen who love to work with wood to get the blanks embossed surfaces, various geometric patterns, as well as cutting slots, grooves, sockets (both simple and shaped), etc. the Machine consists of two main parts: a base attached to it the guide posts and spring-loaded platform on which is mounted an electric motor.

Present Board milling machine come in handy craftsmen who love to work with wood to get the blanks embossed surfaces, various geometric patterns, as well as cutting slots, grooves, sockets (both simple and shaped), etc. the Machine consists of two main parts: a base attached to it the guide posts and spring-loaded platform on which is mounted an electric motor.